Preparation method and application of iron-nickel oxide coated carbon material

An oxide and carbon-coated technology, which is applied in the field of electrochemistry, can solve the problems of instability of transition metals, achieve uniform contact, excellent comprehensive performance, and simple implementation of the preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

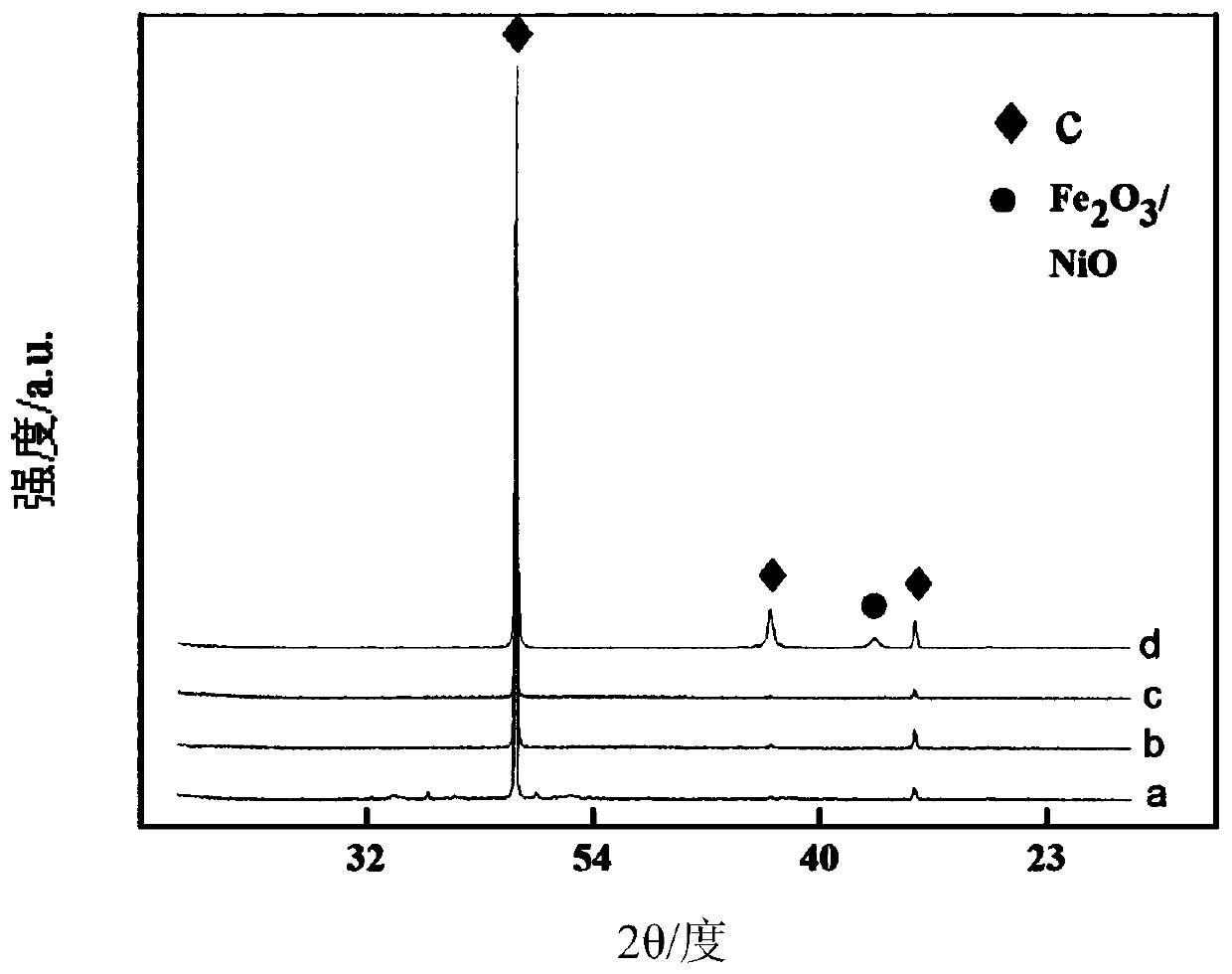

Embodiment 1

[0028] Add 100g of ferrous sulfate and 100g of nickel chloride into 500ml of deionized water, then add 1g of sodium dodecylmethylbenzenesulfonate and 20g of citric acid, and then sonicate for 30 minutes until completely dispersed to obtain an iron-containing nickel source solution. Pour the iron-nickel source solution into the electrolytic cell. The bottom of the electrolytic cell is a stainless steel sheet. The natural flake graphite that has been degreased by alkali washing is placed on the surface of the cathode, and the iron plate and nickel plate with an area ratio of 1:1 are used as the anode. Into 0.5A / cm 2 Electrodepositing at a current density for 30 minutes yielded an intermediate composite. Adsorbed by a magnet, washed with a large amount of deionized water, and dried in a blast drying oven for 12 hours to obtain an iron-nickel oxide-coated carbon material. The iron-nickel oxide-coated carbon material and polytetrafluoroethylene (PTFE) were pressed on the nickel fo...

Embodiment 2

[0030] Change the ratio of iron and nickel sources, add 200g ferrous sulfate and 100g nickel chloride to 500ml deionized water, then add 1g sodium dodecylmethylbenzenesulfonate and 20g citric acid, and then ultrasonically disperse for 30min until completely dispersed to obtain Iron nickel source solution. Pour the iron-nickel source solution into the electrolytic cell. The bottom of the electrolytic cell is a stainless steel sheet. The natural flake graphite that has been degreased by alkali washing is placed on the surface of the cathode. The iron and nickel plates with an area ratio of 1:1 are used as sacrificial anodes. Into 0.5A / cm 2 Electrodepositing at a current density for 30 minutes yielded an intermediate composite. Adsorbed by a magnet, washed with a large amount of deionized water, and dried in a blast drying oven for 12 hours to obtain an iron-nickel oxide-coated carbon material. The iron-nickel oxide-coated carbon material and PTFE were pressed on the nickel foa...

Embodiment 3

[0032] Change the ratio of iron and nickel sources, add 100g ferrous sulfate and 200g nickel chloride to 500ml deionized water, then add 1g sodium dodecylmethylbenzenesulfonate and 20g citric acid, and then ultrasonically disperse for 30min to obtain Iron nickel source solution. Pour the iron-nickel source solution into the electrolytic cell. The bottom of the electrolytic cell is a stainless steel sheet. The natural flake graphite that has been degreased by alkali washing is placed on the surface of the cathode. The iron and nickel plates with an area ratio of 1:1 are used as sacrificial anodes. Into 0.5A / cm 2 Electrodepositing at a current density for 30 minutes yielded an intermediate composite. Adsorbed by a magnet, washed with a large amount of deionized water, and dried in a blast drying oven for 12 hours to obtain an iron-nickel oxide-coated carbon material. The iron-nickel oxide-coated carbon material and PTFE were pressed on the nickel foam at a ratio of 8:1 under a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com