Nickel electrode and alkali storage battery using the same

A storage battery, alkaline technology, applied in the field of alkaline storage batteries, can solve the problems of insufficient high capacity of alkaline storage batteries, reduced conductivity between powders, and reduced cycle life, etc., to improve charging efficiency, improve ion conductivity, improve The effect of cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] (Example 1, Ti solid solution)

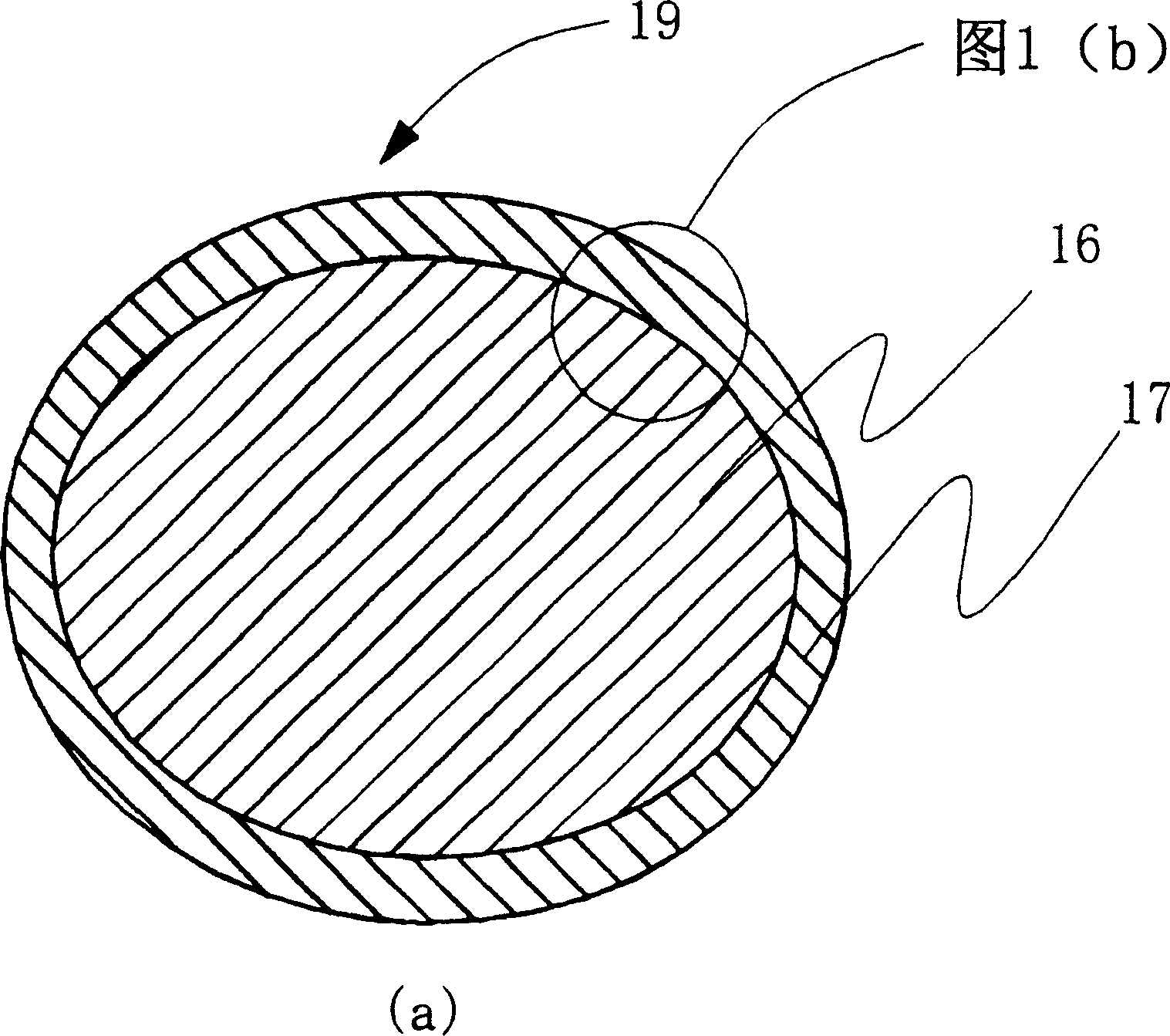

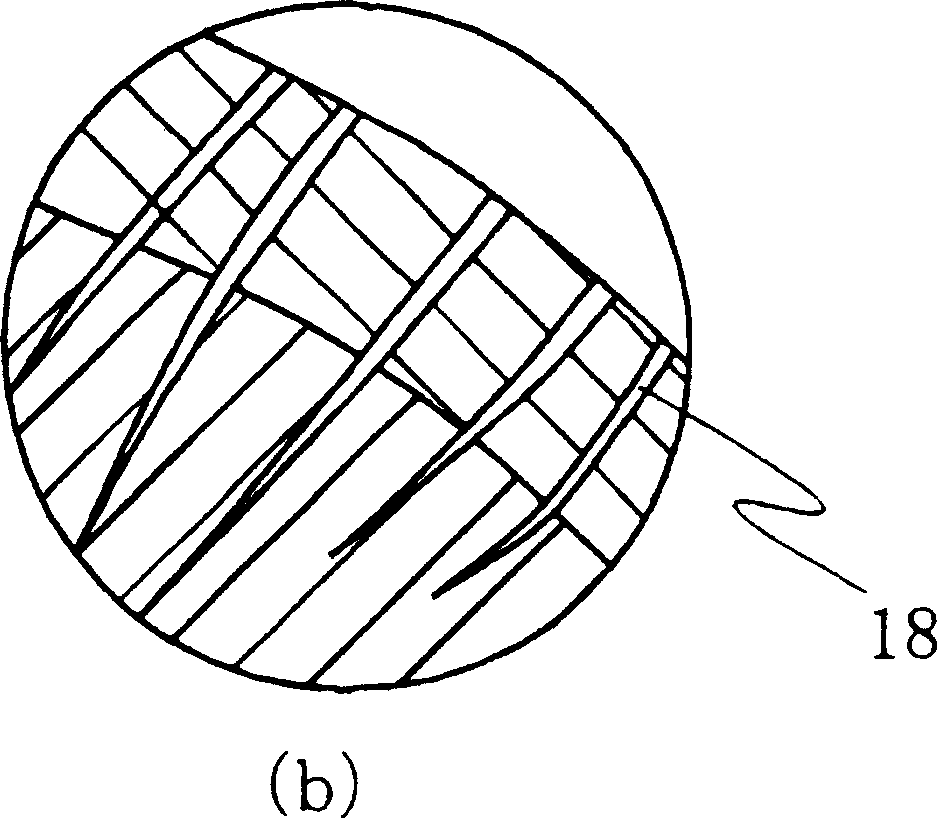

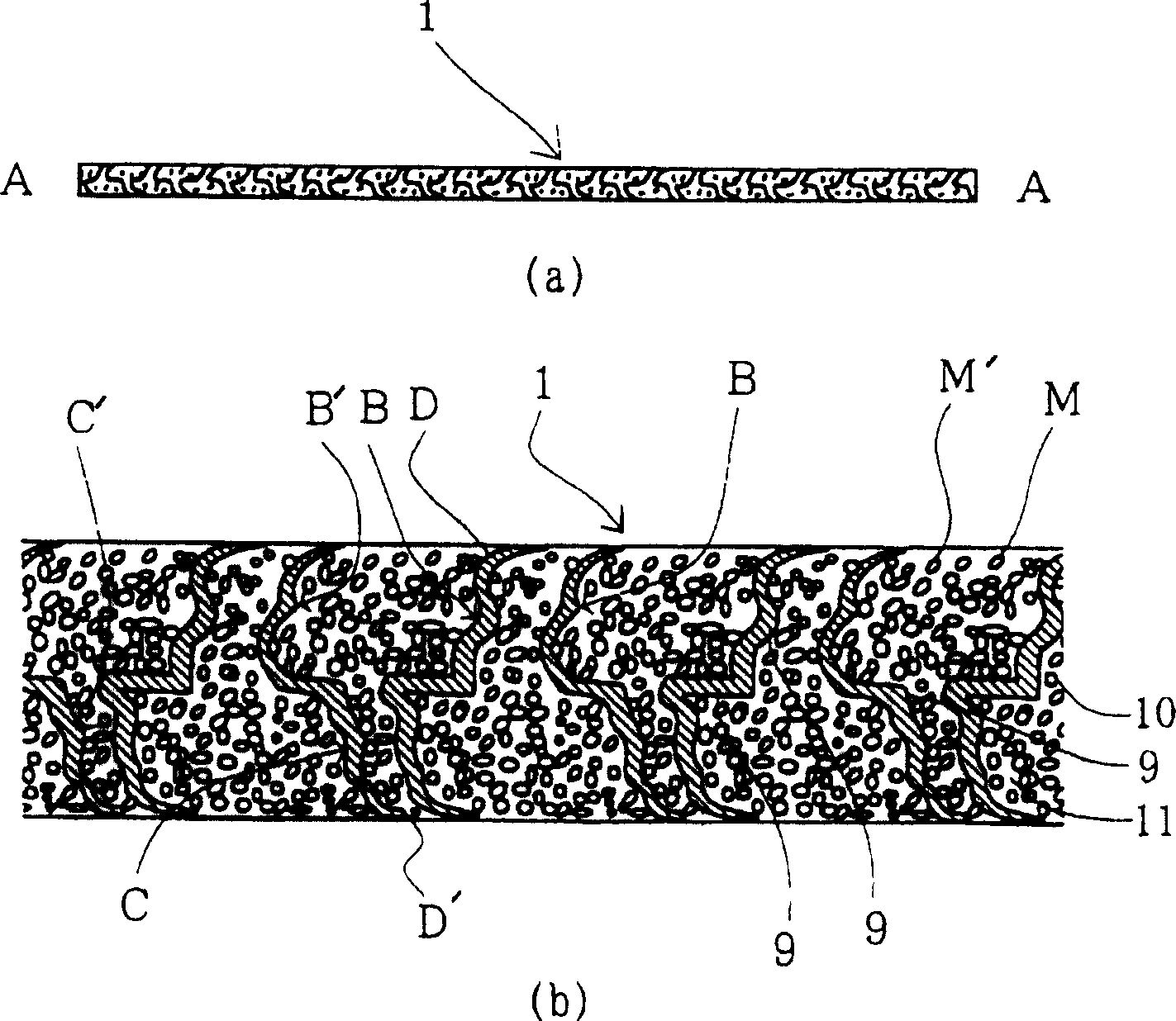

[0072] A ring-shaped nickel foil with a thickness of 30 μm is passed between molds (or between rollers) provided with conical unevenness and pressurized to produce a three-dimensional conductive electrode substrate with numerous microscopic hollow unevenness. All of the closest to the convex part (concave part) is the concave part (convex part), and the hollow of the concave part (convex part) is generally conical in diameter, with a diameter of 60 to 80 μm at the root and 35 to 45 μm at the tip. A flat plate mold is subjected to intensive processing to reduce the wall thickness of the latter, and most of the front ends are opened. The thickness of the conductive electrode substrate three-dimensionalized by the concavo-convex portion was set at 500 μm, which was about 100 μm thicker than the thickness of the final electrode. The pitch between protrusions and protrusions (or the pitch between recesses and recesses) is set to be 350 to 45...

Embodiment 2

[0076] (Example 2, Y solid solution)

[0077] In addition to using nickel oxide coated with cobalt oxide, that is, the nickel oxide contains about 2% by weight of Co and about 4% by weight of Zn in terms of Ni metal in a solid solution state, the above-mentioned cobalt oxide is in a solid solution state A powder material containing about 8% by weight of Ti in terms of Co metal and a particle size of 15 to 20 μm, instead of nickel oxide coated with cobalt oxide, that is, the nickel oxide contains about 2% by weight of Co and about 4% by weight of Zn, the above-mentioned cobalt oxide contains about 8% by weight of Ti in terms of Co metal in a solid solution state, and the above-mentioned cobalt oxide contains 6% by weight relative to the nickel oxide. A Ni / MH storage battery of Example 2 was obtained in the same manner as in Example 1 except for the active material powder which was a spherical powder having a diameter of approximately 15 μm.

Embodiment 3

[0078] (Example 3, Cd solid solution)

[0079] In addition to using nickel oxide coated with cobalt oxide, that is, the nickel oxide contains about 2% by weight of Co and about 4% by weight of Zn in terms of Ni metal in a solid solution state, the above-mentioned cobalt oxide is in a solid solution state A powder material containing about 8% by weight of Cd in terms of Co metal and having a particle size of 15 to 20 μm replaces nickel oxide coated with cobalt oxide, that is, the nickel oxide contains about 2% by weight of Co and about 4% by weight of Zn. The above-mentioned cobalt oxide contains about 8% by weight of Ti in terms of Co metal in a solid solution state, and the above-mentioned cobalt oxide contains about 6% by weight relative to the nickel oxide. The Ni / MH storage battery of Example 3 was obtained in the same manner as in Example 1 except that the active material powder was spherical powder with a diameter of about 15 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com