A method for preparing nickel hydroxide-nickel oxide thin film electrodes based on in-situ growth

A technology of nickel hydroxide and thin film electrodes, which is applied in the manufacture of circuits, electrical components, cables/conductors, etc., can solve the problems of complicated electrode preparation process, and achieve the effects of low production cost, overcoming complex processes and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

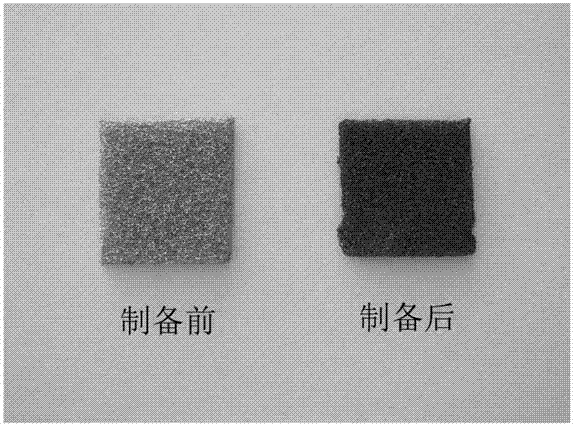

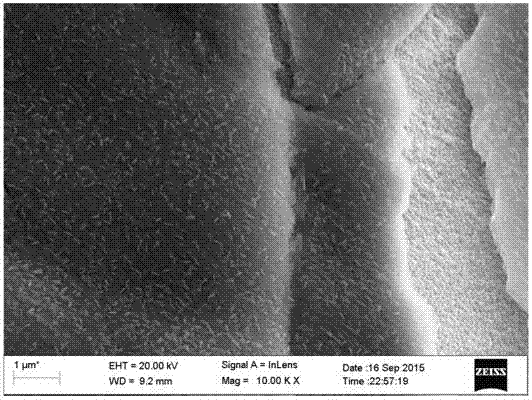

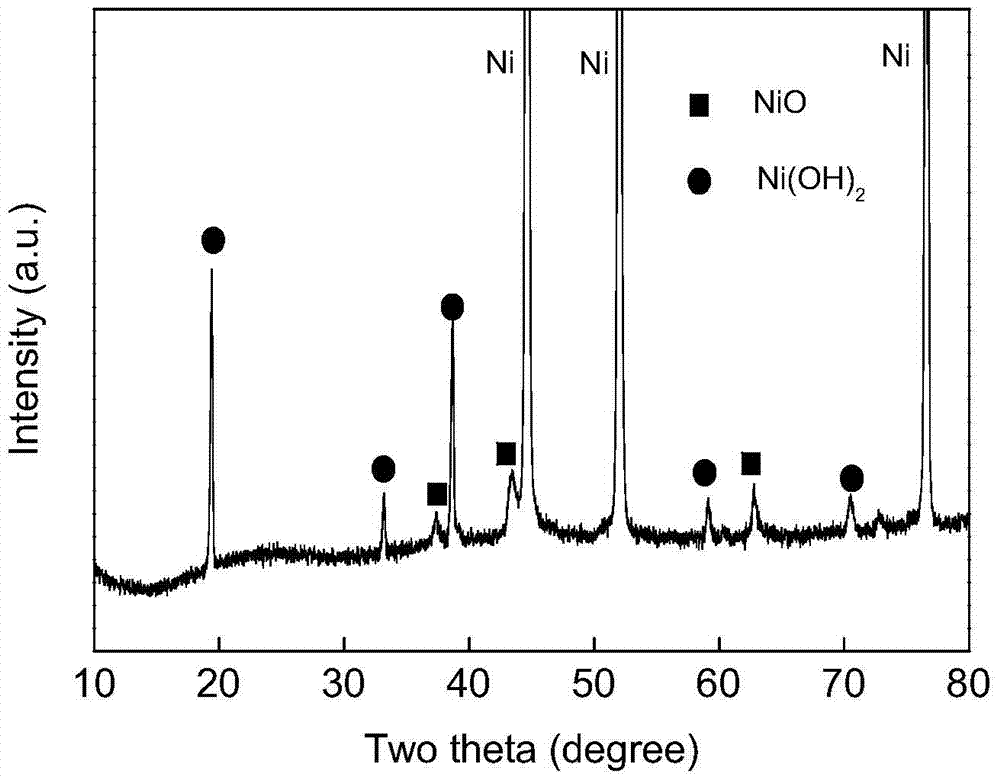

[0019] First, clean the industrial foam nickel substrate to remove dust, rust, and oil to obtain a clean nickel surface; then, configure a KOH solution with a concentration of 50g / L, and add hydrogen peroxide to it so that the concentration of hydrogen peroxide is 1g / L L; secondly, put the electrolyte solution into the reaction kettle, and at the same time immerse the clean nickel substrate in the electrolyte solution; after that, put the reaction kettle in a muffle furnace for hydrothermal reaction at 180°C for 24 hours, so that the surface of the metal nickel An oxidation reaction occurs; finally, the metallic nickel after hydroheating is taken out, cleaned and dried to obtain a nickel hydroxide-nickel oxide thin film electrode based on in-situ growth. Such as figure 1 As shown, through the method for preparing nickel hydroxide-nickel oxide thin film electrode based on in-situ growth of the present invention, a uniform product film can be obtained in situ on the substrate (s...

Embodiment 2

[0021] First, the flat nickel substrate is cleaned to remove dust, rust, and oil to obtain a clean nickel surface; then, a NaOH solution with a concentration of 300g / L is configured, and ammonia water is added to it so that the concentration of ammonia water is 5g / L; secondly, the The electrolyte solution is put into the reaction kettle, and the clean nickel substrate is immersed in the electrolyte solution at the same time; after that, the reaction kettle is placed in a muffle furnace for a hydrothermal reaction at 250°C for 1 hour, so that the surface of the metal nickel undergoes an oxidation reaction; finally , take out the electrode after hydroheating, clean it and dry it, then the nickel hydroxide-nickel oxide thin film electrode based on in-situ growth can be obtained.

Embodiment 3

[0023] First, the stainless steel nickel-plated substrate is cleaned to remove dust, rust, and oil to obtain a clean nickel surface; then, configure a KOH solution with a concentration of 100g / L, and add sodium carbonate to it so that the concentration of sodium carbonate is 10g / L; Secondly, put the electrolyte solution into the reaction kettle, and at the same time immerse the clean nickel substrate in the electrolyte solution; after that, put the reaction kettle in a muffle furnace for 96 hours of hydrothermal reaction at 120°C, so that the metal nickel surface Oxidation reaction; finally, the hydrothermal electrode is taken out, cleaned and dried to obtain a nickel hydroxide-nickel oxide thin film electrode based on in-situ growth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com