Silver telluride nanowire flexible thermoelectric film welded at room temperature and preparation method thereof

A technology of tellurium nanowires and thermoelectric thin films, which is applied in the field of flexible thermoelectric thin films of silver telluride nanowires and its preparation, can solve the problems of low electrical conductivity and power factor of thin films, and achieve the advantages of connection, improvement of electrical conductivity and power factor, The effect of flexibility improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] (1) Take 50 ml of tellurium nanowire dispersion liquid (0.04 mg / ml) and carry out vacuum filtration to obtain a tellurium nanowire thin film with a thickness of 1 μm.

[0048] (2) Add 6 ml of the prepared silver nitrate solution (6 mg / ml) dropwise to the tellurium nanowire film, wash it with ethanol after reacting for 120 s, and finally dry it in an oven at 50 °C for 1 h to obtain the silver telluride welded at room temperature Nanowire flexible thermoelectric films.

Embodiment 2

[0050] (1) Take 50ml of silver telluride nanowire dispersion liquid (0.07mg / ml), carry out vacuum filtration, and then dry it in an oven at 50°C for 1 hour to obtain an unwelded silver telluride nanowire thermoelectric film

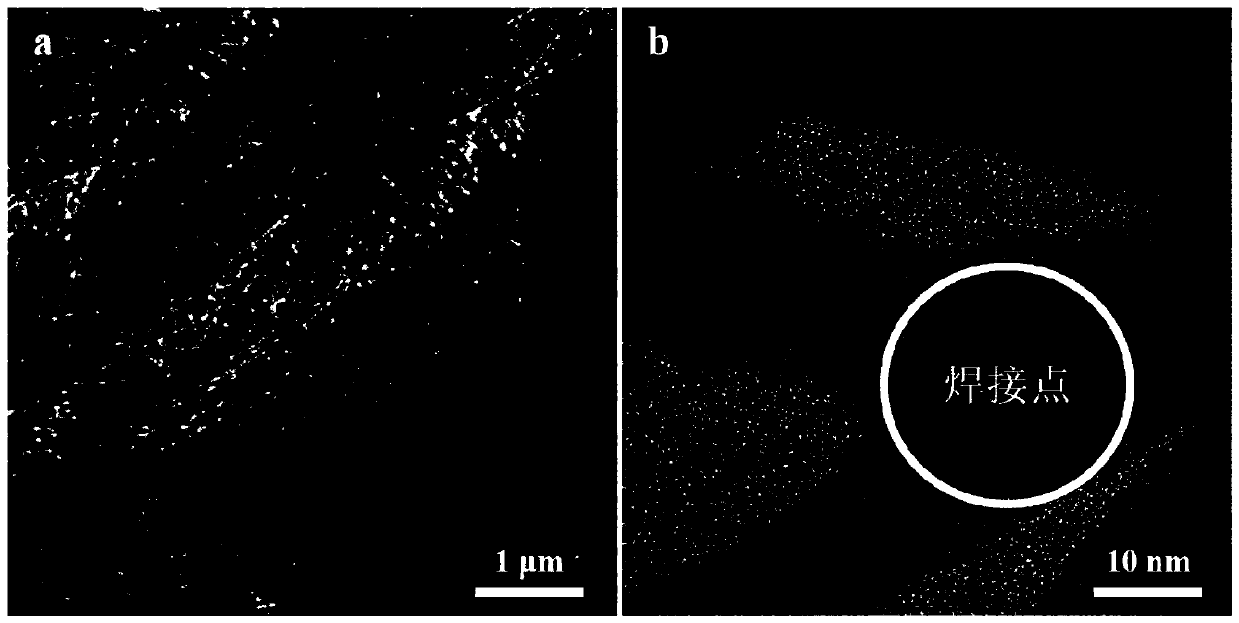

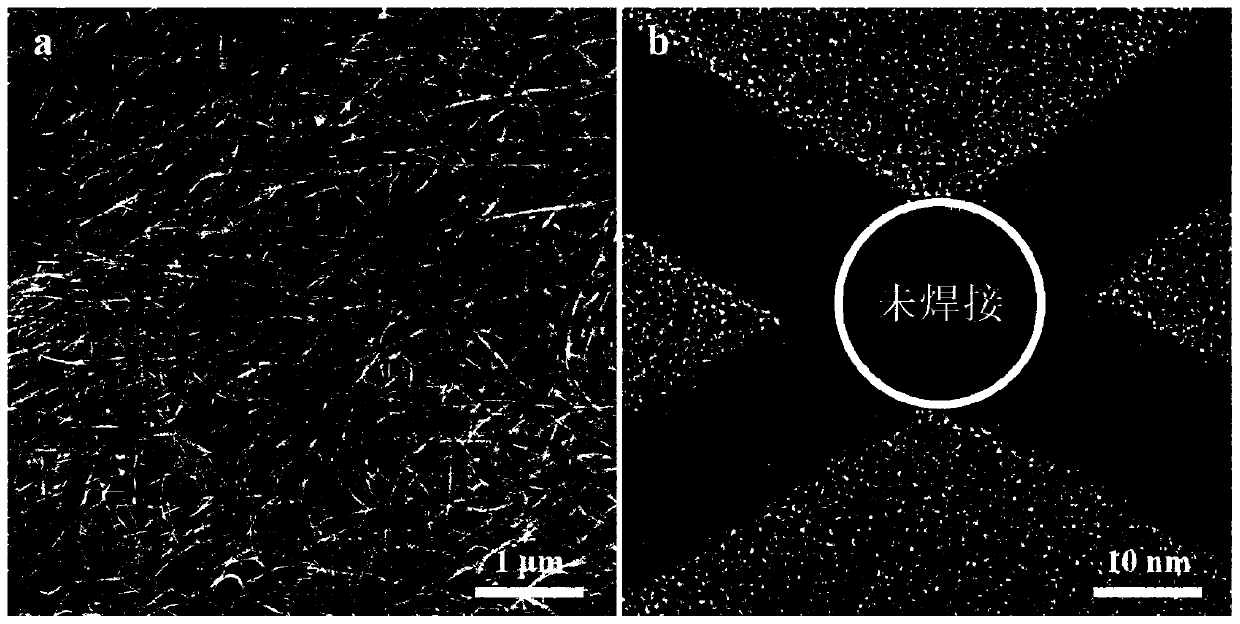

[0051] figure 1 and figure 2 Electron microscope images of the silver telluride nanowire flexible thermoelectric film welded at room temperature in Example 1 and the unwelded silver telluride nanowire thermoelectric film in Example 2, respectively. It can be observed that the prepared silver telluride nanowires have uniform diameter and good shape, but the flexible thermoelectric film of silver telluride nanowires welded at room temperature can be seen to form welding points between the silver telluride nanowires, and the nanowires are welded together. Welded up.

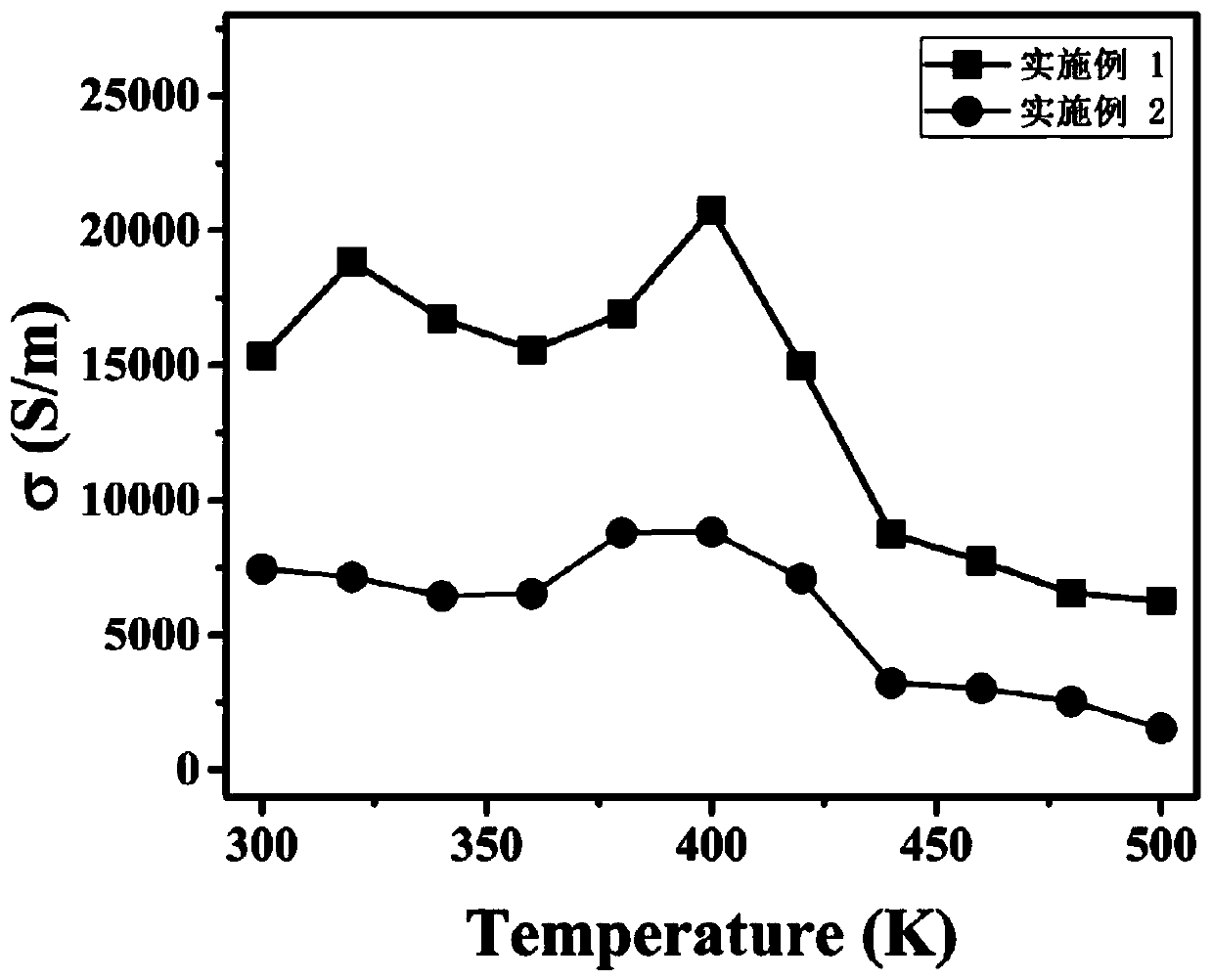

[0052] The electrical conductivity of the prepared thermoelectric films in the above-mentioned 1 and 2 embodiments at different temperatures is as follows: image 3 As shown, it can be seen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com