Celadon glaze and manufacturing method thereof

A production method and celadon technology, applied in the field of celadon firing, can solve the problems of weak auxiliary color rendering effect, difficult to control dosage, yellowish glaze color, etc., and achieve the effects of good stability, simple operation and stable glaze color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of preparation method of celadon glaze, comprises the following steps:

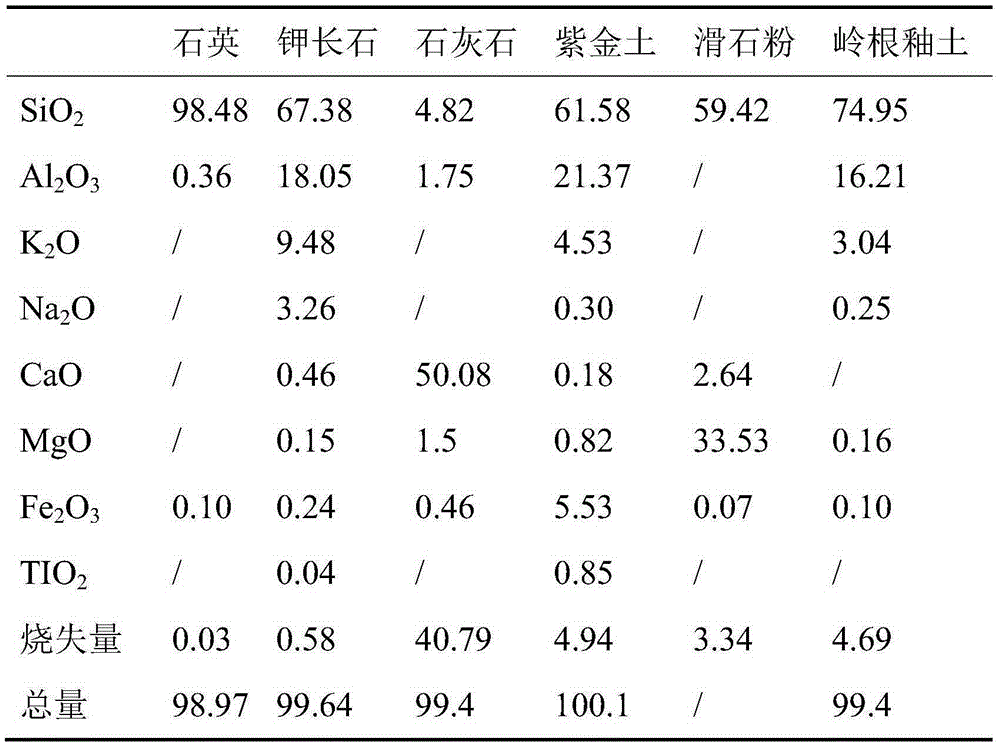

[0033] (1) Use the following raw materials to prepare glaze slurry:

[0034] In parts by weight, the raw materials are composed of: 20 parts of agate stone, 295 parts of quartz, 85 parts of potassium feldspar, 110 parts of limestone, 8 parts of purple gold soil, 180 parts of ridge root glaze soil, 5 parts of this medicine, 9 parts of talcum powder, 24 parts of copper ore, 6 parts of bovine bone, 3 parts of copper oxide, 1 part of zinc oxide, 2 parts of cobalt oxide, 2 parts of nickel monoxide, 3 parts of composite superplasticizer and 6 parts of tin oxide. The composite water reducer is a binary composite water reducer composed of sodium pyrophosphate-naphthalene series high-efficiency water reducer and sodium pyrophosphate-sodium citrate at a mass ratio of 1:1; The high-efficiency water reducer is compounded with a mass ratio of 2:3, and the other component is compounded with sodium pyroph...

Embodiment 2

[0049] A kind of preparation method of celadon glaze, comprises the following steps:

[0050] (1) Use the following raw materials to prepare glaze slurry:

[0051] In parts by weight, the raw materials are composed of: 22 parts of agate stone, 290 parts of quartz, 155 parts of potassium feldspar, 75 parts of limestone, 6 parts of purple gold soil, 130 parts of ridge root glaze soil, 7 parts of this medicine, 14 parts of talcum powder, 22 parts of copper ore, 5 parts of bovine bone, 4 parts of copper oxide, 1 part of zinc oxide, 3 parts of cobalt oxide, 3 parts of nickel monoxide, 2 parts of composite superplasticizer and 7 parts of tin oxide.

[0052] The composition of the composite water reducer is the same as in Example 1.

[0053] The preparation method of the glaze slurry is as follows: the above raw materials are crushed and mixed according to a preset ratio, and then 35% of the total amount of mixed raw materials is added to water for wet grinding; the slurry obtained ...

Embodiment 3

[0062] A kind of preparation method of celadon glaze, comprises the following steps:

[0063] (1) Use the following raw materials to prepare glaze slurry:

[0064] In parts by weight, the raw materials are composed of: 28 parts of agate stone, 356 parts of quartz, 93 parts of potassium feldspar, 86 parts of limestone, 10 parts of purple gold soil, 195 parts of ridge root glaze soil, 4 parts of this medicine, 12 parts of talcum powder, 23 parts of copper ore, 4 parts of bovine bone, 4 parts of copper oxide, 1 part of zinc oxide, 1 part of cobalt oxide, 2 parts of nickel monoxide, 3 parts of composite superplasticizer and 8 parts of tin oxide.

[0065] The preparation method of the glaze slurry is as follows: the above raw materials are crushed and mixed according to a preset ratio, and then 30% of the total amount of mixed raw materials is added to water for wet grinding; the slurry obtained through wet grinding is passed through a 300-mesh sieve, and the old After 30 hours, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com