Cellulose/sliver/silver chloride composite material and preparation method thereof

A technology of composite materials and cellulose, which is applied in the field of cellulose-based hybrid materials and its preparation, can solve the problems of cellulose/silver/silver chloride composite materials such as less reports, and achieve narrow particle size distribution range and particle size Uniform, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] 1. Preparation of cellulose solution

[0076] 1A) Add 7g of sodium hydroxide and 12g of urea into 81g of water, stir and dissolve evenly to obtain a sodium hydroxide / urea aqueous solution, wherein the mass percentage of sodium hydroxide is 7%, and the mass percentage of urea is 12%; The mass ratio of sodium hydroxide to urea is 7:12;

[0077] 1B) Add 3.24g of microcrystalline cellulose into the above sodium hydroxide / urea aqueous solution and stir to prepare a uniformly dispersed cellulose solution, wherein the mass percent concentration of cellulose in the cellulose solution is 3.24%.

[0078] In the present invention, the mass ratio of sodium hydroxide and urea in the sodium hydroxide / urea aqueous solution is except 7:12, and the mass ratio of other sodium hydroxide and urea is 5-15:5-20, which is applicable to the present invention .

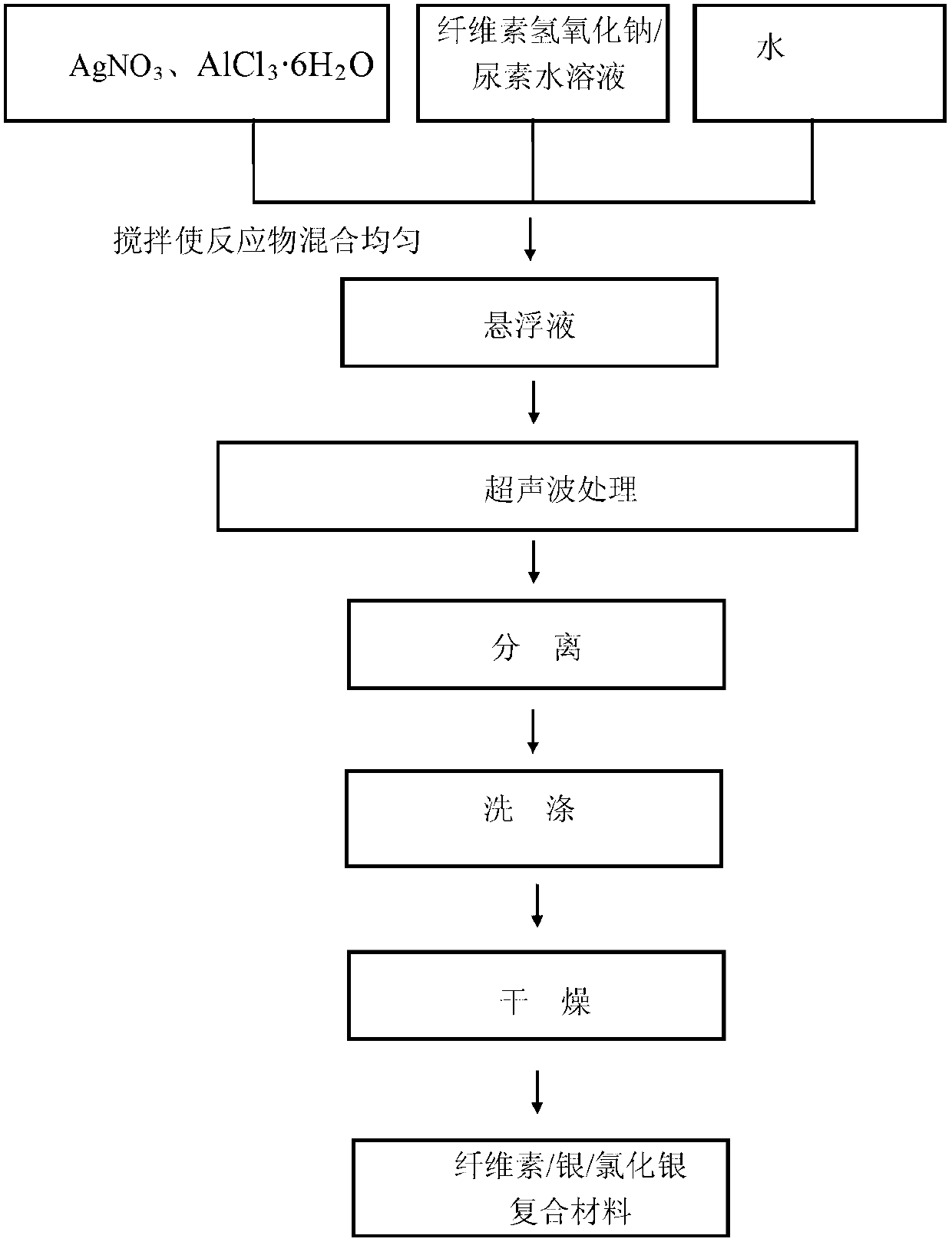

[0079] 2. Preparation of cellulose / silver / silver chloride composites

[0080] 2A) Preparation of suspension

[0081] 10mL cellulo...

Embodiment 2

[0091] In addition to adding 10mL of cellulose solution, 0.287g of silver citrate, and 0.0985g of sodium chloride into 30mL of water during the preparation of the cellulose / silver / silver chloride composite material, the molar ratio of silver ions to chloride ions is 1:1 The amount of cellulose solution added per millimole of silver ions is 5.88mL; during ultrasonic treatment, the temperature is 90±2°C; the frequency of ultrasonic treatment is 24kHz; the pulse time of ultrasonic is 1S:1S, that is, the duration of ultrasonic wave is 1S (on), ultrasonic stop generation time (ie intermittent time) 1S (off), ultrasonic treatment time is 20min, the rest is the same as in Example 1.

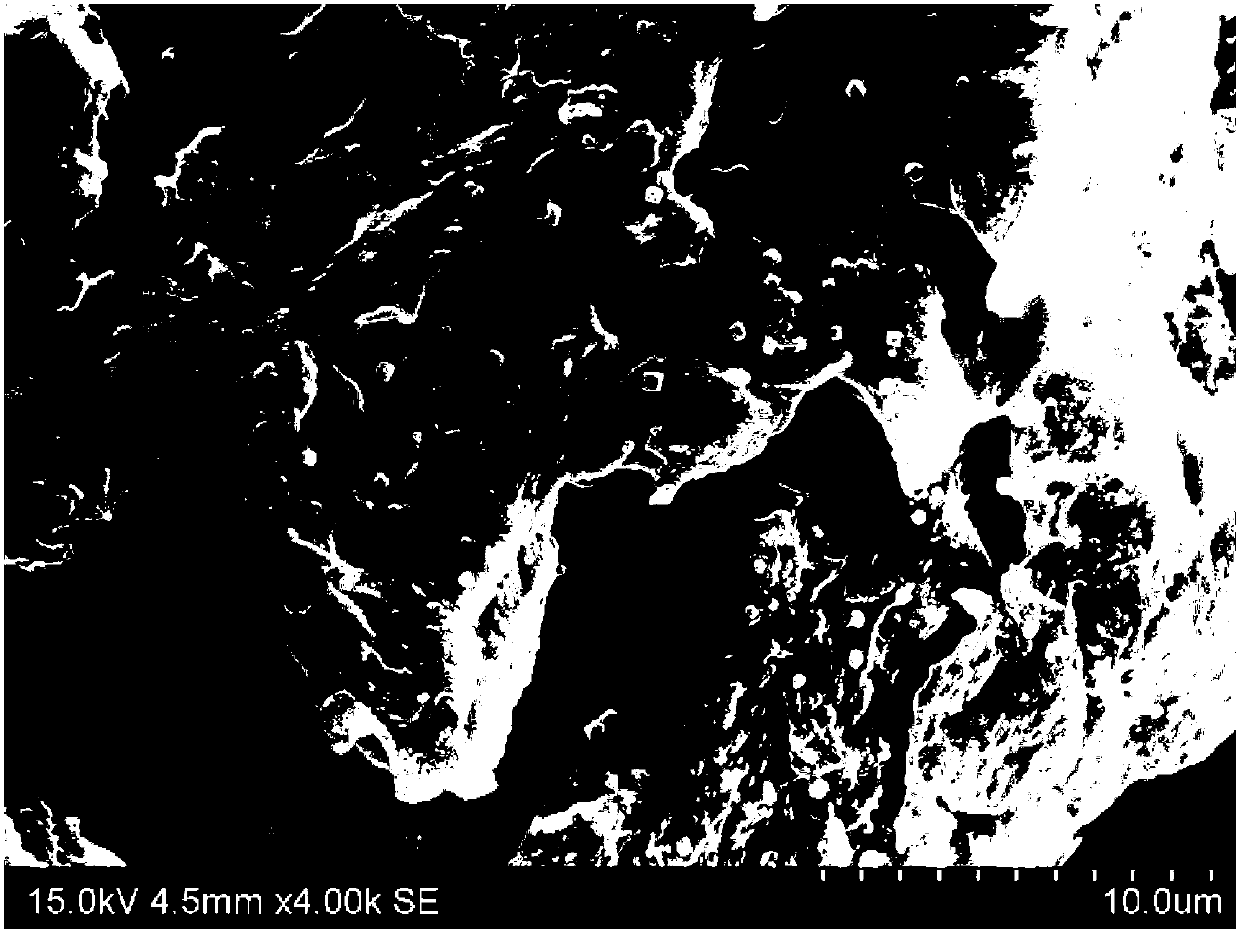

[0092] The morphology of the prepared cellulose / silver / silver chloride composite was examined by scanning electron microscopy. Figure 4 Scanning electron micrographs of the cellulose / silver / silver chloride composite material prepared for this example. Scanning electron micrographs show that the silver...

Embodiment 3

[0094] In addition to adding 10.0g of sodium hydroxide and 15g of urea to 75g of water during the preparation of the cellulose solution to form a sodium hydroxide / urea solution, wherein the mass percent content of sodium hydroxide is 10%, and the mass percent concentration of urea is 15%; The mass ratio of sodium hydroxide to urea is 10:15; 2.0g of cellulose is dissolved in sodium hydroxide / urea solution to make a cellulose solution with a concentration of 2.0% by mass;

[0095] During ultrasonic treatment, the temperature is 90±2°C; the frequency of ultrasonic treatment is 20kHz; the pulse time of ultrasonic is 5S:5S, that is, the continuous time of ultrasonic wave is 5S (on), and the time of ultrasonic stop (ie intermittent time) is 5S ( off), the ultrasonic treatment time is 40min; the absolute pressure of vacuum drying is 0.01MPa, the vacuum drying temperature is 40°C, and the moisture content of the prepared cellulose / silver / silver chloride composite material is 3%, the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com