Synthesis method of small core gold-coated ferric oxide core-shell structure nanoparticles

A technology of ferric oxide and nanoparticles, which is applied in the direction of microcapsule preparation and microsphere preparation, can solve the problems of complex reaction process and cumbersome reaction device, and achieve the effect of avoiding complicated process, simple operation and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

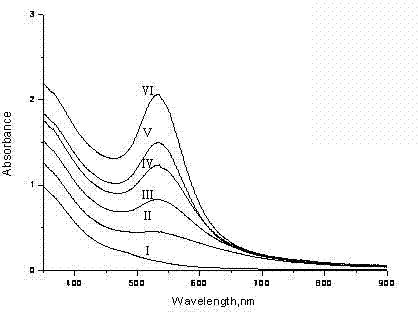

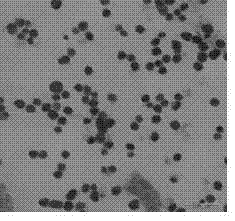

[0015] Example 1: γ-Fe in 30ml solution system 2 o 3 Synthesis of Au nanoparticles

[0016] Weigh 1.08g FeCl 3 ?6H 2 0 and 0.4g FeCl 2 ?4H 2 0 was dissolved in 5ml of water containing 0.172ml of concentrated HCl at a molar ratio of 2:1, and was added dropwise to 50ml of 1.5M NaOH with vigorous stirring. The resulting black precipitate was collected with a magnet, the supernatant was removed, and washed with water for 3 Once, use 100ml 0.01M HCl solution to neutralize the anions on the nanoparticles, collect the precipitate with a magnet, remove the supernatant, wash twice with water, and fresh Fe 3 o 4 Nanoparticles dissolved in 0.01M HNO 3 In the medium, the water bath is heated to boiling and stirred vigorously for 6-8 hours, until it is completely oxidized into γ-Fe 2 o 3 , cooled to room temperature, centrifuged at 6000rpm for 20min to collect the precipitate, washed twice with water and once with 0.1M TMAOH, dissolved in 0.1M TMAOH solution and stored stably for ...

Embodiment 2

[0020] Embodiment 2: γ-Fe in 50ml solution system 2 o 3 Synthesis of Au nanoparticles

[0021] Weigh 1.08g FeCl 3 ?6H 2 0 and 0.4g FeCl 2 ?4H 2 0 was dissolved in 5ml of water containing 0.172ml of concentrated HCl at a molar ratio of 2:1, and was added dropwise to 50ml of 1.5M NaOH with vigorous stirring. The resulting black precipitate was collected with a magnet, the supernatant was removed, and washed with water for 3 Once, use 100ml 0.01M HCl solution to neutralize the anions on the nanoparticles, collect the precipitate with a magnet, remove the supernatant, wash twice with water, and fresh Fe 3 o 4 Nanoparticles dissolved in 0.01M HNO 3 In the medium, the water bath is heated to boiling and stirred vigorously for 6-8 hours, until it is completely oxidized into γ-Fe 2 o 3 , cooled to room temperature, centrifuged at 6000rpm for 20min to collect the precipitate, washed twice with water and once with 0.1M TMAOH, dissolved in 0.1M TMAOH solution and stored stably f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com