Gas sensitive material for detecting low-temperature formaldehyde at room temperature and preparation method thereof as well as formaldehyde gas sensor

A gas-sensing material and formaldehyde gas technology, applied in the field of gas-sensing sensors, can solve problems such as poor accuracy, large volume, and large power consumption, and achieve remarkable effects, high sensitivity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

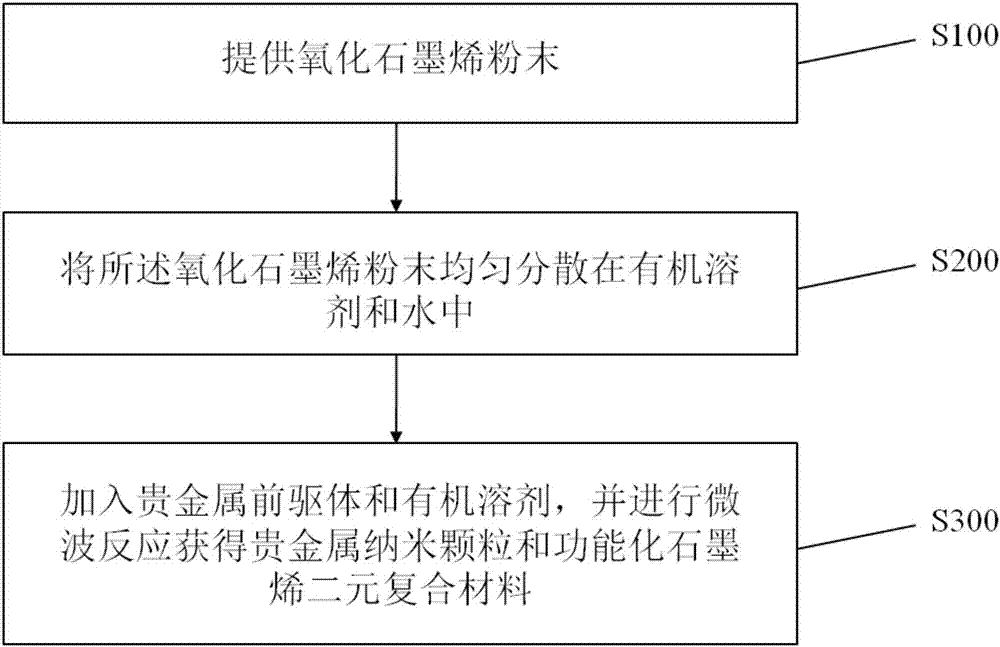

Method used

Image

Examples

Embodiment Construction

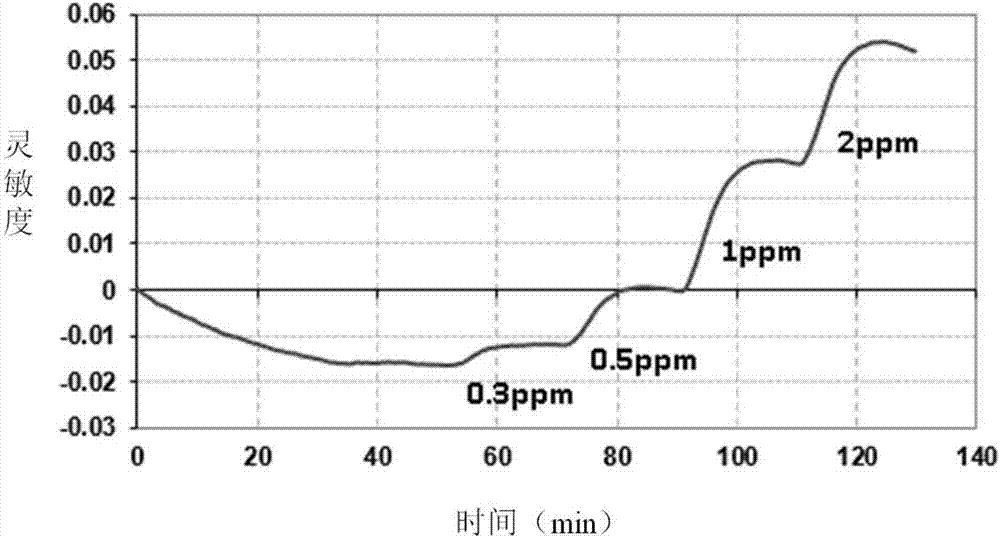

[0036] An embodiment of the present invention provides a gas-sensing material for detecting low-concentration formaldehyde at room temperature. The gas-sensing material is a binary composite material of noble metal nanoparticles and functionalized graphene, wherein the mass ratio of the noble metal nanoparticles to functionalized graphene is 1:0.1-30. The gas-sensitive material can detect the formaldehyde gas with a concentration of ppb level at room temperature. The noble metal nanoparticles are Pt, Au or Pd nanoparticles.

[0037] In a preferred embodiment, the gas-sensitive material is redox graphene supported Pt nanoparticles, and the mass ratio of the Pt nanoparticles to the redox graphene can be 1:0.2, 1:0.3, 1:1, 1 :3, 1:5, 1:10 or 1:15. The mass ratio can also be any value in 1:0.2-15, or the mass ratio can also be any value in 1:0.3-10. Wherein, the particle size of the Pt nanoparticles is 2nm, 3nm, 4nm, 6nm, 8nm, 9nm or 10nm, or any value in 2-10nm.

[0038]When ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com