Zero-valent iron-mineral composite material with high reduction activity and preparation method therefor

A technology of composite materials and zero-valent iron, which is applied in the fields of chemical instruments and methods, water pollutants, and textile industrial wastewater treatment, etc. Passivation and other issues, to achieve excellent solution buffering capacity, improve continuous reduction capacity, and efficient reduction degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation of zero-valent iron-mineral composite material with high reduction activity, the specific steps are as follows:

[0029] Weigh the elemental iron and inorganic non-metallic minerals according to the mass ratio of 4.3:10, keep the iron content at 30% of the total sample, weigh a total of 2g samples and put them into the ball mill jar, control the ball-to-material ratio at 35, and set the speed at 500rpm , the ball milling time is 8h, and the zero-valent iron-mineral composite material with high reduction activity is obtained. The prepared composite material is taken out and stored in a sealed and dry condition.

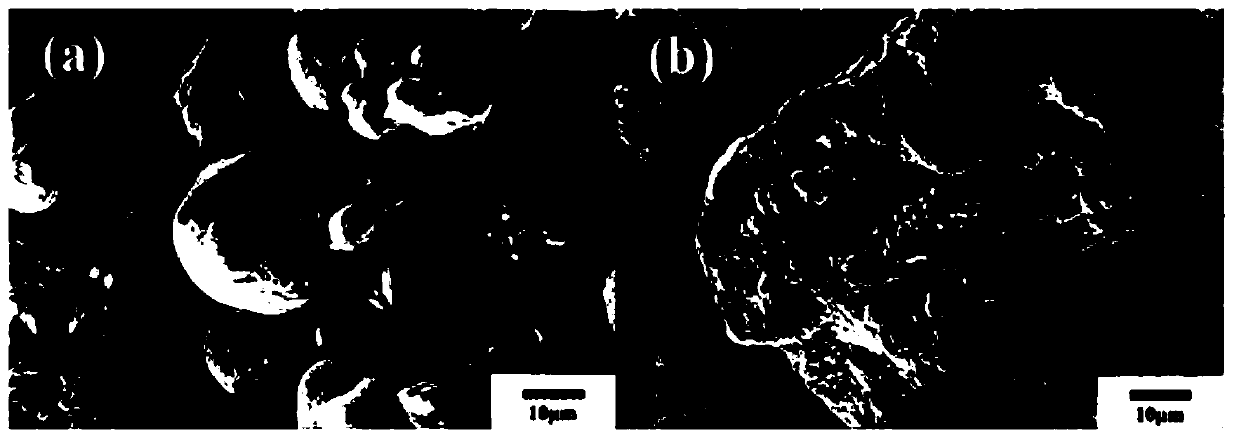

[0030] Test the d of the zero-valent iron-mineral composite material prepared in this embodiment 10 、d 50 and d 90 , and compared with the sample of elemental iron raw material, the elemental iron of ball milling alone (ball milling conditions are the same as this embodiment) and elemental iron and inorganic non-metallic mineral ball milling 2h...

Embodiment 2

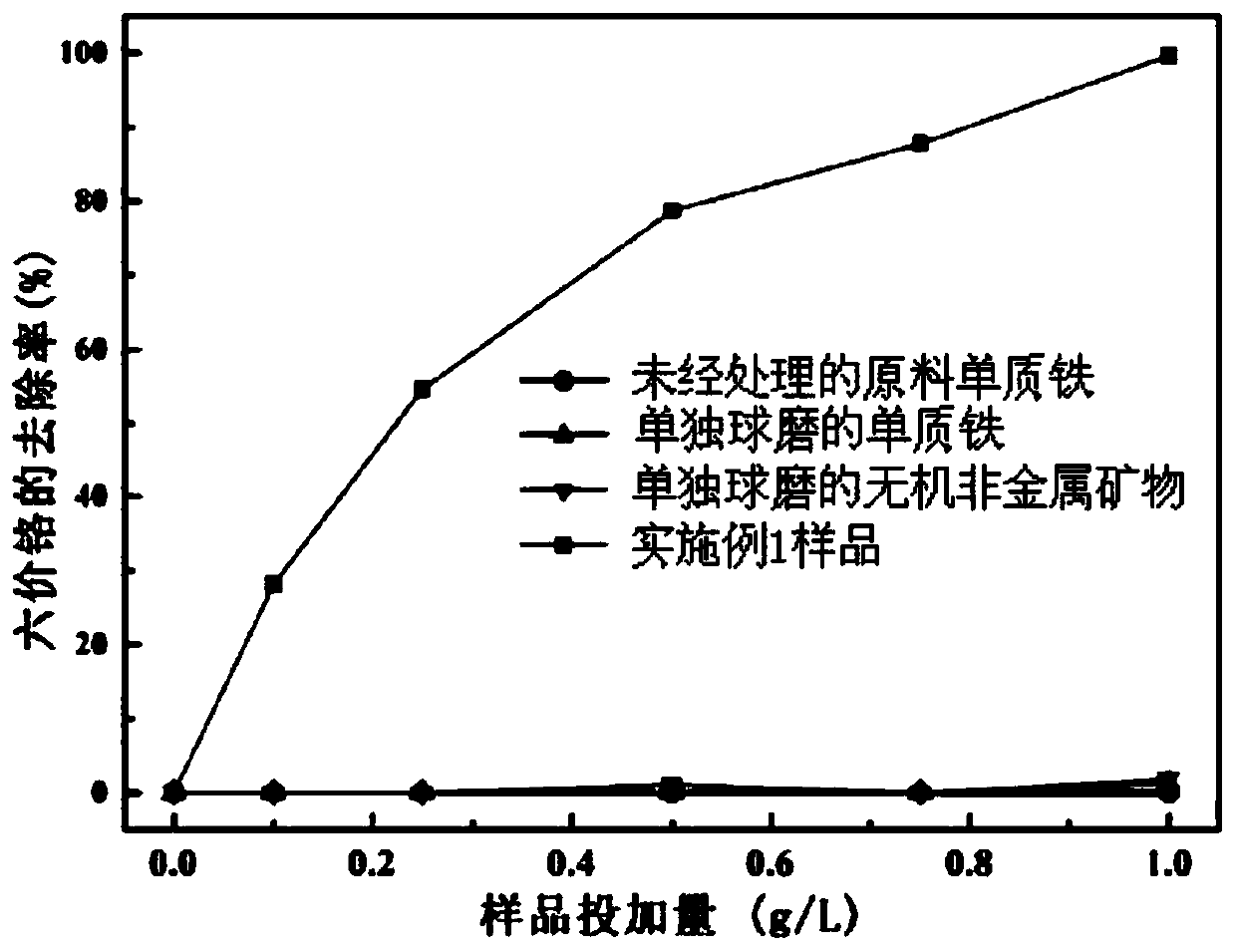

[0036]Effect test of zero-valent iron-mineral composite materials with high reducing activity on treatment of hexavalent chromium in polluted water

[0037] Use 100ml of potassium dichromate solution with hexavalent chromium concentration of 10mg / L to simulate chromium-containing wastewater, the pH value of the solution is 6.72, and the temperature is 25°C. Add 0.1g of the highly reducing active zero-valent iron-mineral composite prepared in Example 1 Material samples were placed in an oscillator with a rotating speed of 250r / min for half an hour, samples were taken regularly, and the removal effect of hexavalent chromium was determined.

[0038] As a contrast, the above-mentioned hexavalent chromium removal was performed on the untreated raw material elemental iron, the elemental iron independently ball-milled, and the inorganic non-metallic minerals independently ball-milled (the elemental iron and inorganic non-metallic ball milling conditions were the same as in Example 1) ...

Embodiment 3

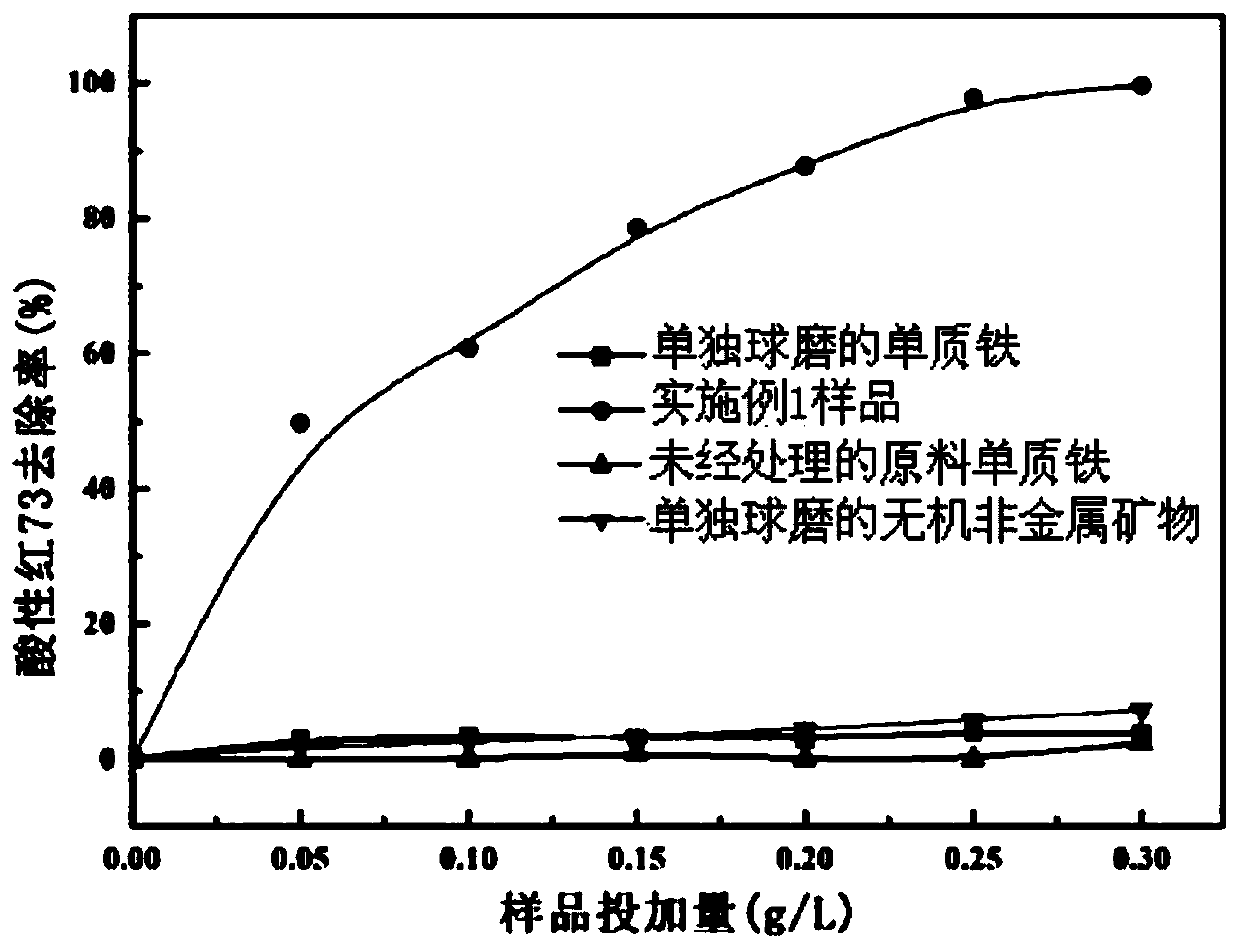

[0047] Effect test of zero-valent iron-mineral composite material with high reducing activity in treating acid red 73 in polluted water

[0048] Use 100ml acid red 73 concentration to be the acid red 73 solution of 50mg / L to simulate azo-type dye wastewater, the pH value of the solution is 6.55, the temperature is 25 ℃, add 0.03g of highly reducing activity zero-valent iron-mineral prepared in Example 1 Composite material samples were placed in an oscillator with a rotation speed of 250r / min for half an hour, samples were taken regularly, and the removal effect of hexavalent chromium was determined.

[0049] As a control, the untreated raw material elemental iron, the elemental iron independently ball-milled, and the inorganic non-metallic minerals independently ball-milled (the elemental iron and inorganic non-metallic ball milling conditions are the same as in Example 1) were subjected to the above-mentioned acid red 73 removal under the same conditions. In the experiment, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com