Carbon fiber opening fixture frame and preparation method thereof

A technology of carbon fiber and carbon fiber tube, which is applied in the field of carbon fiber open inspection tool frame and its preparation, can solve the problems of long processing cycle, uneven force deformation, low efficiency, etc., to increase the occlusal strength and stability, improve work efficiency, The effect of shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation of the present invention will be described in detail below in conjunction with examples. It should be understood that the examples are provided to illustrate the invention and not to limit the invention. The scope and essential content of the present invention are defined by the claims.

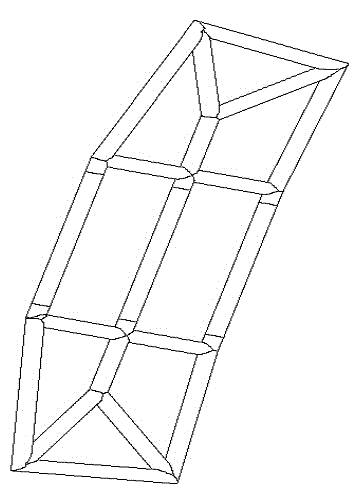

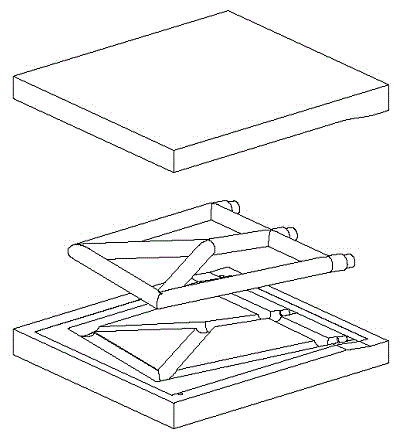

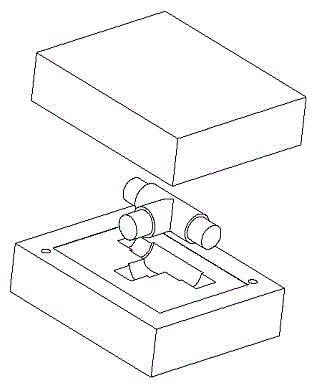

[0019] The carbon fiber opening checker frame of the present invention is assembled by several carbon fiber tubes and several carbon fiber joints according to the structural form of the opening checker, wherein the carbon fiber joints are in the form of a multi-terminal structure, and the outer diameter of the middle part can be compared with the outer diameter of the carbon fiber tube. The diameter is the same, the outer diameter of the end is the same as the inner diameter of the carbon fiber tube, and the length is 5-20mm, so adding joints can increase the bite strength and stability of the joint and the carbon fiber tube, and at the same time improve the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com