Silver vanadate/silver carbonate p-n heterojunction composite photocatalyst as well as preparation method and application thereof

A photocatalyst, silver carbonate technology, applied in the field of chemistry, can solve the problems of small flat-band potential difference of semiconductor, unable to form built-in electric field, unable to further improve the separation of photogenerated electron-hole pairs, etc., to achieve stable photocatalytic performance, convenient The effect of industrialized utilization and good practical application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

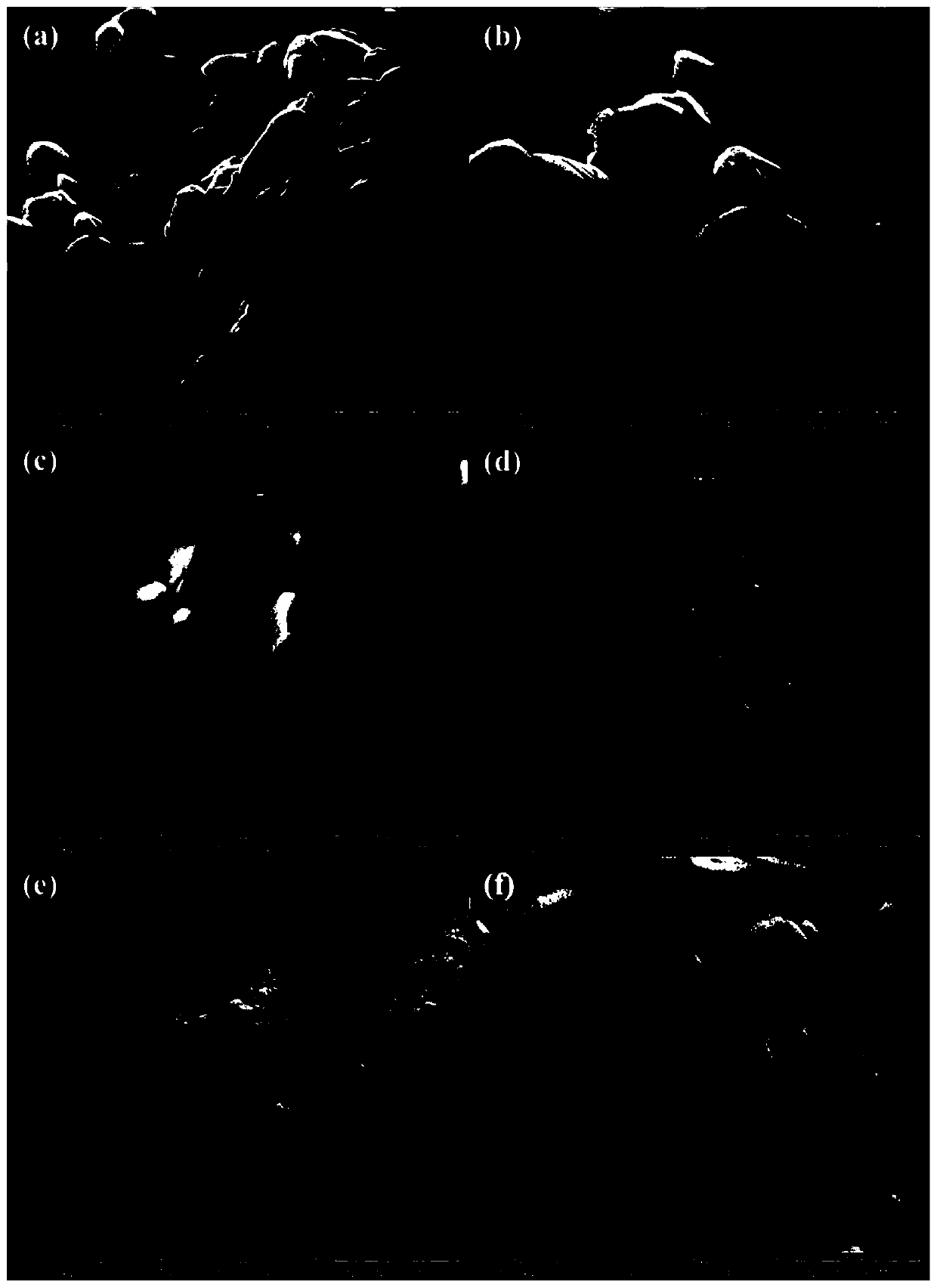

[0036] A silver vanadate / silver carbonate p-n heterojunction composite photocatalyst, the silver vanadate / silver carbonate p-n heterojunction composite photocatalyst uses silver carbonate as a carrier, and the silver vanadate is modified on the silver vanadate.

[0037] In this embodiment, the mass percentage of silver carbonate in the silver vanadate / silver carbonate composite photocatalyst is 50%, and the mass percentage of silver vanadate is 50%.

[0038] In this embodiment, silver carbonate has a rod-like structure and is a p-type semiconductor; silver vanadate has a nano-particle structure and is an n-type semiconductor.

[0039] A kind of preparation method of the silver vanadate / silver carbonate composite photocatalyst of above-mentioned present embodiment, comprises the following steps:

[0040] (1) Dissolve 1.0499 g of silver nitrate in 20 mL of deionized water under dark stirring conditions, and continue stirring for 20 minutes to obtain a silver nitrate solution.

[...

Embodiment 2

[0049] A silver vanadate / silver carbonate composite photocatalyst is basically the same as the silver vanadate / silver carbonate composite photocatalyst in embodiment 1, the difference is only: vanadic acid in the silver vanadate / silver carbonate composite photocatalyst of embodiment 2 The mass percentage of silver is 33%, and the mass percentage of silver carbonate is 67%.

[0050] A preparation method of the above-mentioned silver vanadate / silver carbonate composite photocatalyst of the present embodiment is basically the same as the preparation method in Example 1, the difference is only that the quality of silver nitrate used in Example 2 is 1.5913g, sodium bicarbonate The mass of 0.2675g,.

[0051] The silver vanadate / silver carbonate composite photocatalyst prepared in Example 2 is named VC-12.

[0052] figure 1 The silver vanadate / silver carbonate composite photocatalyst (VC-12) that the embodiment of the present invention 2 makes, the rod-shaped silver carbonate (Ag ...

Embodiment 3

[0054] A silver vanadate / silver carbonate composite photocatalyst is basically the same as the silver vanadate / silver carbonate composite photocatalyst in embodiment 1, the difference is only: vanadic acid in the silver vanadate / silver carbonate composite photocatalyst of embodiment 3 The mass percentage of silver is 25%, and the mass percentage of silver carbonate is 75%.

[0055] A preparation method of the silver vanadate / silver carbonate composite photocatalyst of the above-mentioned present embodiment is basically the same as the preparation method in Example 1, the difference is only that the quality of silver nitrate used in Example 2 is 2.1304g, sodium bicarbonate The mass of 0.4008g,.

[0056] The silver vanadate / silver carbonate composite photocatalyst prepared in Example 3 is named VC-13.

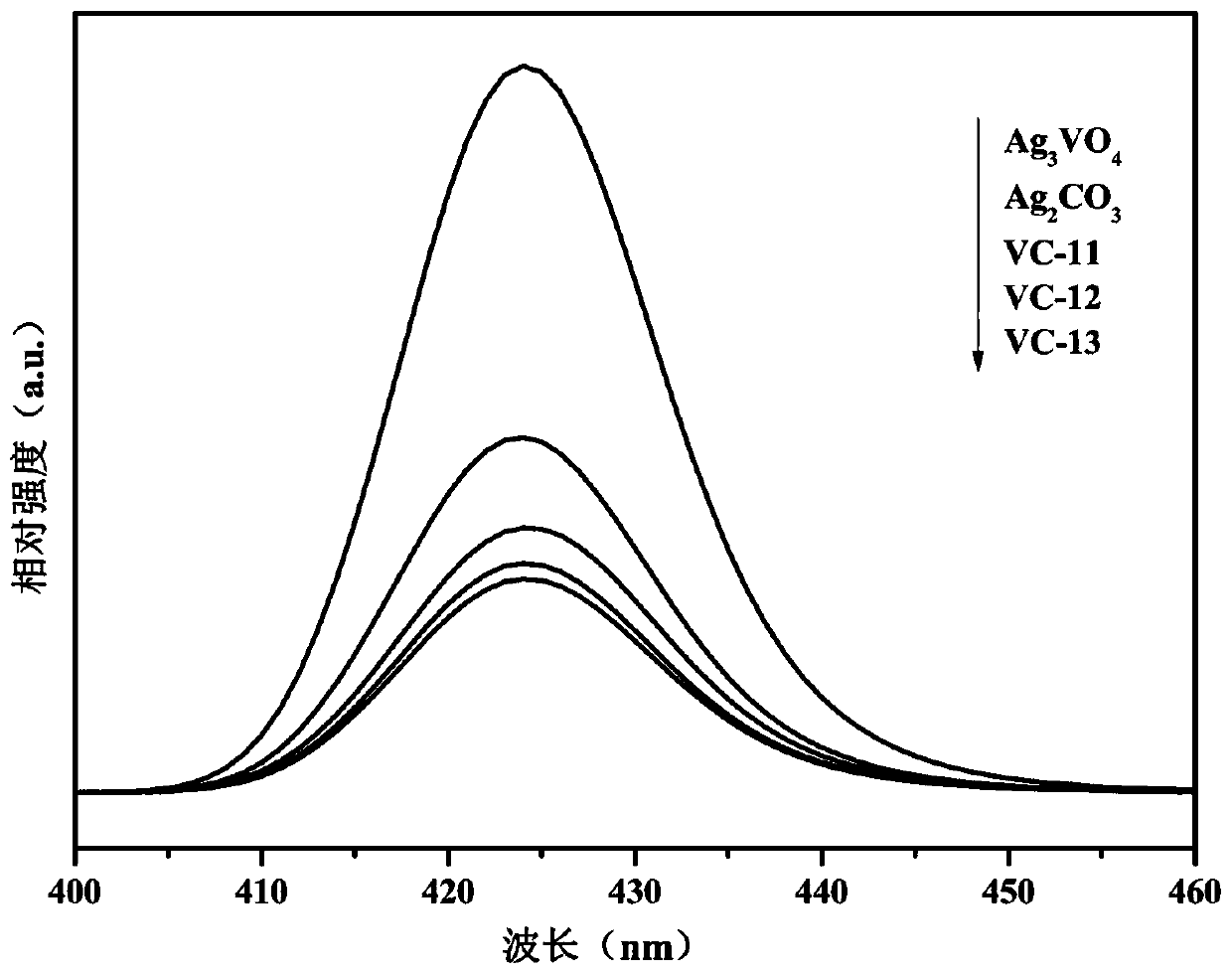

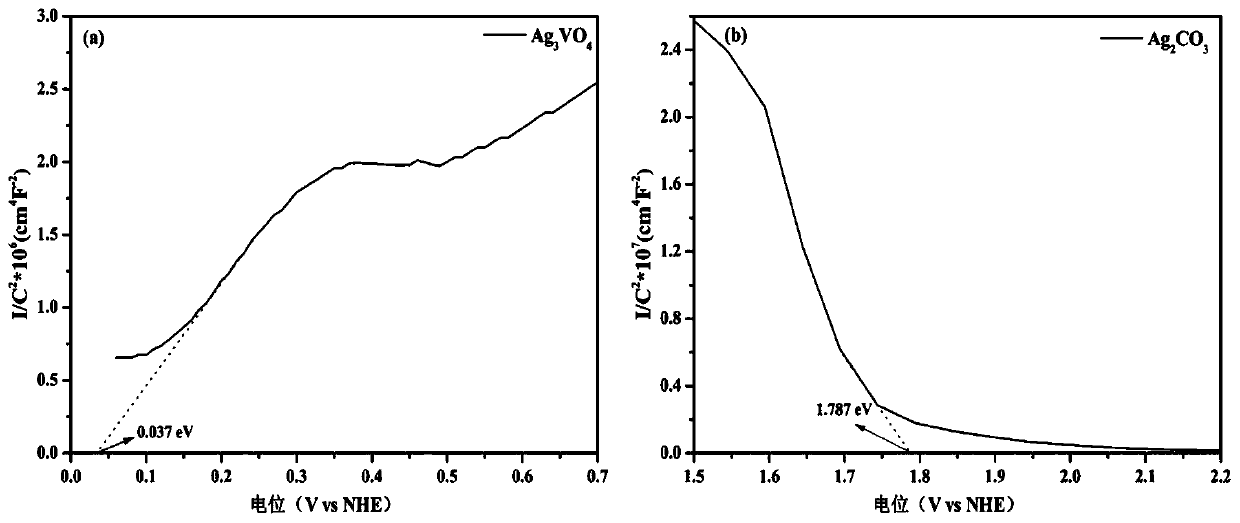

[0057] Ag in the silver vanadate / silver carbonate composite photocatalyst VC-11 that embodiment 1~3 makes, VC-12, VC-13, comparative example 1 2 CO 3 and Ag in Comparative Exa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com