Waste paper/high-density polyethylene luminescent composite and preparation method thereof

A high-density polyethylene and composite material technology, applied in the field of wood-plastic composite materials, can solve the problems of reducing the structural strength of the board, destroying the integrity of the board, increasing the process steps, etc., and achieving the effects of high production efficiency, low cost and abundant resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

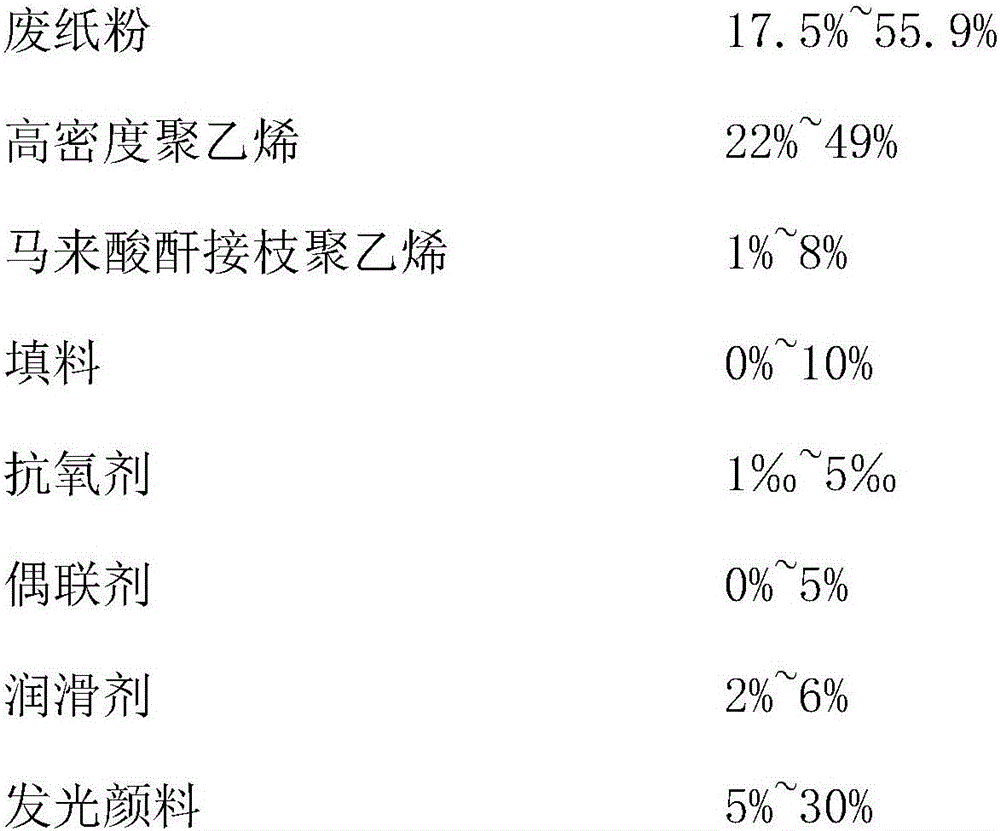

[0027] The raw materials and mass fractions used in the preparation of a waste paper / high-density polyethylene luminescent composite material are as follows:

[0028]

[0029]

[0030] (1) Put the recovered waste newspapers into a shredder and crush them, the size of the fragments is 5*20mm, and then mix the newspapers with a 1% sodium hydroxide solution, and the mass ratio of the two mixtures is 1:10. Stir at a speed of 20r / min until the newspaper is completely submerged, filter after reacting for 8 minutes, and dry in a drying oven at a drying temperature of 90°C and a drying time of 24 hours. The dried waste paper is pulverized with a cutting grinder to obtain 40-80 mesh paper powder.

[0031] (2) Put paper powder, high-density polyethylene and other raw materials into a high-speed mixer according to the proportion and mix them evenly. The mixing temperature is 120°C and the mixing time is 30 minutes.

[0032] (3) Extrude and granulate the mixed material with a twin-...

Embodiment 2

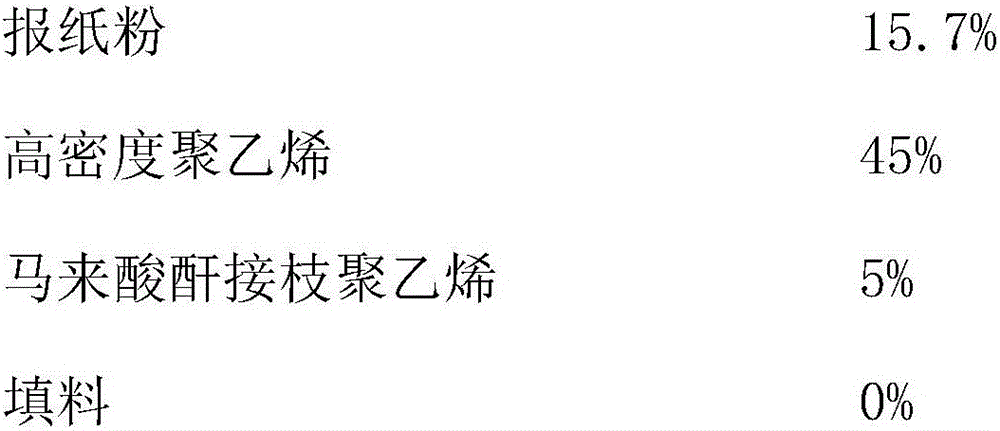

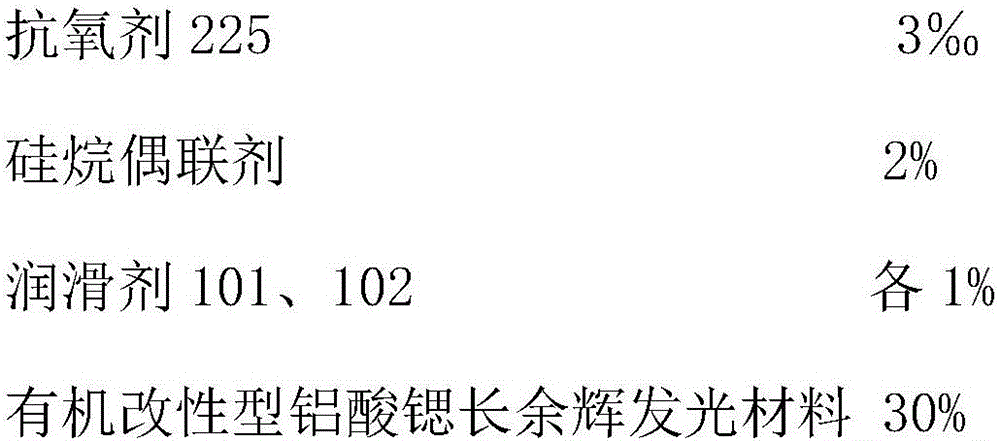

[0036] The raw materials and mass fractions used in the preparation of a waste paper / high-density polyethylene luminescent composite material are as follows:

[0037]

[0038] (1) Put the recovered milk carton into a pulverizer to crush, the size of the fragments is 5*5mm, and then mix the milk carton with 2.5% sodium hydroxide solution, and the mass ratio of the two mixed is 1:12. Stir at a speed of 30r / min until the milk carton is completely submerged, filter after reacting for 12 minutes, and dry in a drying oven at a drying temperature of 110°C and a drying time of 18 hours. The dried waste paper is pulverized with a cutting grinder to obtain 40-80 mesh paper powder.

[0039] (2) Put paper powder, high-density polyethylene and other raw materials into a high-speed mixer according to the proportion and mix them evenly. The mixing temperature is 140°C and the mixing time is 20 minutes.

[0040] (3) Extrude and granulate the mixed material with a twin-screw extruder. The...

Embodiment 3

[0044] The raw materials and mass fractions used in the preparation of a waste paper / high-density polyethylene luminescent composite material are as follows:

[0045]

[0046] (1) Put the recovered office waste paper into a paper shredder and crush it, the size of the pieces is 5*20mm, and then mix the waste paper with a sodium hydroxide solution with a concentration of 2%, and the mass ratio of the two mixed is 1:8 . Stir at a speed of 20r / min until the waste paper is completely submerged, filter after reacting for 10min, and dry in a drying oven at a drying temperature of 100°C and a drying time of 20h. The dried waste paper is pulverized with a cutting grinder to obtain 40-80 mesh paper powder.

[0047] (2) Put paper powder, high-density polyethylene and other raw materials into a high-speed mixer according to the proportion and mix them evenly. The mixing temperature is 130°C and the mixing time is 25 minutes.

[0048] (3) Extrude and granulate the mixed material with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com