Patents

Literature

36 results about "Nickel(II) oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nickel(II) oxide is the chemical compound with the formula NiO. It is notable as being the only well-characterized oxide of nickel (although nickel(III) oxide, Ni₂O₃ and NiO₂ have been claimed). The mineralogical form of NiO, bunsenite, is very rare. It is classified as a basic metal oxide. Several million kilograms are produced in varying quality annually, mainly as an intermediate in the production of nickel alloys.

Spinel type high-entropy oxide electrode material and preparation method thereof

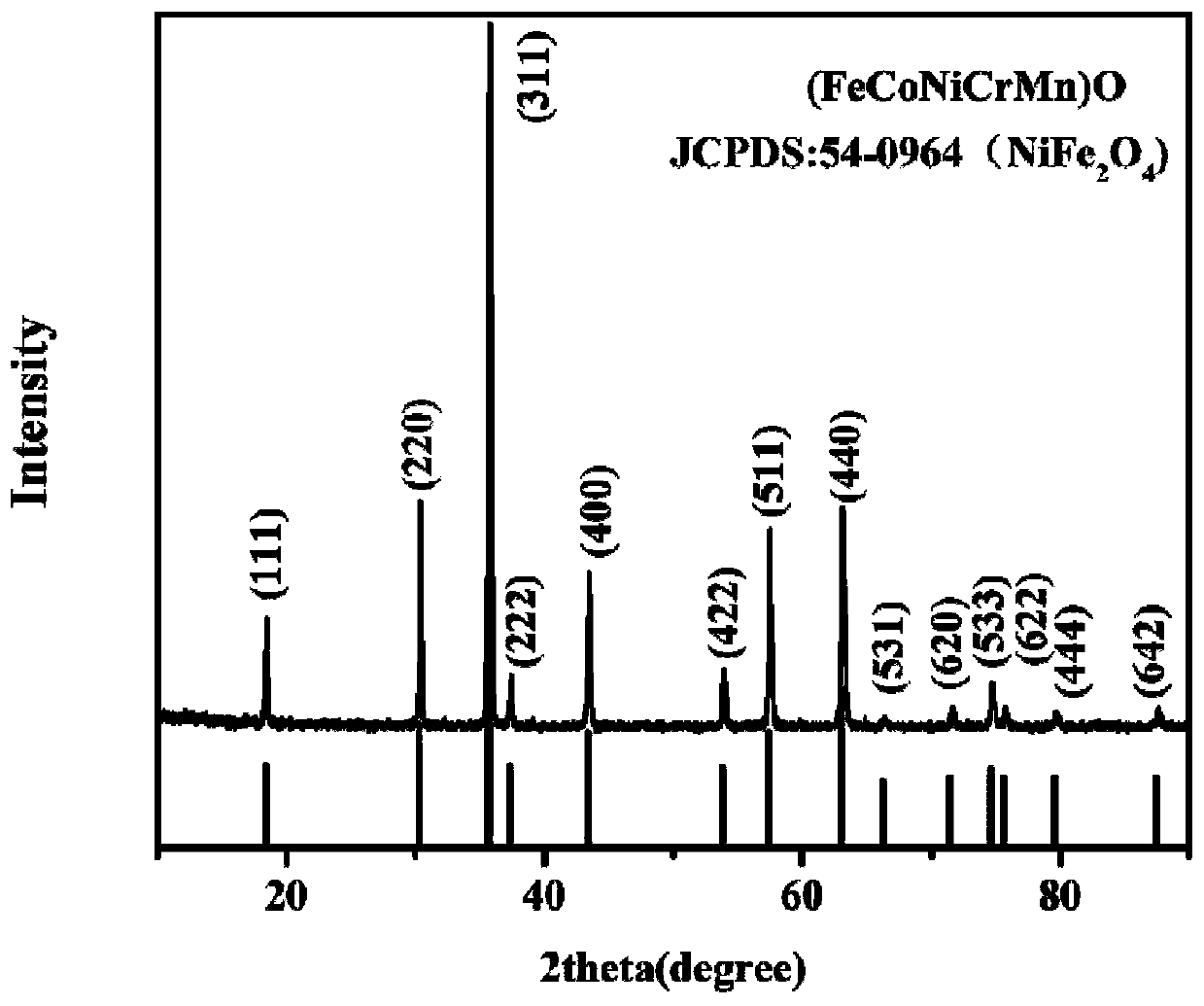

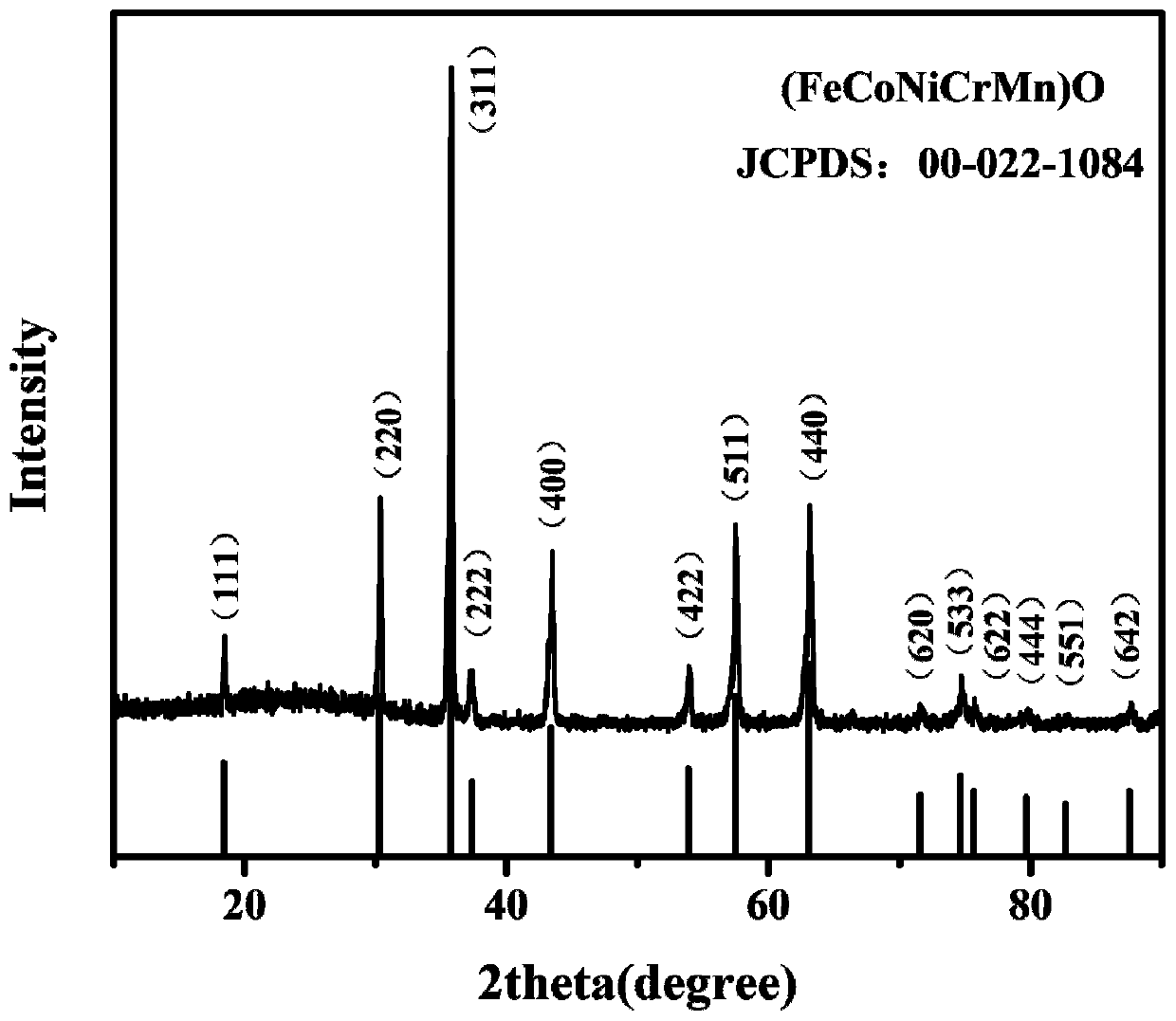

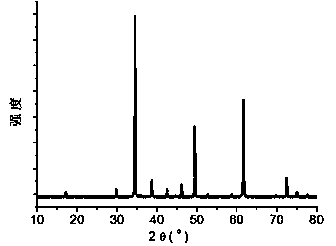

ActiveCN110364717AHigh specific capacityImprove cycle stabilityNegative electrodesSecondary cellsIron(II) oxideSpace group

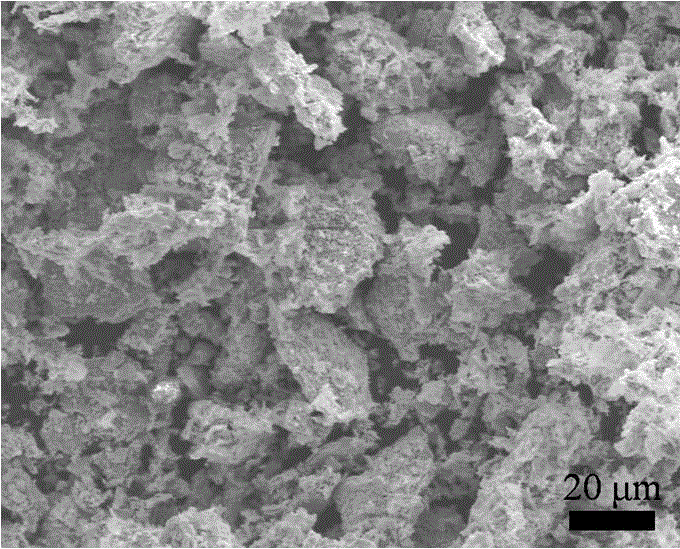

The invention relates to a spinel type high-entropy oxide electrode material and a preparation method thereof, and belongs to the field of nanomaterial preparation and new energy. The chemical formulaof the high-entropy oxide electrode material is one of (FeCoNiCrMn)O, (FeZnNiCrMn)O, (FeCoZnCrMn)O and (FeCoNiCrMnCu)O. The preparation method includes the steps of 1) mixing and ball-milling iron oxide, chromium oxide, manganese oxide and M metal oxide, wherein the M metal oxide is two or more of nickel oxide, zinc oxide, copper oxide and cobalt oxide; and 2) carrying out high-temperature calcination, and obtaining the spinel type high-entropy oxide electrode material by adopting a cooling mode of furnace cooling, air quenching and liquid nitrogen quenching. The particle diameter of the high-entropy oxide is 100-500nm, and the high-entropy oxide is determined to be in a spinel structure according to XRD; and the space group of the material is Fd-3m, and the specific surface area is 5-100m<2>g<-1>.

Owner:东北大学秦皇岛分校

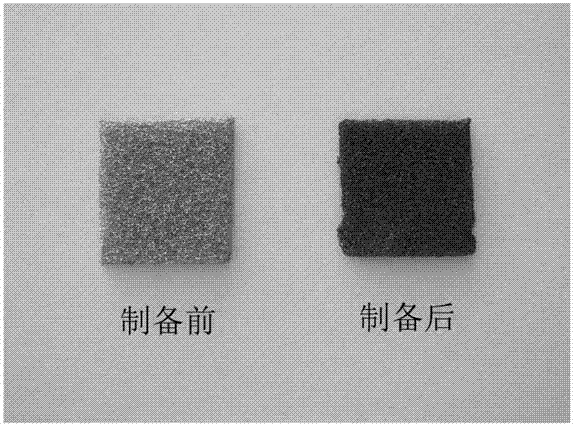

Preparation method of iron-cobalt-nickel oxide/carbon cloth composite flexible electrode

InactiveCN109243856AImprove flexibilityImprove electrochemical performanceHybrid capacitor electrodesHybrid/EDL manufactureCotton clothOxygen

This patent uses cotton cloth as raw material, carbonizes it into carbon cloth, and obtains flexible supercapacitor electrode base material with high specific surface area, oxyge functional groups andgood mechanical properties then through mixed acidification treatment. The obtained treated carbon is added into ferric trichloride hexahydrate, Cobalt chloride hexahydrate, nickel chloride hexahydrate and ethanol solution after a period of time, ammonium bicarbonate is added and continuously stirred, after that reaction is completed, the mixture is washed with deionize water several times, dried, calcined in a high-temperature tubular furnace for a period of time, and taken out after the mixture is cooled to room temperature, so as to prepare an iron cobalt nickel oxide / carbon cloth composite flexible electrode material. By adjusting the reaction time and the amount of iron, cobalt and nickel sources to control the loading amount and morphology of multicomponent transition metal oxides,the flexible supercapacitor electrode materials with good flexibility and excellent electrochemical performance were prepared.

Owner:TIANJIN POLYTECHNIC UNIV

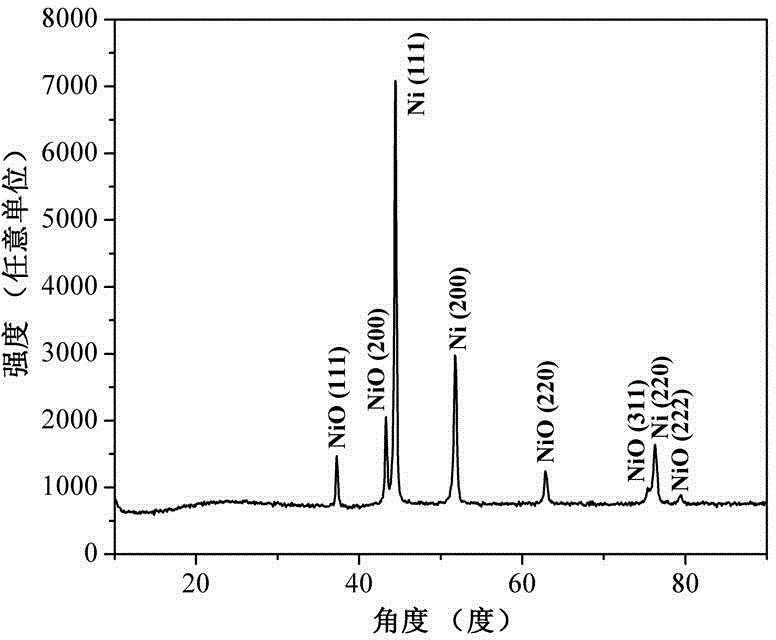

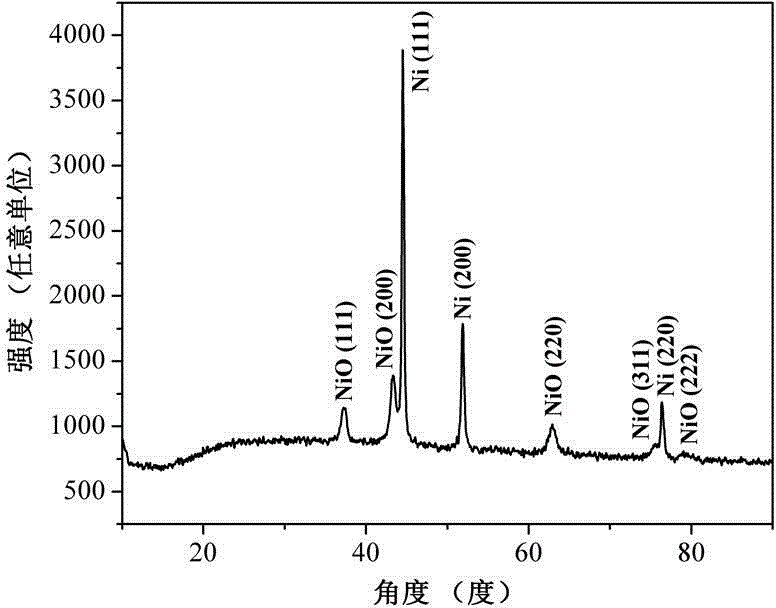

Carbon-coated nickel oxide/metallic nickel and simple synthesis method thereof

ActiveCN104815983AImprove conductivityImprove crystal qualityNickel oxides/hydroxidesNickel saltNew energy

The invention belongs to the field of new materials and new energy resources, and particularly relates to carbon-coated nickel oxide / metallic nickel (NiO / Ni) and a simple synthesis method of the carbon-coated NiO / Ni. The simple synthesis method comprises the following steps that soluble nickel salt, organic fuel and combustion additives are weighed and mixed to form an aqueous solution through preparation, and the aqueous solution is stirred and dissolves, so that a transparent solution is formed; the solution is heated to be at the temperature ranging from 50 DEG C to 100 DEG C, and moisture is continuously evaporated, so that the solution is in a sticky gel state; the gel is heated to be at the temperature ranging from 140 DEG C to 290 DEG C, self-propagating combustion of the gel happens, black loose powder can be obtained, and the obtained powder is added to solvent to be cleaned and dried, so that a high-purity target material is obtained. According to the invention, the technology is simple, operation is easy, and the raw materials are low in cost and easy to obtain. The prepared NiO / Ni is high in crystal quality, the conductive capacity of the carbon-coated NiO / Ni is enhanced through black carbon, and the carbon-coated NiO / Ni can be applied to devices such as lithium ion batteries and supercapacitors. The technological cost is low, conventional multi-step complex technologies, the long technology period and high-priced devices are avoided, and the carbon-coated NiO / Ni is applicable to large-scale industrial production.

Owner:FAREAST KINGSTAR CHEM

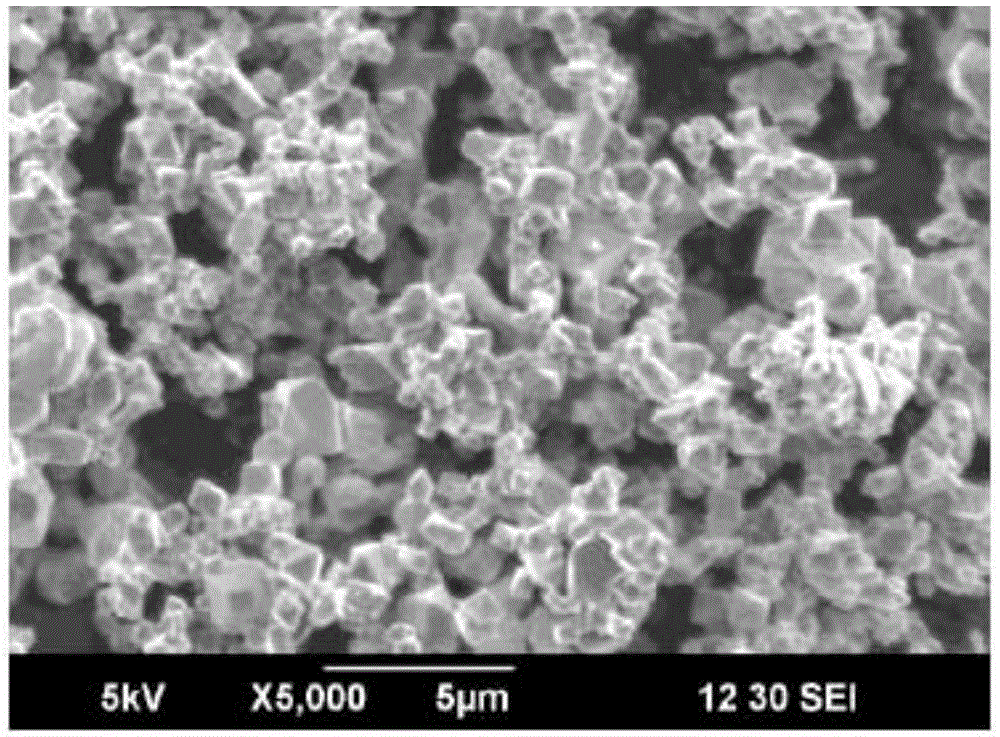

Improved method for preparing layered enriched lithium-manganese-nickel oxide by low-heat solid-phase reaction

ActiveCN102219262APromote growthSimple processCell electrodesManganese oxides/hydroxidesMANGANESE ACETATEOXALIC ACID DIHYDRATE

The invention provides an improved method for preparing layered enriched lithium-manganese-nickel oxide by low-heat solid-phase reaction. The method comprises the following steps: weighing lithium hydroxide monohydrate, nickel acetate and manganese acetate, and oxalic acid dihydrate according to the stoichiometry as follows: Li1+xMnyNi1-x-yO2, x being more than 0 and less than or equal to 1 / 3, y being more than 0 and less than 1, and x+y being more than 0 and less than 1 (wherein the mole ratio of LiOH.H2O to C2H2O4.2H2O is 1:1-1.2), and adding into a ball milling tank together for balling milling for 0.5-2h; obtaining slurry, adding deionized water in the slurry to adjust concentration, spraying and drying the slurry, and roasting the dried powder to obtain the final product -Li1+xMnyNil-x-yO2. The improved method has the following advantages: the process flow is short, the component of the material can be accurately controlled, the problems of material loss and inaccurate stoichiometry caused by repeatedly washing the product in a liquid phase method are overcome, the generation of a large quantity of waste water is avoided; simultaneously, the shape and particle size of a synthesized material can be controlled, the engineering index requirement can be achieved, the impurity pollution caused by dependence of a synthetic material by a solid phase method on crushing process can be overcome, the enriched lithium-manganese-nickel oxide has typical layered structure property, the particle size is 3-12mum, the specific capacity is high, and the cyclic performance is stable.

Owner:湖南金富力新能源股份有限公司

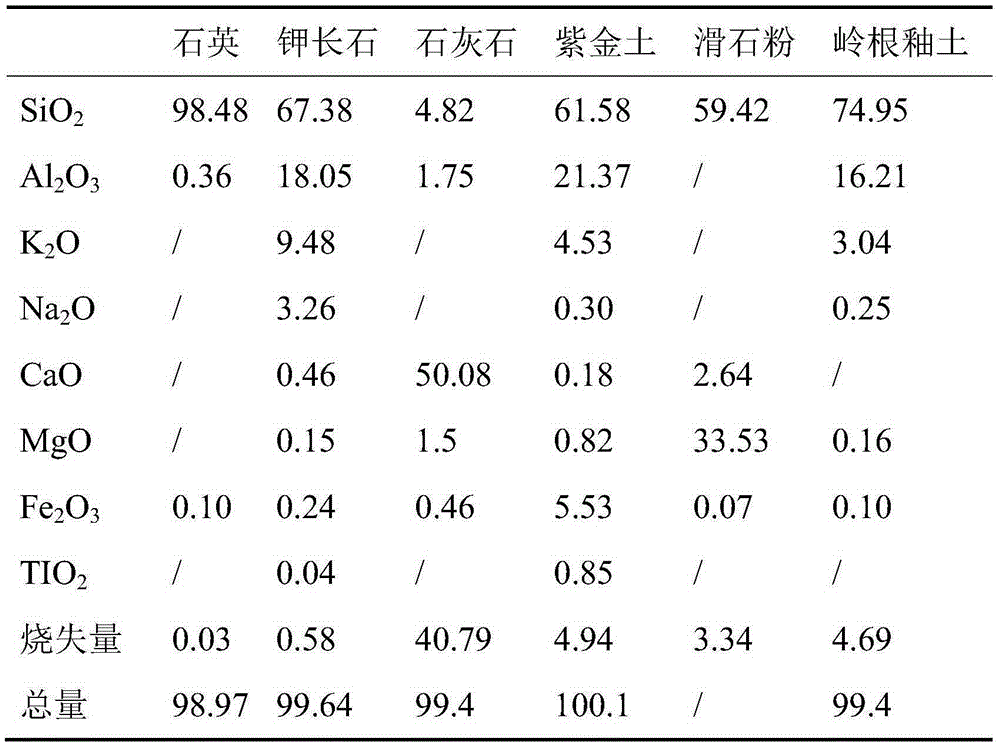

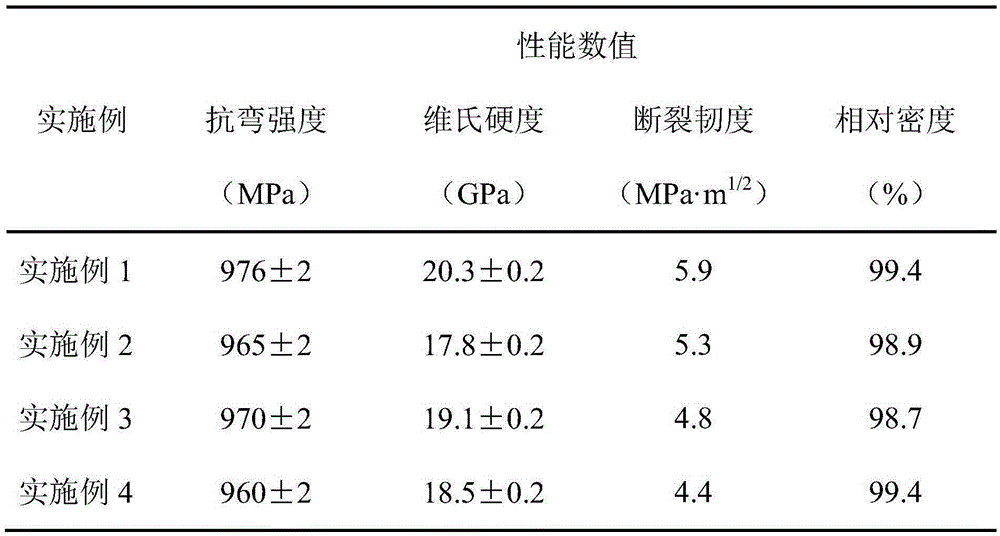

Celadon glaze and manufacturing method thereof

The invention discloses a celadon glaze and a manufacturing method thereof. The celadon glaze is prepared from the following raw materials in parts by weight: 15 to 30 parts of carnelian cobble, 280 to 400 parts of quartz, 60 to160 parts of potassium feldspar, 70 to 120 parts of limestone, 6 to 10 parts of purple clay, 70 to 230 parts of ridge glaze clay, 4 to 8 parts of glarizonae, 7 to 15 parts of talcum powder, 22 to 26 parts of copper ore, 4 to 7 parts of ox bone, 2 to 4 parts of copper oxide, 1 to 2 parts of zinc oxide, 1 to 3 parts of cobaltous oxide, 1 to 3 parts of nickel oxide and 1 to 4 parts of composite reducing water agent. The zinc oxide, the cobaltous oxide and the nickel oxide are combined to enable the glazing color to display different degrees of cyan, and with the addition of the nickel oxide, the phenomenon that the glazing color is slightly yellow due to excessive ferric iron content in the glaze can be avoided; after synergizing and compounding with the copper oxide, the glazing color is more stable and is not easy to be slightly blue or yellow; the celadon glaze is fired in the oxidizing atmosphere, the fuels can be fully burned, the energy is saved, and the harmful gas is reduced.

Owner:LONGQUAN JINHONG PORCELAIN

Modified nickel oxide negative material and preparation method thereof

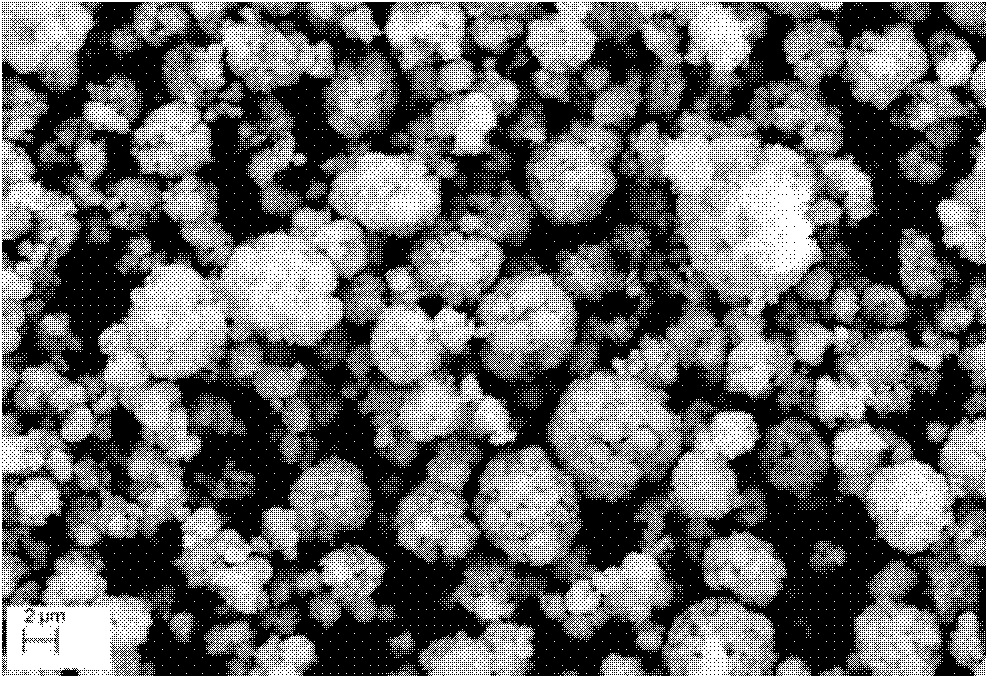

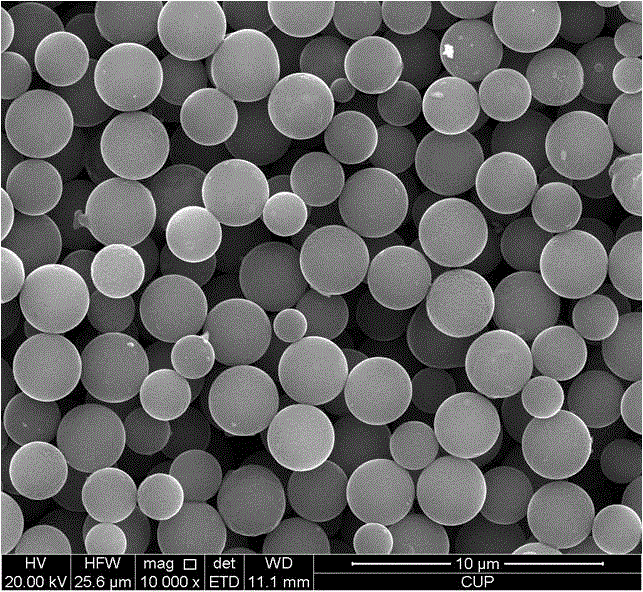

ActiveCN105514421AIncrease the number ofIncrease potential energyCell electrodesSecondary cellsLithiumNitrate

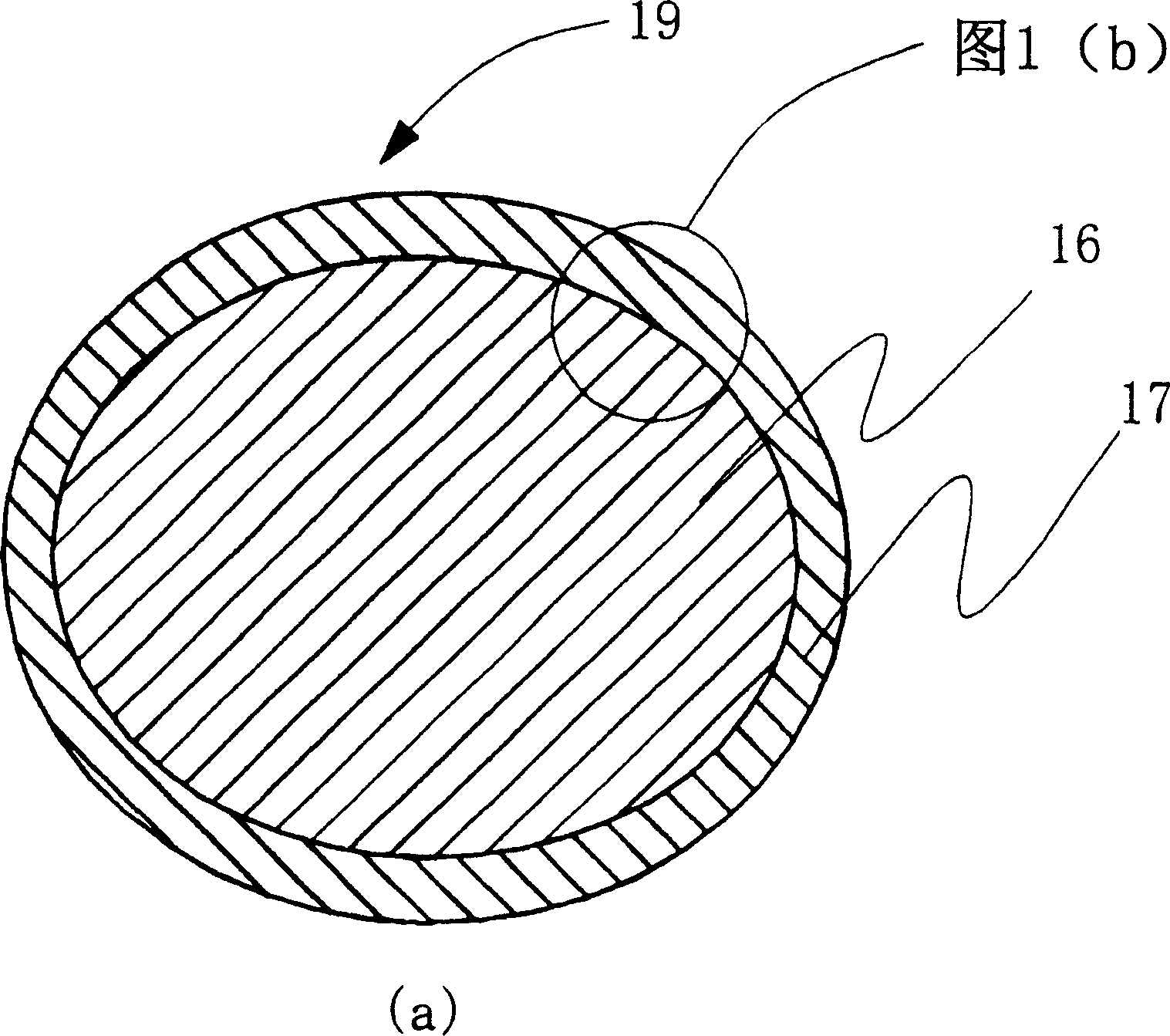

The invention discloses a modified nickel oxide negative material. Nickel oxide with a hollow structure is taken as a matrix and is doped with metal elements (including one or more of lithium, sodium and potassium). A preparation method of the modified nickel oxide negative material comprises the following steps: dissolving metal element nitrate and nickel nitrate in water for mixing uniformly to obtain a mixed liquor, and then performing spray pyrolysis treatment on the obtained mixed liquor, thereby obtaining the modified nickel oxide negative material, wherein a metal element is one or more of lithium, sodium and potassium, and the molar concentration ratio of metal ions and nickel ions in the mixed liquor is equal to (1:100)-(10:100). The nickel oxide negative material has a hollow spherical feature, so that diffusion paths of lithium ions are reduced, and the volume change in a circulating process is alleviated to a certain degree. As nickel oxide is doped with the metal elements including lithium, sodium and potassium, the conductivity of the material is improved, the charge transfer impedance is lowered, and the electrochemical performance of a battery is improved.

Owner:CENT SOUTH UNIV

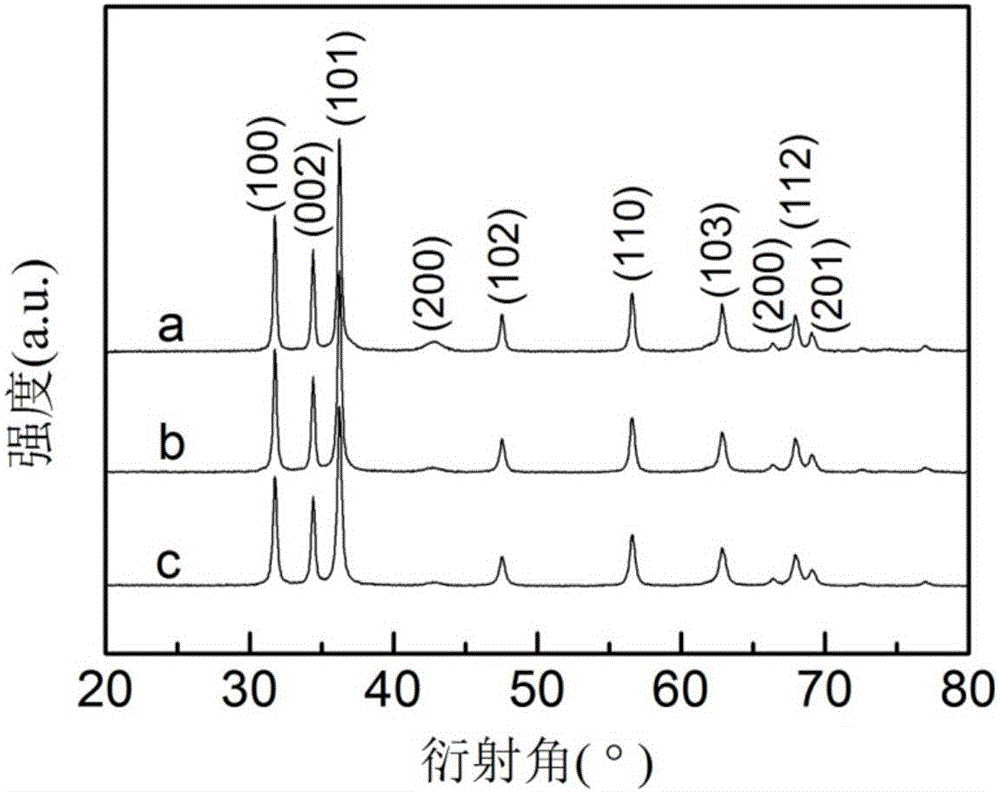

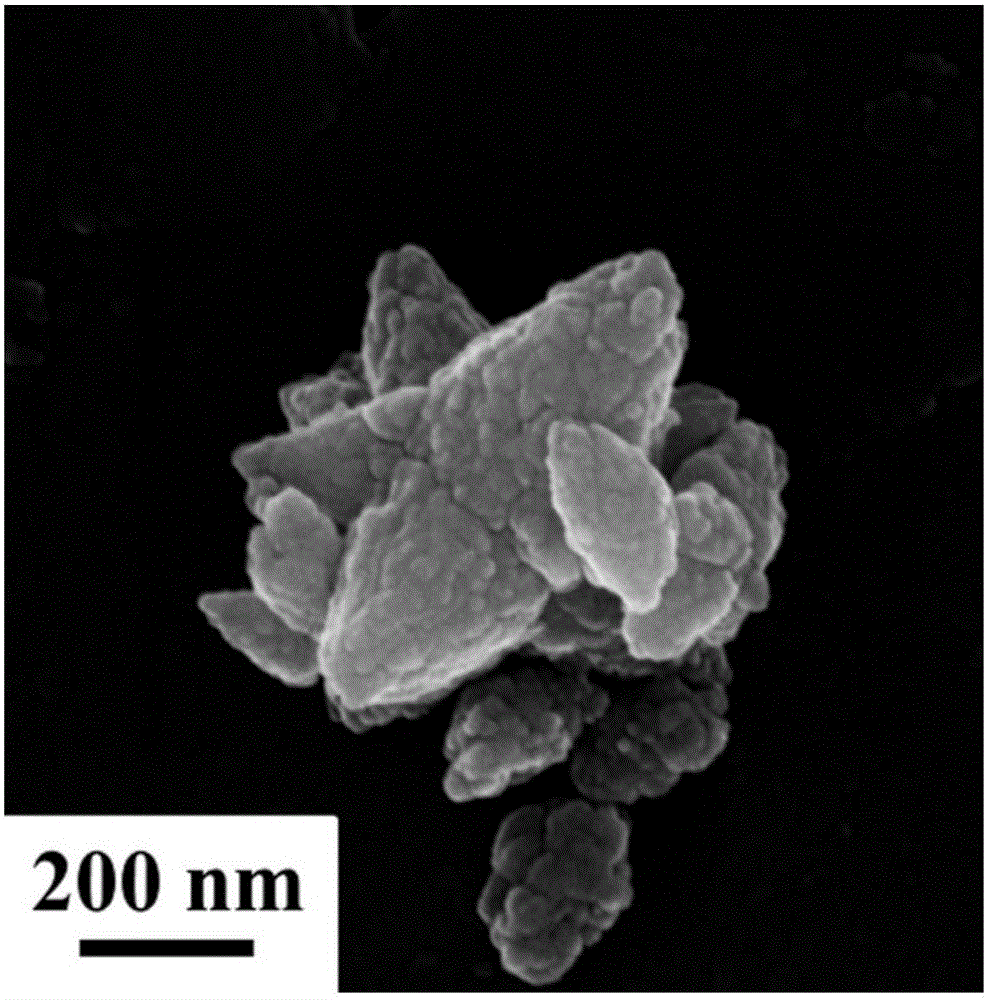

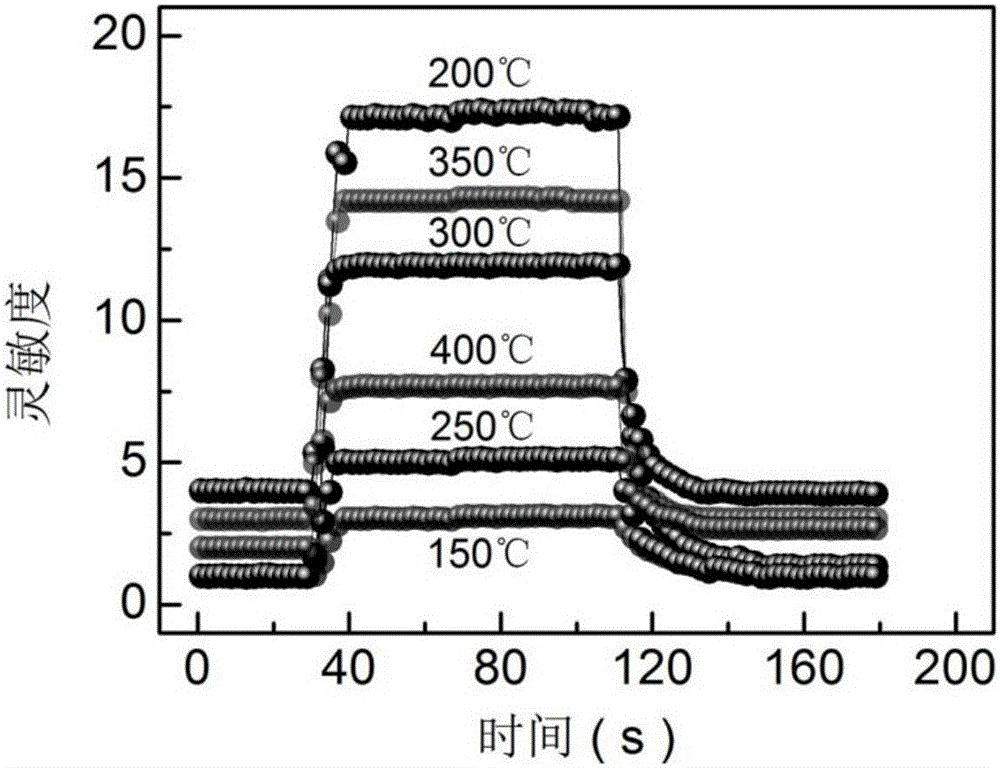

Method for preparing nickel oxide/zinc oxide heterojunction nanometer materials

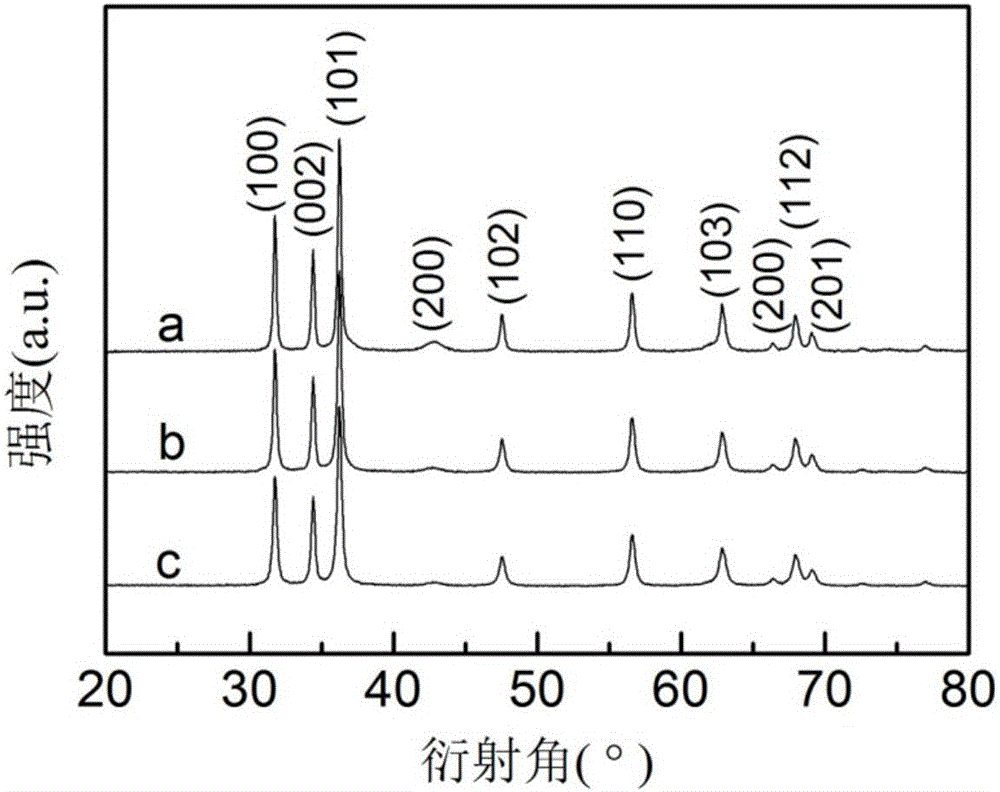

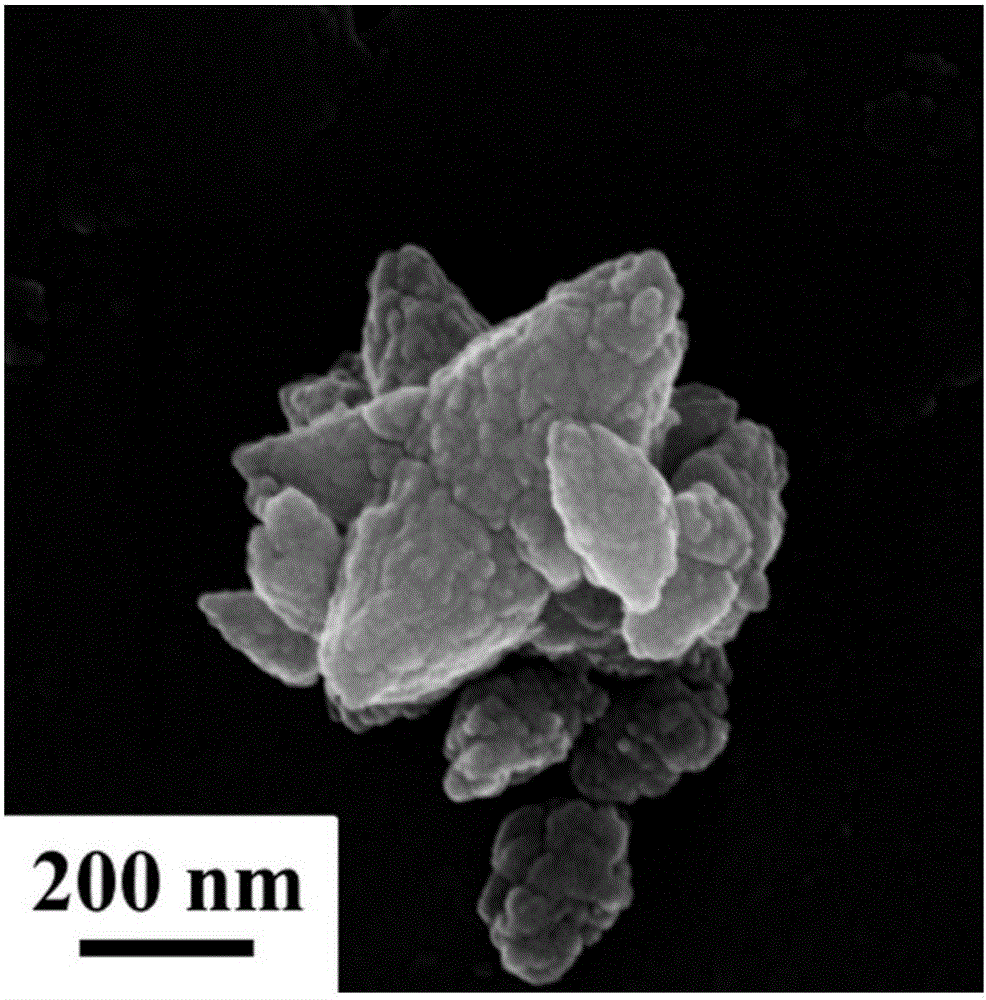

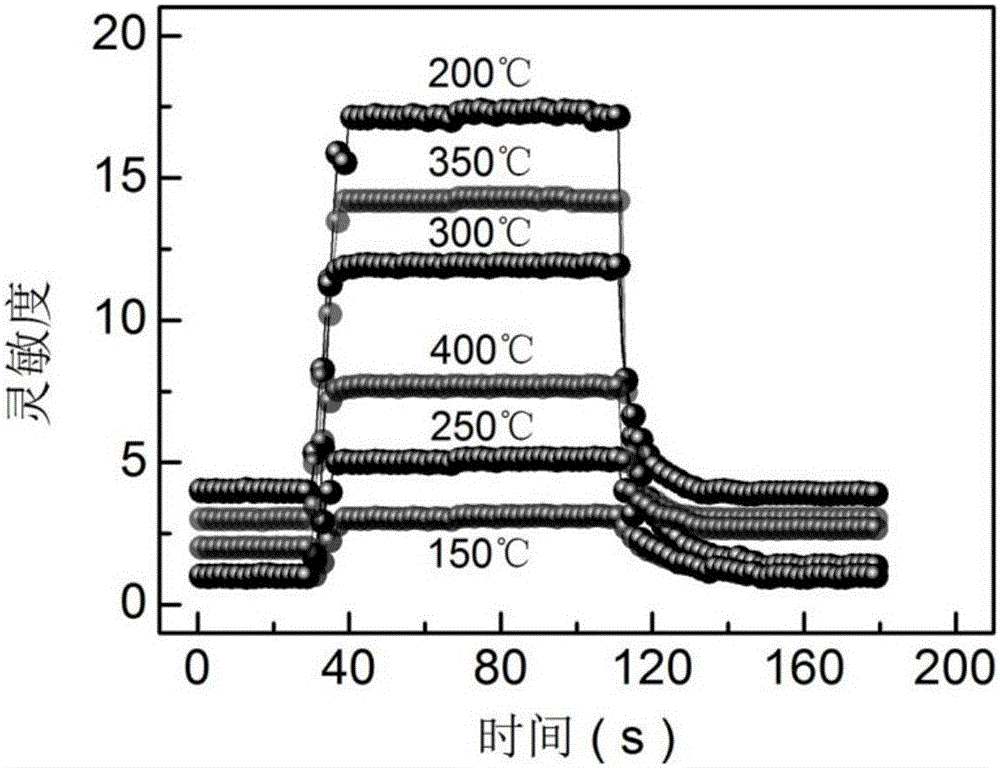

ActiveCN105776357AHigh sensitivityShort reaction timeZinc oxides/hydroxidesMaterial analysis by electric/magnetic meansHeterojunctionWorking temperature

The invention discloses a method for preparing nickel oxide / zinc oxide heterojunction nanometer materials. By the aid of the method, the technical problem of low sensitivity of nickel oxide / zinc oxide heterojunction nanometer materials prepared by the aid of existing methods can be solved. The technical scheme includes that the method comprises synthesizing nickel oxide / zinc oxide heterojunction pre-sintered powder from mixed solution by the aid of a one-step hydrothermal process; calcining the nickel oxide / zinc oxide heterojunction pre-sintered powder to obtain the nickel oxide / zinc oxide heterojunction nanometer materials. The mixed solution is prepared from nickel acetate tetrahydrate, zinc nitrate hexahydrate and sodium hydroxide. The method has the advantages that the method only includes one reaction step instead of two reaction steps in the prior art, and the reaction time is shortened and is 12 h instead of the reaction time of 60 h in the prior art; as shown in gas sensitivity tests, the working temperatures of gas sensors made of the nickel oxide / zinc oxide heterojunction nanometer materials prepared by the aid of the method are lowered and are 200 DEG C instead of the working temperatures of 330 DEG C in the prior art; the sensitivity of the gas sensors for 100 ppm acetone gas is improved and reaches 15-17 instead of the sensitivity of 12 in the prior art.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Nickel oxide-titanium dioxide nano composite material

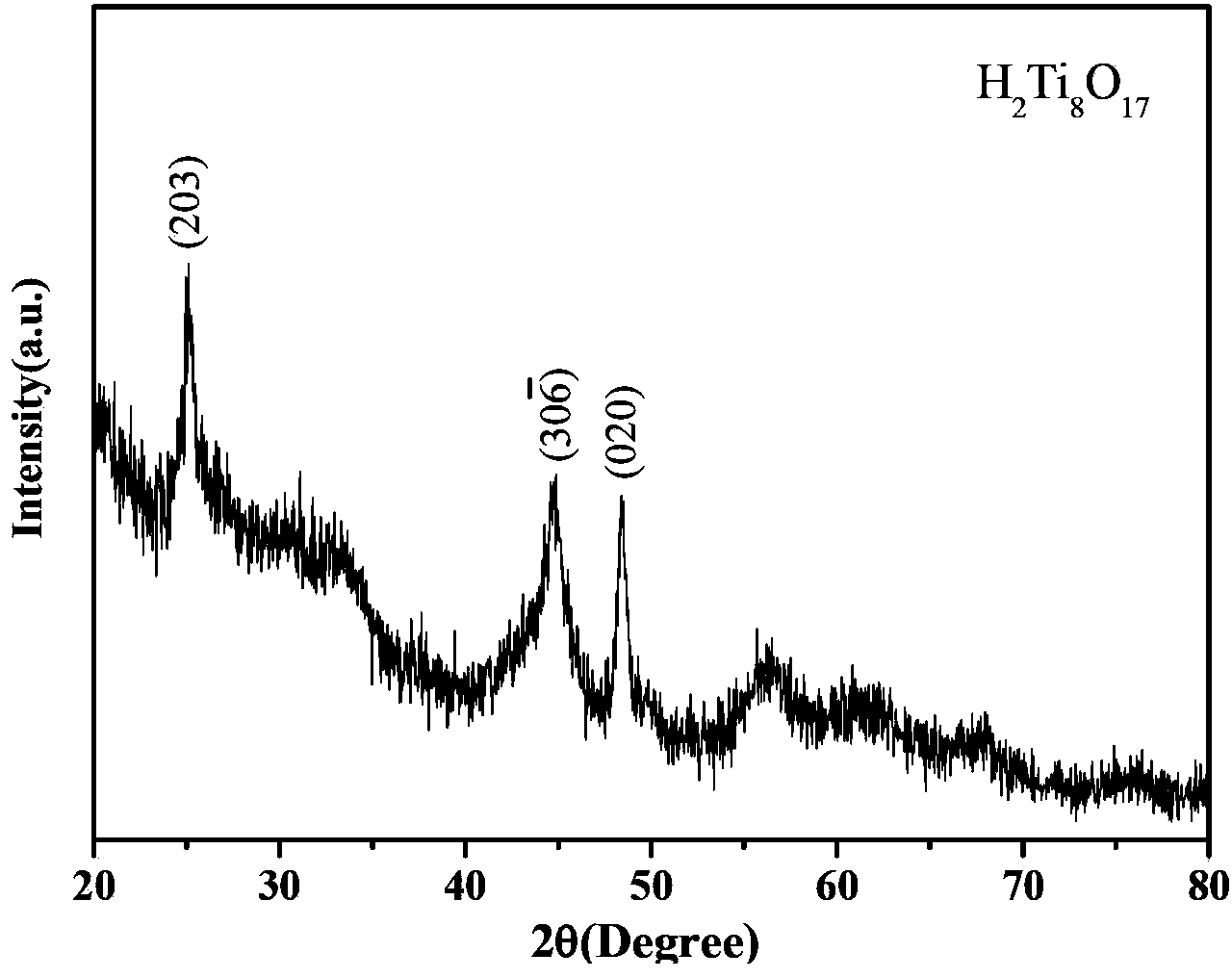

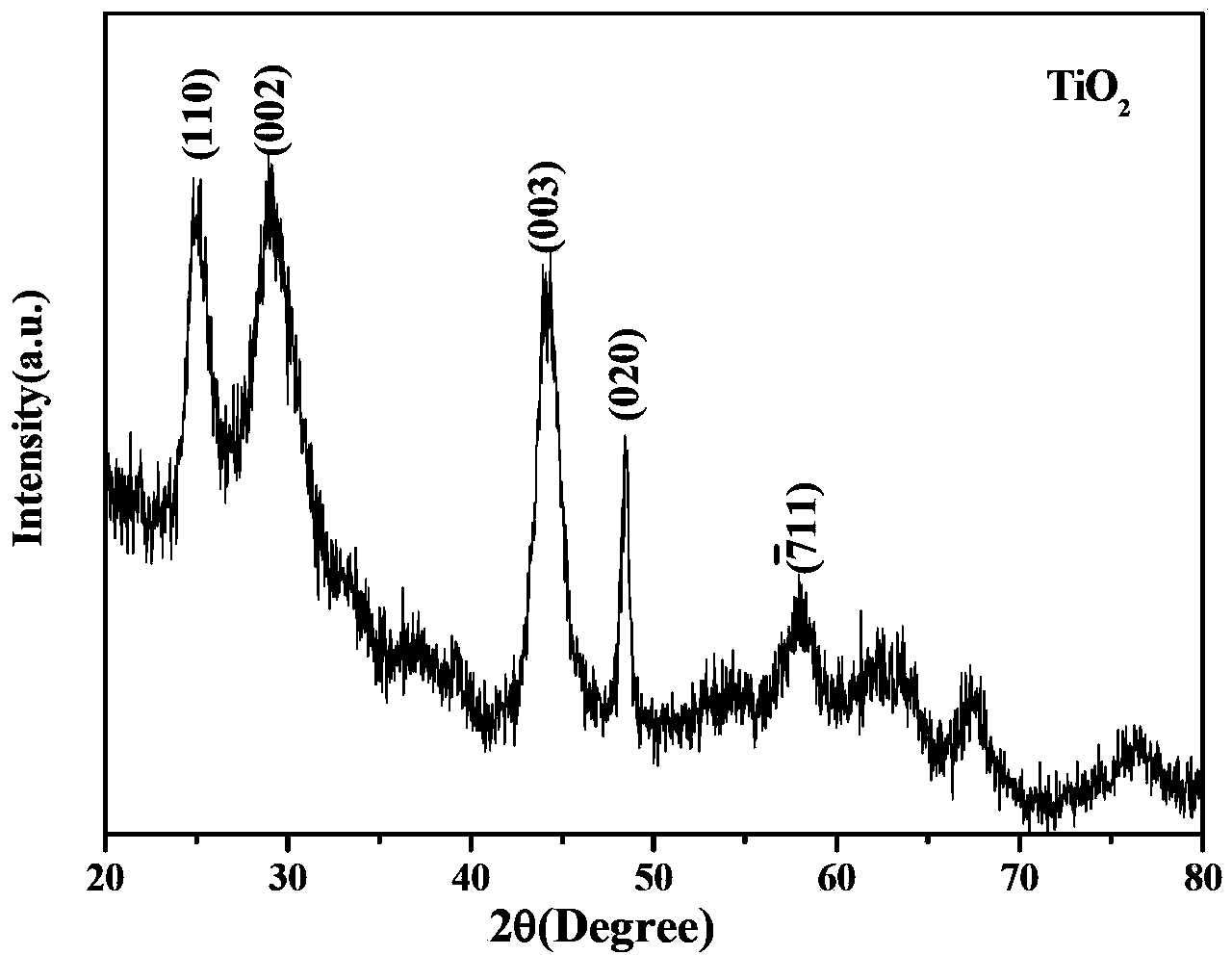

InactiveCN103833076ALow costNo pollution in the processMaterial nanotechnologyTitanium dioxideFiltrationSolvent

The invention provides a nickel oxide-titanium dioxide nano composite material, belonging to the technical field of inorganic functional materials. The nano composite material is prepared by preparing a strip-shaped Na2Ti8O17 precursor from TiO2 serving as a basic raw material and a NaOH solution serving as a reaction solvent by using a hydrothermal method, then soaking, pickling and performing suction filtration to obtain strip-shaped H2Ti8O17, and putting the strip-shaped H2Ti8O17 into a muffle furnace for calcining for 2 hours so as to obtain a TiO2 nano strip; by taking urea, nickel nitrate, water and TiO2 as raw materials, keeping the temperature of 120 DEG C for 4-6 hours by using a homogeneous precipitation method, and then calcining for 2 hours at 400 DEG C so as to obtain a novel nickel oxide-titanium dioxide one-dimensional nano composite material which has the advantages of no toxicity, low cost, no pollution, high specific capacity, good security, good catalytic performance and the like, and has wide application prospects in fields such as lithium ion batteries, photocatalysis and the like.

Owner:王泰林

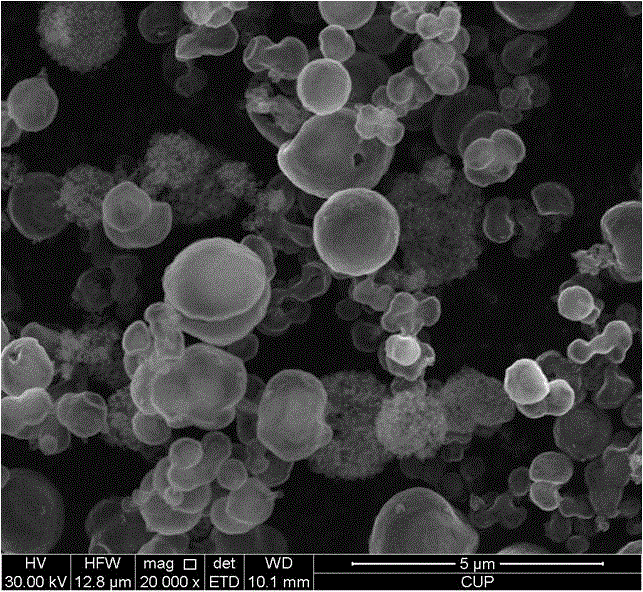

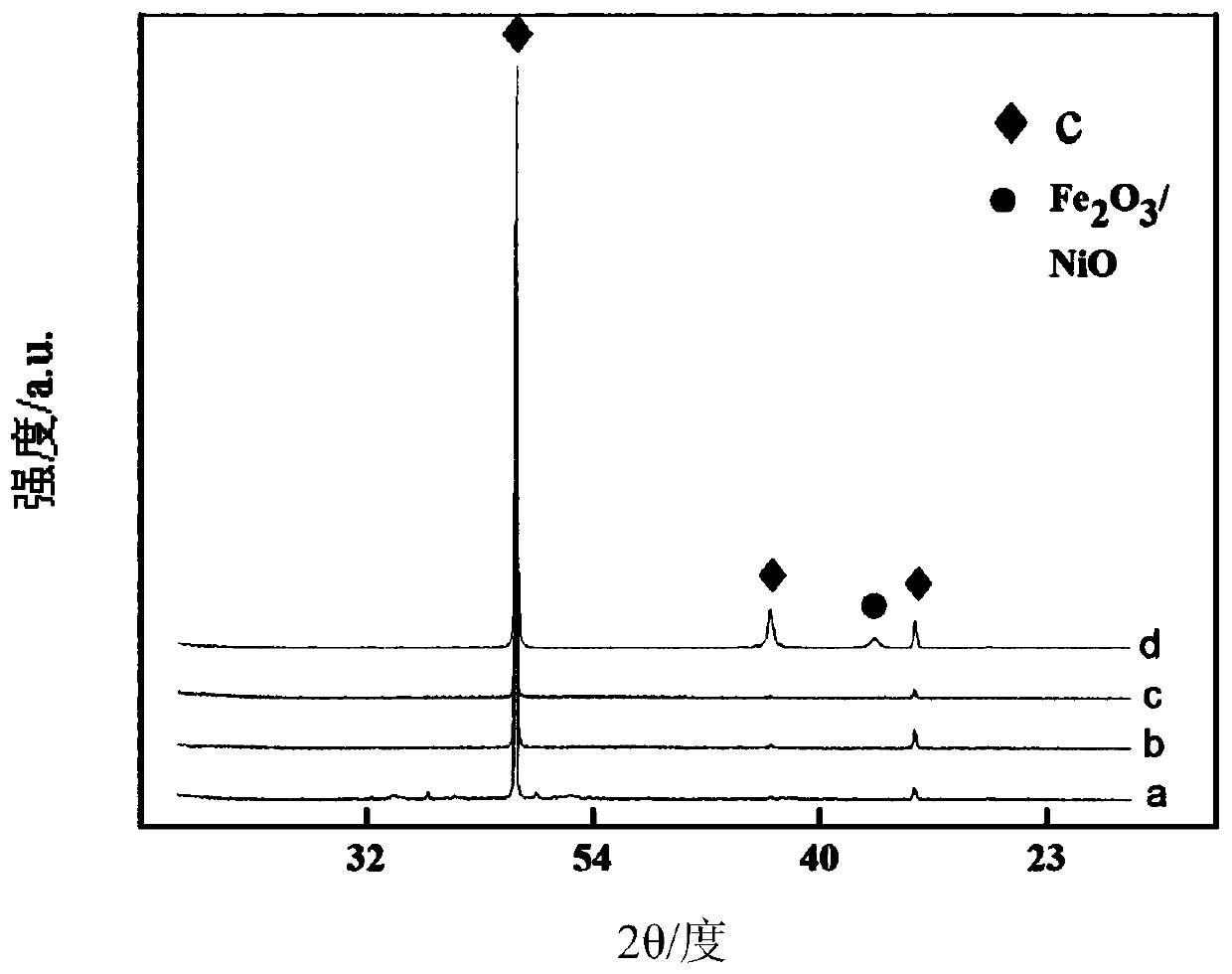

Preparation method of carbon nanotube and nickel oxide composite material

ActiveCN105006376AEasy to manufactureTightly boundHybrid capacitor electrodesCell electrodesCarbon nanotubeChemical vapor deposition

The invention discloses a preparation method of a carbon nanotube and nickel oxide composite material, and belongs to the technical field of nano-materials. Firstly by a hydrothermal method, a spherical structure is prepared by using a Ni(No3)26H2O and D-glucose mixing solution; the prepared nickel hydroxide of the spherical structure is placed on a silicon-based plate, argon is fed into a chemical vapor deposition system, then heating is performed to enable nickel hydroxide to be converted into nickel oxide; then hydrogen is simultaneously fed into the chemical vapor deposition system to reduce partial nickel oxide balls to nickel simple substances; and then ethene gas is fed, and carbon nanotubes grow on the surface of the partially reduced nickel oxide balls in an in-situ catalytic manner. By adopting the method, the nickel oxide and carbon nanotube composite material can be prepared simply and highly efficiently. Compared with the prior art, by adopting the method, the combination of nickel oxide and carbon tubes is more tighter, the electricity conductivity is better, the composite material is more stable, so that the performance of the composite material is effectively improved. The composite material has a wide application prospect in the field of electrochemistry devices such as a super capacitor and a lithium battery.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Preparation method of nano nickel oxide used for propane catalytic combustion reaction

ActiveCN105817227ALow priceRich sourcesIncinerator apparatusMetal/metal-oxides/metal-hydroxide catalystsNickel catalystExtremely good

The invention discloses a preparation method of nano nickel oxide used for propane catalytic combustion reaction and particularly relates to a preparation method of a microenvironment containing nano nickel oxide regulated and controlled by trace variable-valence metal. The catalyst disclosed by the invention is prepared from the following components by mol percentage: 0-95% of nickel and the trace variable-valence metal M (M is Mn, Co and Fe); and hydrogen peroxide is introduced into a variable-valence metal salt to regulate and control a metal valence of the variable-valence metal, so that the nickel oxide is subjected to microenvironment regulation and control, and the redox property and the oxidization property are improved. The preparation method disclosed by the invention is simple and raw materials are cheap and easy to obtain, so that the preparation method is suitable for large-scale and production; and a catalytic material obtained by the invention has an extremely good catalytic property on low-concentration C3H8 and the like.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

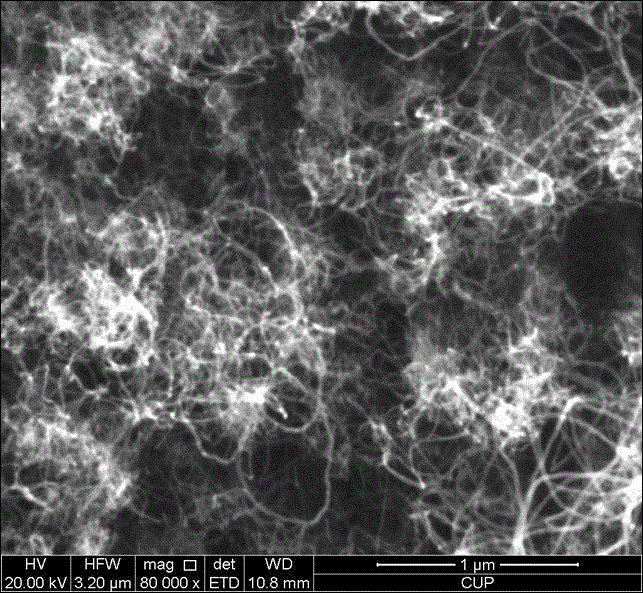

Nanocrystalline metal oxide functionalized carbon nanotube material and formaldehyde gas sensor

The invention discloses a nanocrystalline metal oxide functionalized carbon nanotube material and a formaldehyde gas sensor prepared by using the material. The material comprises carbon nanotube and nickel oxide, and the mass ratio of the carbon nanotube to the nickel oxide is (1:0.1)-(1:30). The nanocrystalline metal oxide functionalized carbon nanotube material provided by the invention, can have a well response to the formaldehyde gas when used as gas sensitive material applied to the formaldehyde gas sensor through special proportion between the carbon nanotube and the nickel oxide, is relative low in cost, and can facilitate the industrialized implementation of the formaldehyde gas sensor.

Owner:SUZHOU NANOGRID TECH

Hydrodesulfurization catalyst for removing sulfur compounds in medium/low-temperature coal tar and application thereof

InactiveCN102688772AHigh mechanical strengthAppropriate pore volume and pore sizeMolecular sieve catalystsRefining to eliminate hetero atomsHydrodesulfurizationBULK ACTIVE INGREDIENT

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Nickel electrode and alkali storage battery using the same

InactiveCN1725546AIncrease capacityImprove conduction abilityElectrode carriers/collectorsPositive electrodesLanthanideOxygen

The present invention provides an anode of excellent charge efficiency that can inhibit the generation of O2 even at the high temperature of the charging process and an alkaline battery that adopts the anode and has excellent battery capacity. The alkaline battery adopts the anode that contains nickel oxide as the main material and so on, and is characterized in that:(1) the nickel oxide is coated by cobalt oxide; (2) the nickel oxide is in solid solution state and at least contains elements that are chosen from Co, Zn, Mg, Mn, Ag and Al; (3) the cobalt oxide has elements of solid solution that are chosen from the elements which are symbolized by Ti, Y, Zn, Cd, Pb, Cr, Ag and Ln (wherein, Ln is one or mixture of lanthanide elements). The alkaline battery for power use, which can reach a high temperature when used and has significant high-speed discharging characteristics, in particular can inhibit the reduction of discharge capacity.

Owner:M&G ECO BATTERY INST

Ni-doped CuCrO2-based oxide thermoelectric material and preparation method thereof

InactiveCN106006738AImprove conductivityReduce carrier concentrationThermoelectric device manufacture/treatmentChromates/bichromatesThermoelectric materialsChromium sesquioxide

The invention provides a Ni-doped CuCrO2-based oxide thermoelectric material. A chemical combination formula of the Ni-doped CuCrO2-based oxide thermoelectric material is CuCr1-xNixO2, and x is 0.001-0.08. A preparation method comprises the following steps: taking copper oxide, chromium sesquioxide and nickel oxide as starting materials; mixing, pre-sintering, carrying out tablet compressing and sintering to obtain the Ni-doped CuCrO2-based oxide thermoelectric material. The prepared nickel-doped CuCrO2 metal oxide thermoelectric material is excellent in thermoelectric property, the power factor of the thermoelectric material can reach up to 100 (mu)W / (mK<2>) to a maximum extent when the working temperature is 300 DEG C; meanwhile, by a solid-phase reaction mode, a preparation technology is simple in technological process, easy to control and suitable for large-scale production.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

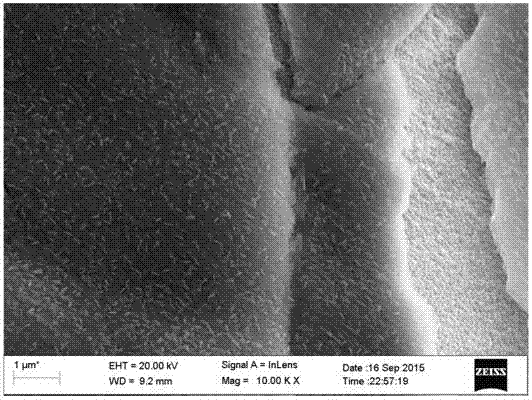

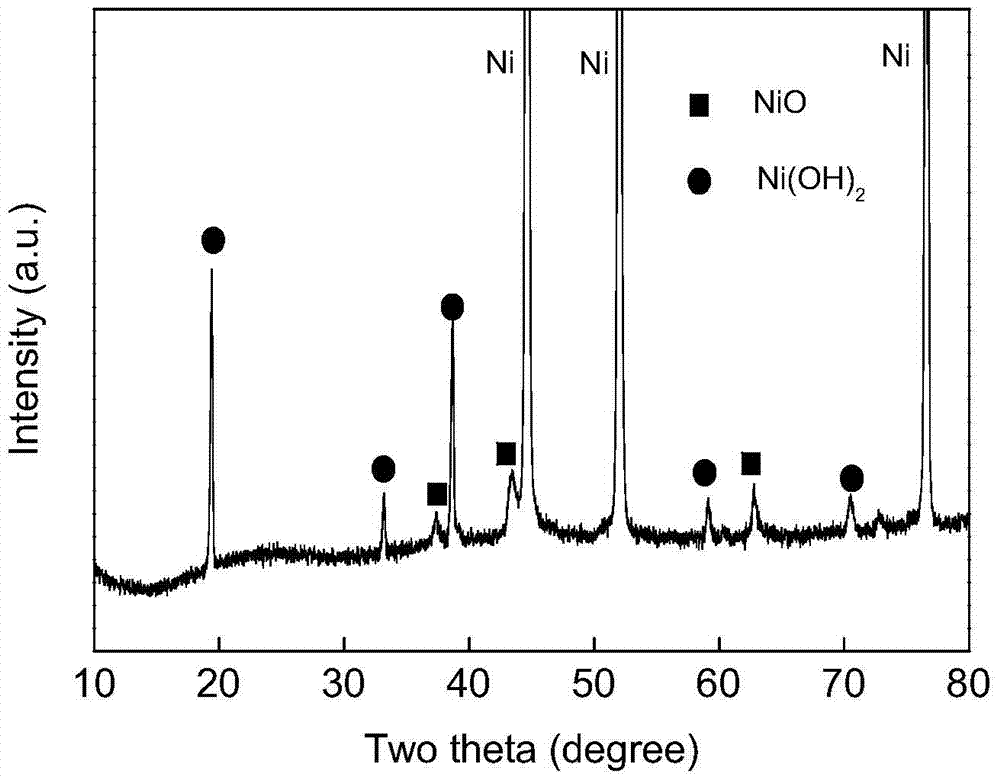

Preparation method of porous titanium-substrate-loaded nickel oxide (nickel hydroxide) electrode with electroconductive ceramic interface

InactiveCN108281291AImprove corrosion resistancePorosityHybrid capacitor electrodesHybrid/EDL manufactureCathodic polarizationContact resistance

The invention discloses a preparation method of a porous titanium-substrate-loaded nickel oxide (nickel hydroxide) electrode with an electroconductive ceramic interface. The preparation method includes (1), ball-milling and mixing metal titanium hydride powder and nickel powder to obtain a metal powder mixture;(2), putting a certain amount of the metal powder mixture into a steel die, and performing pressurization to obtain a metal pressed blank; (3), putting the metal pressed blank into a tubular furnace, and controlling sintering atmosphere and temperature time to obtain the porous titanium-substrate-loaded nickel oxide electrode with the electroconductive ceramic interface; (4), washing the surface of the electrode by dilute acid and deionized water; (5), in nickel nitrate, depositing acertain amount of nickel hydroxide on the surface of the electrode according to a cathodic polarization method to obtain the porous titanium-substrate-loaded nickel hydroxide electrode with the electroconductive ceramic interface. The preparation method has the advantages that the porous electroconductive ceramic interface TinO2n-1-Ti*NiOy generated during high-temperature hypoxic sintering is utilized, contact resistance between active substances and a substrate is reduced, and contact strength between the active substances and the substrate is improved.

Owner:陈军

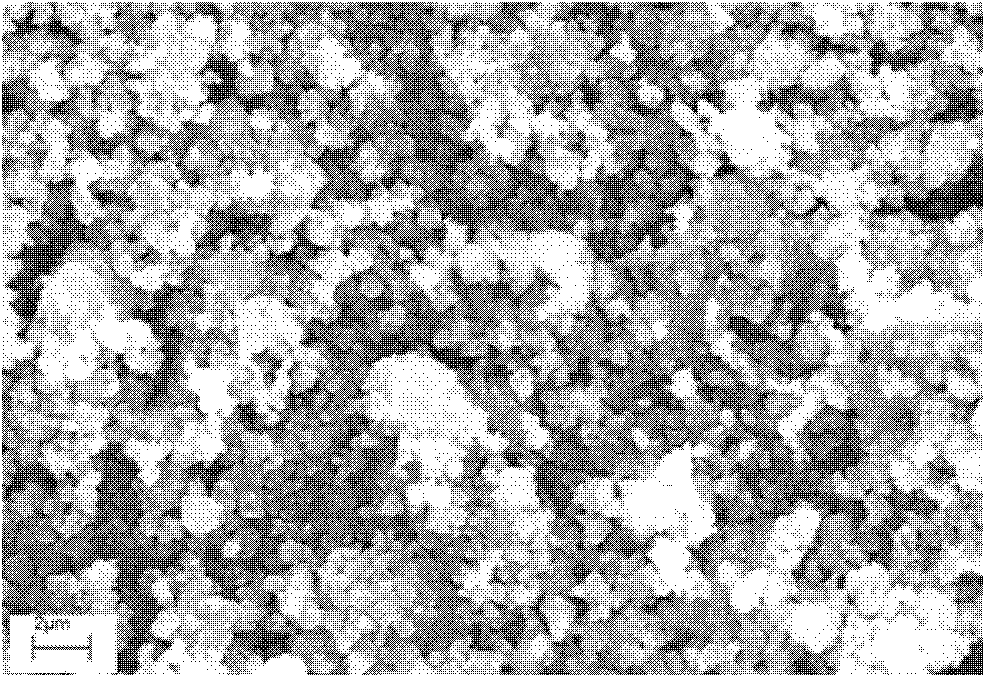

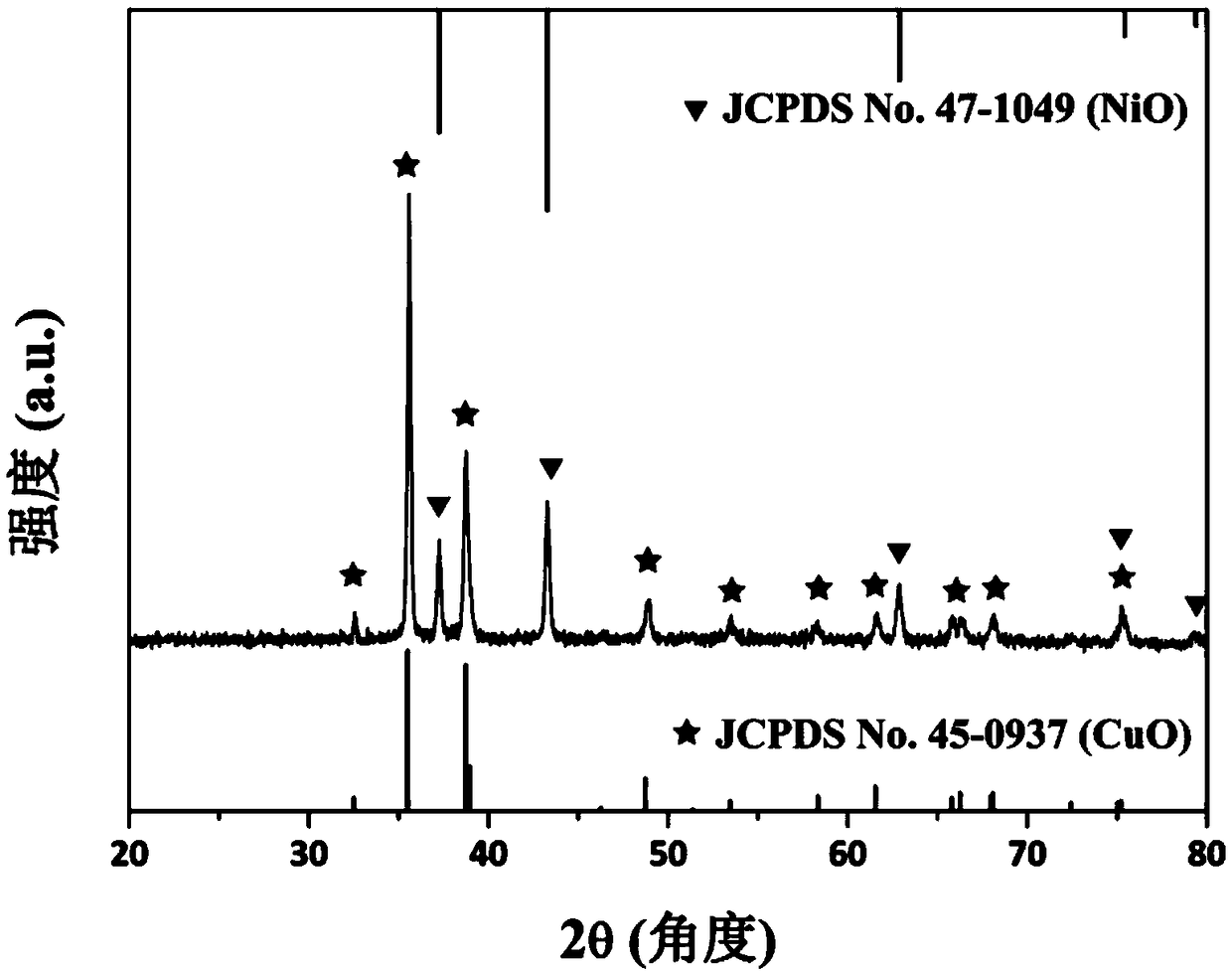

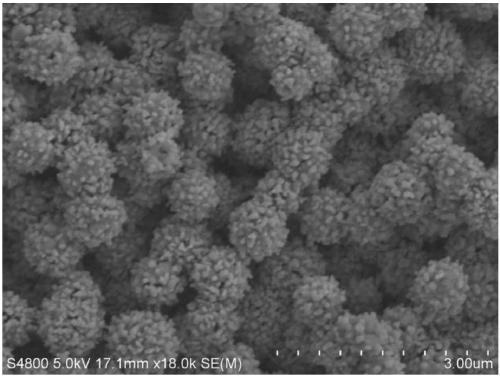

Nickel oxide/copper oxide composite nanomaterial with hollow sphere structure and preparation method of nickel oxide/copper oxide composite nanomaterial

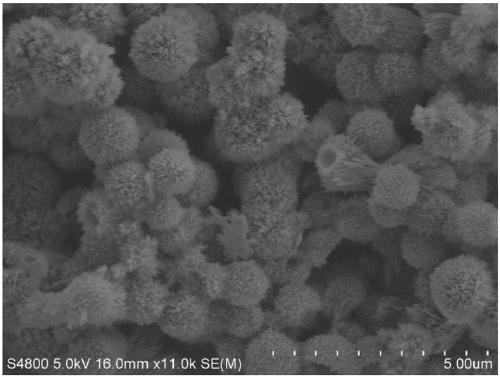

ActiveCN108996557AUniform structureUniform sizeCopper oxides/halidesNickel oxides/hydroxidesNickel saltSolvent

The invention discloses a nickel oxide / copper oxide composite nanomaterial with a hollow sphere structure and a preparation method of the nickel oxide / copper oxide composite nanomaterial. The preparation method comprises steps as follows: nickel salt and bivalent copper salt are dissolved in a solvent, a mixed solution is obtained, a polymer-supported reagent and urea are added to the mixed solution in sequence and stirred until the polymer-supported reagent and urea are dissolved completely, then a mixture is subjected to a hydrothermal reaction, an obtained product is further calcined, and the nickel oxide / copper oxide composite nanomaterial with the hollow sphere structure is obtained after calcination. Compared with the prior art, the raw materials are cheap and available, a template is not required to be added to a reaction system for obtaining of the hollow structure, the synthesis process is simple, the obtained product is controllable in structure and size, and product yield ishigh.

Owner:ANHUI NORMAL UNIV

Preparation method of magnesium oxide-nickel oxide-titanium dioxide composite material

The invention relates to a preparation method of a magnesium oxide-nickel oxide-titanium dioxide composite material and belongs to the technical field of the inorganic nonmetallic material. The magnesium chloride, nickel chloride and titanyl sulfate are taken as the raw materials, the preparation method comprises the following steps: preparing the solution from the raw materials in parts by weight: 80-90 parts of MgO, 5-10 parts of NiO, 5-10 parts of TiO2, adding alkali and titrating, controlling the ph value to be 12-13 to obtain the precipitate, washing, drying, keeping the temperature for 0.5-1h at 600-650 DEG C to obtain the composite powder, dry pressing the composite powder via the pressure more than 150MPa, keeping the temperature for 3h at 1400-1500 DEG C and calcining to obtain the composite material. The composite powder prepared by the method is high in purity and small in granularity; the oxides are evenly mixed and the activity is great; the composite material is obtained by calcining the composite powder, the firing temperature is low, the clinker structure is compact, the apparent porosity is low and the hydrate resistance property is good.

Owner:TANGSHAN GUOLIANG SPEICAL REFRACTORY MATERIAL

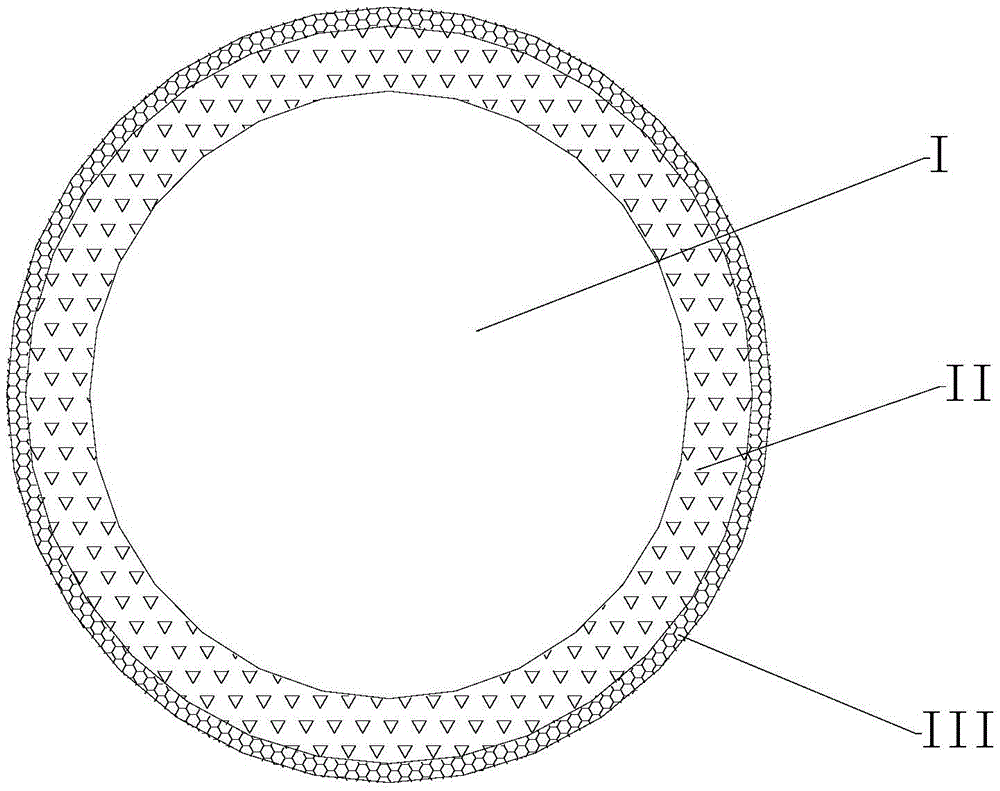

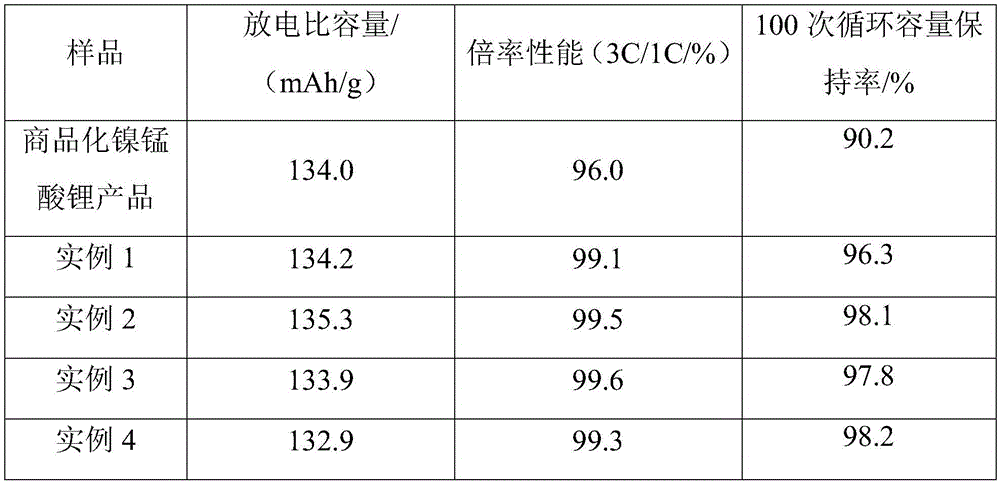

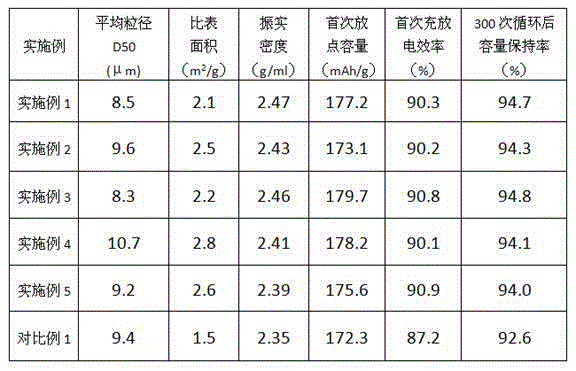

5V spinel nickel lithium manganate material and preparation method thereof

ActiveCN105680033AHigh specific capacityImprove cycle performanceCell electrodesSecondary cellsAir atmosphereNickel salt

The invention discloses a 5V spinel nickel lithium manganate material and a preparation method thereof. The method comprises the following steps that 1, lithium salt, a nickel salt or nickel oxide, a manganese salt or manganese oxide, a metallic salt or metallic oxide and simple-substance carbon are mixed to be uniform to obtain a material; 2, primary roasting is performed on the material in a roasting kiln, and primary treatment matter is obtained; 3, the primary treatment matter and zirconium oxide are mixed to be uniform, secondary matter to be roasted is obtained, secondary roasting is performed on the secondary matter to be roasted in an air atmosphere in the roasting kiln, and then the 5V spinel nickel lithium manganate material is obtained. The molecular formula of the 5V spinel nickel lithium manganate material is (0.995-0.998)[Li(1-1.5)Ni(0.5)Mn(1.5-x)MxO4] / (0.002-0.005)ZrO2, wherein M is selected from Fe and Ti, x=0.01-0.05, and the structure comprises three layers from inside to outside. The preparation method is simple and high in applicability, and the prepared product is high in specific capacity and good in cycle performance.

Owner:TIANJIN B&M SCI & TECH

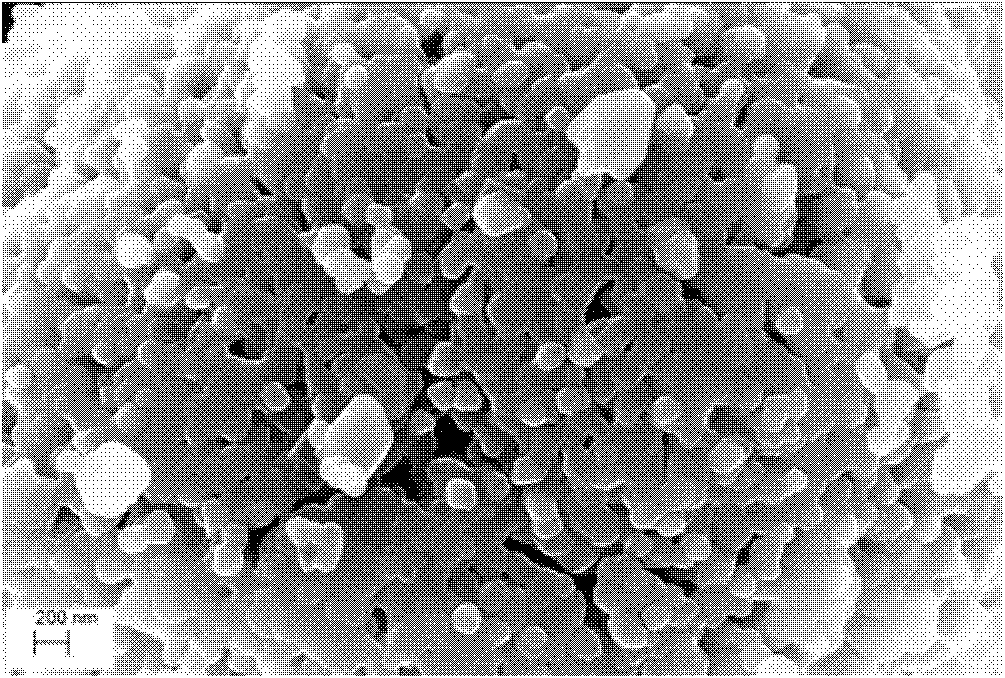

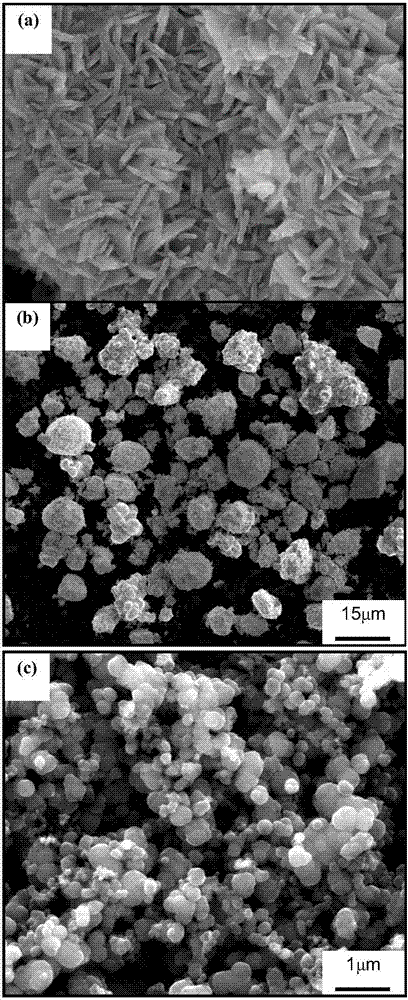

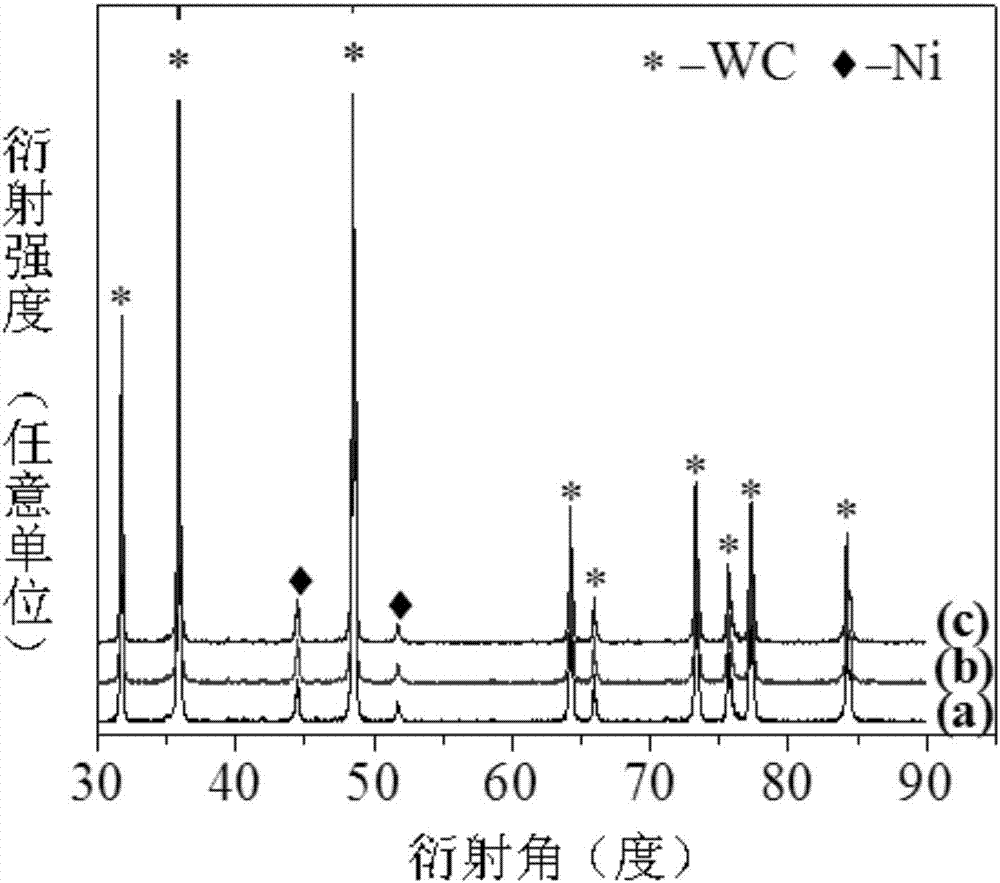

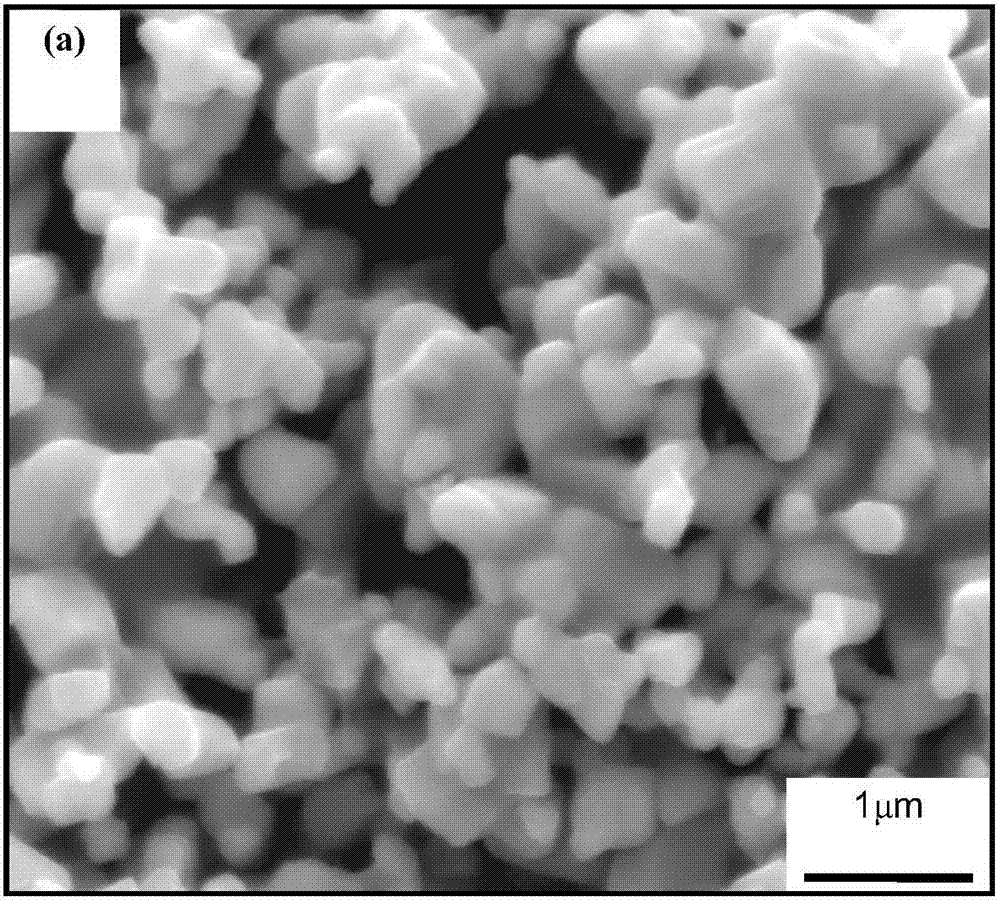

Preparation method of ultrafine WC-Ni composite powder

The invention discloses a preparation method of ultrafine WC-Ni composite powder and belongs to the technical field of preparation of hard alloy materials. Violet tungsten oxide, nickel oxide and carbon black are used as raw materials, a nanoscale initial mixture with all phases dispersed evenly is obtained through stirring, grinding and refining firstly and then is placed in a vacuum furnace for in-situ reduction and carbonization reaction, and the WC-Ni composite powder in the ultrafine particle size is synthetized in one step. The metal oxide is high in brittleness, the raw materials can be refined and evenly mixed through ball milling for a short time, and the energy barrier for production of WC through continuous carbonization of W produced through reduction of the violet tungsten oxide is effectively reduced through formation of an intermediate product W-Ni-C in the in-situ reaction process, so that the synthetic temperature of WC and Ni is substantially reduced. Thus, compared with a traditional method, the method has the advantages that the technological process is short, the cost is low, the dispersity of Ni in the prepared powder is good, and adjustment of the composition and the particle size of the powder is facilitated.

Owner:BEIJING UNIV OF TECH

Heteropolyacid ammonium salt type catalyst and preparation method thereof

ActiveCN106944136AHigh low temperature activityGood choiceOrganic-compounds/hydrides/coordination-complexes catalystsHeterogenous catalyst chemical elementsSilicon oxideHigh selectivity

The present invention discloses a heteropolyacid ammonium salt type catalyst and a preparation method thereof. The catalyst comprises an active component and an auxiliary agent-containing carrier, wherein the active component is a heteropolyacid ammonium salt, the carrier is silicon oxide containing auxiliary agents such as nickel and boron, the heteropolyacid ammonium salt content is 3-35% by adopting the weight of the catalyst as the reference, and the auxiliary agents comprise (calculated as the oxide) 3-18% of nickel oxide, 1-6% of boron oxide and 41-93% of silicon oxide. According to the present invention, the catalyst is particularly suitable for the ethylene preparation reaction through dehydration by using the low-concentration ethanol aqueous solution as the raw material, and has advantages of high low-temperature activity, high selectivity, high carbon deposition resistance and good stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrodesulfurization catalyst for removing sulfur compounds in medium/low-temperature coal tar and application thereof

InactiveCN102688772BHigh mechanical strengthAppropriate pore volume and pore sizeMolecular sieve catalystsRefining to eliminate hetero atomsHydrodesulfurizationBULK ACTIVE INGREDIENT

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Synthetic method for lithium ion cathode material LiNiO2/C

InactiveCN105047869AIncreased diffusion rateImprove conductivityCell electrodesSecondary cellsCarbon coatedHeat treated

A synthetic method for a lithium ion cathode material LiNiO2 / C is characterized by comprising the following steps of: 1) adding water and mixing nickel oxide and an organic carbon source, carrying out spray granulation after ball-grinding treatment, and pre-treating the obtained powder in an inert atmosphere to obtain carbon-coated nickel oxide powder; 2) dissolving a lithium source in the water, adding the nickel oxide powder obtained in the step 1), and carrying out spray granulation after ball-grinding treatment to obtain dried powder; and 3) treating the dried powder obtained in the step 2) in the inert atmosphere, carrying out high-temperature heat treatment, and performing air classification, thereby obtaining the lithium ion cathode material LiNiO2 / C. According to the synthetic method, nickel oxide is firstly coated with carbon, so that lithium nickel oxide is prevented from agglomeration due to subsequent high-temperature treatment, over large grains of the lithium nickel oxide are prevented, the conductivity of the material is improved, and the cycling stability of the lithium nickel oxide is enhanced.

Owner:田东

Preparation method and application of iron-nickel oxide coated carbon material

The invention provides a preparation method and application of an iron-nickel oxide coated carbon material. The preparation method of the iron-nickel oxide coated carbon material comprises the preparation step, the electrodeposition step and the drying step, wherein the preparation step is conducted, specifically, an iron-containing compound, a nickel-containing compound, a surfactant and a bufferagent are dissolved into a solvent to form an iron-nickel source containing solution; the electrodeposition step is conducted, specifically, the iron-nickel source containing solution is put into anelectrolytic cell to serve as an electrodeposition solution, a carbon material serves as a cathode, an iron plate and a nickel plate serve as double anodes, electrodeposition is conducted at the set current density, then still standing is conducted, a solvent is removed, and thus an intermediate complex is obtained; and the drying step is conducted, specifically, after the intermediate compound isdried, the iron-nickel oxide coated carbon material is obtained.

Owner:ZHEJIANG NARADA POWER SOURCE CO LTD +1

Catalyst for treating chemical industry organic wastewater

InactiveCN106391041AHigh hardnessExtended service lifeMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationChemical industryCatalytic oxidation

The present invention provides a catalyst for treating chemical industry organic wastewater. The catalyst comprises, by mass, 45-70 parts of Al2O3, 25-45 parts of nickel oxide, 8-18 parts of manganese oxide, and 2-10 parts of lanthanum oxide, wherein the Al2O3 is a carrier and supports the nickel oxide, the manganese oxide, and the lanthanum oxide. According to the present invention, the catalyst has excellent performances in the field of hardness, active component stability, service life and catalytic oxidation efficiency, the preparation process is simple, and the industrial production can be achieved; and the catalyst can be used in the fixed bed and the fluidized bed in the engineering, and provides good competitive strength in the treatment effect and the engineering application prospects compared to the traditional active carbon.

Owner:JIANGSU JIHUA CHEMICAL CO LTD

A kind of modified nickel oxide negative electrode material and preparation method thereof

ActiveCN105514421BImprove conductivityShorten the diffusion pathCell electrodesSecondary cellsLithiumNitrate

The invention discloses a modified nickel oxide negative material. Nickel oxide with a hollow structure is taken as a matrix and is doped with metal elements (including one or more of lithium, sodium and potassium). A preparation method of the modified nickel oxide negative material comprises the following steps: dissolving metal element nitrate and nickel nitrate in water for mixing uniformly to obtain a mixed liquor, and then performing spray pyrolysis treatment on the obtained mixed liquor, thereby obtaining the modified nickel oxide negative material, wherein a metal element is one or more of lithium, sodium and potassium, and the molar concentration ratio of metal ions and nickel ions in the mixed liquor is equal to (1:100)-(10:100). The nickel oxide negative material has a hollow spherical feature, so that diffusion paths of lithium ions are reduced, and the volume change in a circulating process is alleviated to a certain degree. As nickel oxide is doped with the metal elements including lithium, sodium and potassium, the conductivity of the material is improved, the charge transfer impedance is lowered, and the electrochemical performance of a battery is improved.

Owner:CENT SOUTH UNIV

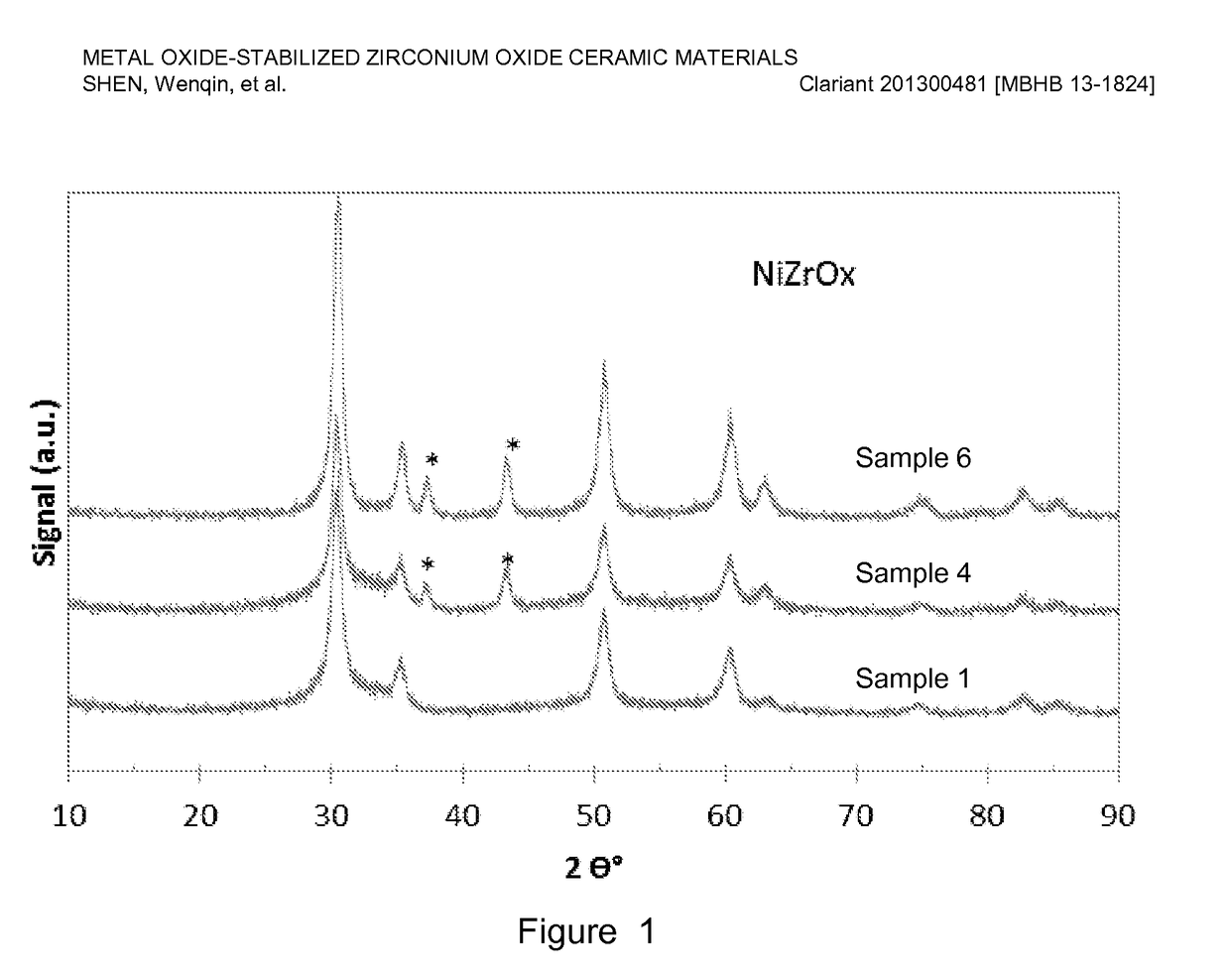

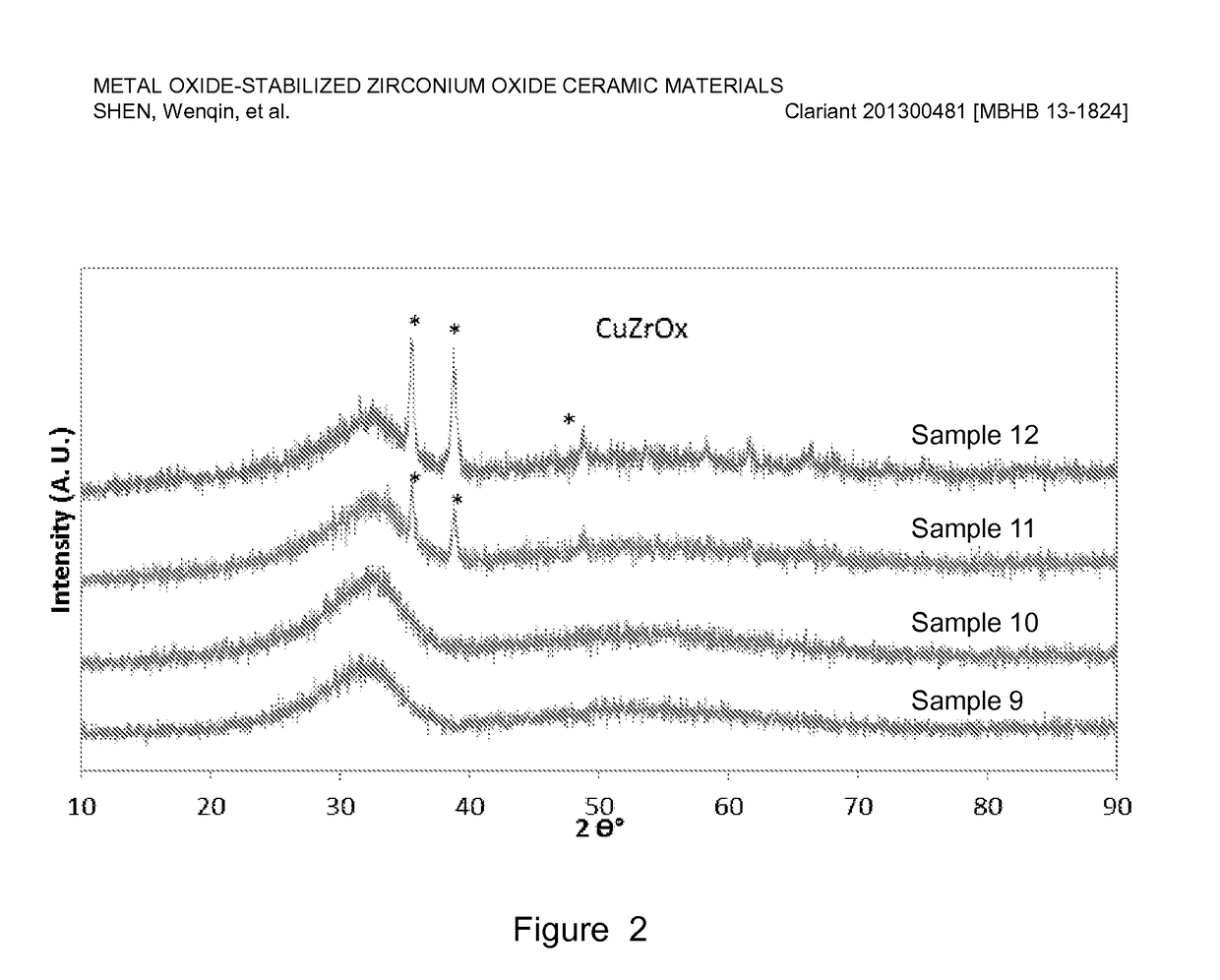

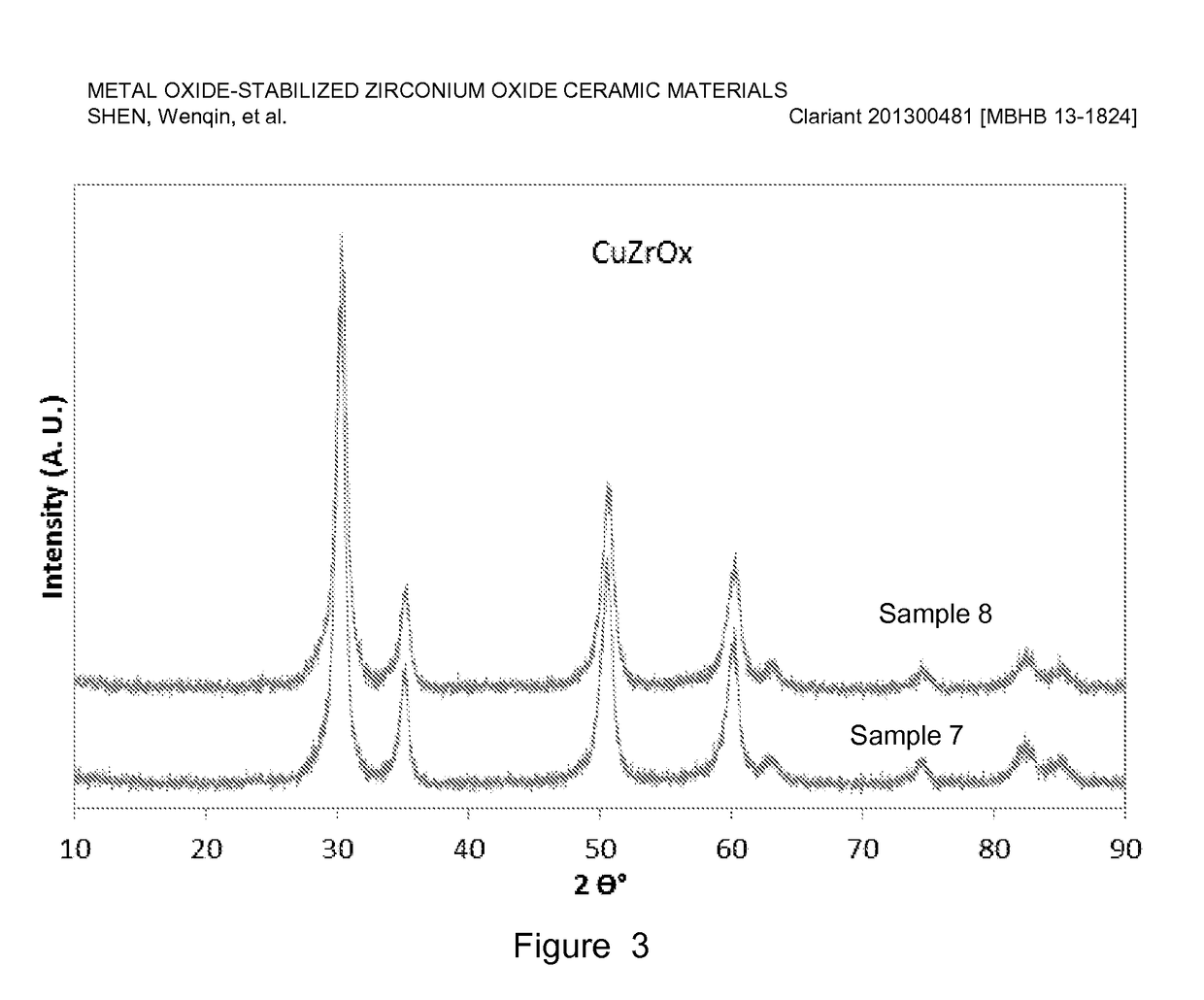

Metal Oxide-Stabilized Zirconium Oxide Ceramic Materials

InactiveUS20170190643A1Extrusion process is simpleImprove catalytic performanceOrganic compound preparationHeterogenous catalyst chemical elementsIron(II) oxideAlcohol sugars

The present disclosure relates generally to ceramic materials suitable for use as catalyst support materials, catalysts using such materials and methods for using them, such as methods for converting sugars, sugar alcohols, glycerol, and bio-renewable organic acids to commercially-valuable chemicals and intermediates. One aspect of the invention is a ceramic material including zirconium oxide and one or more metal oxides selected from nickel oxide, copper oxide, cobalt oxide, iron oxide and zinc oxide, the ceramic material being at least about 50 wt. % zirconium oxide. In certain embodiments, the ceramic material is substantially free of any binder, extrusion aid or additional stabilizing agent.

Owner:CLARIANT CORP

Preparation method of nickel oxide/zinc oxide heterojunction nanomaterial

ActiveCN105776357BHigh sensitivityShort reaction timeZinc oxides/hydroxidesMaterial analysis by electric/magnetic meansHeterojunctionWorking temperature

The invention discloses a method for preparing nickel oxide / zinc oxide heterojunction nanometer materials. By the aid of the method, the technical problem of low sensitivity of nickel oxide / zinc oxide heterojunction nanometer materials prepared by the aid of existing methods can be solved. The technical scheme includes that the method comprises synthesizing nickel oxide / zinc oxide heterojunction pre-sintered powder from mixed solution by the aid of a one-step hydrothermal process; calcining the nickel oxide / zinc oxide heterojunction pre-sintered powder to obtain the nickel oxide / zinc oxide heterojunction nanometer materials. The mixed solution is prepared from nickel acetate tetrahydrate, zinc nitrate hexahydrate and sodium hydroxide. The method has the advantages that the method only includes one reaction step instead of two reaction steps in the prior art, and the reaction time is shortened and is 12 h instead of the reaction time of 60 h in the prior art; as shown in gas sensitivity tests, the working temperatures of gas sensors made of the nickel oxide / zinc oxide heterojunction nanometer materials prepared by the aid of the method are lowered and are 200 DEG C instead of the working temperatures of 330 DEG C in the prior art; the sensitivity of the gas sensors for 100 ppm acetone gas is improved and reaches 15-17 instead of the sensitivity of 12 in the prior art.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

A method for preparing nickel hydroxide-nickel oxide thin film electrodes based on in-situ growth

InactiveCN105469901BAvoid complex processesGood for electrochemical activityCable/conductor manufactureElectrolytic agentNickel(III) oxide

The invention relates to an in-situ-growth-based method for preparing nickel hydroxide-nickel oxide film electrode. The method comprises: cleaning, dedusting, rust removing, and oil removing are carried out on a metallic nickel substrate to obtain a clean nickel surface; preparation of an alkaline electrolyte is carried out, wherein the main raw material is KOH or NaOH alkali metal and the concentration is 5-300g / L and the auxiliary raw material is one of hydrogen peroxide, ammoniacal liquor, sodium carbonate, sodium oxalate, urea, and glycol and the concentration is 1-20g / L; the electrolyte is placed in an reaction still and the clean nickel substrate is immersed into the electrolyte; the reaction still is placed in a muffle furnace to carry out hydrothermal reaction for 1 to 96 houses at the temperature of 120 to 250 DEG C, so that oxidation reaction is carried out on the metallic nickel surface; and then the metallic nickel is taken out after water heating and is cleaned and dried, thereby obtaining the nickel hydroxide-nickel oxide film electrode prepared based on in-situ growth. The preparation method has advantages of simple process, low price of raw materials, easy operation, and low production price; the thickness of the prepared film material can be controlled; and the activity is high. The method is suitable for industrial large-scale production.

Owner:YANSHAN UNIV

Compound perovskite oxide and preparation method thereof

The invention discloses a compound perovskite oxide and a preparation method thereof. A general formula of the compound perovskite oxide is CaCu3Me4O12, wherein Me is one of Ni, Sb and Bi. The preparation method comprises the steps of taking calcium oxide, cupric oxide, nickel oxide, antimony pentoxide and bismuth trioxide as raw materials, mixing and ballmilling for 4-24h at the ballmilling rate of 200-450rpm, conducting pressure molding on ballmilled powder under 200-400MPa unidirectional pressure, sintering under high pressure, boosting 3-5GPa high pressure, heating to 1000-1200 DEG C with a heating rate of 30-50 DEG C / min, sintering for 30-120min, cooling to the room temperature at a rate of 20-50 DEG C / min, and removing the high pressure. Under the extra high pressure, the metastable compound perovskite oxide CaCu3Me4O12 can be kept stable; related compounds remain extra high pressure states in a whole high-temperature synthetic process; and a second phase due to lattice strain and the like is inhibited, so that the pure compound perovskite oxide can be obtained.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

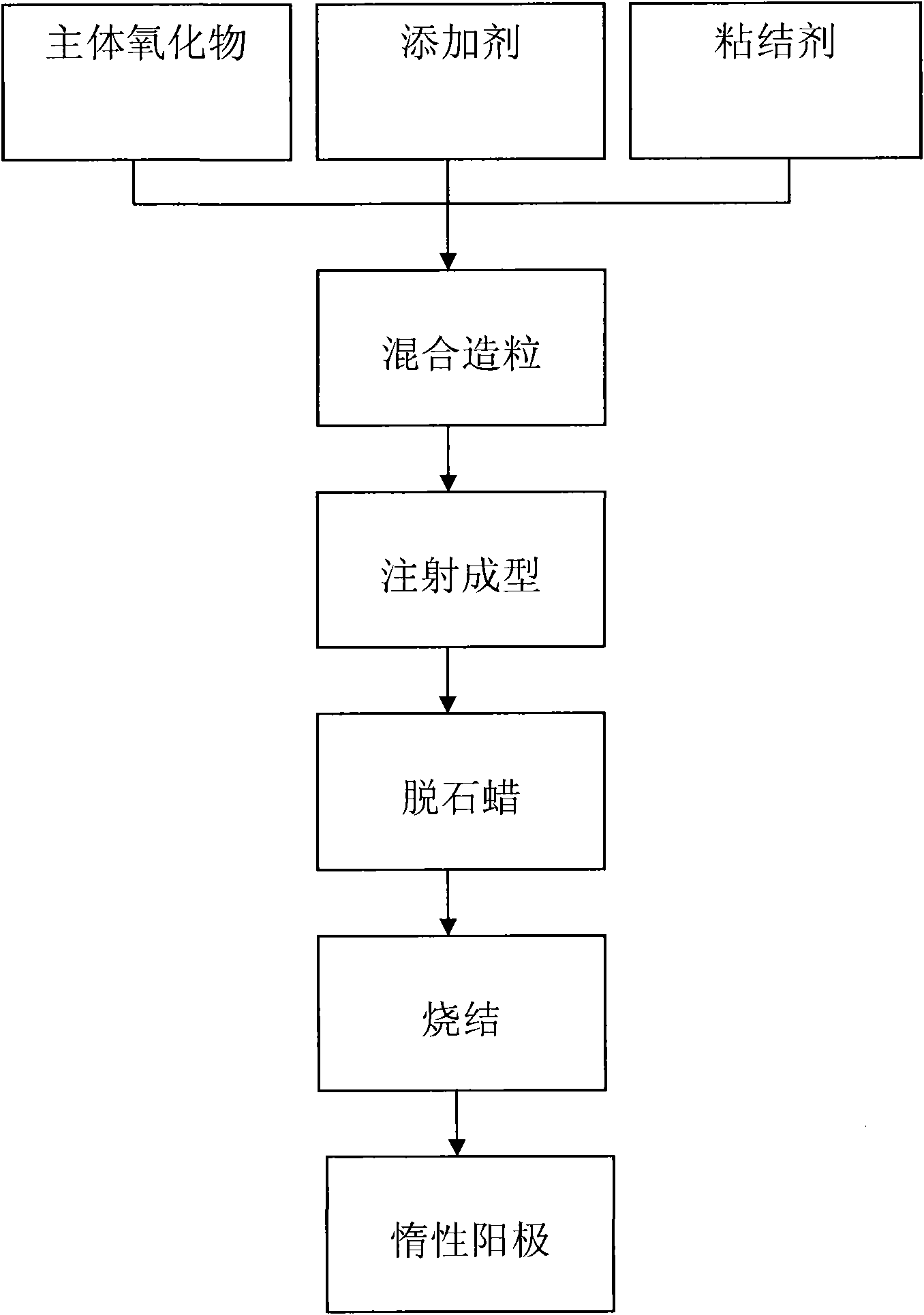

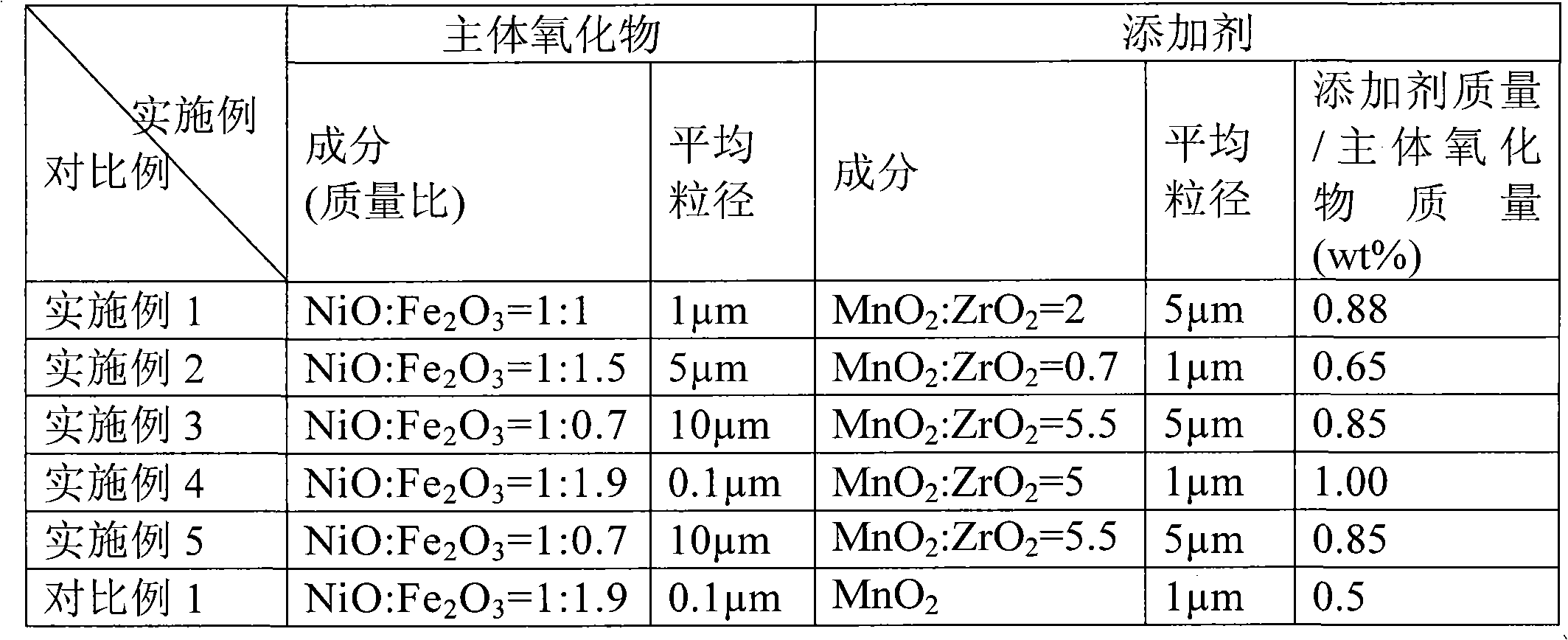

Inert anode and preparation method thereof

InactiveCN102206837BSolve the technical problem of low conductivityConductivity average increaseElectrodesOxide ceramicsElectrolysis

The invention belongs to the technical field of electrolysis, in particular to the technical field of metal oxide ceramic inert anodes. The invention provides an inert anode, which comprises main oxides and additives, wherein the main oxides comprise nickel oxide and ferric oxide; and the additives are at least two of magnesium oxide, titanium oxide, tin oxide, zinc oxide, zirconium oxide and alumina, and are 0.1 to 1 percent of the weight of the main oxides. The inert anode solves the technical problem of low electric conductivity when the conventional metal oxide ceramics serve as inert anodes, and the electric conductivity is averagely improved by about 8.4S / cm. In addition, the corrosion resistance of the inert anode is also improved. Correspondingly, the invention also provides an inert anode production method.

Owner:BYD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com