Multifunctional polyester fiber quilt mattress

A polyester fiber and polyester chip technology, applied in the field of polyester fiber, can solve the problems of easy contamination, easy pilling, low moisture content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

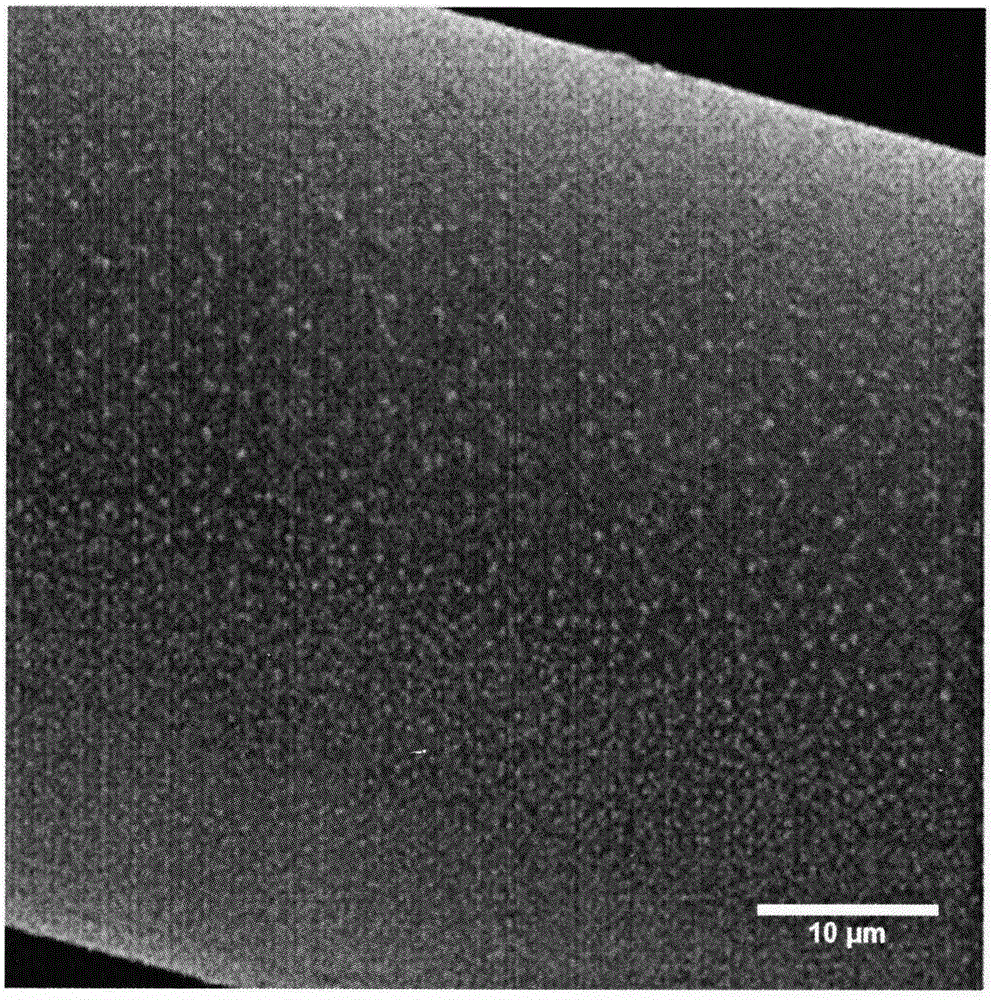

Image

Examples

Embodiment 1

[0024] (1) the particle diameter is 150nm nano-germanium ore, the particle diameter is 100nm nano-silver colloidal particles, aluminate, lubricant, cetyltrimethylammonium bromide, organic dibasic acid and dibasic alcohol polycondensation The formed polyester chip carrier is mixed in parts by weight of 5:5:1:1:1:87, then melted and extruded, pelletized, and dried to obtain the raw material masterbatch, wherein the lubricant is made of octaisobutyl cage Silsesquioxane and white oil are mixed in a weight ratio of 1:100;

[0025] (2) Proportioning the masterbatch and the polyester chip carrier in 1:10 parts by weight, then cleaning, mixing, shredding and drying;

[0026] (3) Put the dried raw materials into the screw extruder to melt to form a melt and extrude with the screw. The temperatures in the first zone to the sixth zone of the screw extruder are: 299°C for the first zone and 295°C for the second zone. , The third zone is 291°C, the fourth zone is 287°C, the fifth zone is ...

Embodiment 2

[0032] (1) the nano-germanium ore with a particle diameter of 75nm, the particle diameter of 50nm nano-silver colloidal particles, titanate, lubricant, cetyltrimethylammonium bromide, organic dibasic acid and dibasic alcohol polycondensate The formed polyester chip carrier is mixed in parts by weight of 8:8:2:2:2:78, then melted and extruded, pelletized, and dried to obtain raw material master batches, wherein the lubricant is made of octaisobutyl cage Silsesquioxane and white oil are mixed at a weight ratio of 0.1:100;

[0033] (2) Proportioning the masterbatch and the polyester chip carrier in 1:35 parts by weight, then cleaning, mixing, shredding and drying;

[0034] (3) Put the dried raw materials into the screw extruder to melt to form a melt and extrude with the screw. The temperatures in the first zone to the sixth zone of the screw extruder are: 298°C for the first zone and 294°C for the second zone. , The third zone is 290°C, the fourth zone is 286°C, the fifth zone ...

Embodiment 3

[0040] (1) Polycondensation of nano-germanium ore with a particle size of 105nm, nano-silver particles with a particle size of 80nm, silane coupling agent, lubricant, cetyltrimethylammonium bromide, organic dibasic acid and dibasic alcohol The resulting polyester chip carrier is mixed in parts by weight of 10:10:3:3:3:71, melt extruded, pelletized, and dried to obtain raw material master batches, wherein the lubricant is made of octaisobutyl It is obtained by mixing cage silsesquioxane and white oil in a weight ratio of 0.6:100;

[0041] (2) Proportioning the masterbatch and polyester chips in 1:5 parts by weight, then cleaning, mixing, shredding and drying;

[0042] (3) Put the dried raw materials into the screw extruder to melt to form a melt and extrude with the screw. The temperatures in the first zone to the sixth zone of the screw extruder are: 297°C for the first zone and 293°C for the second zone. , The third zone is 289°C, the fourth zone is 285°C, the fifth zone is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com