Patents

Literature

30results about How to "High reduction potential" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

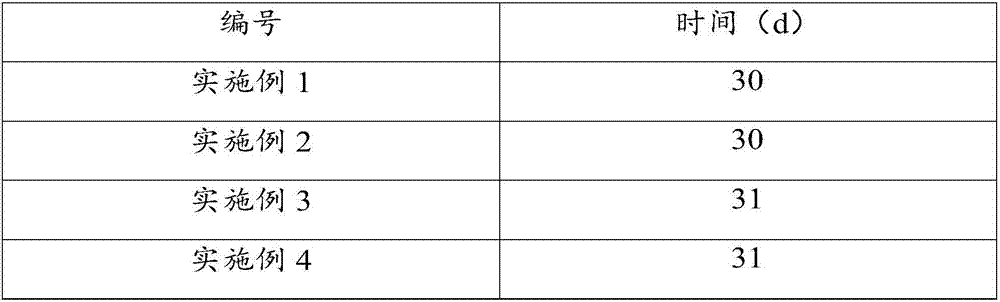

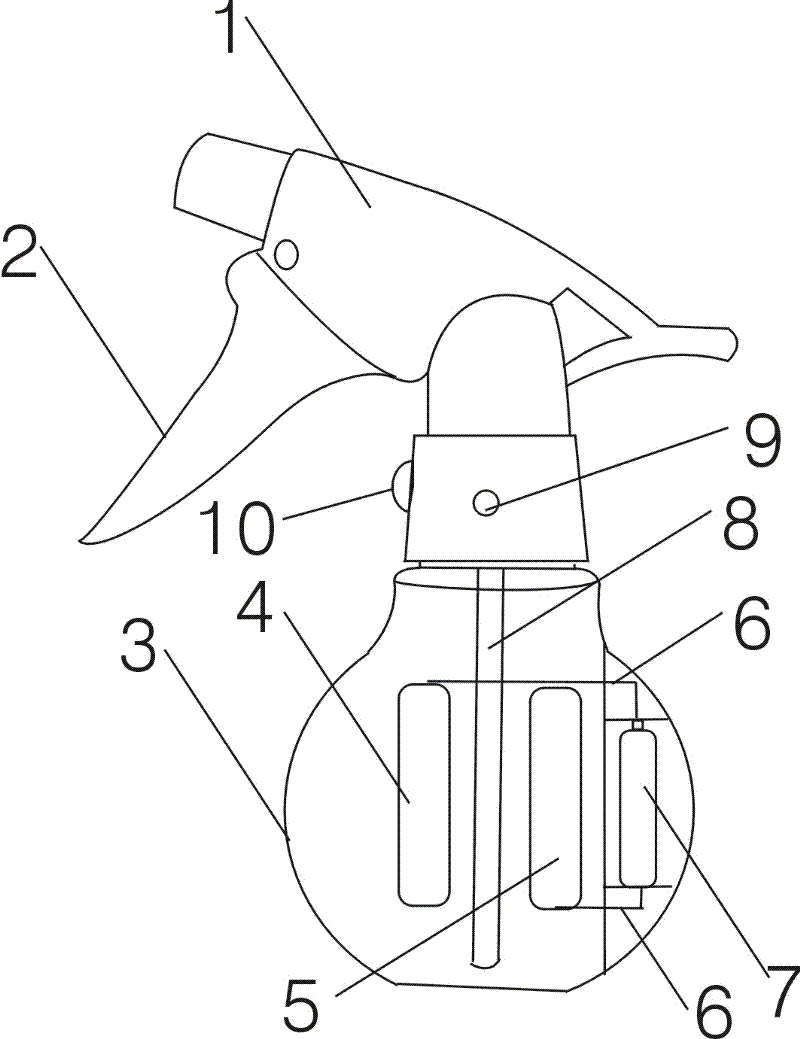

Cellulose/sliver/silver chloride composite material and preparation method thereof

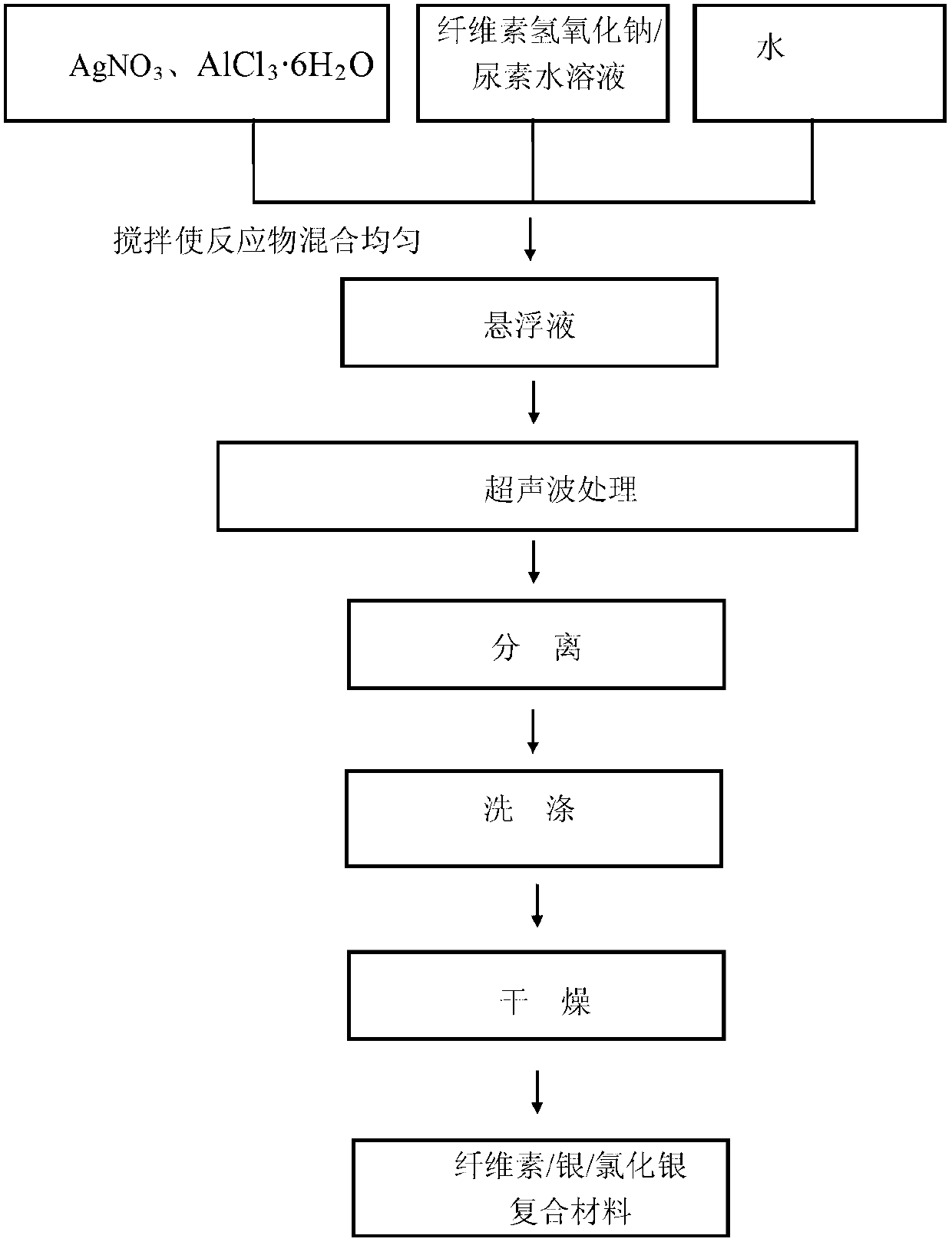

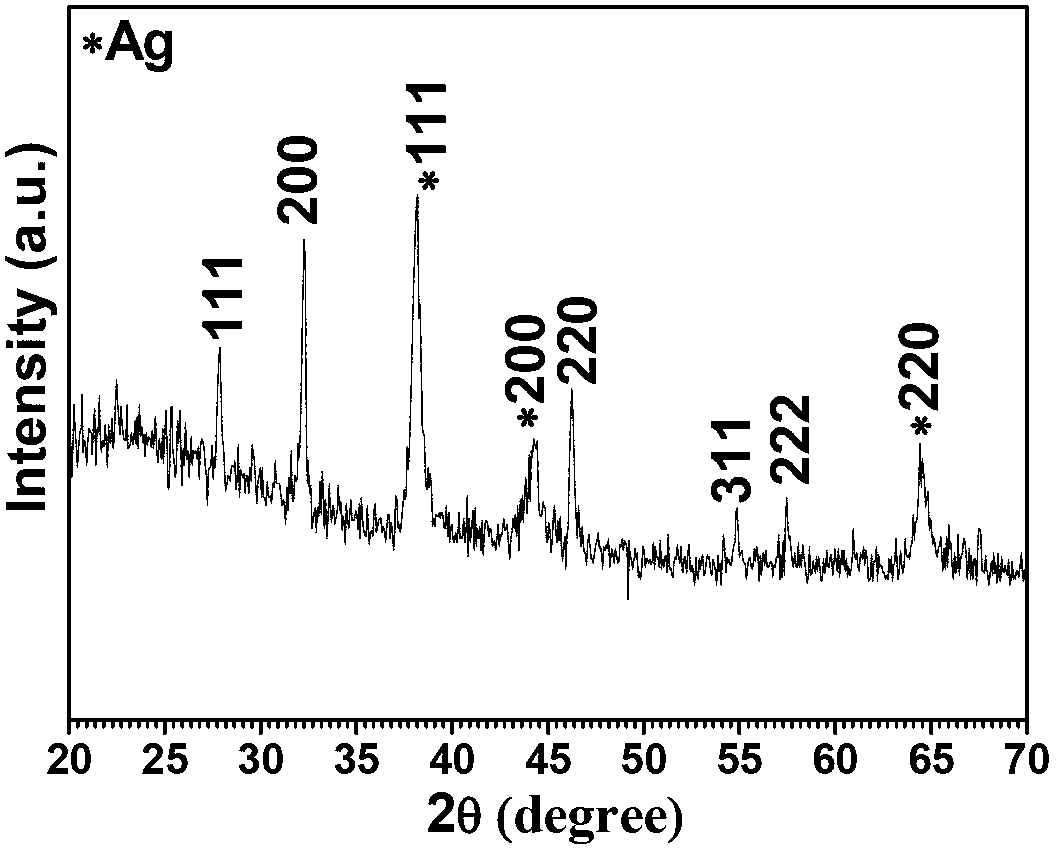

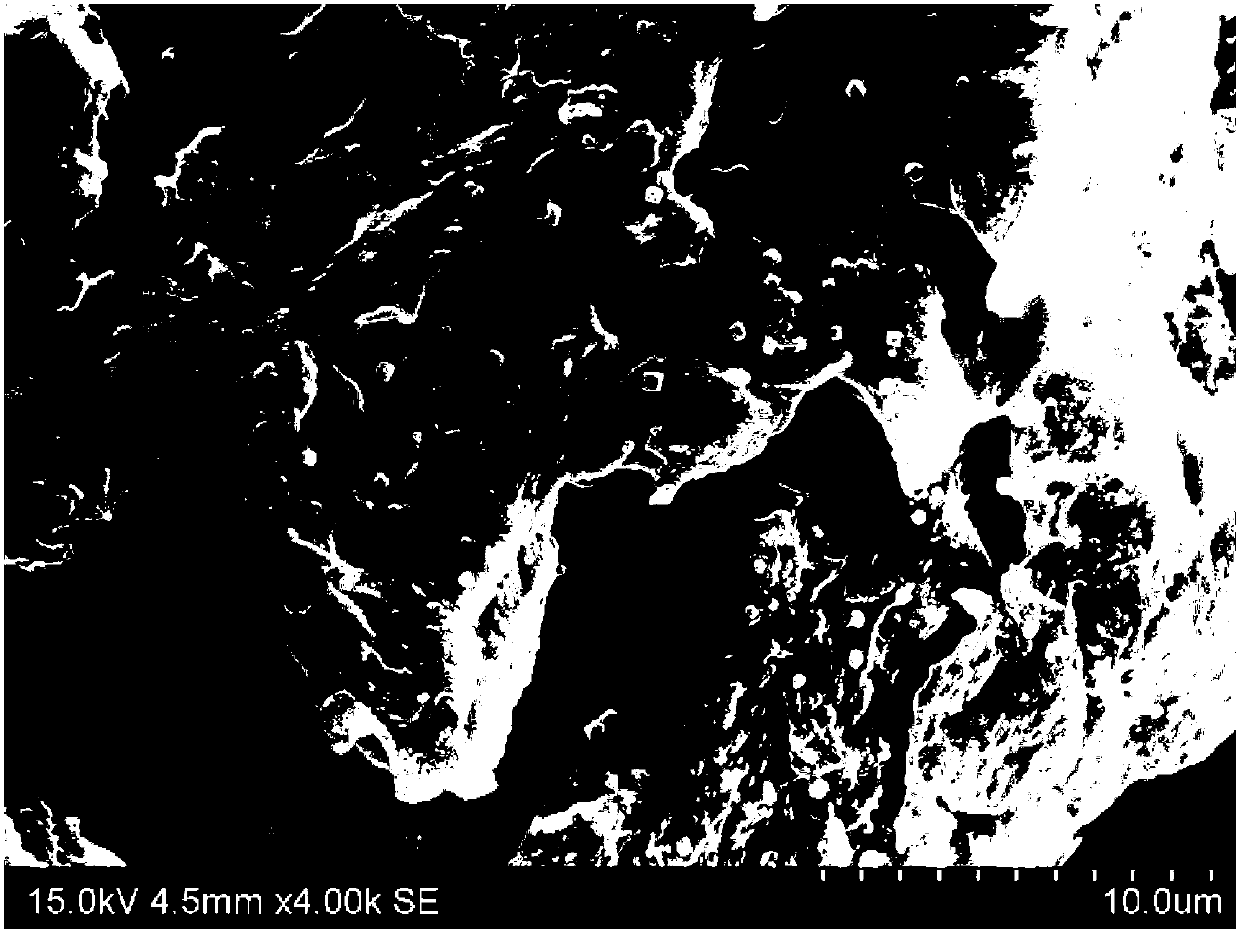

The invention provides a cellulose / silver chloride composite material and a preparation method thereof. The cellulose / silver chloride composite material is quickly prepared by adopting microcrystalline cellulose, sliver salt and chlorine compound as the materials, adopting water as solvent and adopting an ultrasonic-wave treatment method. The cellulose / silver chloride composite material prepared by the preparation method disclosed by the invention is uniform in silver / silver chloride nanometer particle, capable of being uniformly distributed on a cellulose substrate and is extensive in application prospect in the antibacterial filed and the photocatalysis filed. Moreover, according to the preparation method disclosed by the invention, the materials are cheap, the process is simple, the operation is convenient, the preparation is quick and the process conditions are easy to control, so that the production process is greatly simplified, the time is saved and the cost is reduced. Meanwhile, the preparation method is free of any expensive and complex equipment and is beneficial to the industrial popularization.

Owner:BEIJING FORESTRY UNIVERSITY

Diatom ooze coating and preparation method thereof

InactiveCN105176216AGuaranteed StrengthReduce contentAntifouling/underwater paintsPaints with biocidesEmulsionUltimate tensile strength

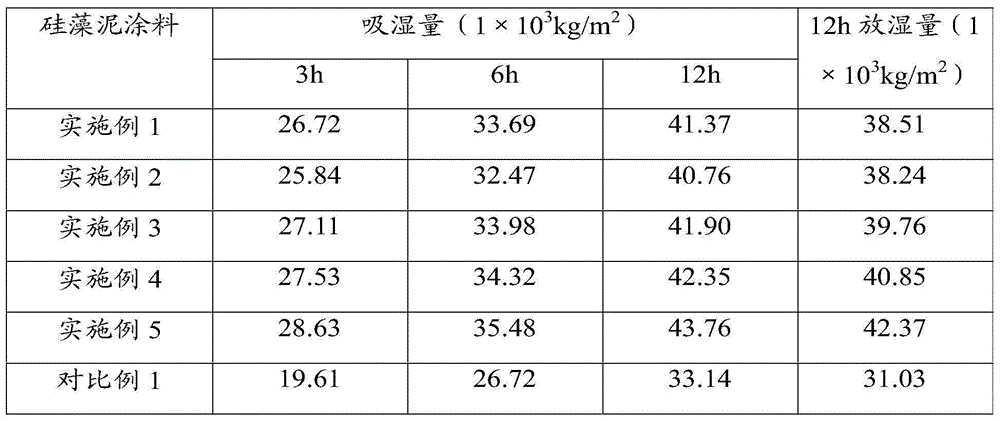

The invention provides a diatom ooze coating, belonging to the technical field of decoration coatings. Components of the diatom ooze coating mainly comprise synthesized emulsion, a dispersant, kieselguhr, a filler, a silver ion antibacterial agent, an additive and water and the like. The aperture of the selected kieselguhr is 280-580 meshes, and a micropore structure of the kieselguhr can be kept, and actions of humidifying and absorbing and dissolving formaldehyde can be achieved. The content of emulsion is reduced, and the strength of the coating after a wall is coated is ensured, and powder falling is avoided, and kieselguhr particles are not fully wrapped due to a formed membrane thus the micropores are not blocked, so that the functionality is not affected. The silver ion antibacterial agent is added into the coating, so the growth and propagation of microorganisms are effectively inhibited. The diatom ooze coating is obtained in a manner of charging materials in batches and stirring. Before the emulsion is added, under stirring, a thickener and a pH regulator are added, and the thickener can be fully dissolved by a shearing action, and an advanced dissolving step for the thickener is reduced.

Owner:BEIJING DAIJIN DIATOMITE NEWLY BUILDING MATERIAL

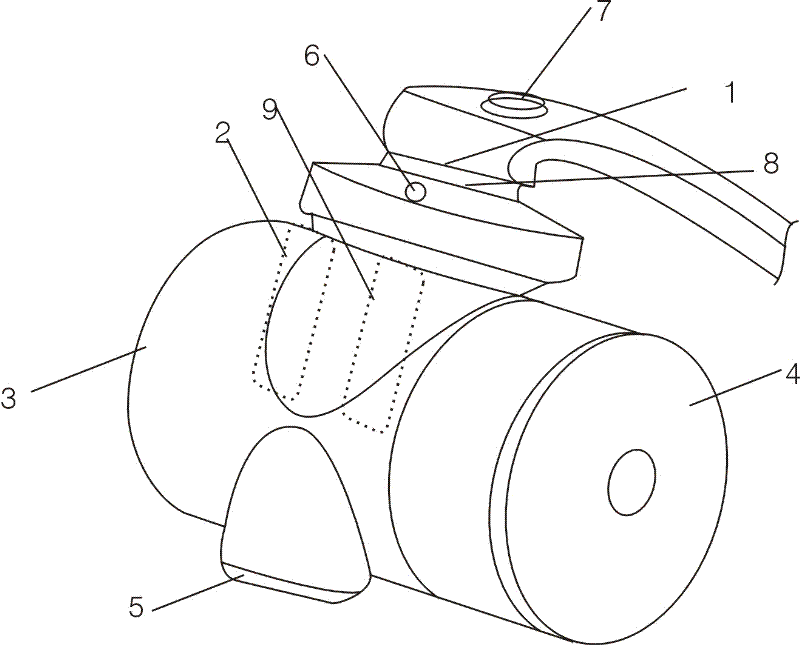

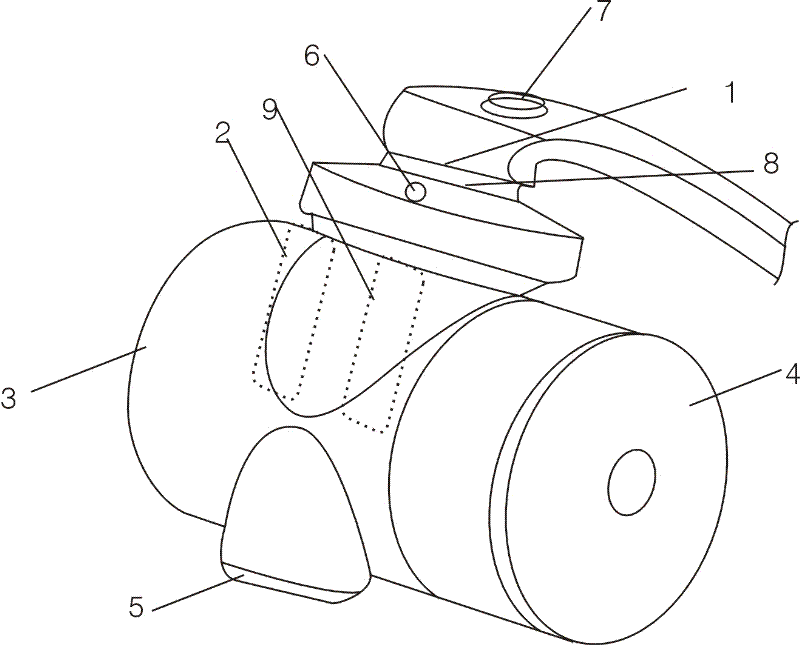

Silver ion water tap

InactiveCN102330844AImprove catalytic performanceAvoid infectionValve arrangementsWater/sewage treatment using germicide/oligodynamic-processSilver ionMicro power generator

The invention relates to a silver ion water tap. The silver ion water tap comprises a water tap and is characterized in that an accommodating body with an inner cavity space is fixed at the water inlet of the water tap, the water inlet of the accommodating body is connected with the water inlet of the water tap, a water outlet is arranged at the lower part of the accommodating body, a silver ion generator is installed in the accommodating body, a microgenerator is installed at one side in the accommodating body, the silver ion generator comprises a silver metal positive electrode plate and a silver metal negative electrode plate, and positive electrode and negative electrode are connected with the output circuit of the microgenerator through a power line. Since the silver ion generator is installed in the water tap, the silver ion is used for sterilizing and disinfecting, the silver ion water tap is practical and convenient.

Owner:张圣坤

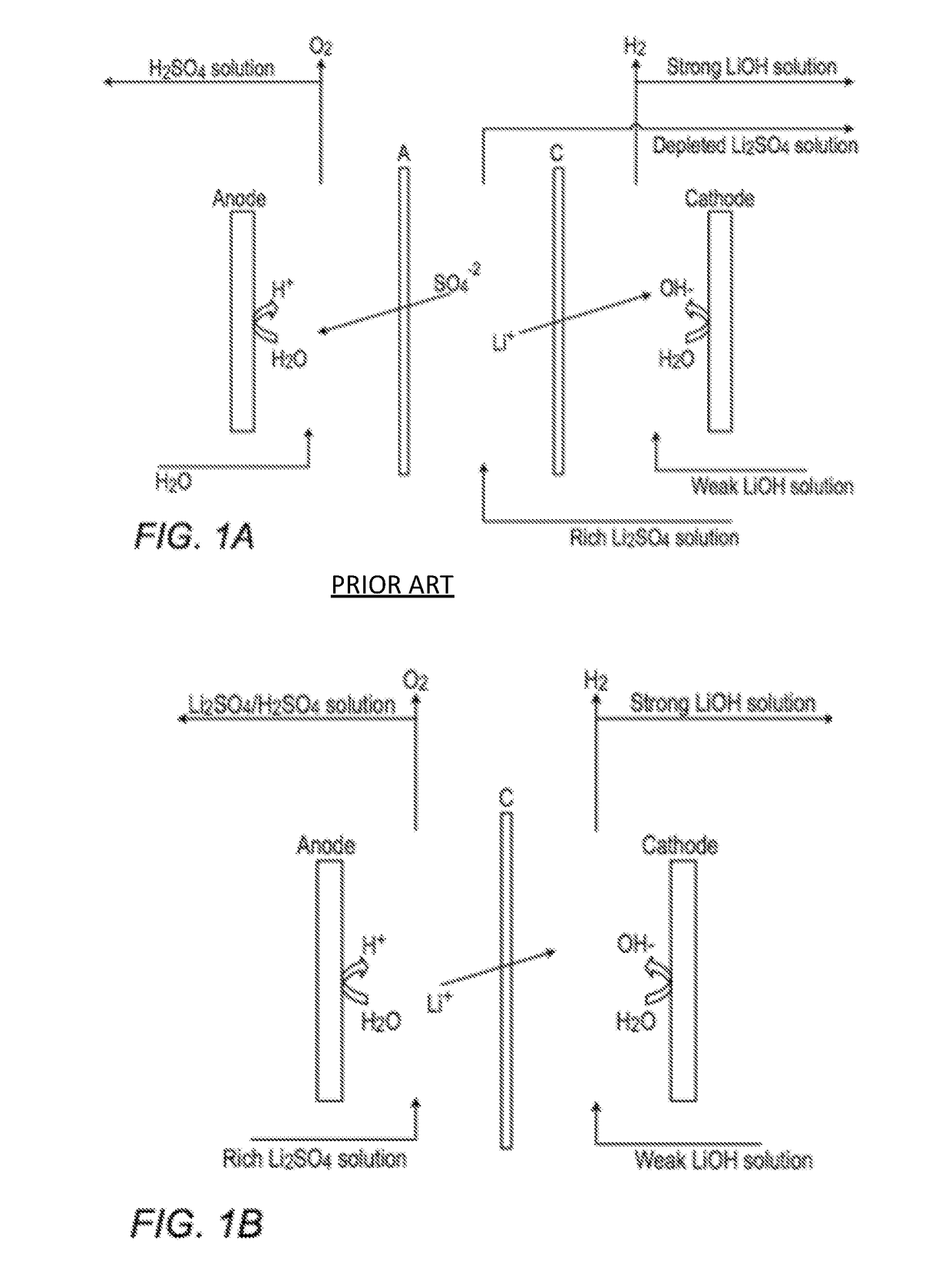

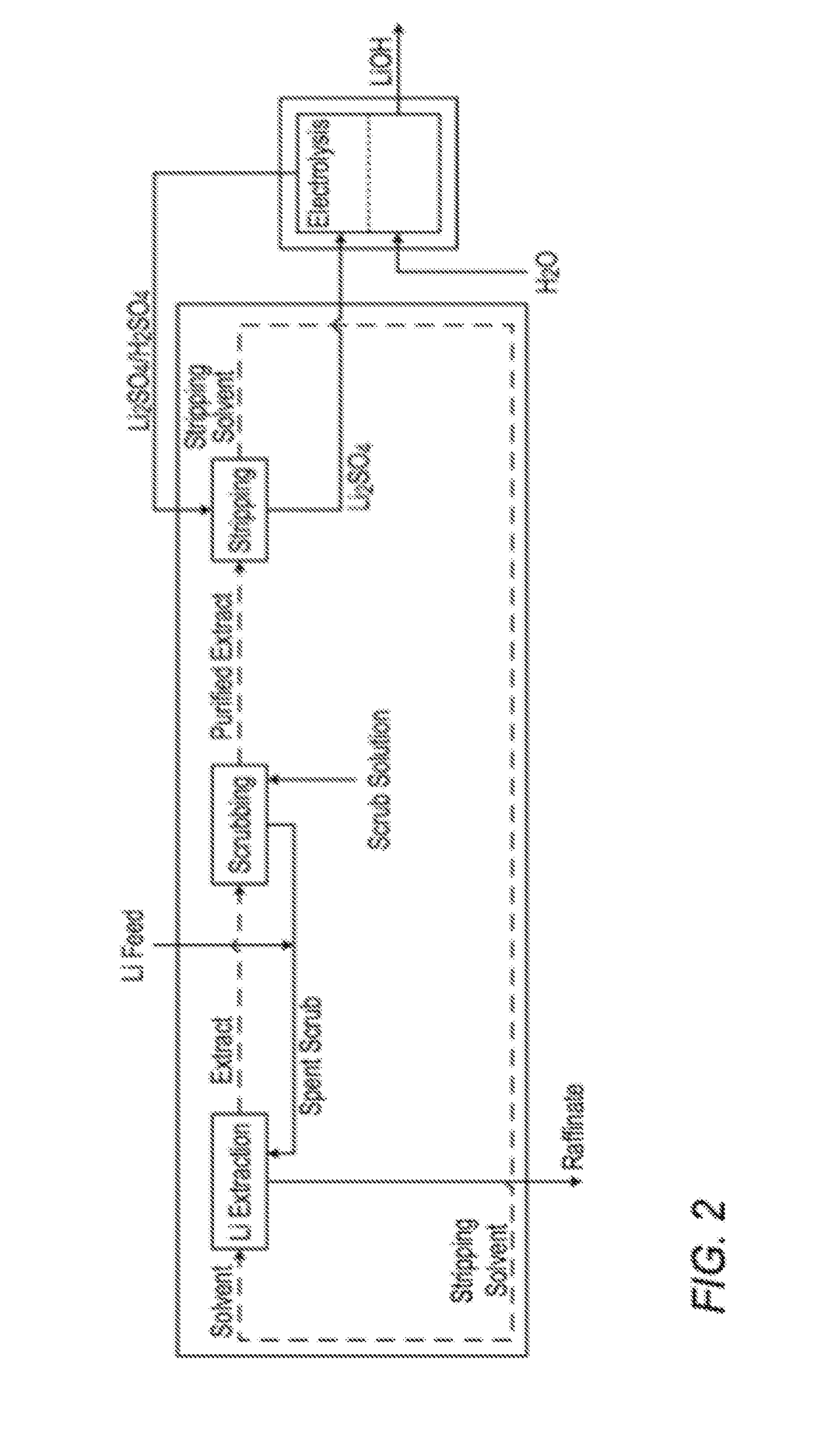

Integrated lithium production process

ActiveUS20190032227A1High reduction potentialCellsProcess efficiency improvementElectrolysisLithium hydroxide

Owner:TENOVA ADVANCED TECH LTD

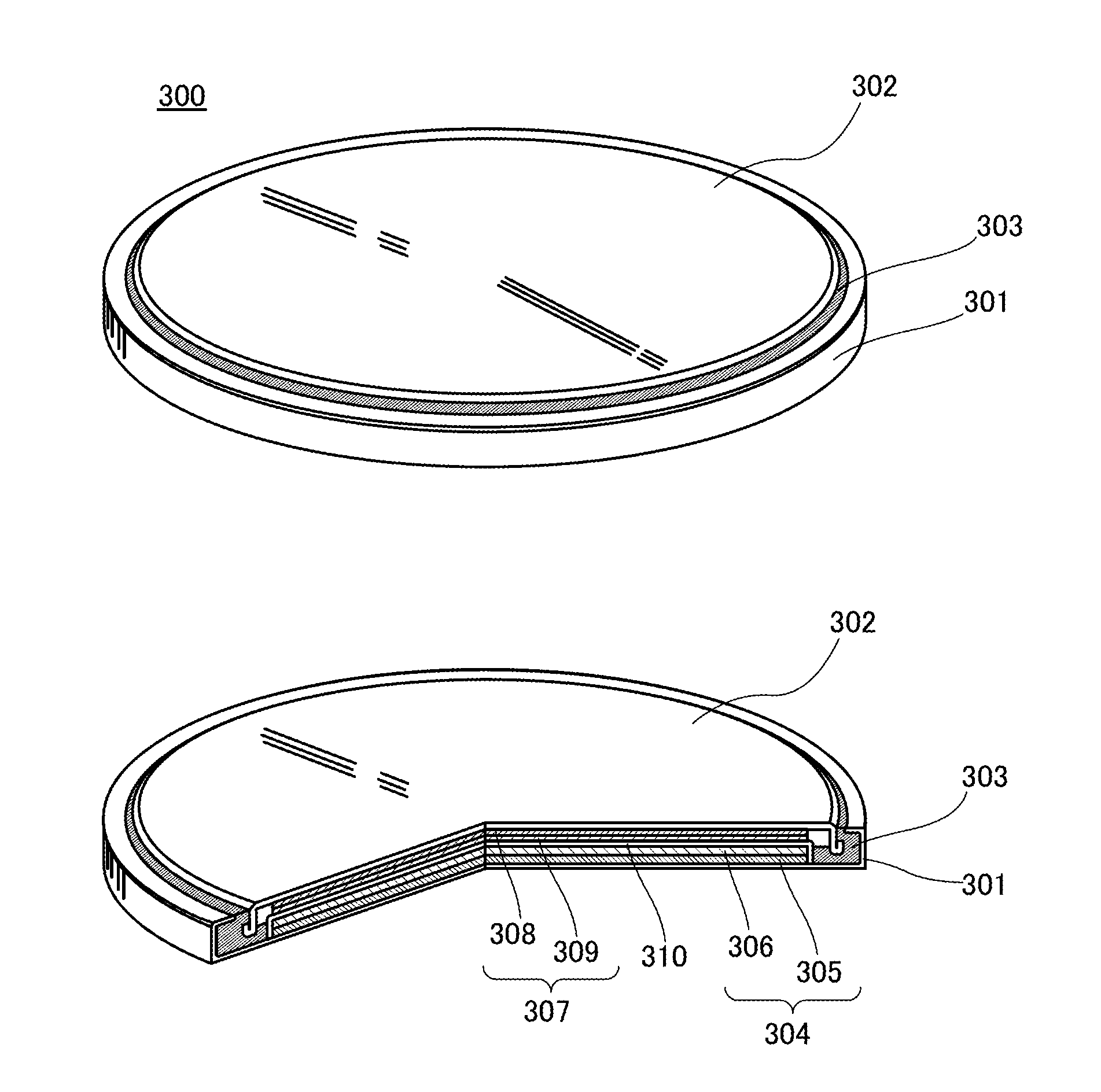

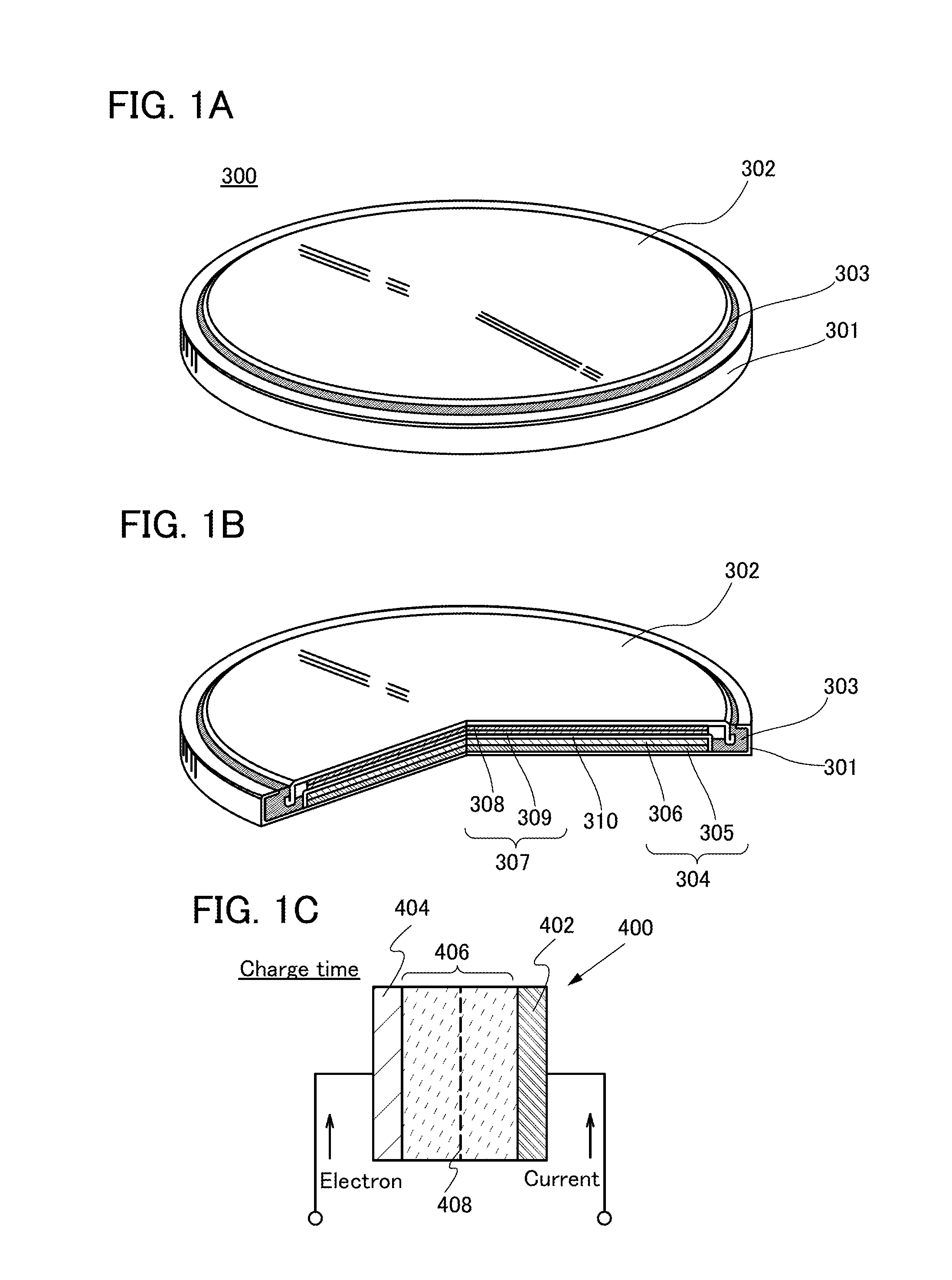

Compound, nonaqueous electrolyte, and power storage device

InactiveUS20150140449A1Wide usable temperature rangeHigh lithium conductivityOrganic chemistryCell electrodesSolventIonic liquid

Provided are a nonaqueous solvent containing a compound with high conductivity and low viscosity and a high-performance power storage device using the nonaqueous solvent. The power storage device includes an ionic liquid. The ionic liquid contains an anion and a cation having a five-membered heteroaromatic ring having one or more substituents. At least one of the substituents is a straight chain formed of four or more atoms and includes one or more of C, O, Si, N, S, and P.

Owner:SEMICON ENERGY LAB CO LTD

Silver-ion antibacterial plastic

The invention relates to silver-ion antibacterial plastic, which consists of the following raw materials by weight percent: 80 percent of plastic, 5 percent of nano silver powder, 7 percent of flame retardant agent, 5 percent of bond and 3 percent of lubricant. The silver-ion antibacterial plastic can realize the broad-spectrum antibacterial and has a flame retardant effect.

Owner:GUANGDONG JUYUAN PLASTIC TECH

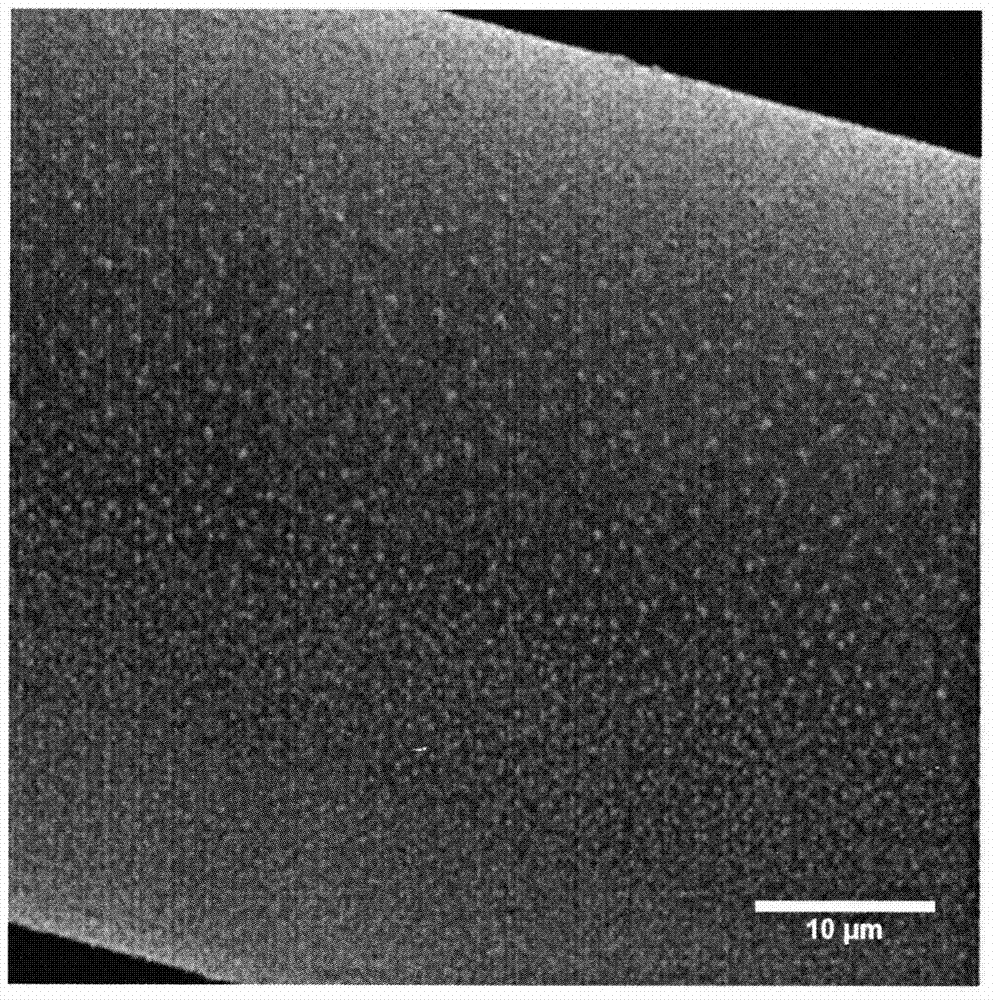

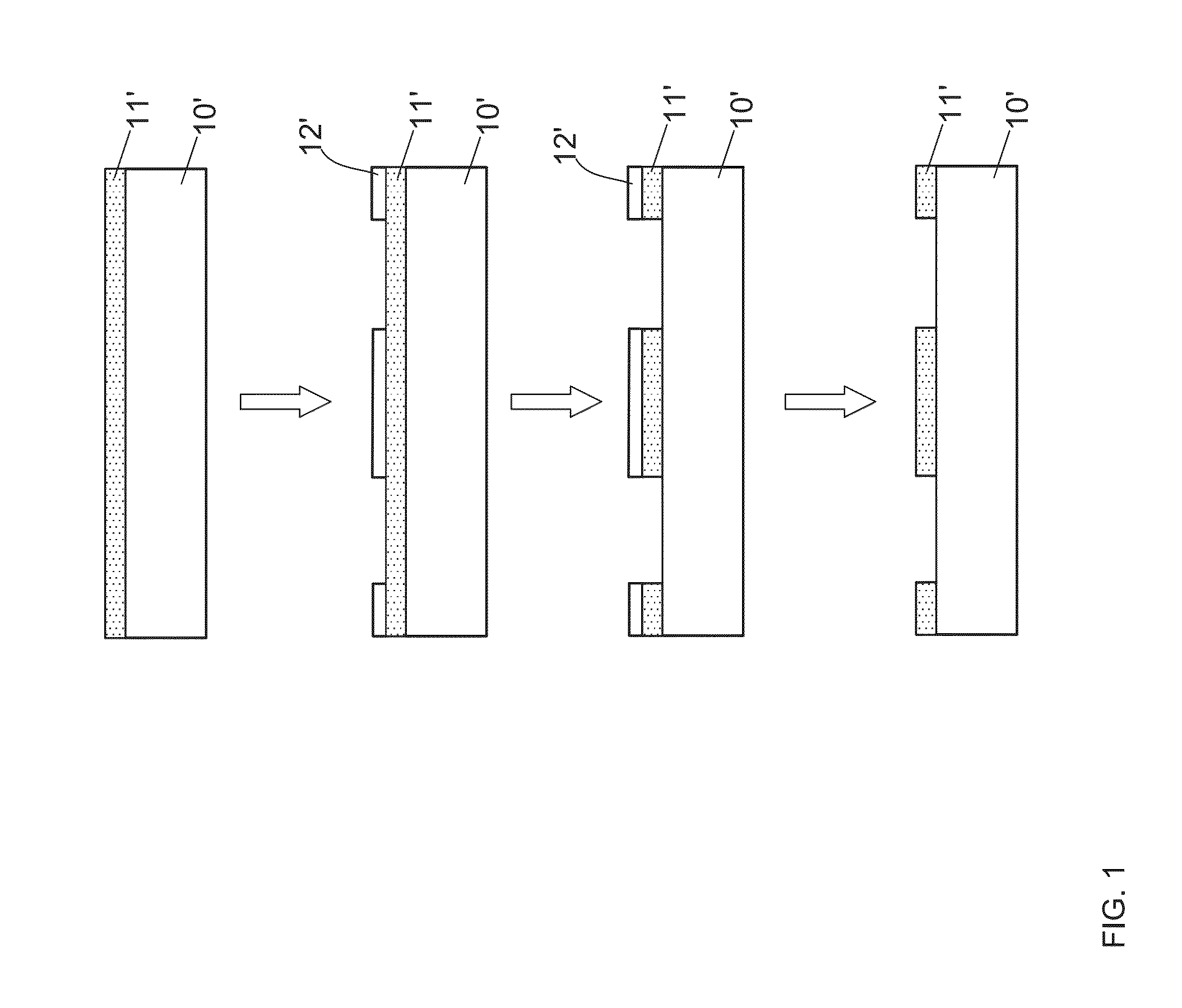

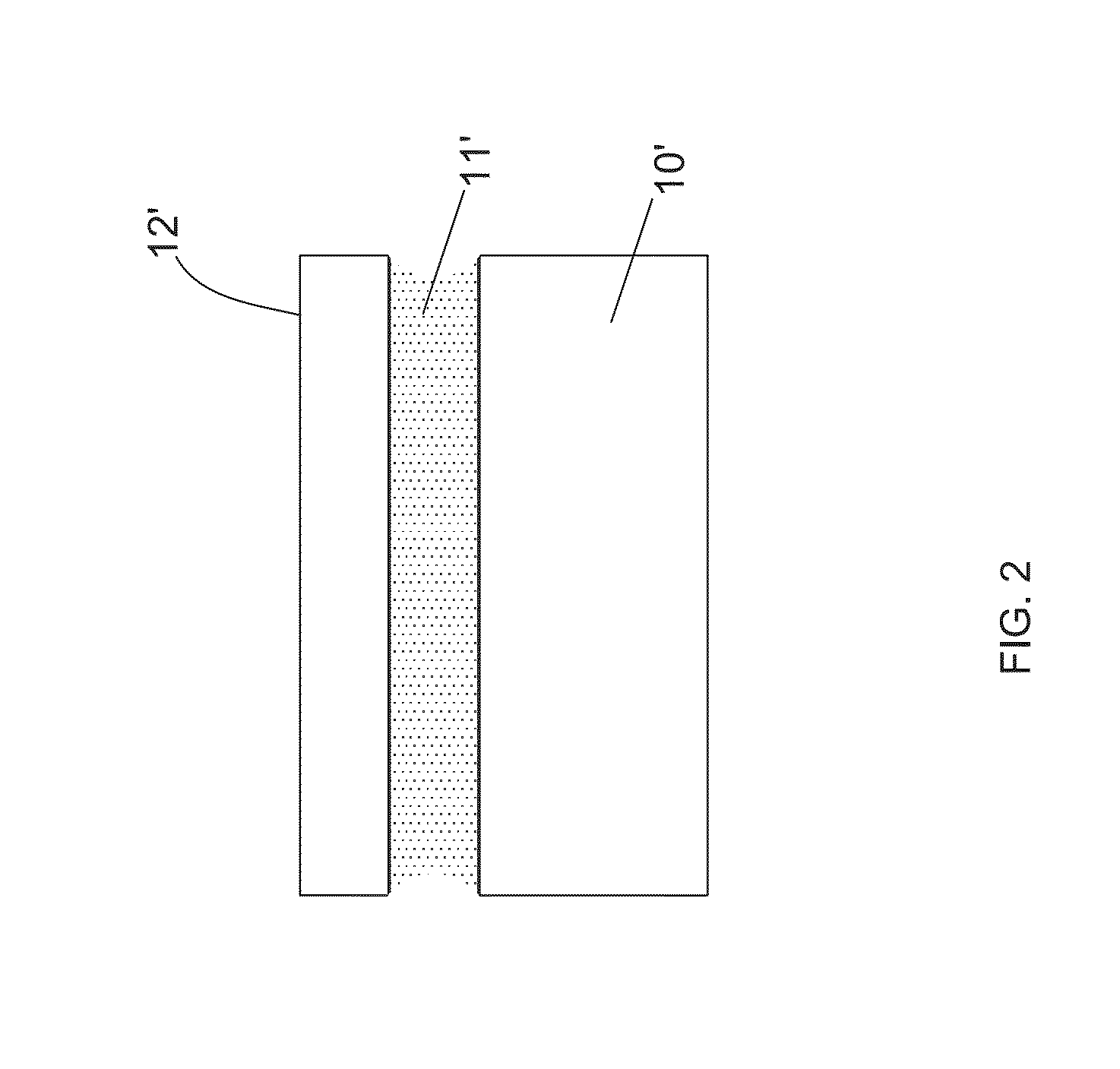

Organic electroluminescent device

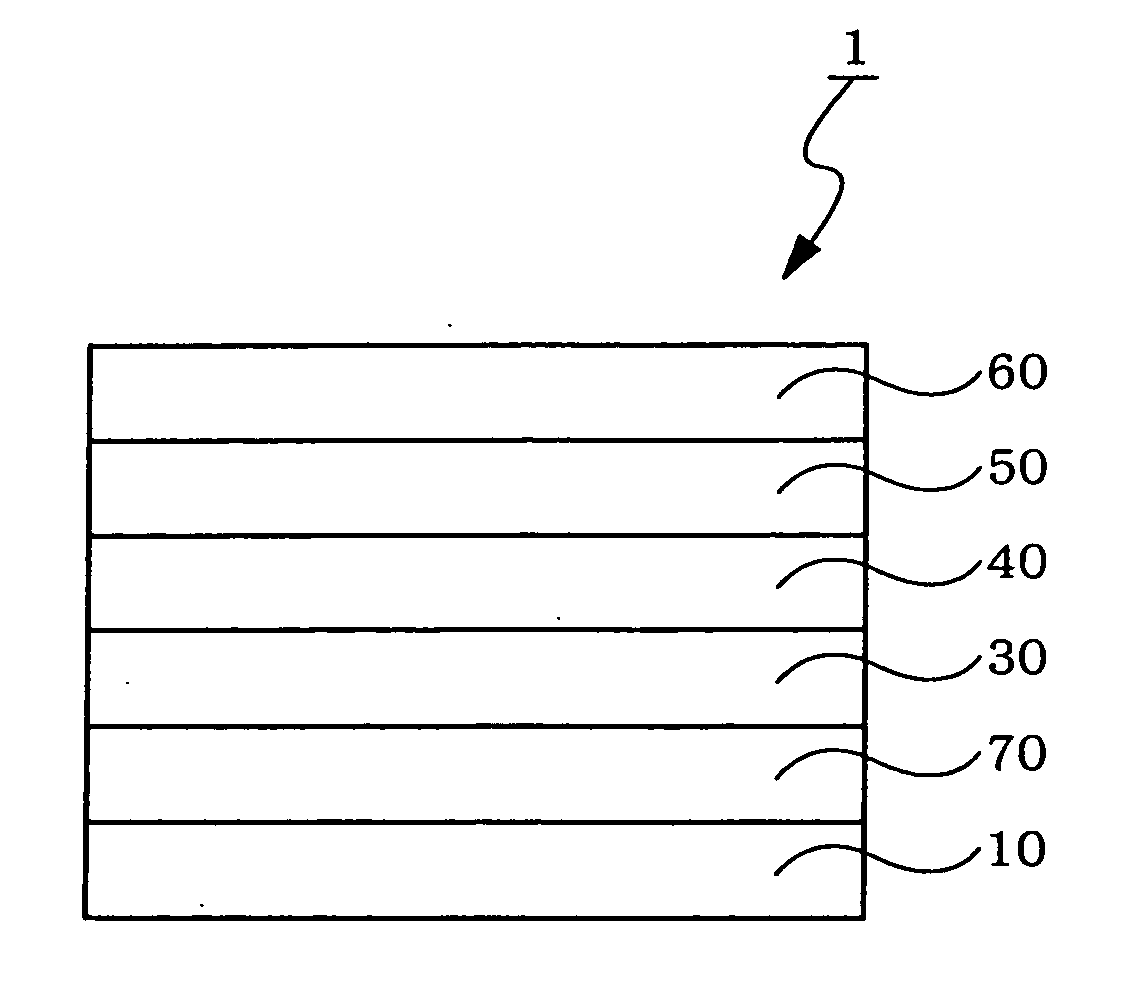

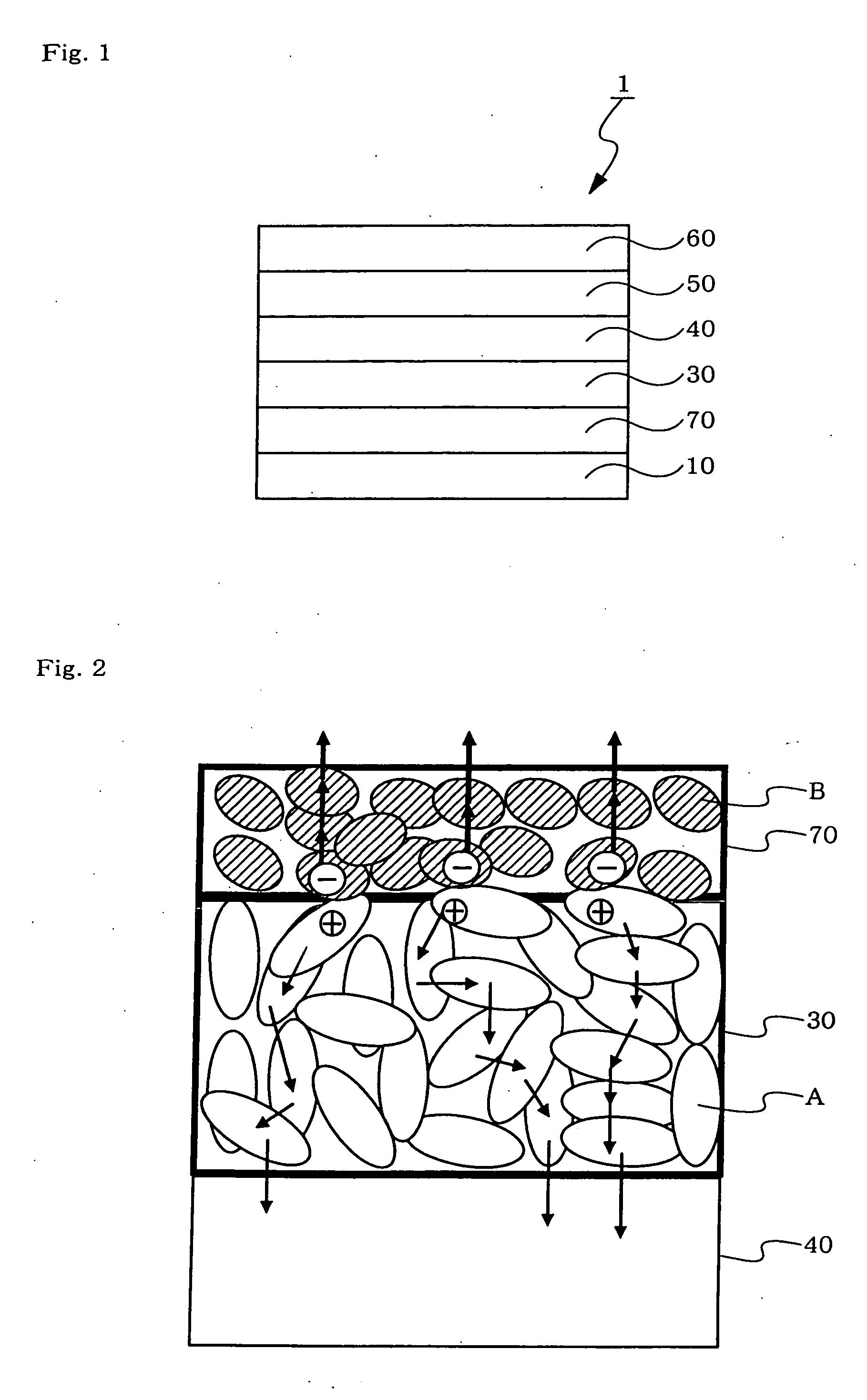

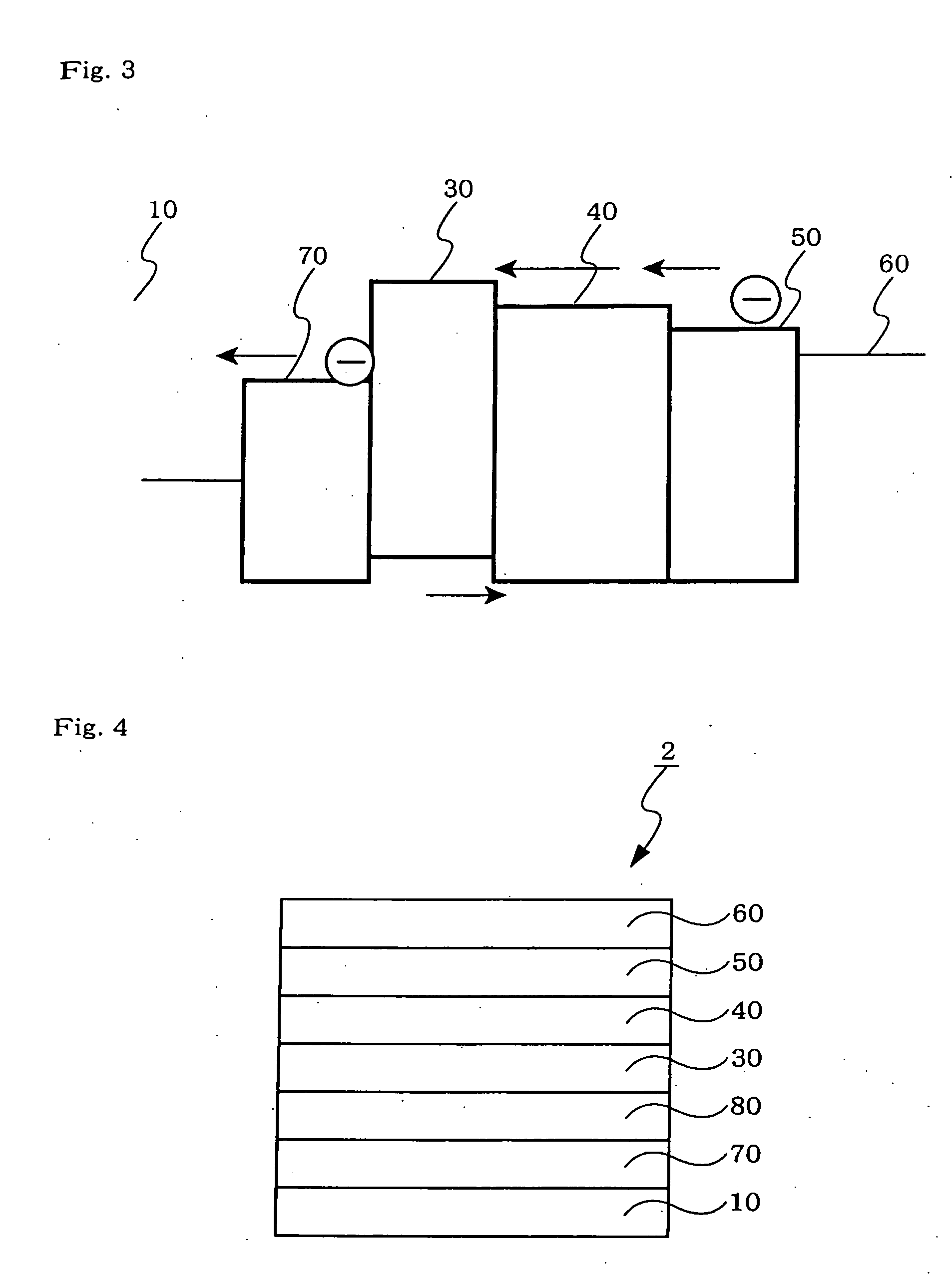

InactiveUS20070108894A1High reduction potentialReduce compoundingDischarge tube luminescnet screensElectroluminescent light sourcesElectronic transmissionLow voltage

An organic EL device which has a long lifetime and requires only a low voltage is provided. The organic electro luminescent device including: an emitting layer (40) between an anode (10) and a cathode (60), an acceptor-containing layer (70) which contains an acceptor and is electron-transportable, and a hole-transporting layer (30), the acceptor-containing layer and the hole-transporting layer being disposed between the anode (10) and the emitting layer (40) in this order from the anode.

Owner:IDEMITSU KOSAN CO LTD

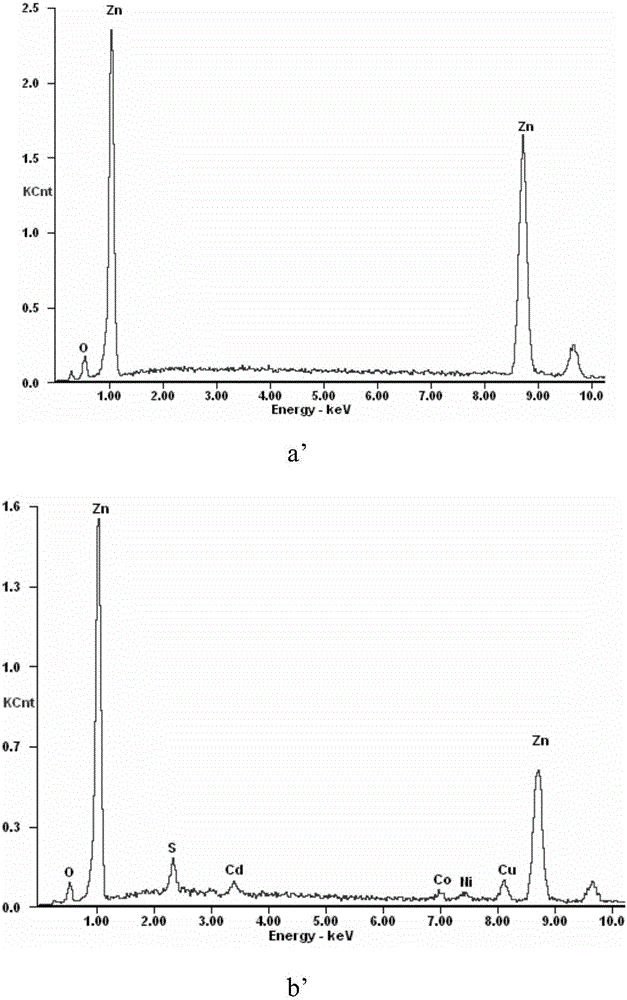

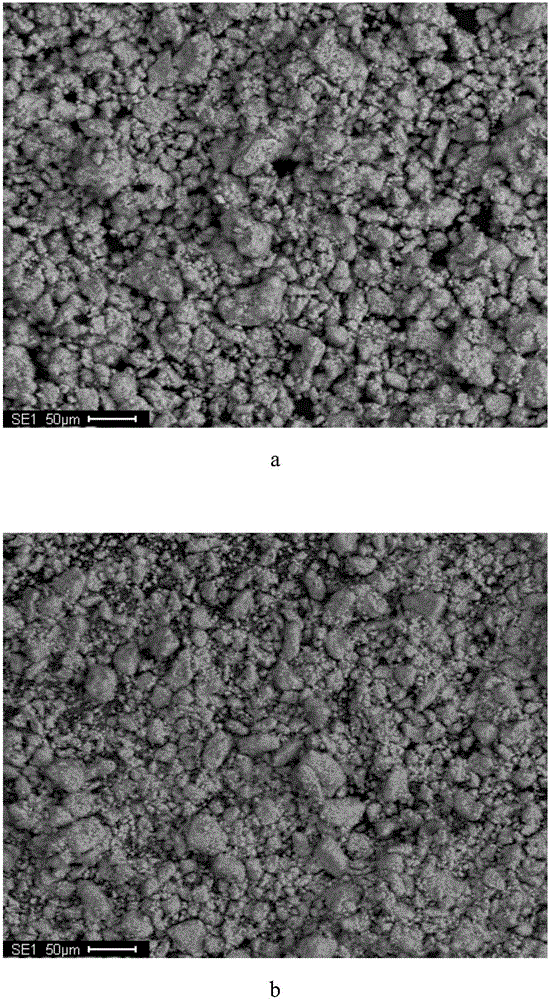

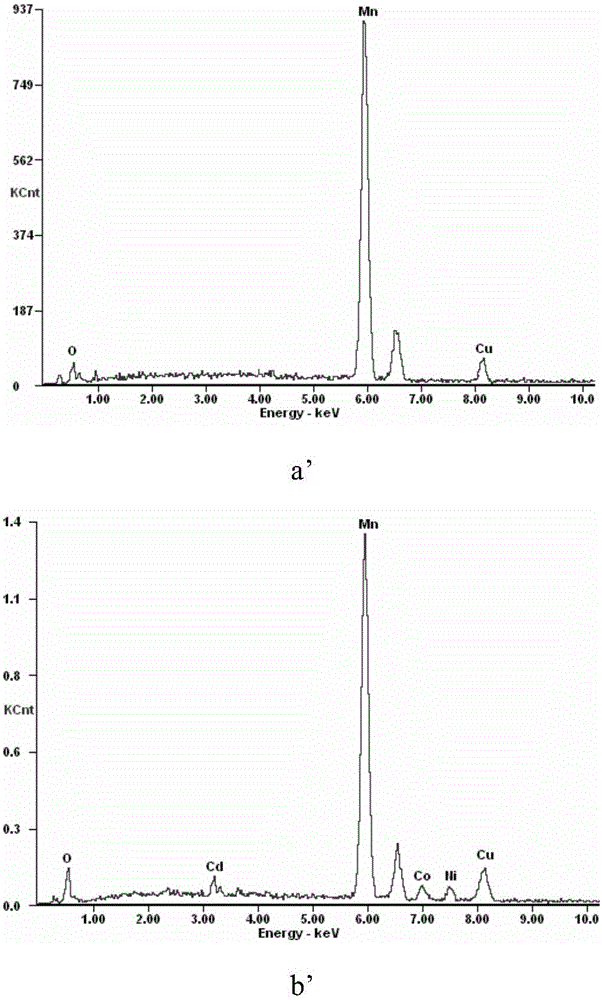

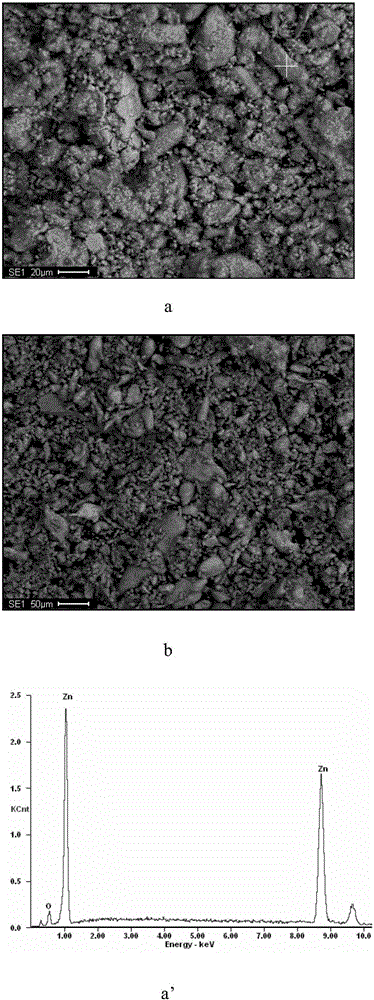

Method for removing copper, cadmium, nickel and cobalt out of zinc sulfate solution through one step

The invention discloses a method for removing copper, cadmium, nickel and cobalt out of a zinc sulfate solution through one step. The method comprises the steps that manganese metal powder and / or manganese-based alloy powder are / is added into the zinc sulfate solution containing copper, cadmium, nickel and cobalt, wherein the temperature of the zinc sulfate solution ranges from 45 DEG C to 70 DEG C, and the pH of the zinc sulfate solution is larger than 4.0; and stirring is carried out for a reaction, after the reaction is finished, filtering separation is carried out, and the zinc sulfate solution with the contents of copper, cadmium, nickel and cobalt all lower than 0.8 ppm is obtained. According to the method, copper, cadmium, nickel and cobalt can be efficiently removed out of the zinc sulfate solution through one step at the same time, no impurities endangering zinc electrolyzing are introduced, the technological process is simple and low in cost, no complex and special equipment is needed, and good industrial application prospects are achieved.

Owner:CENT SOUTH UNIV

Method for deep removing nickel and cobalt impurities in zinc hydrometallurgy solution

The invention discloses a method for deep removing nickel and cobalt impurities in a zinc hydrometallurgy solution. According to the method, manganese metal powder and / or manganese base alloy powder are / is added in a zinc sulfate solution containing nickel and cobalt under the conditions of a certain temperature and a certain pH value, the stirring is conducted for the reaction, and after the reaction is finished, filtering and separating are conducted, and the zinc sulfate solution with the nickel content and the cobalt content both lower than 0.8 mg / L is obtained. According to the method, the nickel impurity and the cobalt impurity in the zinc sulfate solution containing the nickel and the cobalt can be deep removed with the high efficiency and the low cost while impurities doing harm to zinc electrolysis are not guided. The technology process is simple, complex and special equipment is not needed, and good industrial application prospects are achieved.

Owner:CENT SOUTH UNIV

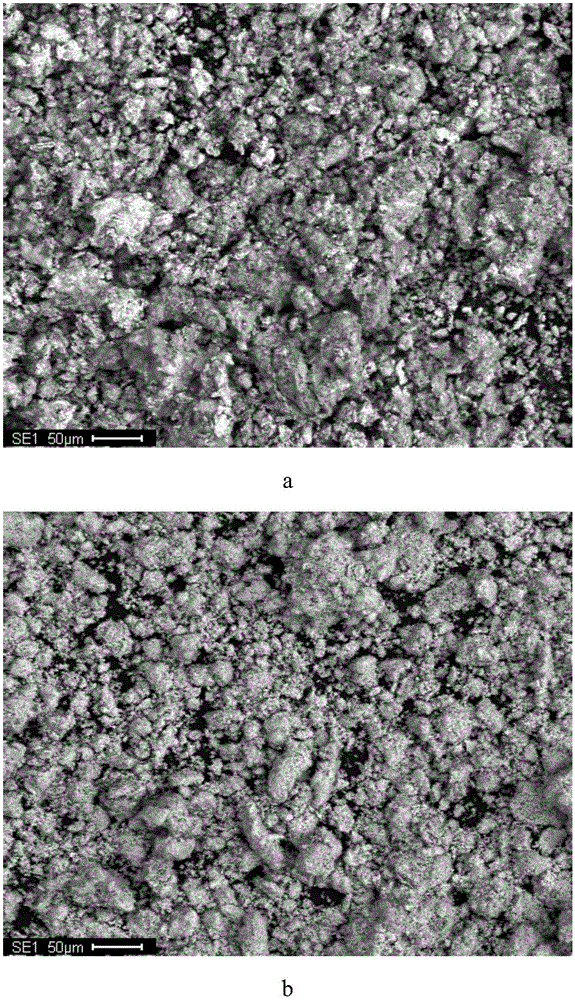

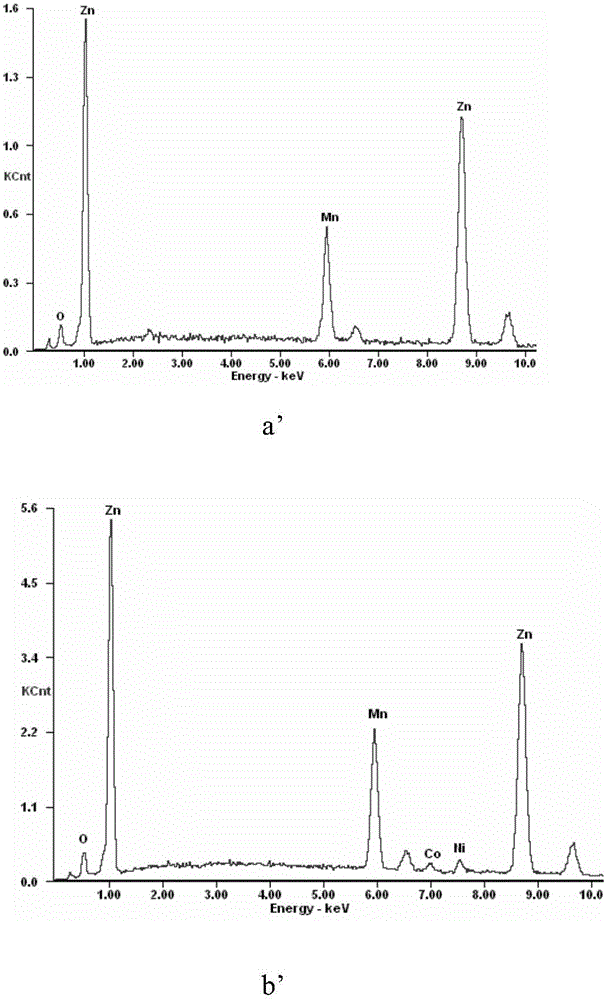

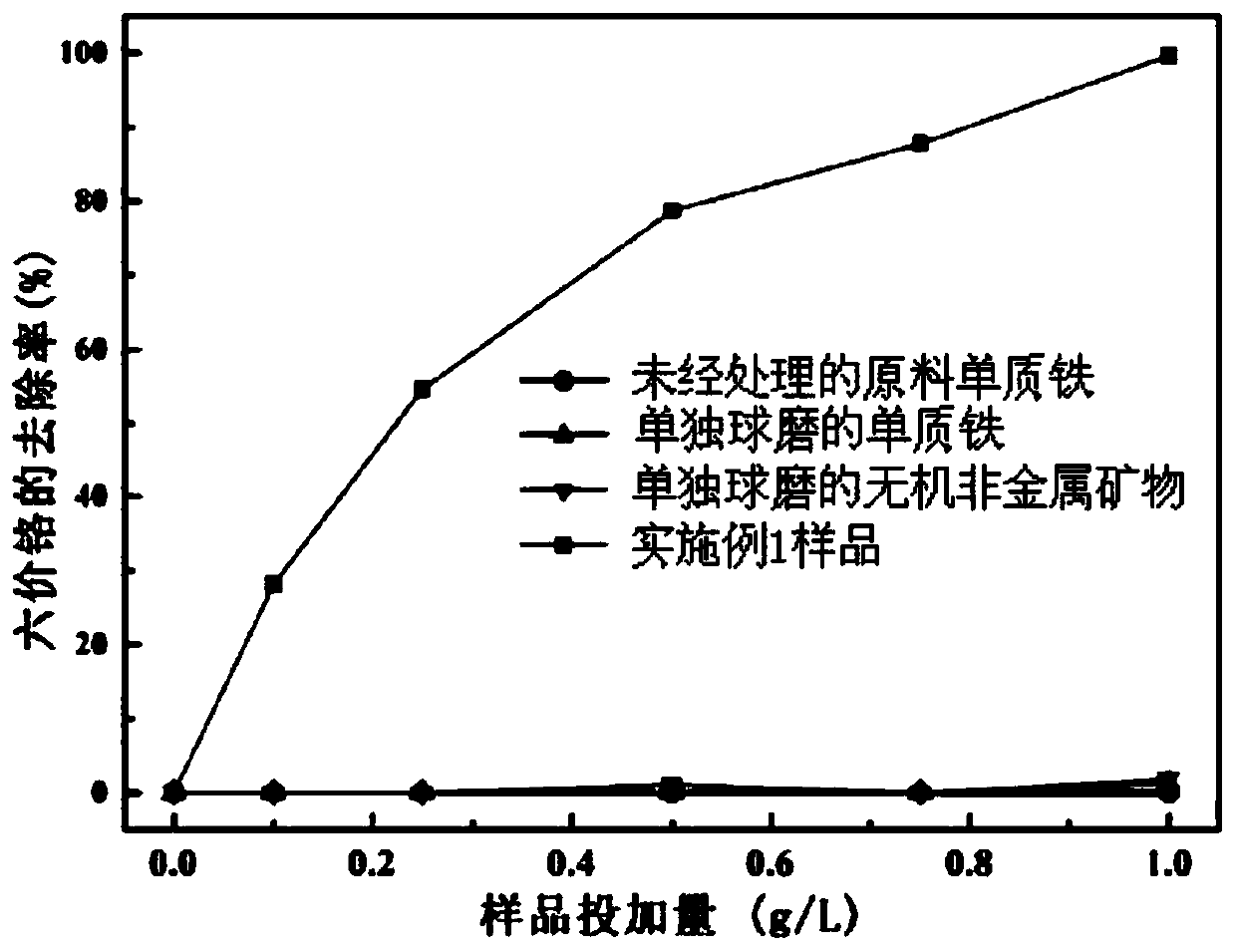

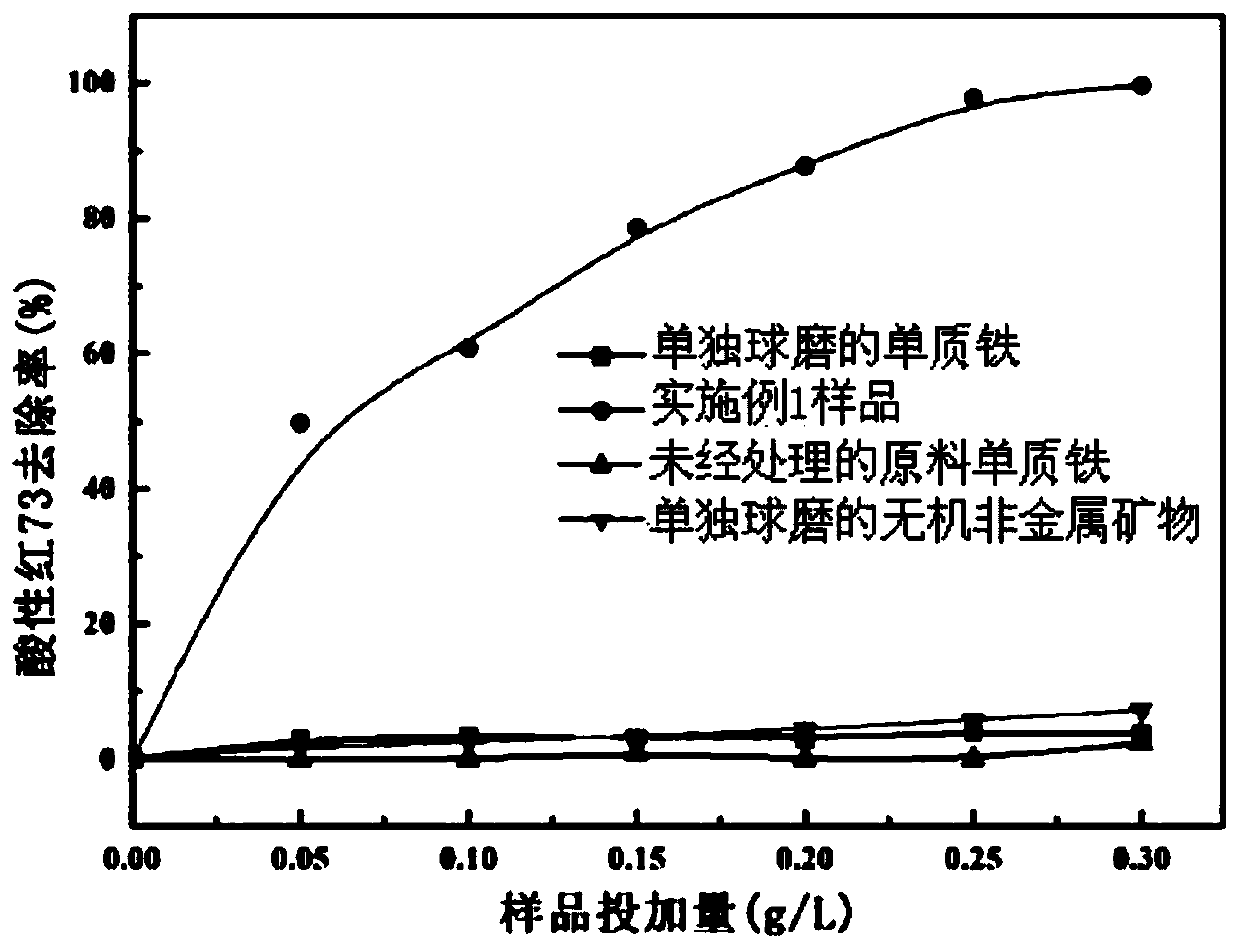

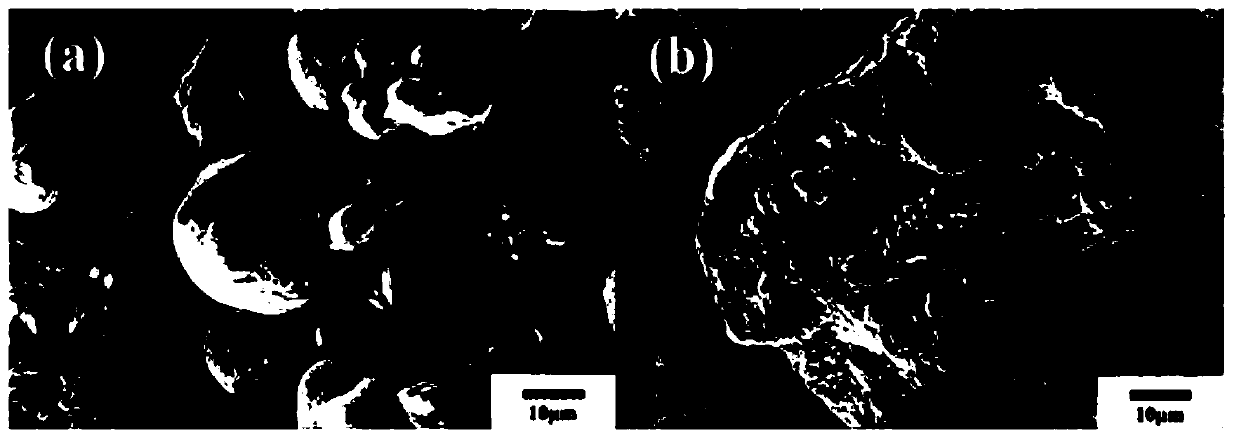

Zero-valent iron-mineral composite material with high reduction activity and preparation method therefor

InactiveCN110498494AHigh reduction potentialEffective recoveryWater contaminantsWaste water treatment from textile industryReduction ActivityMaceral

The invention relates to a zero-valent iron-mineral composite material with high reduction activity. The zero-valent iron-mineral composite material is obtained through subjecting elemental iron and an inorganic nonmetallic mineral, which are in a mass ratio of (4 to 10): 10, to ball milling in a planetary ball milling tank, wherein specific ball milling process conditions are as follows: the ratio of grinding media to material is 30 to 45, the ball milling time is 7 to 8 hours, and the revolution rate of ball milling is 500rpm to 600rpm. According to the zero-valent iron-mineral composite material with high reduction activity and the preparation method therefor, the inorganic nonmetallic mineral material and the elemental iron are combined, a specific ball milling process is employed, andthus, the inorganic nonmetallic mineral can form a dense amorphous-structured oolitic protective layer on the surface of zero-valent iron, so that on one hand, the sustained reduction power of the zero-valent iron is improved, in addition, the reactivity of the ball-milling-activated inorganic nonmetallic mineral is higher, and the zero-valent iron in the composite material is exposed.

Owner:WUHAN UNIV OF TECH

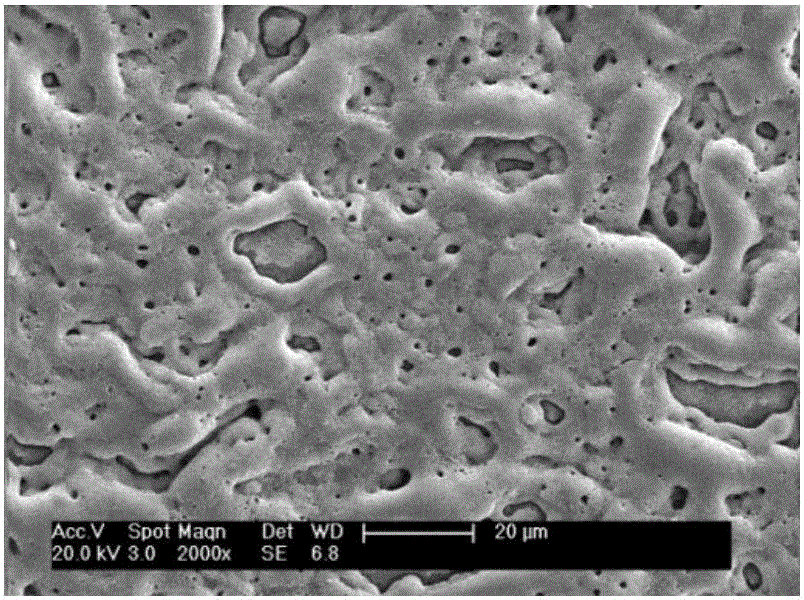

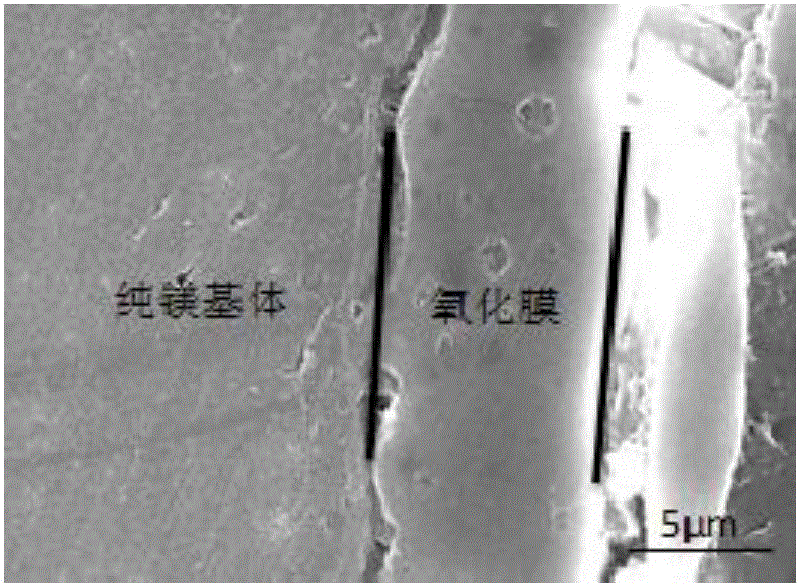

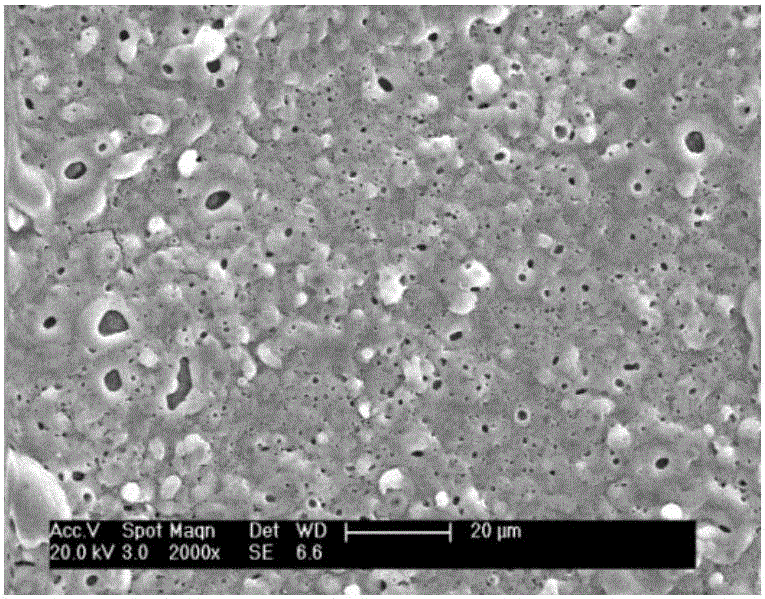

Method for preparing anti-microbial, mildew-resistant and corrosion-resistant membrane layer on magnesium metal surface

InactiveCN106480487AReduce porosityFacilitate depositionAnodisationAlternating currentMaterials science

The invention discloses a method for preparing an anti-microbial, mildew-resistant and corrosion-resistant membrane layer on a magnesium metal surface. Firstly a magnesium metal is pretreated, and then is put in an oxidation fluid. An alternating current with a current density of 0.5-2.5 A / dm<2> is connected. A layer of oxidation functional membrane is formed after the treatment is carried out for 10-40 minutes at the temperature of 15-30 DEG C. Then the magnesium metal is rinsed by deionized water and is sealed t in the pure water. The oxidation membrane layer with the thickness of 3-15[mu]m is obtained on the magnesium metal surface. The oxidation fluid contains the following solute: 40-80g / L NaOH, 50-90g / L Na2SiO3, 40-80g / L Na2B4O7, and 8-16g / L citric acid, and also contains soluble anti-microbial and mildew-resistant functional element salts. The magnesium metal surface after treatment by the method of the invention has a layer of the oxide membrane which takes a magnesia ceramic phase as a matrix. The anti-microbial and mildew-resistant functional elements Ag and Ni are dispersed and distributed in a matrix phase. The membrane layer has the good anti-microbial and mildew-resistant performance and good corrosion resistance, and can be used in many fields such as package and storage of food and clothing, and human body implantation medical instruments.

Owner:SOUTHEAST UNIV

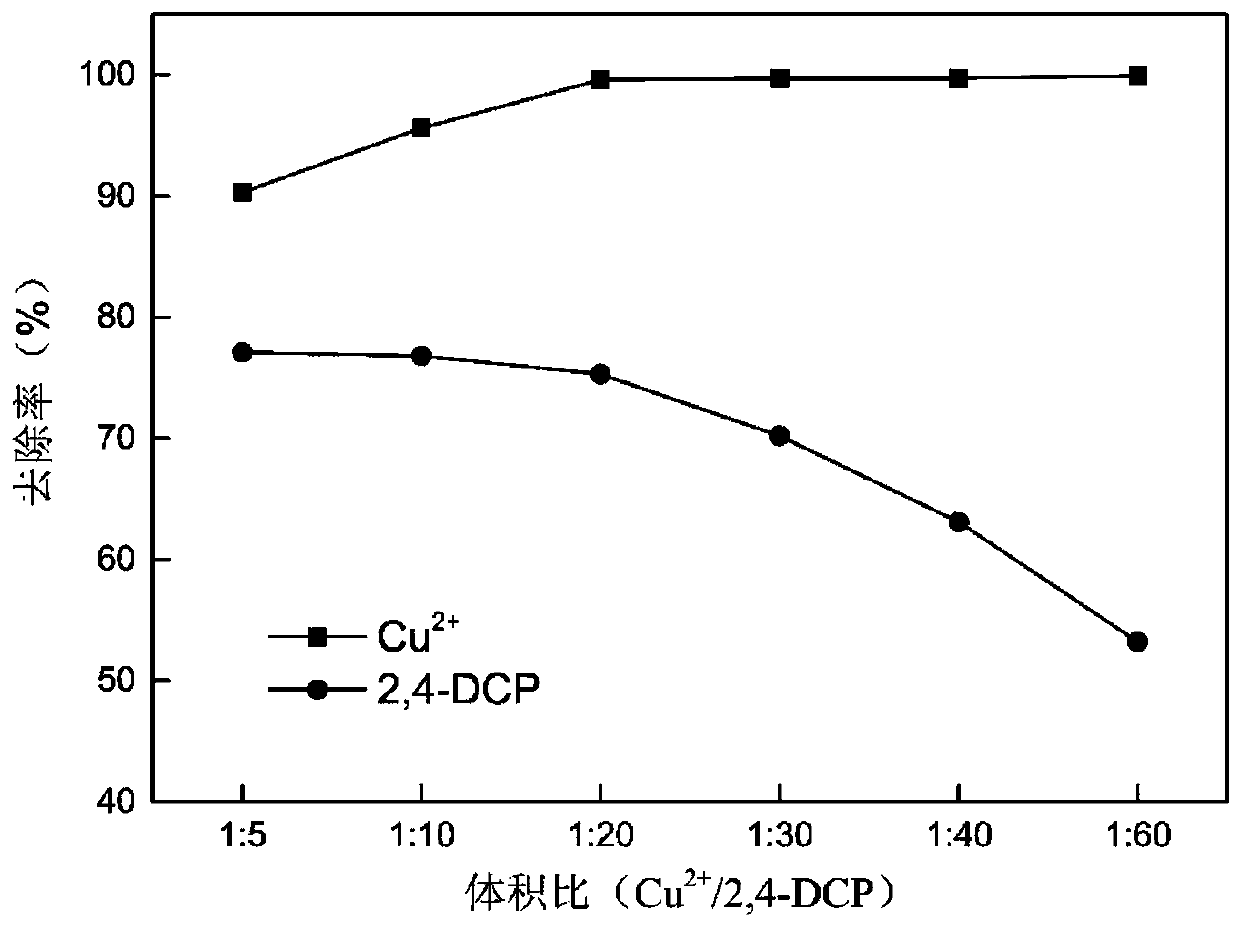

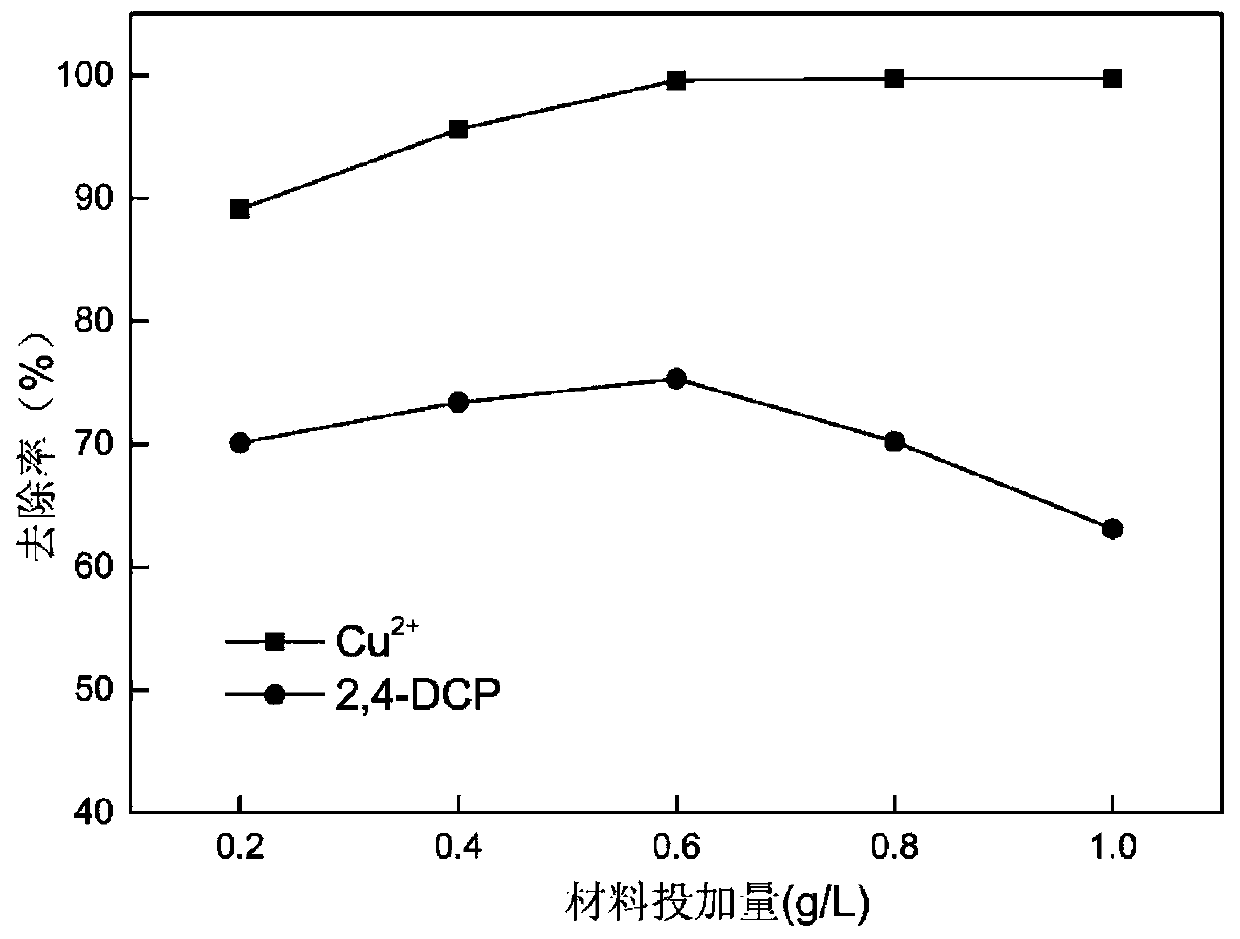

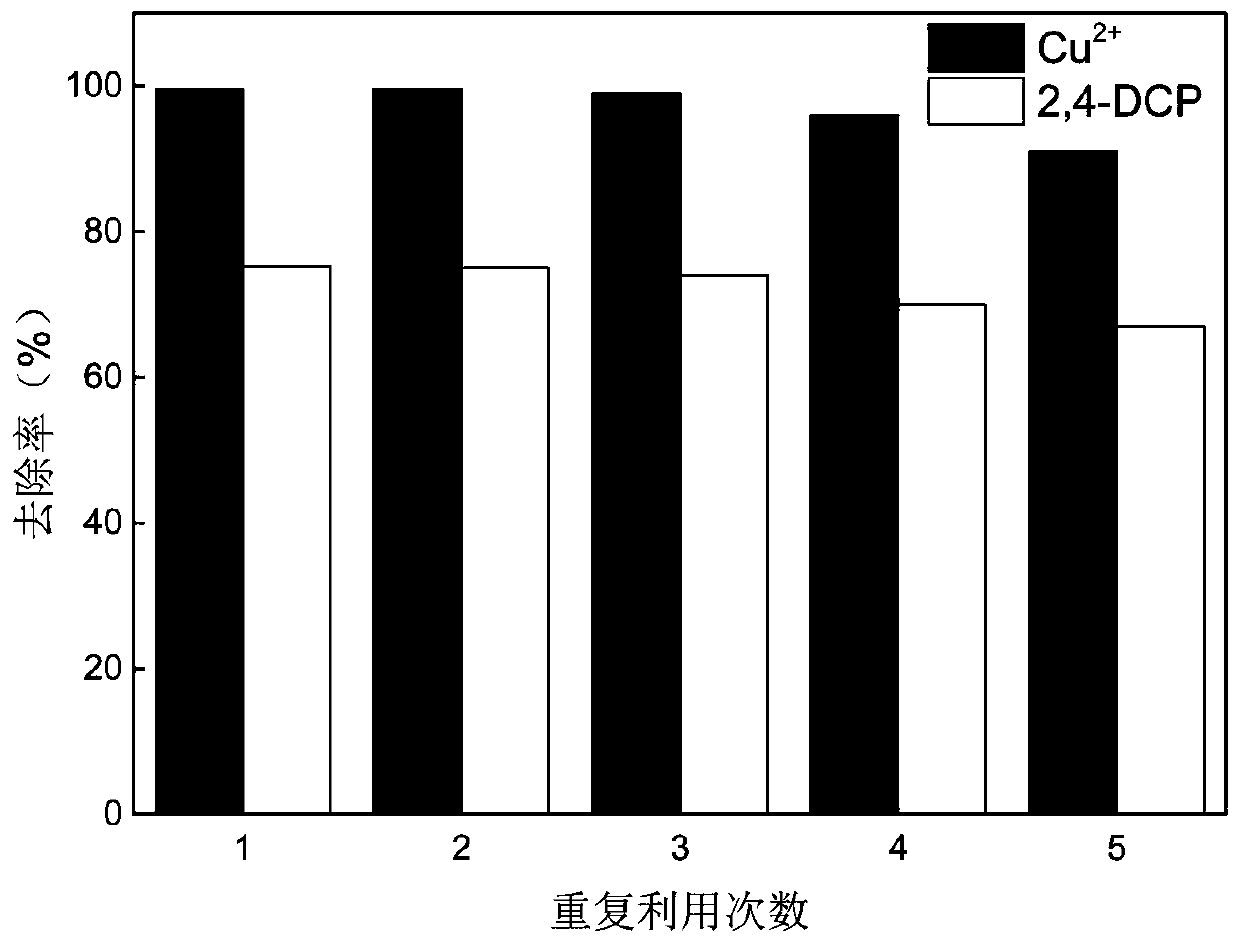

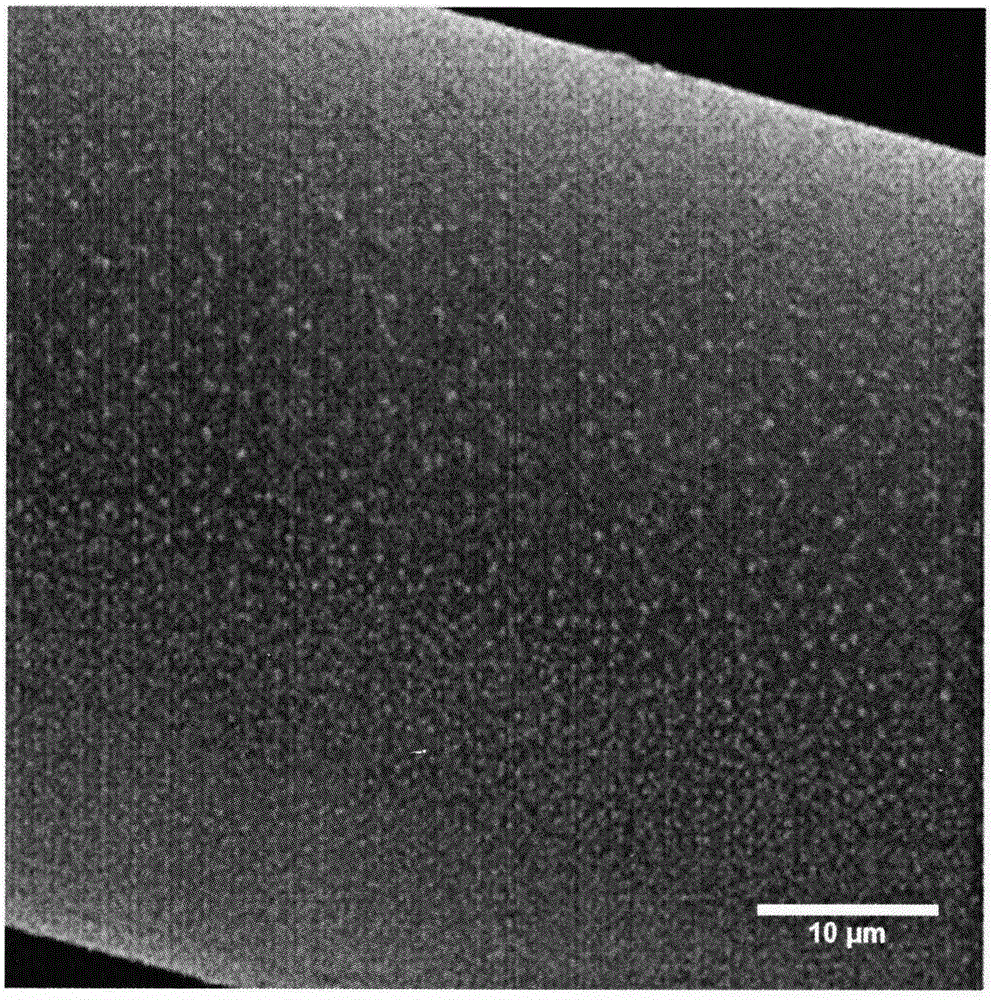

Application of zero-valent iron-loaded biochar in wastewater treatment

ActiveCN111573813AHigh reduction potentialEfficient degradationWater contaminantsWaste water treatment from metallurgical processZerovalent ironOrganic matter

The invention belongs to the technical field of environmental protection and industrial emission reduction and provides an application of zero-valent iron-loaded biochar in wastewater treatment. According to the application, zero-valent iron-loaded biochar is added into wastewater containing metal ions, wherein the wastewater is electroplating wastewater or a mixture of the electroplating wastewater and organic wastewater, the reduction potential of the metal ions is higher than that of zero-valent iron, the metal ions are reduced into elementary substances by the nano zero-valent iron, the elementary substances and elementary substance iron on the biochar form a multi-metal composite material, and organic matters are efficiently catalyzed to be degraded; and meanwhile, the electroplatingwastewater and the organic polluted wastewater are mutually diluted, so that the aim of treating wastes with wastes is fulfilled; the zero-valent iron loaded biochar has magnetism, can be convenientlyrecycled by an electromagnet, and still has good treatment capacity after being repeatedly used. The application of the zero-valent iron-loaded biochar in wastewater treatment achieves a good effectin wastewater treatment; and the material has magnetism and is easy to recycle, so that the zero-valent iron-loaded biochar has a good application prospect.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Multifunctional polyester fiber quilt mattress

ActiveCN105177750AHigh reduction potentialHigh affinityFilament forming substance formingBlanketPolyesterChemistry

The invention discloses a multifunctional polyester fiber quilt mattress. The multifunctional polyester fiber quilt mattress is characterized in that melting extrusion, grain-sized dicing and drying are carried out on nanometer germanium ore, nano-silver, coupling agents, modified lubricating agents, dispersing agents and polyester chip carriers, and raw-material master particles are obtained; the obtained raw-material master particles and polyester chip carriers are mixed to be subjected to melt spinning, and multifunctional polyester fibers are obtained; then the polyester fiber quilt mattress is manufactured through the multifunctional polyester fibers. According to the multifunctional polyester fiber quilt mattress, the nanometer germanium ore and the nano-silver are evenly doped into polyester chips through the special lubricating agents, the functional complex fibers are obtained, and the multifunctional quilt mattress with the effects of resisting and inhibiting bacteria, caring health, promoting metabolism, improving immunity of the human body and resisting aging is manufactured with the complex fibers as materials.

Owner:NINGBO XINTAISHENG TEXTILE SCI & TECH

Vegetable preservation sterilizing agent and preparation method thereof

InactiveCN107156289AExtend freshnessImprove catalytic performanceFood ingredient as antioxidantAcidic food ingredientsGrowth plantAntioxidant

The invention discloses a vegetable preservation sterilizing agent and a preparation method thereof, and relates to the technical field of preservation. The vegetable preservation sterilizing agent is mainly prepared from the following raw materials in parts by weight: 10-15 parts of nano silver, 5-9 parts of film coating agent, 15-18 parts of plant growth accelerator, 3-7 parts of plant growth inhibitor and 1-2 parts of antioxidant. The vegetable preservation sterilizing agent can effectively act on vegetables, the preservation sterilizing effect on the vegetables is improved, and the quality keeping and freshness retaining duration of the vegetables is prolonged. The preparation method of the vegetable preservation sterilizing agent comprises the following steps: according to parts by weight, adding 10-15 parts of the nano silver, 5-9 parts of the film coating agent, 15-18 parts of the plant growth accelerator, 3-7 parts of the plant growth inhibitor and 1-2 parts of the antioxidant into water,; stirring and pulping in turn. The preparation method has the advantages of simple operation steps, mild operation conditions, easiness in implementation and relatively great industrial application prospect.

Owner:重庆凰巢实业有限公司

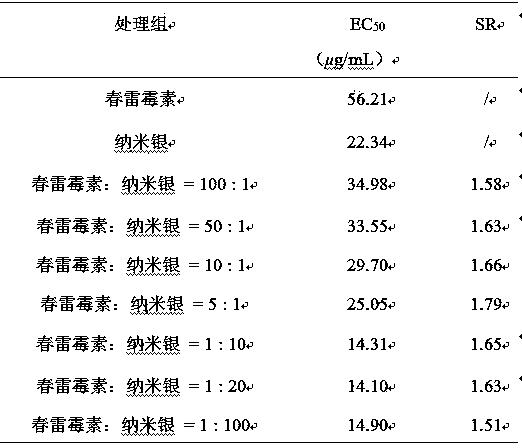

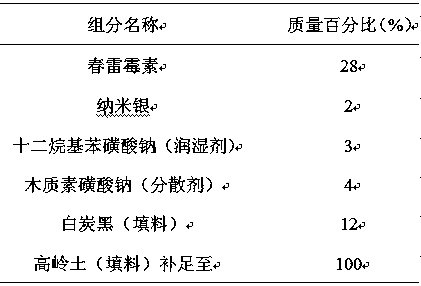

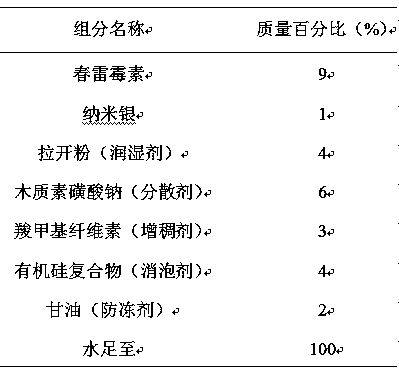

Pesticide composition by taking kasugamycin and nano-silver as active components and application thereof

ActiveCN111109295AImprove catalytic performanceHigh reduction potentialBiocideDisinfectantsOrganic chemistryToxicology

The invention relates to a pesticide composition by taking kasugamycin and nano-silver as active components and application thereof. The pesticide composition comprises the active components kasugamycin and nano-silver in a mass ratio of (100:1)-(1:100). After kasugamycin and nano-silver are compounded, an obvious synergistic effect is achieved.

Owner:陕西麦可罗生物科技有限公司

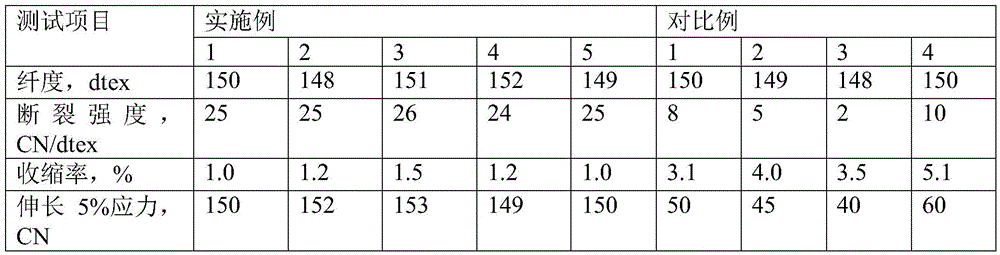

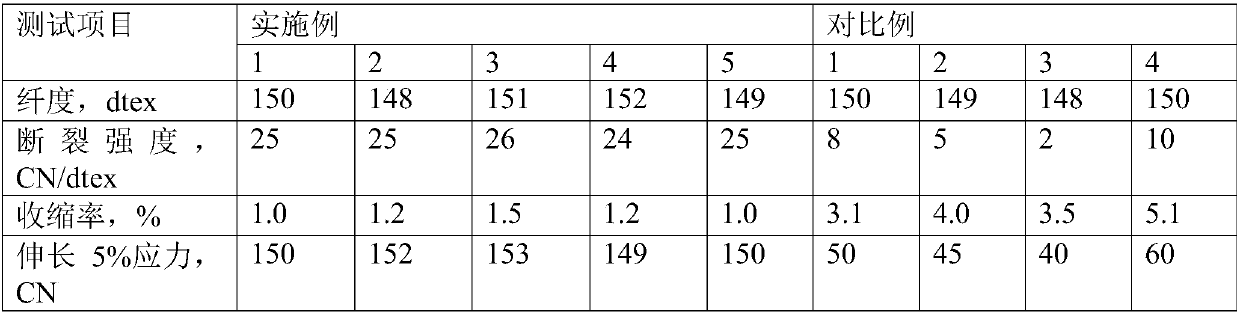

Pre-orientated polyester filament yarn and manufacturing method thereof

ActiveCN105420841AHigh breaking strengthIncrease tightnessMonocomponent polyesters artificial filamentArtifical filament manufactureFilamentationEngineering

The invention discloses pre-orientated polyester filament yarn and a manufacturing method thereof. The manufacturing method comprises the following steps that 1, a fiber-grade PET board is cut into chips, and the PET chips are dried for twice to enable the moisture content of the PET chips to be smaller than or equal to 25 ppm; dried PET chips are fused, hexadecyl trimethyl silver ammonium bromide, 1,1'-sulfo-bis(2-naphthol), 2-hydroxybenzophenone and a nickelous EDTA complex are added after the dried PET chips are completely fused, and after the materials are evenly mixed, filamentation is performed through extrusion forming and cooling is performed; 2, PET yarn obtained in the step 1 is sequentially processed through collecting through a first roller, heating through an upper heating box, twisting through a heater, drawing through a second roller, sizing through a lower heating box, further sizing through a third roller, oiling through an oiling device and forming through a winding roll to obtain the pre-orientated polyester filament yarn, wherein a chemical fiber oiling agent is contained in the oiling device, and the production speed of the pre-orientated polyester filament yarn is controlled at 3300 rad / min. The pre-orientated polyester filament yarn has the better anti-ultraviolet property and the higher breaking strength.

Owner:浙江恒百华化纤有限公司

Intelligent facial mask controlled by mobile phone APP

InactiveCN107397531AMaintain disequilibriumPromote circulationElectrotherapyMedical devicesPersonalizationAdditive ingredient

The invention belongs to the technical field of cosmetics intelligence. The intelligent facial mask is composed of a mobile phone APP operating system, an intelligent host 'medium-frequency pulse introducing instrument' and a face pasting membrane. A working procedure is divided into three steps of cleansing, introducing and relieving. According to the principle, the intelligent host with a biological negative current (3V negative current) is utilized for conducting pore dredging and skin cleansing on skin through micro-frequency vibration, essence ingredients in the facial mask are introduced into skin deep layers, absorption of skin to nutrient substances and active substances is promoted, the skin is released, and the using efficiency of the facial mask is improved. The whole process is monitored through the mobile phone APP operating system, the skin conditions before and after the facial mask applying process are embodied digitally, and a rationalized skin care suggestion is given out; and a personalized and customized facial mask using manner is really achieved.

Owner:李大兴

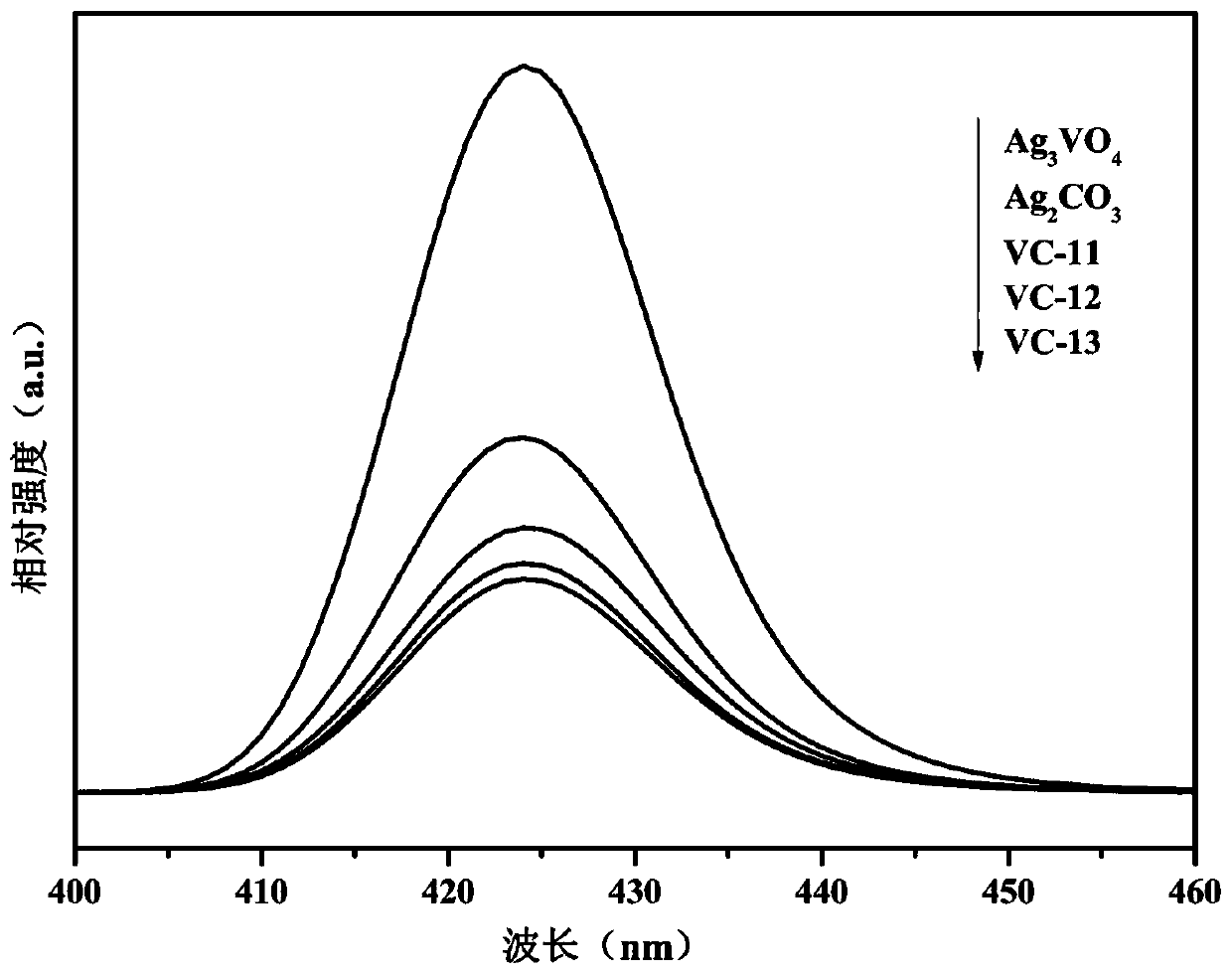

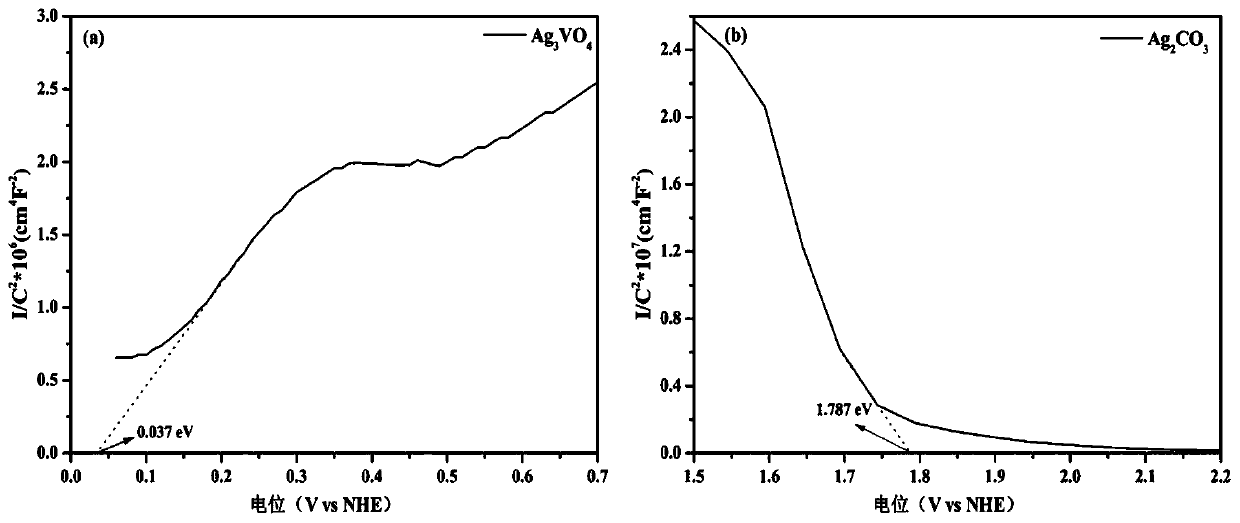

Silver vanadate/silver carbonate p-n heterojunction composite photocatalyst as well as preparation method and application thereof

ActiveCN110975906AImprove separation efficiencyEfficient degradationPhysical/chemical process catalystsWater/sewage treatment by irradiationSilver carbonatePhysical chemistry

The invention discloses a silver vanadate / silver carbonate p-n heterojunction composite photocatalyst as well as a preparation method and application thereof. The silver vanadate / silver carbonate p-nheterojunction composite photocatalyst is prepared by taking silver carbonate as a carrier, and the silver carbonate is coated with silver vanadate. The composite photocatalyst has the advantages of high photo-induced electron-hole separation efficiency, high photocatalytic activity, strong light absorption capability, good stability, corrosion resistance and the like, and is a novel visible lightcatalyst, and the preparation method has the advantages of simple and convenient synthesis method, low raw material cost, low energy consumption, short time consumption, easily-controlled conditionsand the like, and is suitable for popularization and application. The composite photocatalyst disclosed by the invention can be used for degrading antibiotic wastewater and dye wastewater, has the advantages of stable photocatalytic performance, strong corrosion resistance and high pollutant degradation efficiency, and has a very good practical application prospect.

Owner:HUNAN AGRICULTURAL UNIV

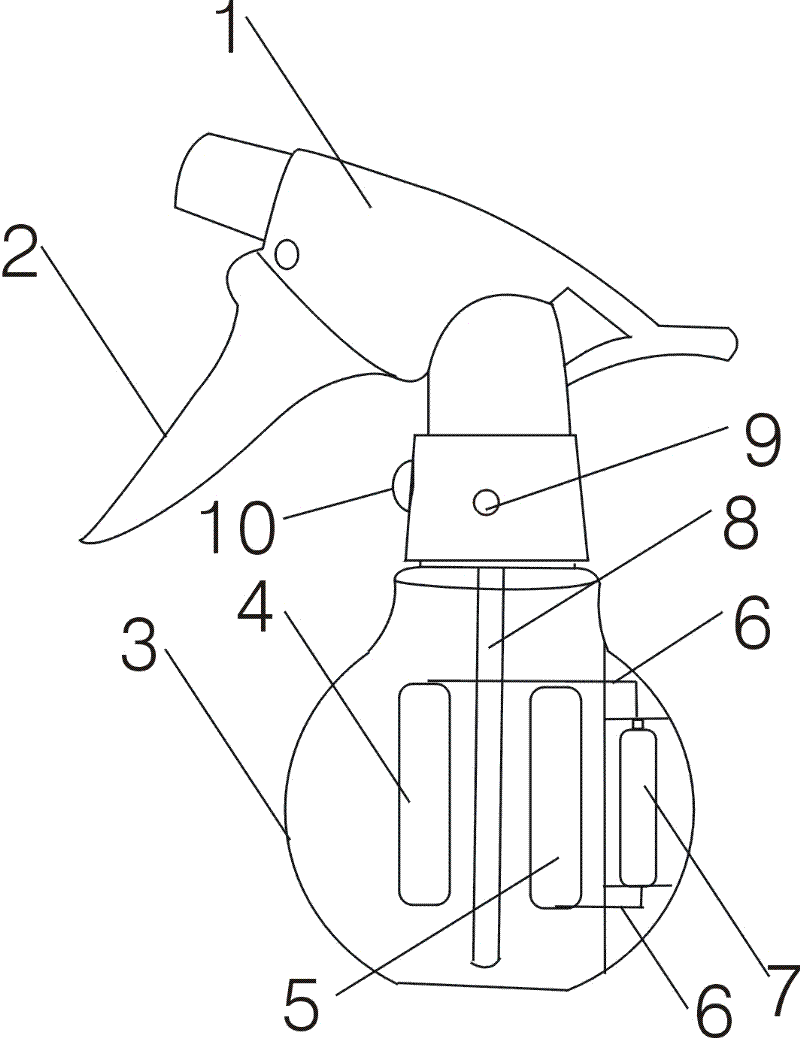

Silver ion water spray bottle

InactiveCN102327833AImprove catalytic performanceAvoid infectionSingle-unit apparatusWater/sewage treatment using germicide/oligodynamic-processElectrical batteryEngineering

The invention relates to a silver ion water spray bottle, which comprises a spray head and a bottle body, wherein a silver ion generator is arranged in the bottle body, and a battery is arranged at one side of the bottle body; the silver ion generator also comprises a silver metal positive electrode plate and a silver metal negative electrode plate, wherein a positive electrode and a negative electrode are connected with the battery through a power wire; and a power switch and a power indicator lamp are arranged in the bottle body. According to the invention, the silver ion generator is arranged in the spray bottle and used for sterilizing, and therefore the silver ion water spray bottle is practical and convenient.

Owner:张圣坤

A multifunctional polyester fiber quilt

ActiveCN105177750BHigh reduction potentialHigh affinityFilament forming substance formingBlanketPolyesterMasterbatch

The invention discloses a multifunctional polyester fiber quilt. The raw material is obtained by melting and extruding nano-germanium ore, nano-silver, coupling agent, modified lubricant, dispersant and polyester chip carrier, dicing and drying. masterbatch, and then the obtained raw material masterbatch and polyester chip carrier are mixed and melt-spun to obtain multifunctional polyester fibers, and then the multifunctional polyester fibers are made into polyester fiber quilts. In the present invention, special lubricants are used to uniformly dope nano-germanium ore and nano-silver in polyester slices to obtain functional composite fibers, and use them as materials to manufacture antibacterial, antibacterial, health care, promote metabolism, and improve human immunity. , Anti-aging multifunctional quilt.

Owner:NINGBO XINTAISHENG TEXTILE SCI & TECH

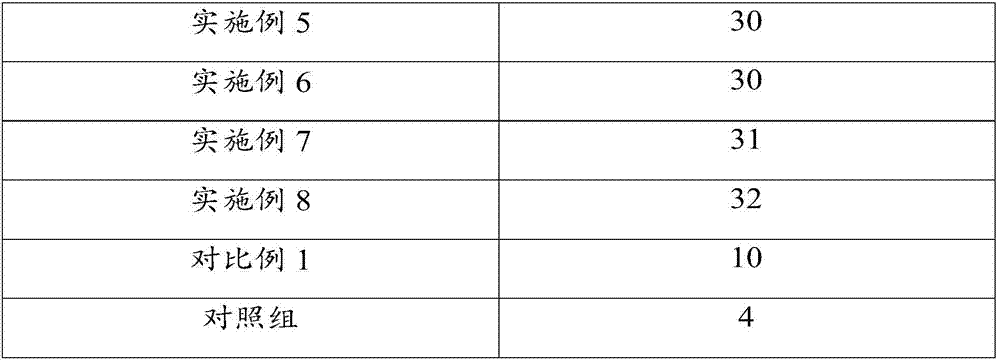

Pesticide composition and application thereof with kasugamycin and nano-silver as active components

ActiveCN111109295BImprove catalytic performanceHigh reduction potentialBiocideDisinfectantsOrganic chemistryToxicology

The invention relates to a pesticide composition with kasugamycin and nano-silver as active components and an application thereof. The pesticide composition comprises active components with a mass ratio of kasugamycin and nano-silver of 100:1-1:100. The compounded kasugamycin and nano silver used in the present invention have obvious synergistic effect.

Owner:陕西麦可罗生物科技有限公司

Scented candle for purifying air and preparation method thereof

InactiveCN103992884AImprove permeabilityImprove adsorption capacityCandlesAuxillary pretreatmentSuspended particlesCandle

The invention discloses a scented candle for purifying the air and a preparation method thereof. The scented candle is prepared from the following raw materials, by weight, 25-90 parts of soybean oil, 3-8 parts of essential oil and 1-5 parts of silver particles. The invention provides an air-purifying scented candle capable of kill bacteria and microbes in the air and purifying the air indoors during the burning process of the candle and a preparation method thereof. As silver particles crashes into moisture in the air to coagulate, suspended particles in the air are carried along with the coagulated silver particles to the ground. Thus, proportions of suspensions in the air are reduced.

Owner:青岛兰兰生物科技有限公司

Etching solution capable of effectively reducing galvanic effect

InactiveUS8999194B1Effectively reducing Galvanic effectHigh reduction potentialSemiconductor/solid-state device manufacturingPrinted circuit manufactureEtchingPower flow

The present invention is to provide an etching solution capable of effectively reducing Galvanic effect, wherein the etching solution is obtained by way of dissolving an etchant and a nitrogen containing five-member heterocyclic compound in water. Thus, when at least one first metal (e.g., gold) and at least one second metal (e.g., copper) disposed on a substrate is treated with a wet etching process by using this etching solution, the nitrogen containing five-member heterocyclic compound would form an organic protecting film on the first metal having higher reduction potential, so as to effectively avoid the second metal from being over etched resulted from the Galvanic effect.

Owner:E CHEM ENTERPRISE CORP

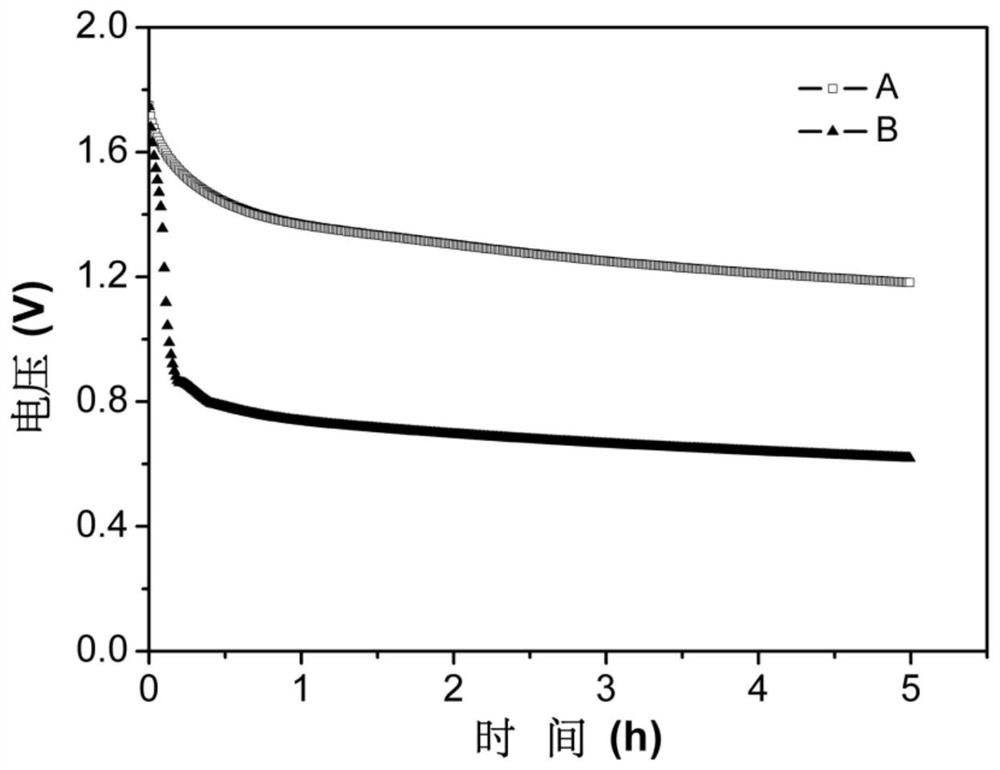

A kind of preparation method of gel polymer electrolyte

ActiveCN109192544BEasy to prepareLow costHybrid capacitor electrolytesHybrid/EDL manufacturePolymer electrolytesLithium sulphate

A preparation method of gel polymer electrolyte disclosed in the invention includes dissolve polymer matrix in water, adding dispersion of halide ionic liquid and carbon nanotube, adding lithium sulfate solution, removing excess wat, and preparing gel polymer electrolyte with redox activity. The preparation method of the gel polymer electrolyte of the invention is simple, and the self-discharge phenomenon of the supercapacitor can be effectively reduced. The invention also discloses the application of the prepared gel polymer electrolyte in a supercapacitor, in particular an active electrolyteenhanced supercapacitor.

Owner:HUAQIAO UNIVERSITY

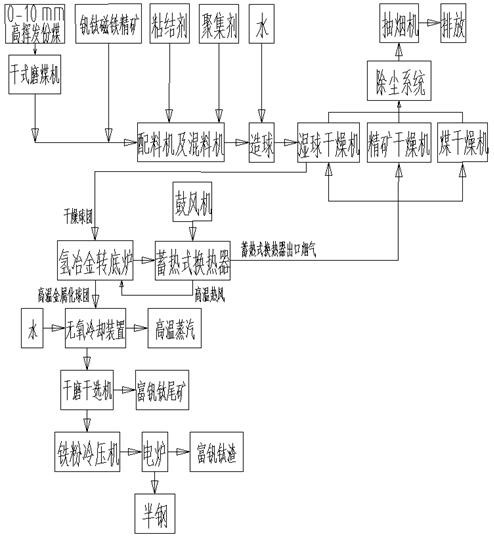

Vanadium-titanium magnetite ore coal-based reduction process

InactiveCN111748687AMeet environmental protection requirementsTake advantage ofElectric furnaceProcess efficiency improvementSlagTitanomagnetite

The invention discloses a vanadium-titanium magnetite ore coal-based reduction process. The adopted production process includes the steps that vanadium-titanium magnetite concentrate, high- volatile coal, a binder and a focusing agent are subjected to batching, blending and pelletizing according to the ratio being 100:(38-40):(1-3):(1-2); in the process of conducting heating and temperature rise on dried pellets in a rotary hearth furnace, reduction is conducted on vanadium-titanium magnetite ore through H2 generated by coal sufficient pyrolysis and H2 generated by carbon gasification reactionwith H2O as a gasification agent, the fire box temperature is controlled at 1250 DEG C to 1300 DEG C, the calcination time is 50-55 min, the vanadium-titanium magnetite ore can be sufficiently reduced, and after reduction materials are subjected to dry grinding dry separation and electric furnace smelting separation, semi-steel, vanadium-titanium-rich tailings and vanadium-titanium-rich slag canbe obtained. The vanadium-titanium magnetite ore coal-based reduction process has the advantages that vanadium-titanium magnetite ore reduction is sufficient, the product metallization ratio is high,the production energy consumption is low, the single-furnace production capacity is high and essence emission reduction is achieved; and after the vanadium-titanium-rich tailings and the vanadium-titanium-rich slag are subjected to acid leaching, iron, vanadium, titanium and other valuable elements in the vanadium-titanium magnetite ore can be recycled.

Owner:JIUQUAN IRON & STEEL GRP

Silver ion and ozone sterilization environment-friendly protection mop bucket

InactiveCN102525369AWon't spoilFacilitated releaseCarpet cleanersFloor cleanersOzone SterilizationMetal

The invention relates to a silver ion and ozone sterilization environment-friendly protection mop bucket, which comprises a bucket body, wherein the inner wall of the bucket body is respectively provided with a silver metal positive electrode plate and a silver metal negative electrode plate, the outer wall of the bucket body is provided with a battery box and batteries, and lead-out wires of the silver metal positive electrode plate and the silver metal negative electrode plate are connected with the batteries. An ozone generator is arranged outside the bucket body, and an ozone outlet is arranged on the lower portion in the bucket body. The silver ion and ozone sterilization environment-friendly protection mop bucket is used to disinfect and sterilize by adopting silver ions or ozone, and is environment-friendly, practical and convenient.

Owner:张月婵

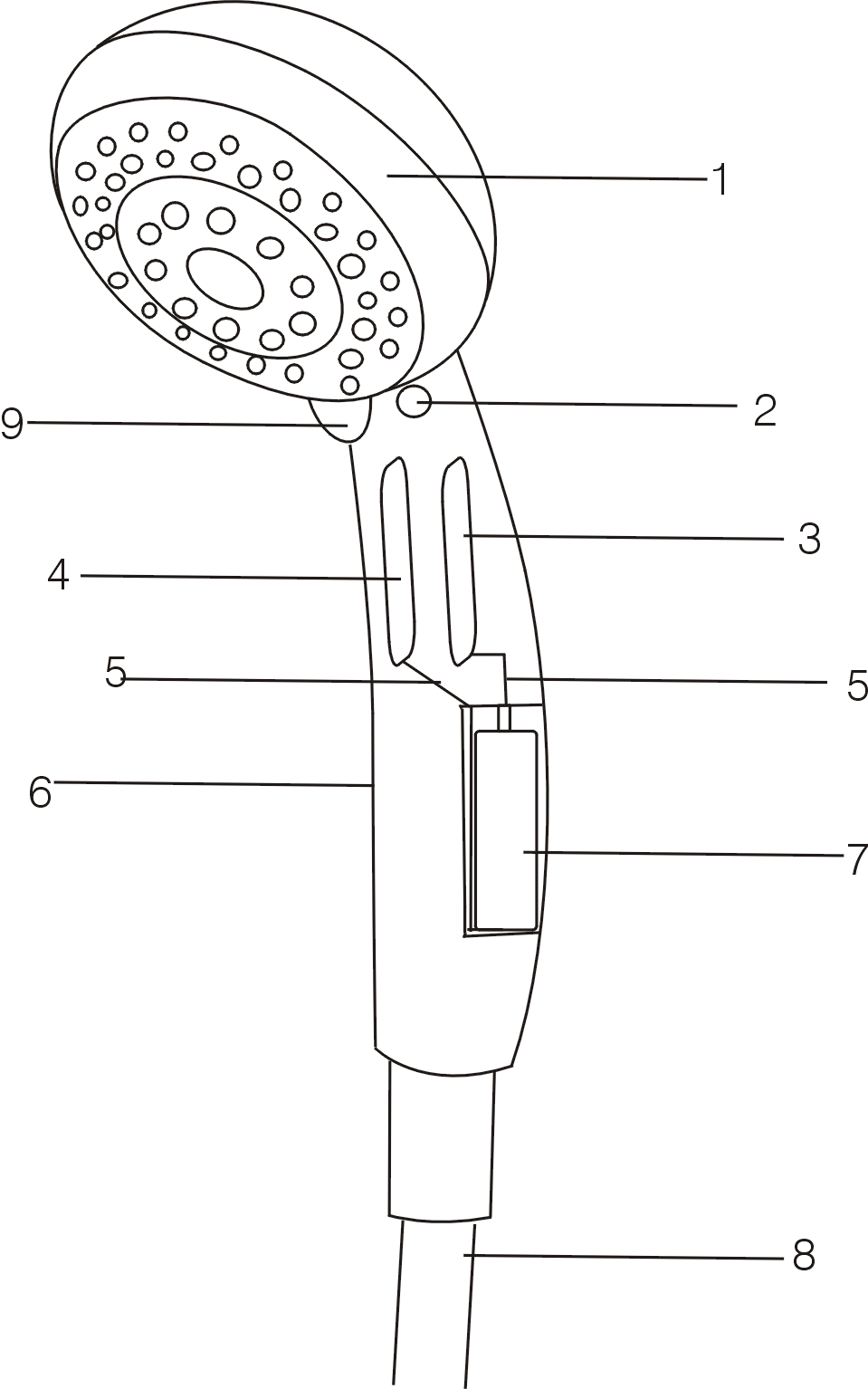

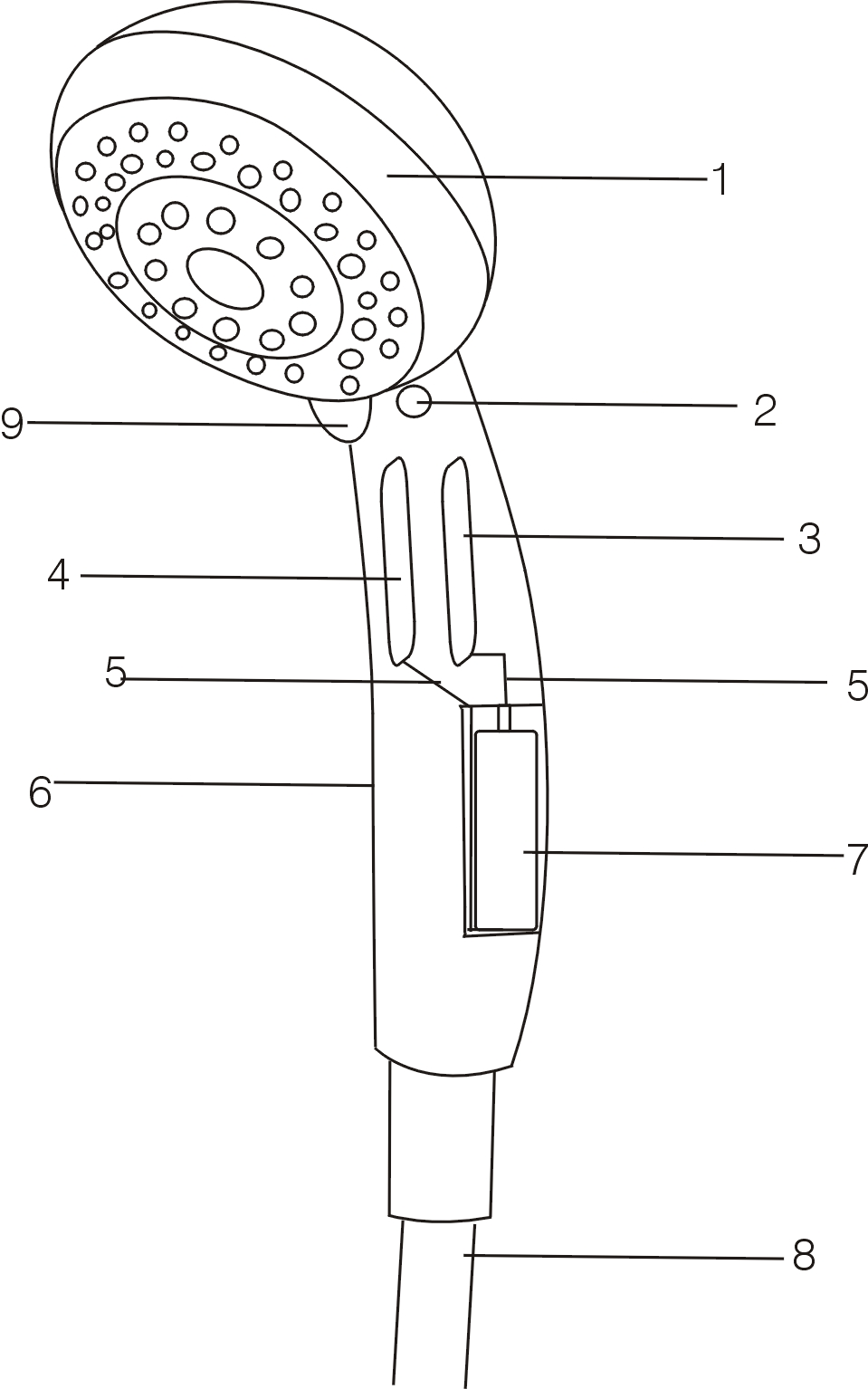

Silver ion shower head

InactiveCN102179320AImprove catalytic performanceAvoid infectionSpray nozzlesWater/sewage treatment using germicide/oligodynamic-processElectrical batteryMetal

The invention relates to a silver ion shower head comprising a spray head, a handle and a water inlet pipe, wherein the handle is internally provided with a silver ion generator, one side of the handle is provided with a battery, the silver ion generator comprises a silver metal positive electrode substrate and a silver metal negative electrode substrate, and the positive electrode and the negative electrode of the silver metal positive electrode substrate and the silver metal negative electrode substrate are connected with the battery through a power line. Water containing silver ions can be used for sterilizing on human bodies and is practicable and convenient.

Owner:张圣坤

Polyester pre-oriented filament and its manufacturing method

ActiveCN105420841BHigh breaking strengthIncrease tightnessMonocomponent polyesters artificial filamentArtifical filament manufacture2-hydroxybenzophenoneBreaking strength

The invention discloses pre-orientated polyester filament yarn and a manufacturing method thereof. The manufacturing method comprises the following steps that 1, a fiber-grade PET board is cut into chips, and the PET chips are dried for twice to enable the moisture content of the PET chips to be smaller than or equal to 25 ppm; dried PET chips are fused, hexadecyl trimethyl silver ammonium bromide, 1,1'-sulfo-bis(2-naphthol), 2-hydroxybenzophenone and a nickelous EDTA complex are added after the dried PET chips are completely fused, and after the materials are evenly mixed, filamentation is performed through extrusion forming and cooling is performed; 2, PET yarn obtained in the step 1 is sequentially processed through collecting through a first roller, heating through an upper heating box, twisting through a heater, drawing through a second roller, sizing through a lower heating box, further sizing through a third roller, oiling through an oiling device and forming through a winding roll to obtain the pre-orientated polyester filament yarn, wherein a chemical fiber oiling agent is contained in the oiling device, and the production speed of the pre-orientated polyester filament yarn is controlled at 3300 rad / min. The pre-orientated polyester filament yarn has the better anti-ultraviolet property and the higher breaking strength.

Owner:浙江恒百华化纤有限公司

Anticorrosion and antibacterial treatment method for wrought iron railings

ActiveCN111058022BEnhanced inhibitory effectHigh antibacterial efficiencyMetallic material coating processesSpecial surfacesAnti bacterialAntibacterial property

Owner:广州市敬业金属实业有限公司

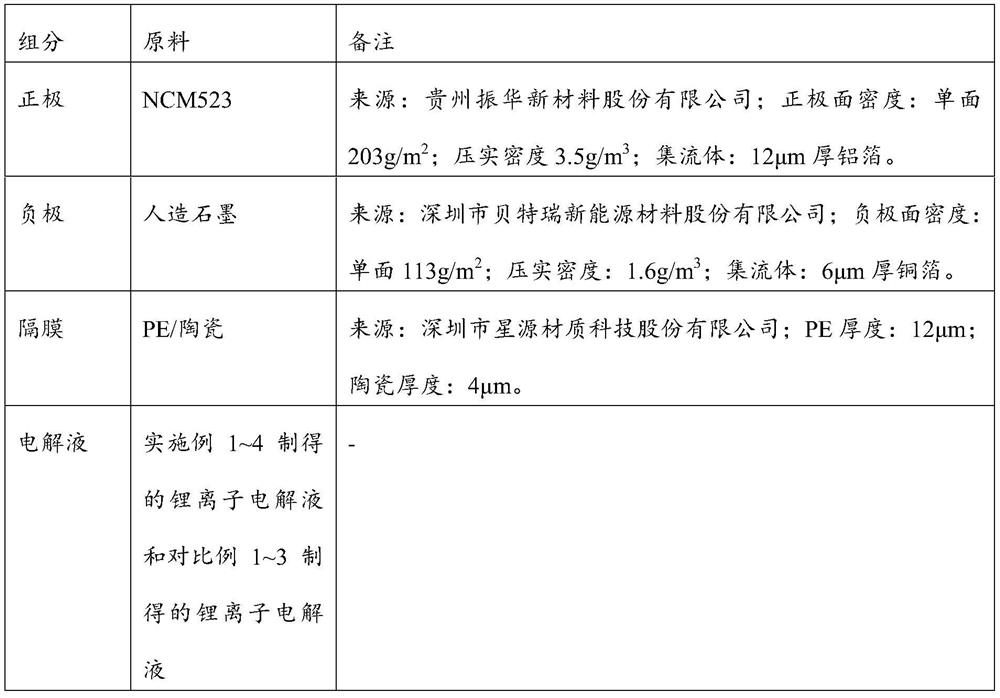

Lithium ion battery electrolyte and preparation method and application thereof

PendingCN114039092AInhibit the combustion chain reactionReduce concentrationSecondary cells servicing/maintenanceOrganic electrolytesOrganosolvLithium electrode

The invention discloses a lithium ion battery electrolyte as well as a preparation method and application thereof. The lithium ion battery electrolyte comprises the following preparation raw materials: an organic solvent, a lithium salt and an additive, and the additive is prepared from dimethyl methylphosphate, di (2, 2, 2-trifluoroethyl) carbonate and diphenyldimethoxysilane. According to the lithium ion battery electrolyte disclosed by the invention, dimethyl methylphosphate, di (2, 2, 2-trifluoroethyl) carbonate and diphenyldimethoxysilane are used as electrolyte additives, and the additives act together, so that the lithium ion battery electrolyte forms a film on the surface of a cathode, the thermal stability of an SEI film is improved, and the SEI film is not easy to decompose under a high-temperature condition; and meanwhile, the cycle performance of the lithium ion battery at high temperature is also improved.

Owner:湖南法恩莱特新能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com