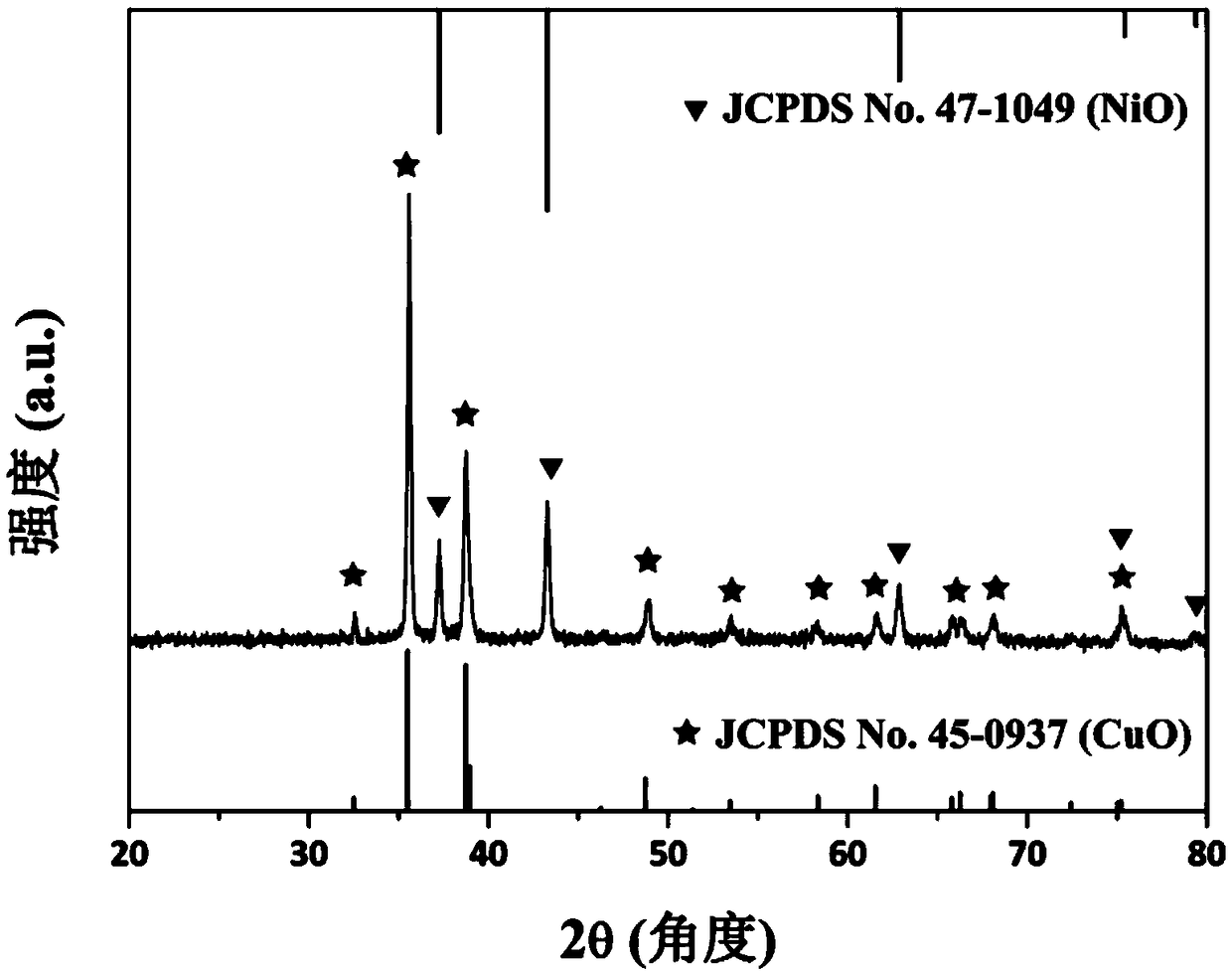

Nickel oxide/copper oxide composite nanomaterial with hollow sphere structure and preparation method of nickel oxide/copper oxide composite nanomaterial

A technology of composite nanomaterials and nickel oxide, which is applied in the direction of nickel oxide/nickel hydroxide, copper oxide/copper hydroxide, etc., can solve the problems of high production cost, cumbersome process, and limitation of practical application and promotion, and achieve performance improvement, The effect of simple reaction device and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

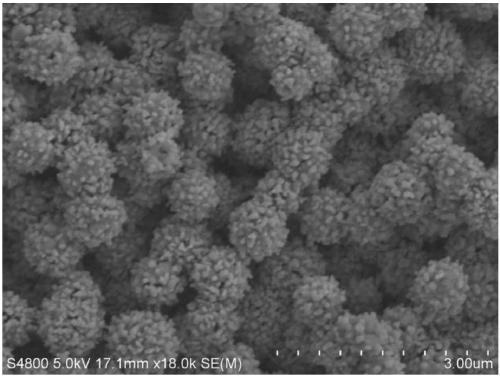

Embodiment 1

[0033] A method for preparing a hollow sphere structure nickel oxide / copper oxide composite nanomaterial, comprising the following steps:

[0034] A, take by weighing 0.8mmol nickel nitrate hexahydrate, 0.8mmol copper nitrate trihydrate, add nickel nitrate hexahydrate and copper nitrate trihydrate into 30mL deionized water and ethylene glycol in the mixed solution that is 2:1 by volume, Stir until completely dissolved to obtain a clear, transparent solution;

[0035] B. Add 0.48g urea and 1.2g polyvinylpyrrolidone to the solution obtained in step A, stir until completely dissolved, and obtain a clear, transparent mixed solution;

[0036] C. Transfer the mixed solution obtained in step B to a polytetrafluoroethylene-lined reaction kettle, seal the reaction kettle and place it in a thermostat, react at a constant temperature of 90°C for 10 hours, and cool to room temperature. The cooled liquid in the reactor was centrifuged to separate the solid product, and the product was was...

Embodiment 2

[0041]A method for preparing a hollow sphere structure nickel oxide / copper oxide composite nanomaterial, comprising the following steps:

[0042] A. Weigh 0.8mmol nickel nitrate hexahydrate and 0.8mmol copper nitrate trihydrate, add nickel nitrate hexahydrate and copper nitrate trihydrate to 30mL deionized water, stir until completely dissolved, and obtain a clear, transparent solution;

[0043] B. Add 0.48g urea and 1.2g polyvinylpyrrolidone to the solution obtained in step A, stir until completely dissolved, and obtain a clear, transparent mixed solution;

[0044] C. Transfer the mixed solution obtained in step B to a polytetrafluoroethylene-lined reaction kettle, seal the reaction kettle and place it in a thermostat, react at a constant temperature of 120° C. for 8 hours, and cool to room temperature. The cooled liquid in the reactor was centrifuged to separate the solid product, and the product was washed and centrifuged with alcohol, and then washed and centrifuged with u...

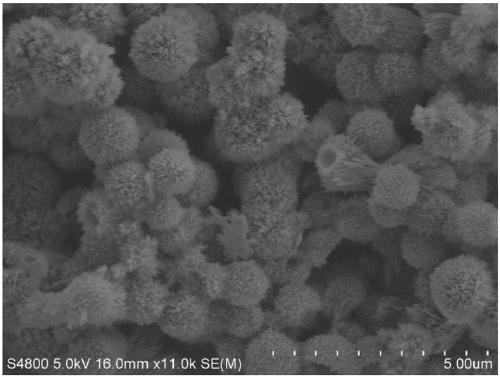

Embodiment 3

[0048] A method for preparing a hollow sphere structure nickel oxide / copper oxide composite nanomaterial, comprising the following steps:

[0049] A. Weigh 0.8mmol nickel nitrate hexahydrate and 0.8mmol copper nitrate trihydrate, add nickel nitrate hexahydrate and copper nitrate trihydrate into a mixed solution composed of 40mL deionized water and ethylene glycol with a volume ratio of 1:1, and stir until completely dissolved to obtain a clear, transparent solution;

[0050] B. Add 1.0 g of urea and 0.8 g of polyvinylpyrrolidone to the solution obtained in step A, stir until completely dissolved, and obtain a clear, transparent mixed solution;

[0051] C. Transfer the mixed solution obtained in step B to a polytetrafluoroethylene-lined reaction kettle, seal the reaction kettle and place it in a thermostat, react at a constant temperature of 70°C for 12 hours, and cool to room temperature. The cooled liquid in the reactor was centrifuged to separate the solid product, the prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com