Nickel oxide-titanium dioxide nano composite material

A nanocomposite material, titanium dioxide technology, applied in the direction of nickel oxide/nickel hydroxide, titanium dioxide, titanium oxide/hydroxide, etc., can solve the problem of low uniformity of one-dimensional nanomaterials, affecting material structure and performance, complicated steps, etc. problems, to achieve significant energy saving and material saving, high specific capacity, and good safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

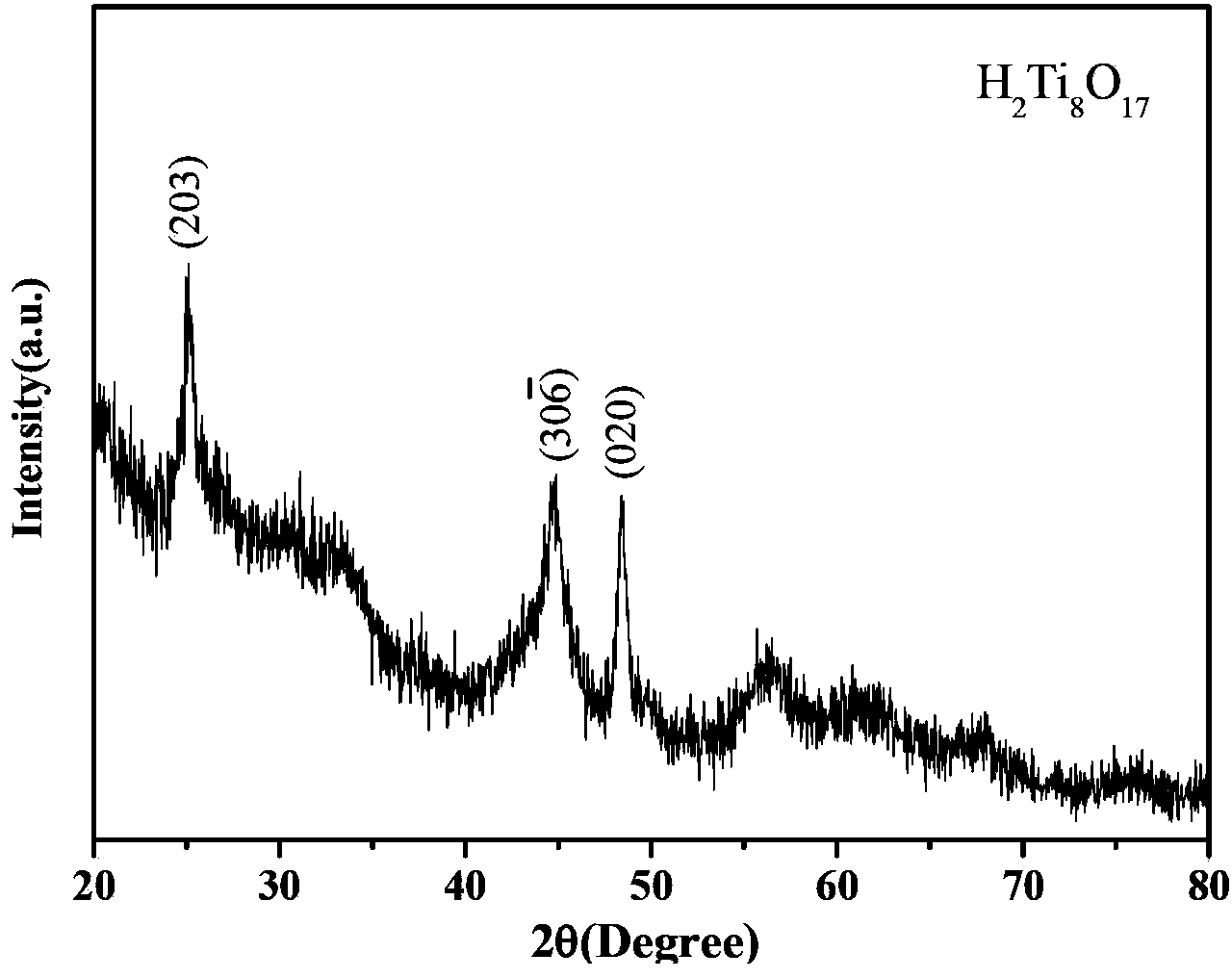

[0014] Place 64g NaOH in a beaker filled with 160ml of distilled water, stir magnetically to room temperature, then add 2g TiO 2 (P-25) Pour it into a beaker, and ultrasonically clean it for 5 minutes to make the solution evenly mixed. Evenly divide the mixed solution into 4 parts, take one part and place it in a 40ml stainless steel reaction kettle lined with polytetrafluoroethylene, close and tighten the reaction kettle, and place the reaction kettle in an electric heating constant temperature drying oven at 180°C. Constant temperature hydrothermal reaction 72h. After the reaction is completed, cool down to room temperature naturally, take out the product with a glass rod and put it into a beaker, add distilled water, repeatedly wash and filter until the solution is neutral, and then put it in 100°C after pickling and filtering. Dry in a dry box for 4h to get H 2 Ti 8 o 17 .

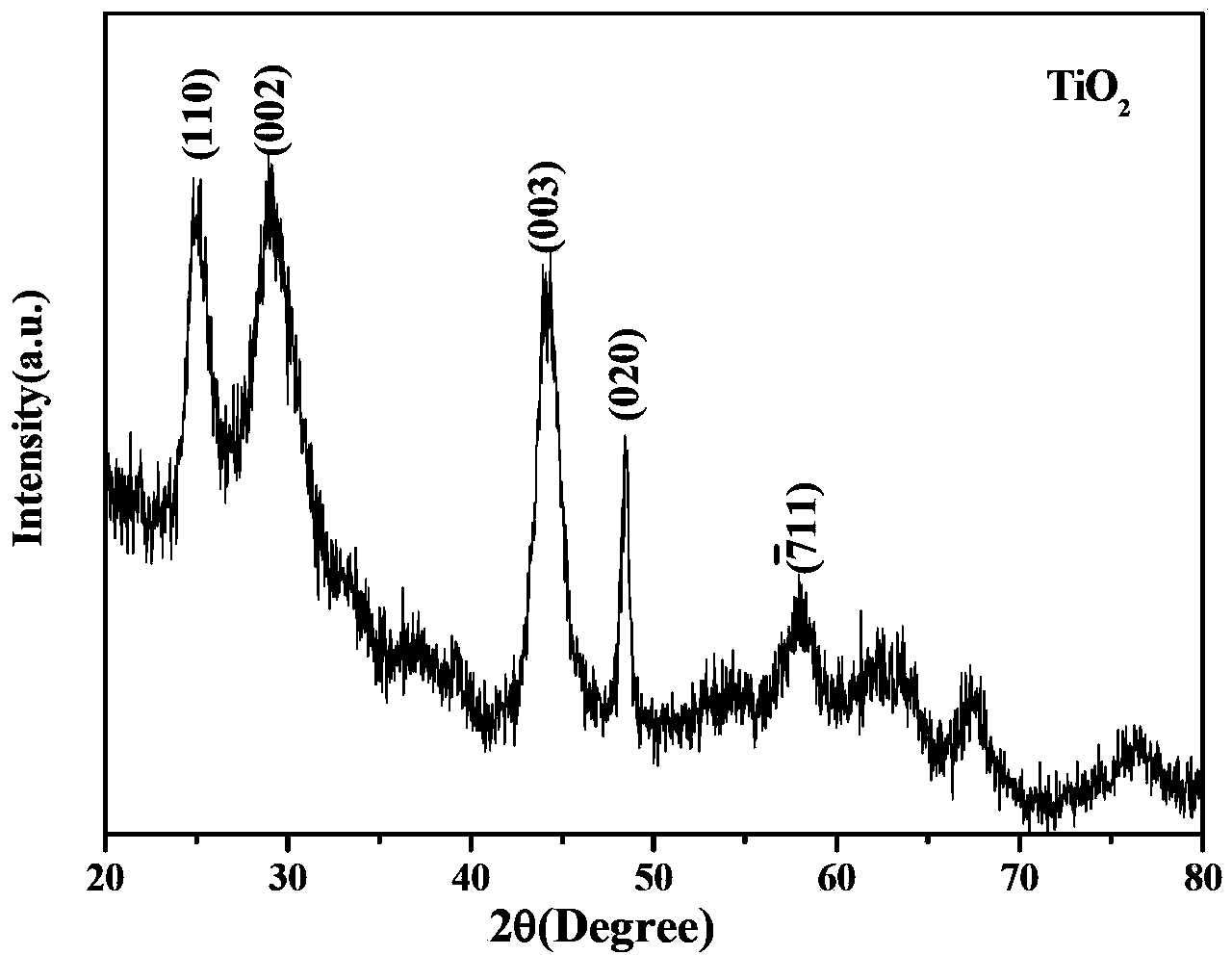

[0015] will get H 2 Ti 8 o 17 Place in a muffle furnace, raise the temperature to 400°C at ...

Embodiment 2

[0021] Place 64g NaOH in a beaker filled with 160ml of distilled water, stir magnetically to room temperature, then add 2g TiO 2 (P-25) Pour it into a beaker, and ultrasonically clean it for 5 minutes to make the solution evenly mixed. The mixed solution was evenly divided into 4 parts, one of which was placed in a 40ml stainless steel reaction kettle lined with polytetrafluoroethylene, the reaction kettle was closed and tightened, and the reaction kettle was placed in an electric heating constant temperature drying oven at 200°C. Constant temperature hydrothermal reaction 48h. After the reaction is completed, cool down to room temperature naturally, take out the product with a glass rod and put it into a beaker, add distilled water, repeatedly wash and filter until the solution is neutral, and then put it in 100°C after pickling and filtering. Dry in a dry box for 4h to get H 2 Ti 8 o 17 .

[0022] will get H 2 Ti 8 o 17 Put it in a muffle furnace, raise the temperatu...

Embodiment 3

[0024] Place 64g NaOH in a beaker filled with 160ml of distilled water, stir magnetically to room temperature, then add 2g TiO 2(P-25) Pour it into a beaker, and ultrasonically clean it for 5 minutes to make the solution evenly mixed. The mixed solution was evenly divided into 4 parts, one of which was placed in a 40ml stainless steel reaction kettle lined with polytetrafluoroethylene, the reaction kettle was closed and tightened, and the reaction kettle was placed in an electric heating constant temperature drying oven at 160°C. Constant temperature hydrothermal reaction 60h. After the reaction is completed, cool down to room temperature naturally, take out the product with a glass rod and put it into a beaker, add distilled water, repeatedly wash and filter until the solution is neutral, and then put it in 100°C after pickling and filtering. Dry in a dry box for 4h to get H 2 Ti 8 o 17 .

[0025] will get H 2 Ti 8 o 17 Place in a muffle furnace, raise the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com