Method for preparing anti-microbial, mildew-resistant and corrosion-resistant membrane layer on magnesium metal surface

A surface antibacterial, antibacterial and antifungal technology, which is applied in the field of preparation of oxide film on the surface of magnesium metal, can solve the problems of oxide film burning, antibacterial and antifungal performance research, etc., and achieve good corrosion resistance, excellent antibacterial and antifungal Mildew performance, promotion of anti-mildew effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

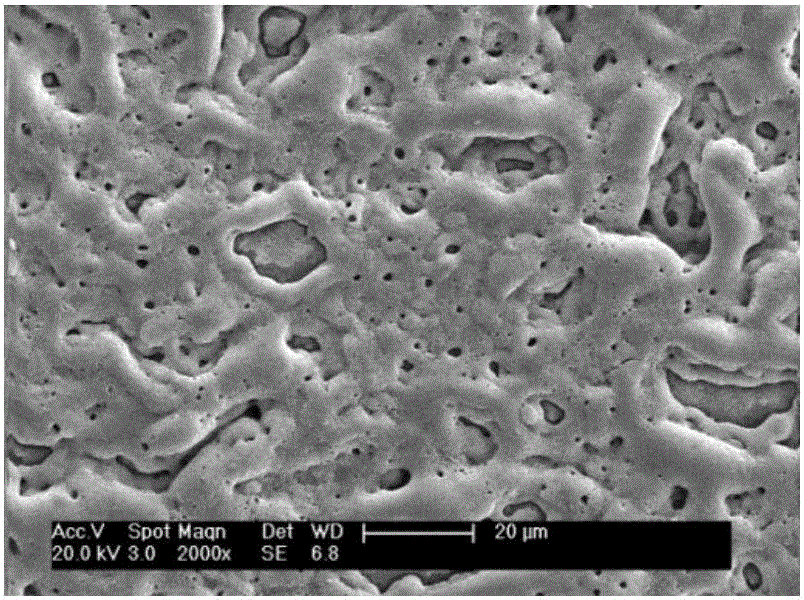

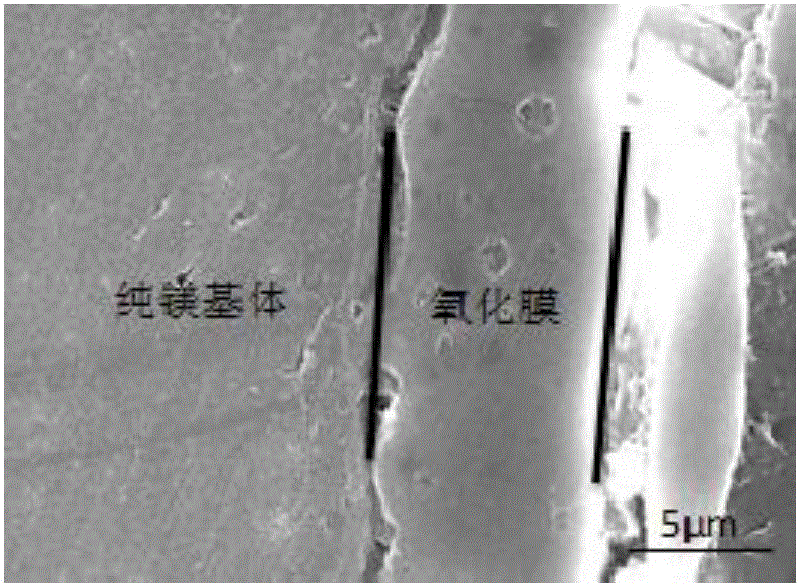

[0031] Preparation of pure magnesium metal, consisting of Mg and unavoidable impurities. Prepare an antibacterial, mildew-proof and corrosion-resistant film layer on the surface of pure magnesium metal, the specific steps are as follows:

[0032] (a) Cut pure magnesium into a cuboid of 20mm×60mm×2mm, polish the surface of pure magnesium step by step with 120#, 800# and 1200# water-grinding paper, clean it with deionized water, place it in acetone for 5min, and then use Rinse well with deionized water and blow dry. Drill a small hole at one end of the sample, use copper wire as the connecting wire, and seal the connection with epoxy resin.

[0033] (b) Preparation of oxidation solution: NaOH-40g / L, Na 2 SiO 3 -90g / L, Na 2 B 4 o 7 -50g / L, citric acid -12g / L, Ag 2 SO 4-2g / L, NiSO 4 -5g / L.

[0034] (c) Place two pretreated pure magnesium plates in an oxidizing solution for anodic oxidation, and pass through an alternating current with a frequency of 50 Hz and a current d...

Embodiment 2

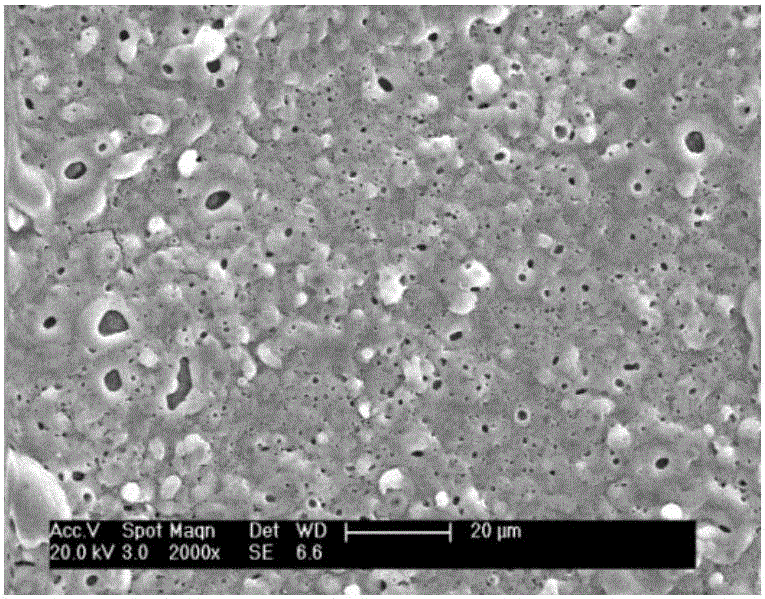

[0038] A Mg-Zn alloy is prepared, the composition of which is Zn-2.0wt%, and the rest is Mg and unavoidable impurities.

[0039] The difference between the process method of this example and example 1 is that the solute of step (b) anodic oxidation solution consists of: NaOH-70g / L, NaOH-70g / L, Na 2 SiO 3 -80g / L, Na 2 B 4 o 7 -60g / L, citric acid -10g / L, AgNO 3 -10g / L, NiSO 4 -16g / L. Step (c) current density is 1.0A / dm 2 , the temperature of the oxidation solution is 20°C, and the oxidation time is 10 minutes. Other processing parameters and operating process are identical with embodiment 1.

[0040] After processing by the above process, the surface film thickness, antibacterial, mildew and corrosion resistance of Mg2Zn magnesium alloy are shown in Table 1.

Embodiment 3

[0042] A Mg-Zn alloy is prepared, the composition of which is Zn-2.0wt%, Ca-0.5wt%, and the rest is Mg and unavoidable impurities.

[0043] The difference between the process method of this example and example 1 is that the solute of step (b) anodic oxidation solution consists of: NaOH-50g / L, NaOH-50g / L, 2 SiO 3 -70g / L, Na 2 B 4 o 7 -80g / L, citric acid -16g / L, Ag 2 SO 4 -4g / L, NiSO 4 -10 g / L; In the step (c), the anodic oxidation AC current density is 2.5A / dm 2 , the temperature of the oxidizing solution is 20° C., and the oxidation time is 30 minutes; the temperature of the pure water in step (d) is 95° C., and the treatment time is 20 minutes. Other processing parameters and operating process are identical with embodiment 1.

[0044] After processing by the above process, the surface film thickness, antibacterial, mildew, and corrosion resistance of the Mg2Zn0.5Ca magnesium alloy are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com