Pre-orientated polyester filament yarn and manufacturing method thereof

A pre-orientation and filament technology, applied in the field of synthetic fibers, can solve problems such as poor UV resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

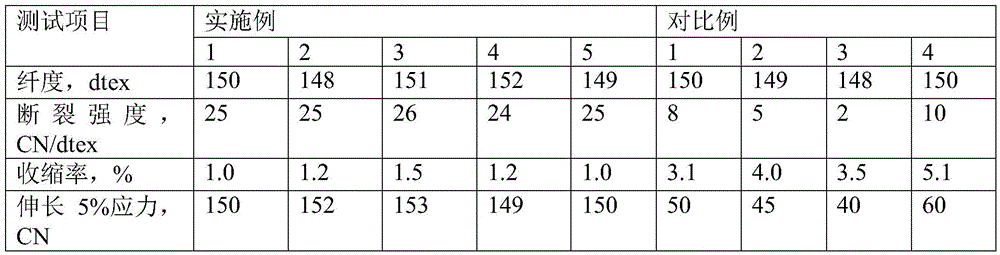

Examples

Embodiment 1

[0021] Step 1) slice fiber-grade PET polyester sheet 90Kg (polyethylene terephthalate sheet, the brand is German Gail), and the thickness of the slice is 0.5mm; the PET polyester sheet is dried for the first time, and dried The temperature is 160°C, and the drying time is 30 minutes; the PET polyester chips are dried for the second time, the drying temperature is 185°C, and the drying time is 4 hours, so that the moisture content of the PET polyester chips is ≤ 25ppm; the PET polyester chips after drying And 0.2Kg of cetyltrimethylsilver ammonium bromide, 1.1Kg of 1,1'-thiobis(2-naphthol), 0.7Kg of 2-hydroxybenzophenone, 0.5Kg of divalent The nickel EDTA complex is fully mixed in a screw extruder, melted at 280°C, extruded into filaments, and cooled, wherein the cooling air temperature is 20°C, the relative humidity is 75%, and the wind speed is 0.5m / s.

[0022] Step 2) Collect the PET polyester yarn obtained in step 1) sequentially through the first roller, heat in the upper ...

Embodiment 2

[0024] Others are the same as in Example 1, except that the drying temperature for the first drying of PET polyester chips is 180°C, the drying time for the second drying is 6 hours, and the melting temperature is 290°C; the wind temperature during cooling is 18°C , the relative humidity is 70%, the wind speed is 0.6m / s; the heating temperature of the upper hot box is 180°C; the raw materials include: fiber-grade PET polyester board 90Kg, cetyltrimethylsilver ammonium bromide 0.4 Kg, 1,1'-thiobis(2-naphthol) 1.3Kg, 2-hydroxybenzophenone 1.2Kg, divalent nickel EDTA complex 0.1Kg, chemical fiber oil 3.2Kg.

Embodiment 3

[0026] Others are the same as in Example 1, except that the drying temperature for the first drying of PET polyester chips is 170°C, the drying time for the second drying is 5 hours, and the melting temperature is 285°C; the wind temperature during cooling is 22°C , the relative humidity is 80%, the wind speed is 0.4m / s; the heating temperature of the upper hot box is 177°C; the raw materials include: fiber-grade PET polyester board 95Kg, hexadecyltrimethylsilver ammonium bromide ( antibacterial agent) 0.5Kg, 1,1'-thiobis (2-naphthol) (antioxidant) 1Kg, 2-hydroxybenzophenone (ultraviolet light absorber) 1Kg, divalent nickel EDTA complex (quenching agent) Killing agent) 0.3Kg, chemical fiber oil 3Kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com