Nanocrystalline metal oxide functionalized carbon nanotube material and formaldehyde gas sensor

A technology of carbon nanotubes and nanometals, which is applied in the field of electronic device manufacturing, can solve problems such as time-consuming, expensive instruments, and increased manufacturing costs of sensors, achieving low-cost and good-response effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

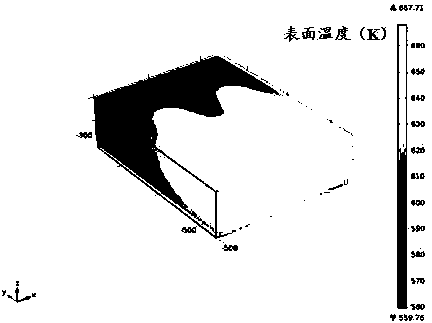

[0061] The mass ratio of carbon nanotubes to nickel oxide is 1:0.5; the specific preparation process: the metal paste is printed on the substrate with conductive electrodes and heating electrodes by screen printing, and after high temperature sintering, inkjet printing is used to print conductive electrodes on the substrate. Print a layer of carbon nanotubes in the electrode area, and then print a layer of Ni(OH) on the carbon nanotubes by inkjet printing or chemical water bath deposition 2 , and finally the formaldehyde gas sensor was obtained after annealing.

[0062] The test curve for the detection of formaldehyde gas is as follows: Figure 17 As shown, it can be seen from the figure that the initial resistance is 9025 ohms. When the input amount of formaldehyde gas is 10.5ppm, the response of the sensor at this time is relatively large; when the input formaldehyde is 5.25ppm, the response of the sensor drops by nearly half ; When the input formaldehyde was 3.15ppm, the r...

Embodiment 2

[0064] The mass ratio of carbon nanotubes to nickel oxide is 1:1; the specific preparation process: the pattern on the mask plate is transferred to the substrate by photolithography, a layer of metal bonding layer is deposited, and then deposited on the metal bonding layer A layer of metal or alloy film is used to obtain heating electrodes and conductive electrodes, and then nanometer metal oxide functionalized carbon nanotubes are deposited on the conductive electrode area, and formaldehyde gas sensors are obtained after high-temperature annealing.

[0065] The test curve for the detection of formaldehyde gas is as follows: Figure 18 As shown, the formaldehyde test concentration of this formaldehyde gas sensor can reach 1.05ppm, which is a little lower than that measured in Example 1. From the perspective of indoor health conditions, the response of the formaldehyde sensor to formaldehyde cannot meet the standard at this time.

Embodiment 3

[0067] The mass ratio of carbon nanotubes to nickel oxide is 1:14; the specific preparation process: prepare heating electrodes on the substrate by physical vapor deposition or printing methods, configure the precursor ink of the insulating layer, and print a Layer precursor ink, annealed at a certain temperature in the air atmosphere to obtain an insulating dielectric layer; on the insulating dielectric layer, use physical vapor deposition or printing methods to prepare conductive electrodes; deposit nanometer metal oxide functionalized carbon nanotubes on the conductive electrodes to obtain formaldehyde Gas sensor, and then use this sensor to detect formaldehyde gas, the test curve is as follows Figure 19 shown. It can be seen from the figure that 10ppb formaldehyde gas can be detected under this condition. As the concentration of formaldehyde gas increases, the response of the gas becomes higher and higher, and the response time and recovery time are both fast, and the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com