Ni-doped CuCrO2-based oxide thermoelectric material and preparation method thereof

A technology of thermoelectric materials and oxides, applied in thermoelectric device node lead-out materials, thermoelectric device manufacturing/processing, chromate/dichromate, etc., can solve complex repeatability, cobalt volatile process, etc. problem, to achieve the effect that the preparation process is simple and easy to master

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

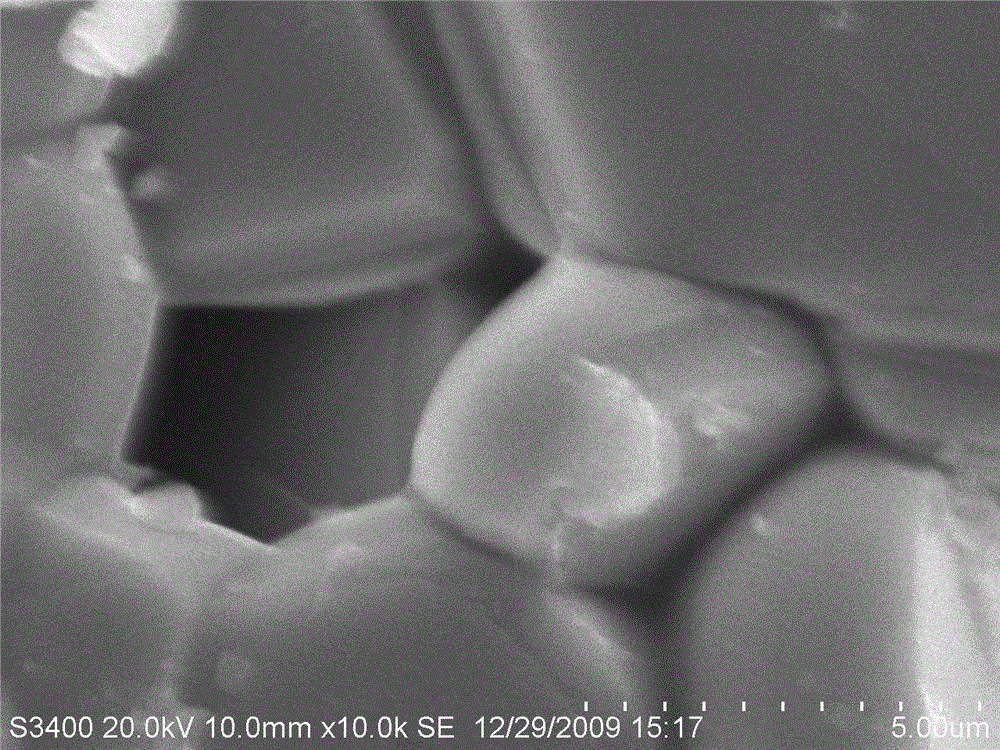

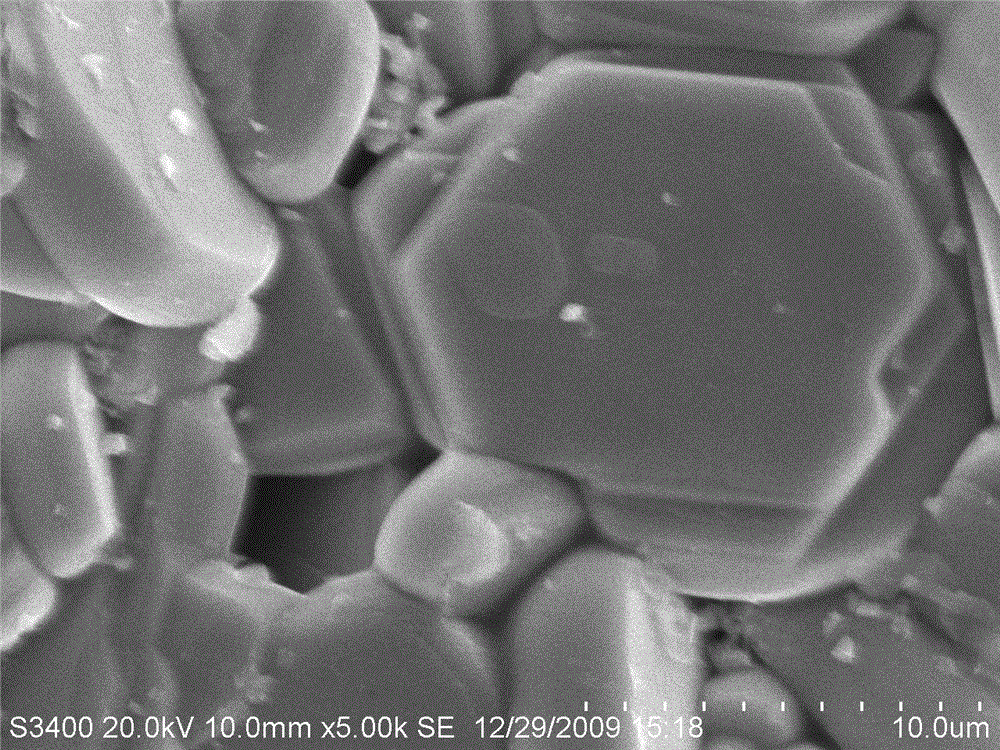

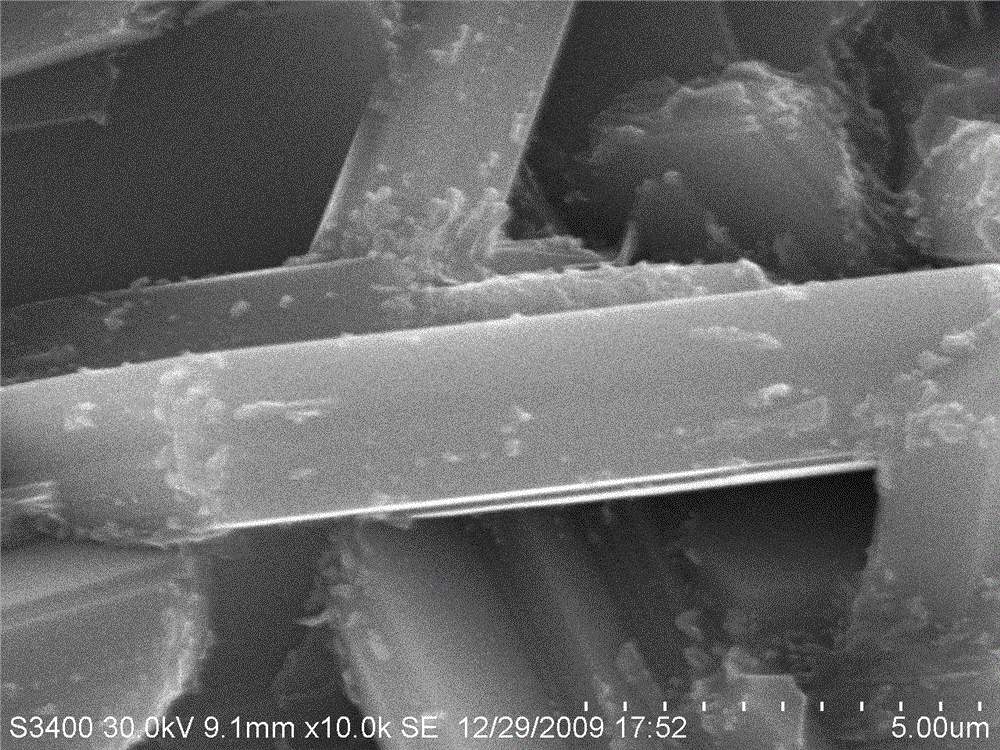

[0030] Ni-doped CuCrO provided by the invention 2 Based oxide thermoelectric material, the compound formula is CuCr 1-x Ni x o 2 , x is 0.001-0.08; the above thermoelectric material is a p-type semiconductor with rod-shaped grains, the length of rod-shaped grains is 20-30 μm, and the aspect ratio is (8-12):1; the structure is layered rhomboid in R-3m space group phase crystal structure.

[0031] The above-mentioned thermoelectric material is prepared from copper oxide, dichromium trioxide and nickel oxide as starting materials through mixing, pre-sintering, tableting and sintering, wherein the amount of copper oxide, dichromium trioxide and nickel oxide is based on Cu, Cr , Ni, the molar ratio is 1: (1-x): x, x is 0.001-0.08.

[0032] Among them, pre-firing can be carried out in stages, using 850-1000 ° C for 12-24 hours, and then pre-firing again after pressing, the above pre-firing steps can be repeated 2-3 times, the final sintering temperature is 1100-1200 ° C, and the...

Embodiment 2

[0041] (1) First, mix copper oxide with a purity of 99.99%, chromium oxide with a purity of 99.99%, and nickel oxide with a purity of 99% (S.P.) according to the ratio of Cu, Cr, and Ni corresponding to 1:0.995:0.005 , the above mixture is ball-milled with absolute ethanol or deionized water as a medium to obtain a paste-like substance;

[0042] (2) The pasty substance obtained in (1) is kept in an oven at 110ºC for 20 hours to obtain a dry powder, and then pre-fired in a muffle furnace at 900ºC for 20 hours in an air environment;

[0043] (3) Grind the reactant prepared in (2) into a fine uniform powder, press it into a disc with a diameter of about 15mm under a pressure of 20~30MPa, then sinter at 1000ºC for 20h, and grind the reactant again into a fine uniform powder, Obtain pre-sintered powder;

[0044] (4) Press the pre-sintered powder prepared in (3) into a disc with a diameter of about 15mm and a thickness of about 4mm under a pressure of about 25~40MPa, and then sinte...

Embodiment 3

[0047] (1) First, mix copper oxide with a purity of 99.99%, chromium oxide with a purity of 99.99%, and nickel oxide with a purity of 99% (S.P.) according to the ratio of Cu, Cr, and Ni corresponding to the amount of the substance at 1:0.99:0.01 , the above mixture is ball-milled with absolute ethanol or deionized water as a medium to obtain a paste-like substance;

[0048] (2) The pasty substance obtained in (1) is kept in an oven at 100ºC for 24 hours to obtain a dry powder, and then pre-fired in a muffle furnace at 860ºC for 20 hours in an air environment;

[0049] (3) Grind the reactant prepared in (2) into a fine uniform powder, press it into a disc with a diameter of about 15mm under a pressure of 20~30MPa, then sinter at 1010ºC for 25h, and grind the reactant again into a fine uniform powder, Obtain pre-sintered powder;

[0050] (4) Press the pre-sintered powder prepared in (3) into a disc with a diameter of about 15mm and a thickness of about 4mm under a pressure of a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com