5V spinel nickel lithium manganate material and preparation method thereof

A technology of lithium nickel manganate and spinel, which is applied in the field of 5V spinel lithium nickel manganate material and its preparation, can solve the problems of disorder, order, and inability to give full play to material properties, and achieves high specific capacity, The effect of high application value and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

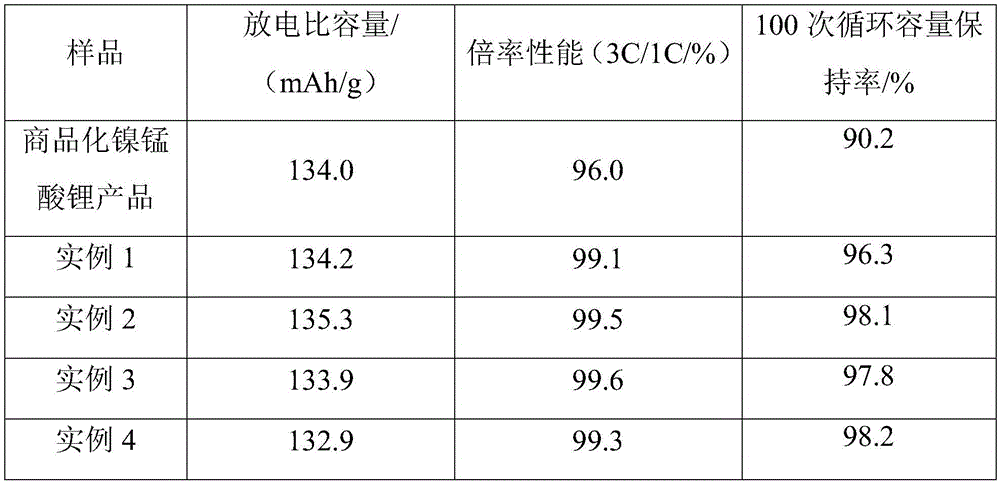

Embodiment 1

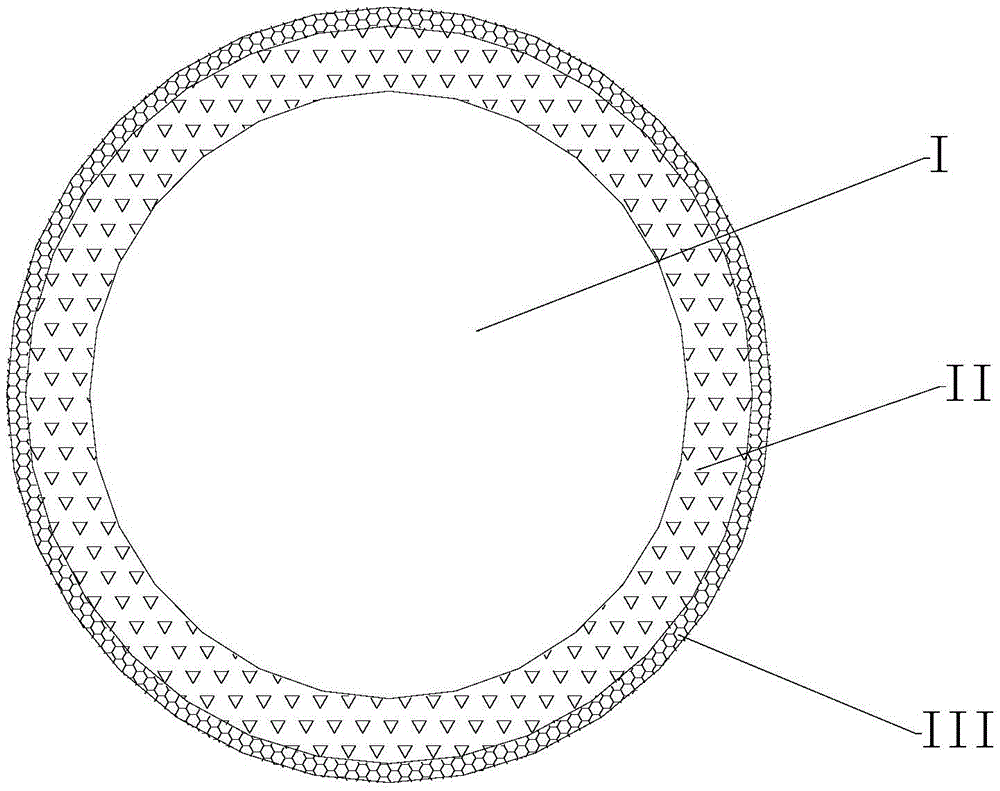

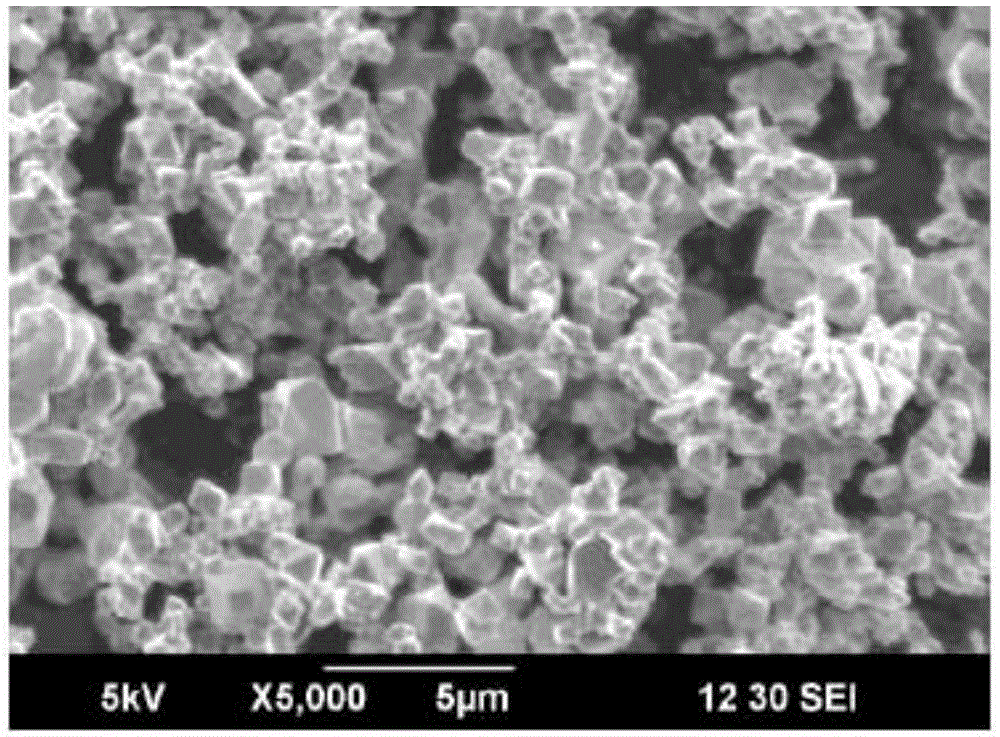

[0022] A preparation method of a 5V spinel lithium nickel manganese oxide material, comprising the steps of:

[0023] 1) Add lithium carbonate, nickel hydroxide, manganese carbonate, ferrous oxalate and SuperP into a ball mill and mix evenly to obtain a material; each component in the material satisfies the molar ratio Li:Ni:Mn:Fe=1.0:0.5:1.49:0.01 ; SuperP quality: (lithium carbonate quality+nickel hydroxide quality+manganese carbonate quality+ferrous oxalate quality)=0.02;

[0024] 2) The material is roasted once in a roasting kiln and air atmosphere, the roasting temperature is 800°C and the roasting time is 4 hours, to obtain the first-time processed product;

[0025] 3) Mixing the primary treated product with 0.5% of its mass of zirconia in a high-speed mixer to obtain a secondary roasted product;

[0026] 4) Carry out the secondary roasting in the roasting kiln in the air atmosphere, the roasting temperature is 700°C, the roasting time is 4h, and the product is obtained...

Embodiment 2

[0029] A preparation method of a 5V spinel lithium nickel manganese oxide material, comprising the steps of:

[0030] 1) Add lithium carbonate, nickelous hydroxide, manganese dioxide, titanium oxide and KS6 into a ball mill and mix evenly to obtain a material; each component in the material satisfies the molar ratio Li:Ni:Mn:Ti=1.05:0.5:1.45:0.05 , KS6 quality: (lithium carbonate quality+nickel oxide quality+manganese dioxide quality+titanium oxide quality)=0.02;

[0031] 2) The material is roasted once in a roasting kiln and air atmosphere, the roasting temperature is 800°C, and the roasting time is 12 hours, to obtain the first-time processed product;

[0032] 3) Mixing the primary treated product with 0.2% of its mass of zirconia in a high-speed mixer to obtain a secondary roasted product;

[0033] 4) Carry out the secondary roasting in the roasting kiln in the air atmosphere, the roasting temperature is 700°C, the roasting time is 12h, and the product is obtained, which i...

Embodiment 3

[0035] A preparation method of a 5V spinel lithium nickel manganese oxide material, comprising the steps of:

[0036] 1) Add lithium carbonate, nickelous hydroxide, manganese dioxide, titanium oxide and ECP600 into a ball mill and mix evenly to obtain a material; each component in the material satisfies the molar ratio Li:Ni:Mn:Ti=1.02:0.5:1.49:0.01 , ECP600 quality: (lithium carbonate quality+nickel hydroxide quality+manganese trioxide quality+titanium oxide quality)=0.05;

[0037] 2) The material is roasted once in a roasting kiln and air atmosphere, the roasting temperature is 850°C, and the roasting time is 8 hours, to obtain the first-time processed product;

[0038] 3) Mixing the primary treated product with 0.5% of its mass of zirconia in a high-speed mixer to obtain a secondary roasted product;

[0039] 4) Carry out the secondary roasting in the roasting kiln in the air atmosphere, the roasting temperature is 750°C, the roasting time is 8h, and the product is obtained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com