A kind of preparation method of gel polymer electrolyte

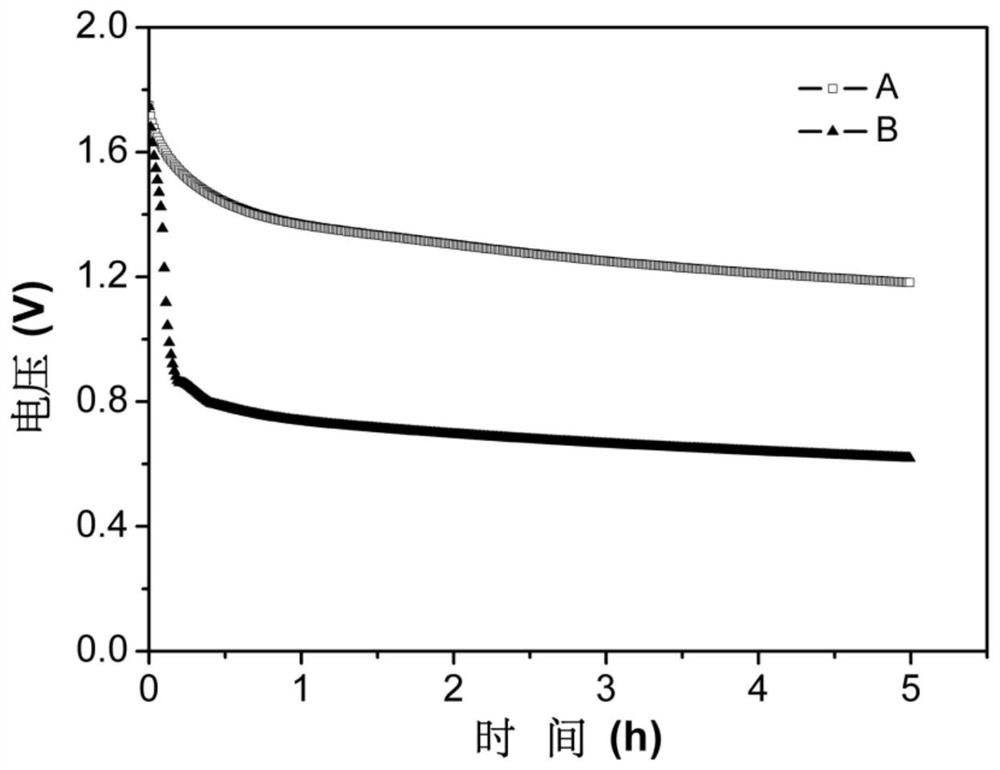

A gel polymer and electrolyte technology, applied in the field of electrochemistry, can solve the problems of reducing open circuit voltage, maintaining for several hours or even shorter time, and achieving the effects of preventing diffusion, low cost and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method of preparing a gel polymer electrolyte comprising the steps of:

[0027] Step 1, the preparation of the raw material:

[0028] (a) mix the polyvinyl alcohol base with water at a mass ratio of 1:10, stirred at 80 ° C to completely dissolve, resulting in a mixed uniform polyvinyl alcohol gel base solution;

[0029] (b) 1-butyl-3-methylimidazole and carbon nanotubes were added to water, and ultrasonic dispersion was performed to give ionic liquid brominated 1-butyl-3-methylimidazole and carbon nanotubes. The dispersion liquid, wherein the concentration of the ionic liquid is 5 mol / L, the concentration of the carbon nanotubes is 0.5 mg / mL;

[0030] (c) Lithium sulfate was dissolved in water, configured as a lithium sulfate solution having a concentration of 1 mol / L;

[0031] Step 2, in the polyvinylcyl gel base solution obtained in 10 ml of step 1 (a), 1-butyl-liquid brominated 1-butyl-3-methylimidazole and carbon nanotubes obtained in 10 ml of step 1 (b) were ad...

Embodiment 2

[0036] A method of preparing a gel polymer electrolyte comprising the steps of:

[0037] Step 1, the preparation of the raw material:

[0038] (a) mixing the polyethylene glycol matrix with water at a mass ratio of 1: 5, stirred at 90 ° C to completely dissolve, resulting in a mixed uniform polyethylene glycol gel matrix solution;

[0039] (b) The ionic liquid iodinated 1,3-dimethylimidazole and carbon nanotubes were added to water, and ultrasonic dispersion was subjected to ionic liquid iodinated 1,3-dimethylimidazole and a dispersion of carbon nanotubes. The concentration of the ionic liquid was 1 mol / L, the concentration of the carbon nanotubes was 0.1 mg / ml;

[0040] (c) Solubidate lithium sulfate in water, configured as a lithium sulfate solution having a concentration of 0.5 mol / L;

[0041] Step 2, in the polyethylene glycol gel base solution obtained in 30 ml of step 1 (a), 1,3-dimethylimidazole and carbon nanotubes obtained in 15 ml of step 1 (b) were added to the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com