Vanadium-titanium magnetite ore coal-based reduction process

A technology of vanadium-titanium magnetite and vanadium-titanium magnetite concentrate, which is applied in the field of vanadium-titanium magnetite coal-based reduction process, can solve the problems of high smelting cost and low metal recovery rate, achieve significant economic benefits and increase the reduction rate , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

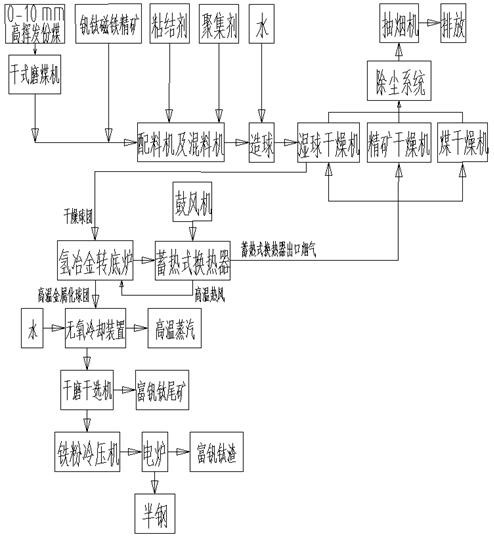

Image

Examples

Embodiment 1

[0058] A kind of vanadium-titanium magnetite coal-based reduction process comprises the following steps:

[0059] Selection of raw materials for S1: the raw materials are iron grade 48-55%, SiO 2 Vanadium-titanium magnetite concentrate with a content of 3-5% and a particle size below 200 mesh accounts for more than 80%; fuel and reducing agent use high-volatile coal, preferably 45-50% volatile matter, 43-48% fixed carbon content, and a particle size of less than 10mm lignite;

[0060] S2 raw material processing: add the vanadium-titanium magnetite concentrate in step S1 to the concentrate dryer for drying, add high-volatile coal to the coal dryer for drying, and remove the moisture in the material; then dry the highly volatile More than 80% of the coal is ground to below 200 mesh;

[0061]Preparation of S3 pellets: According to parts by weight, select 100 parts of vanadium-titanium magnetite concentrate, 38 parts of high-volatile coal, 2 parts of binder, and 1 part of focusi...

Embodiment 2

[0069] A kind of vanadium-titanium magnetite coal-based reduction process comprises the following steps:

[0070] Selection of raw materials for S1: the raw materials are iron grade 48-55%, SiO 2 Vanadium-titanium magnetite concentrate with a content of 3-5% and a particle size below 200 mesh accounts for more than 80%; fuel and reducing agent use high-volatile coal, preferably 45-50% volatile matter, 43-48% fixed carbon content, and a particle size of less than 10mm lignite;

[0071] S2 raw material processing: add the vanadium-titanium magnetite concentrate in step S1 to the concentrate dryer for drying, add high-volatile coal to the coal dryer for drying, and remove the moisture in the material; then dry the highly volatile More than 80% of the coal is ground to below 200 mesh;

[0072] Preparation of S3 pellets: According to parts by weight, select 100 parts of vanadium-titanium magnetite concentrate, 40 parts of high-volatile coal, 1 part of binder, and 2 parts of focus...

Embodiment 3

[0080] A kind of vanadium-titanium magnetite coal-based reduction process comprises the following steps:

[0081] Selection of raw materials for S1: the raw materials are iron grade 48-55%, SiO 2 Vanadium-titanium magnetite concentrate with a content of 3-5% and a particle size below 200 mesh accounts for more than 80%; fuel and reducing agent use high-volatile coal, preferably 45-50% volatile matter, 43-48% fixed carbon content, and a particle size of less than 10mm lignite;

[0082] S2 raw material processing: add the vanadium-titanium magnetite concentrate in step S1 to the concentrate dryer for drying, add high-volatile coal to the coal dryer for drying, and remove the moisture in the material; then dry the highly volatile More than 80% of the coal is ground to below 200 mesh;

[0083] Preparation of S3 pellets: According to parts by weight, select 100 parts of vanadium-titanium magnetite concentrate, 39 parts of high-volatile coal, 3 parts of binder, and 2 parts of focu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com