Preparation method of carbon nanotube and nickel oxide composite material

A technology of composite materials and carbon nanotubes, applied in the field of nanomaterials, can solve the problem of small capacitance and achieve the effect of tight combination and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Add 0.7g Ni(NO3) 2 ·6H 2 O, 0.9g D-glucose and 20 ml deionized water were put into a 50ml beaker, and magnetically stirred for 30 min;

[0026] 2. Transfer the solution to a polytetrafluoroethylene-lined autoclave and react at 140°C for 18 hours, then naturally cool to room temperature;

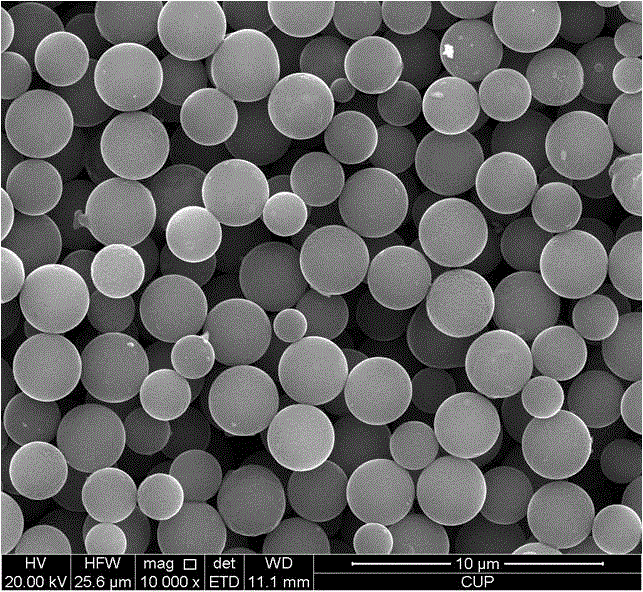

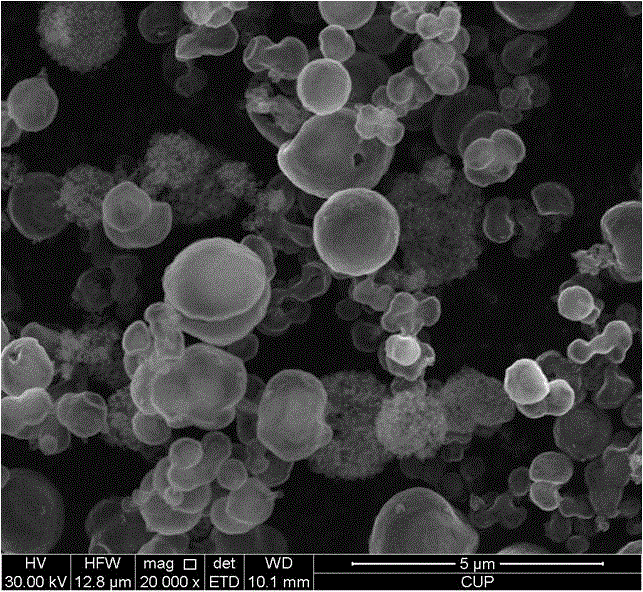

[0027] 3. Wash the obtained solid product with deionized water, suction filter until the filtrate is neutral, and dry at 50°C for 15 hours to obtain nickel hydroxide balls;

[0028] 4. Sprinkle 0.1 g of the prepared nickel hydroxide balls evenly on the silicon wafer substrate, and then place the sample in the quartz tube. Evacuate while introducing argon. Raise the temperature to 500 degrees and keep it for 3 hours to obtain the nickel oxide ball sample;

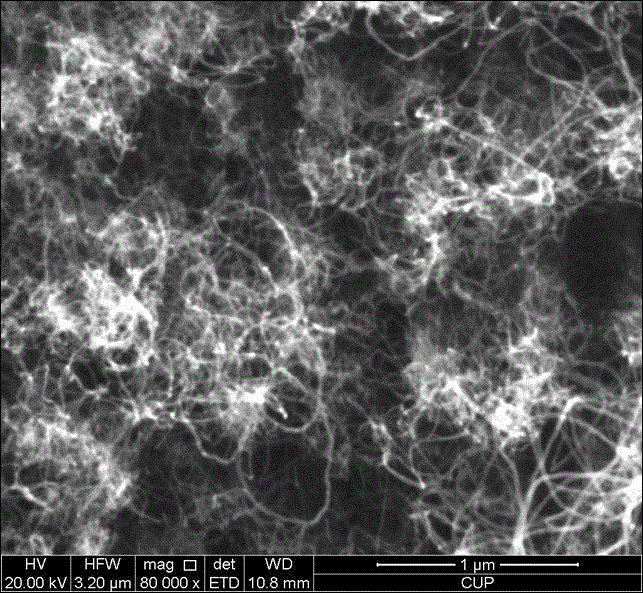

[0029] 5. Introduce hydrogen and argon at the same time, and adjust their flow ratio to 1:3. After heating up to 650°C, keep it for 0.5 hours;

[0030] 6. Raise the temperature to 750°C, introduce methane and keep it for 30 ...

Embodiment 2

[0033] 1. Add 0.9g Ni(NO3) 2 ·6H 2 O, 1.1g of D-glucose and 20 ml of deionized water were put into a 50ml beaker, and magnetically stirred for 30 min;

[0034] 2. Transfer the solution to a polytetrafluoroethylene-lined autoclave and react at 135°C for 17 hours, then naturally cool to room temperature;

[0035] 3. The obtained solid product was washed with deionized water, filtered with suction until the filtrate was neutral, and then dried at 70° C. for 24 hours. Then use a muffle furnace to calcinate at 400°C for 5 hours to obtain nano-nickel oxide balls;

[0036] 4. Sprinkle 0.25g of the prepared nickel hydroxide balls evenly on the silicon substrate, and then place the sample in the quartz tube. Vacuumize, introduce hydrogen and argon at the same time, adjust their ratio to 1:8;

[0037] 5. After heating up to 620°C, keep it for 0.5 hours;

[0038] 6. Raise the temperature to 760°C, introduce methane and keep it for 35 minutes. The ratio of the three gas sources is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com