Preparation method of ultrafine WC-Ni composite powder

A composite powder and powder technology, applied in the field of preparation of ultra-fine WC-Ni composite powder, can solve the problems of uneven distribution of WC and Ni, lower overall performance of the alloy, difficulty in obtaining WC powder, etc., and achieve huge Rayleigh instability Good performance, composition and particle size, easy to grind and refine the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

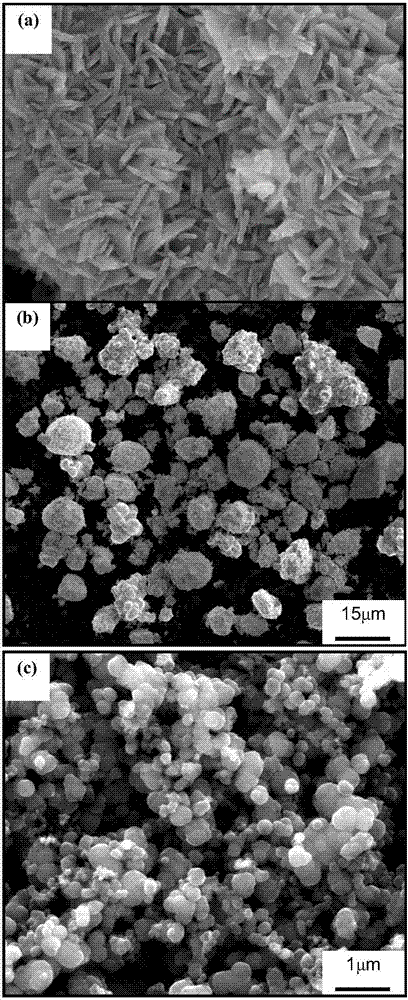

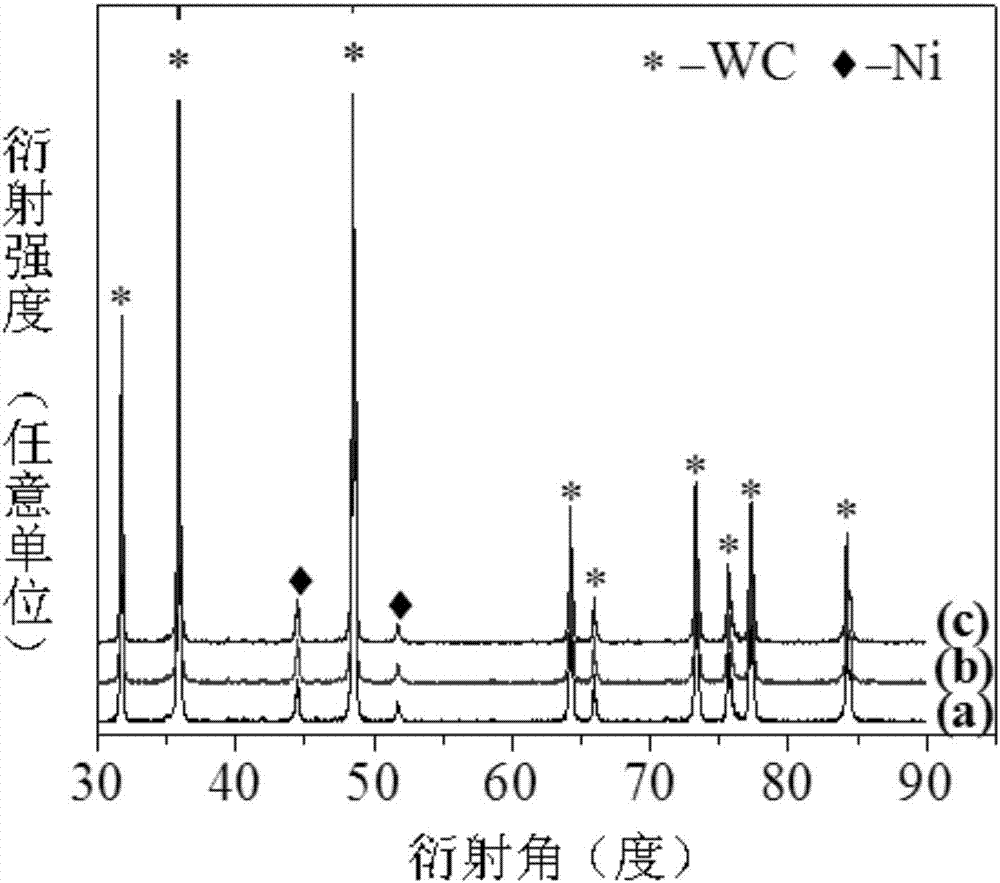

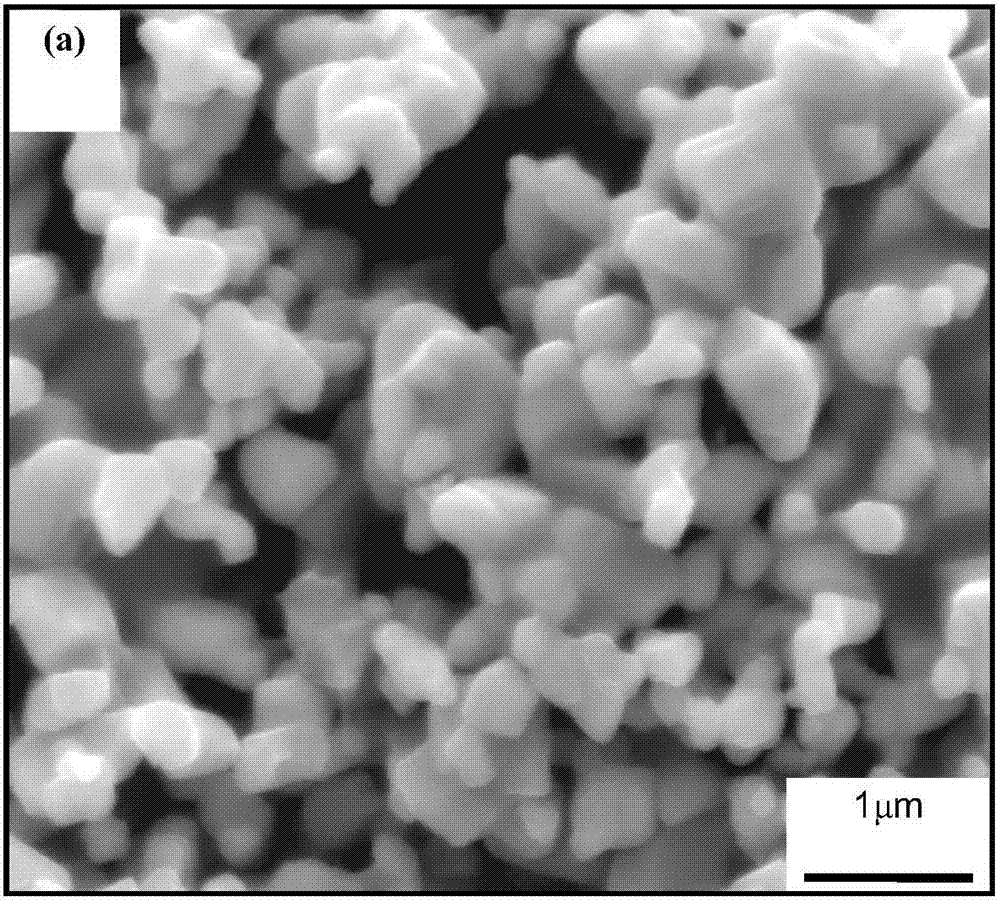

[0017] Violet tungsten powder (morphology such as figure 1 a), nickel oxide powder (morphology such as figure 1 b) and carbon black powder (morphology such as figure 1 c) as raw materials, calculate the proportions of the above three raw materials according to the final preparation of WC-12wt.%Ni composite powder, and mix them. The raw material mixture is carried out vertical stirring and grinding, and the material of the grinding ball and the stirring rod is hard alloy, and the diameter of the grinding ball is 0.8mm, with absolute ethanol as the grinding medium, and the weight ratio of the weight of the grinding ball to the raw material powder is 6: 1. The rotation speed of the stirring shaft is 2000r / min, and the grinding time is 10 hours. The ground mixture was taken out and dried until the humidity of the mixture was 8wt.%, and then pressed into a cylindrical compact with a diameter of 30mm and a height of 30mm, and placed in a drying oven to fully dry. Place the dried ...

Embodiment 2

[0019] Using violet tungsten powder, nickel oxide powder and carbon black powder as raw materials, calculate the proportion of the above three raw materials according to the final preparation of WC-12wt.% Ni composite powder, and mix them. The raw material mixture is carried out vertical stirring and grinding, the material of the grinding ball and the stirring rod is hard alloy, the diameter of the grinding ball is 0.8mm, and absolute ethanol is used as the grinding medium, and the weight ratio of the weight of the grinding ball to the raw material powder is 8: 1. The rotation speed of the stirring shaft is 1750r / min, and the grinding time is 8 hours. The ground mixture was taken out and dried until the humidity of the mixture was 7wt.%, then pressed into a cylindrical compact with a diameter of 40mm and a height of 25mm, and placed in a drying oven to fully dry. Place the dried briquette in a vacuum furnace, raise the furnace temperature to 870°C at a heating rate of 6°C / min,...

Embodiment 3

[0021] Using violet tungsten powder, nickel oxide powder and carbon black powder as raw materials, calculate the proportion of the above three raw materials according to the final preparation of WC-12wt.% Ni composite powder, and mix them. The raw material mixture is carried out vertical stirring and grinding, the material of the grinding ball and the stirring rod is hard alloy, the diameter of the grinding ball is 0.8mm, and absolute ethanol is used as the grinding medium, and the weight ratio of the weight of the grinding ball to the raw material powder is 10: 1. The rotation speed of the stirring shaft is 1500r / min, and the grinding time is 6 hours. The ground mixture was taken out and dried until the humidity of the mixture was 7wt.%, and then pressed into a cylindrical compact with a diameter of 50mm and a height of 20mm, and placed in a drying oven to fully dry. Place the dried briquette in a vacuum furnace, raise the furnace temperature to 880°C at a heating rate of 7°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com