Inert anode and preparation method thereof

An inert anode and oxide technology, applied in the field of electrolysis, can solve problems such as low conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

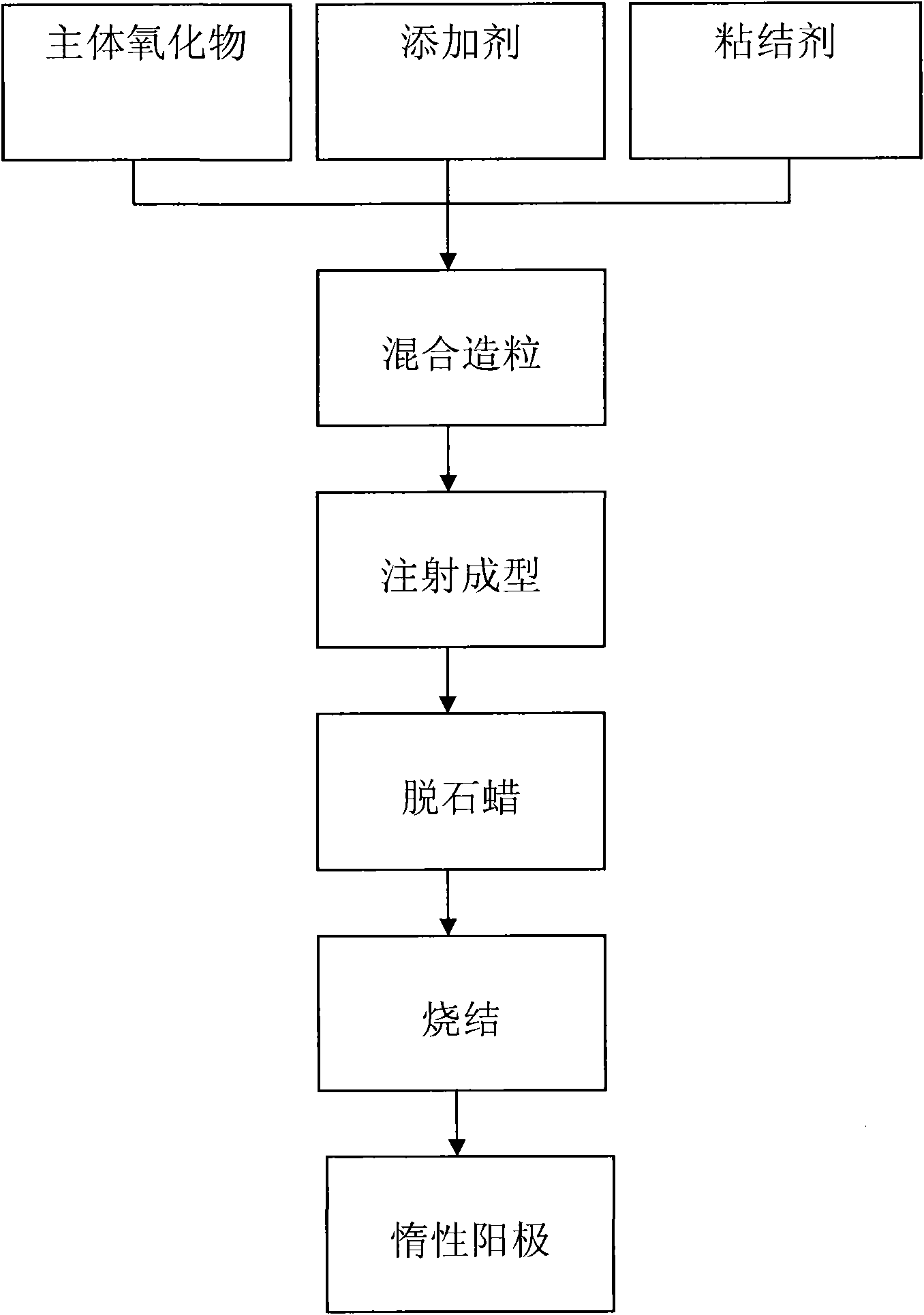

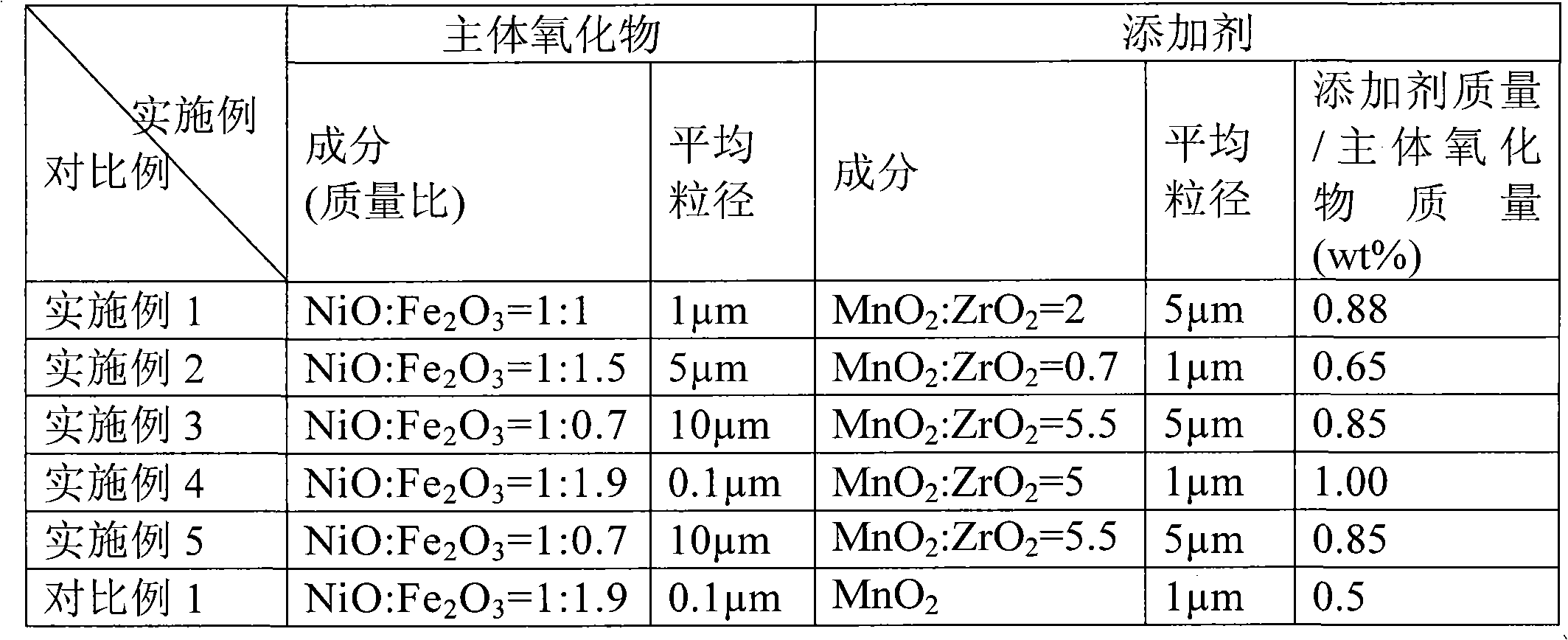

[0016] The method for preparing an inert anode according to a specific embodiment of the present invention includes the following steps: mixing the host oxide, additives, and binders to form an inert anode blank, and then sintering to obtain an inert anode; the host oxide includes nickel oxide and For iron oxide, the additive includes at least two kinds selected from manganese oxide, titanium oxide, tin oxide, zinc oxide, zirconium oxide and aluminum oxide, and the mass of the additive accounts for 0.1-1 wt% of the mass of the main oxide.

[0017] According to the preparation method of the inert anode according to the specific embodiment of the present invention, in the host oxide, the mass percent ratio of nickel oxide to iron oxide is preferably 1:0.5-2.

[0018] According to the preparation method of the inert anode in the specific embodiment of the present invention, the mass of the additive preferably accounts for 0.6-0.85 wt% of the mass of the main oxide.

[0019] Accor...

Embodiment 1

[0025] 1. Prepare raw materials:

[0026] Take main oxide, additive and binding agent by the following mass respectively: nickel oxide 1000g, iron oxide 1000g, manganese oxide 5g, titanium oxide 10g, zirconium oxide 2.5g, paraffin 50g, high-density polyethylene 50g (Lanzhou petrochemical company, Model 5000S), ethylene-vinyl acetate copolymer (Wenzhou Huate Hot Melt Adhesive Co., Ltd.) 10g, stearic acid 10g, diisooctyl phthalate 30g. Among them, the average particle size of nickel oxide and iron oxide is 1 μm (the average particle size is measured by laser particle size test method), and the average particle size of manganese oxide, titanium oxide, and zirconia is 5 μm.

[0027] 2. Mixing and granulation:

[0028] Mix all the raw materials obtained in step 1 evenly and put them into an SK-160 open twin-screw extruder at 200°C for granulation, the granulation time is 4 hours, and the screw speed is 40 rpm.

[0029] 3. Injection molding:

[0030] Put the granulated feed into ...

Embodiment 2

[0037] 1. Prepare raw materials:

[0038] Weigh the main oxides, additives and binders according to the following masses: nickel oxide 800g, iron oxide 1200g, manganese oxide 2g, zinc oxide 5g, zirconia 3g, aluminum oxide 3g, paraffin 100g, high-density polyethylene 50g, ethylene -20 g of vinyl acetate copolymer, 20 g of stearic acid, and 40 g of diisooctyl phthalate. Among them, the average particle size of nickel oxide and iron oxide is 5 μm (the average particle size is measured by laser particle size test method), and the average particle size of manganese oxide, zinc oxide, zirconia, and aluminum oxide is 1 μm.

[0039] 2. Mixing and granulation:

[0040] Mix all the raw materials obtained in step 1 evenly and put them into an SK-160 open twin-screw extruder at 250°C for granulation, the granulation time is 3 hours, and the screw speed is 30 rpm.

[0041] 3. Injection molding:

[0042] Put the granulated feed into an injection molding machine (CJ50E Zhende), control th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com