Sawtooth process for solving yellowing of backlight light-emitting diode (LED) side

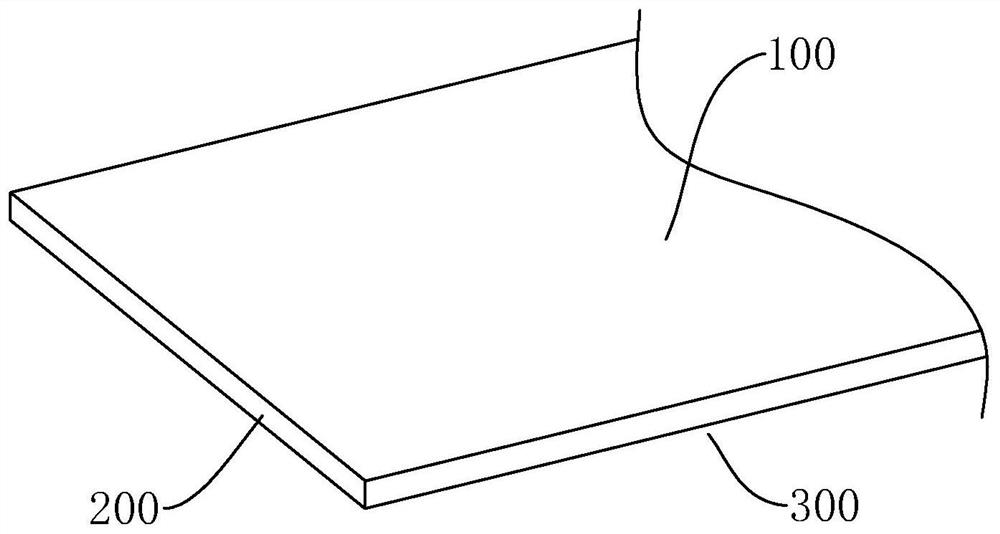

A sawtooth and backlight technology, applied in the field of light guide plates, can solve the problems of chromatic dispersion, yellowish visual effects, and yellowing of backlight LEDs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

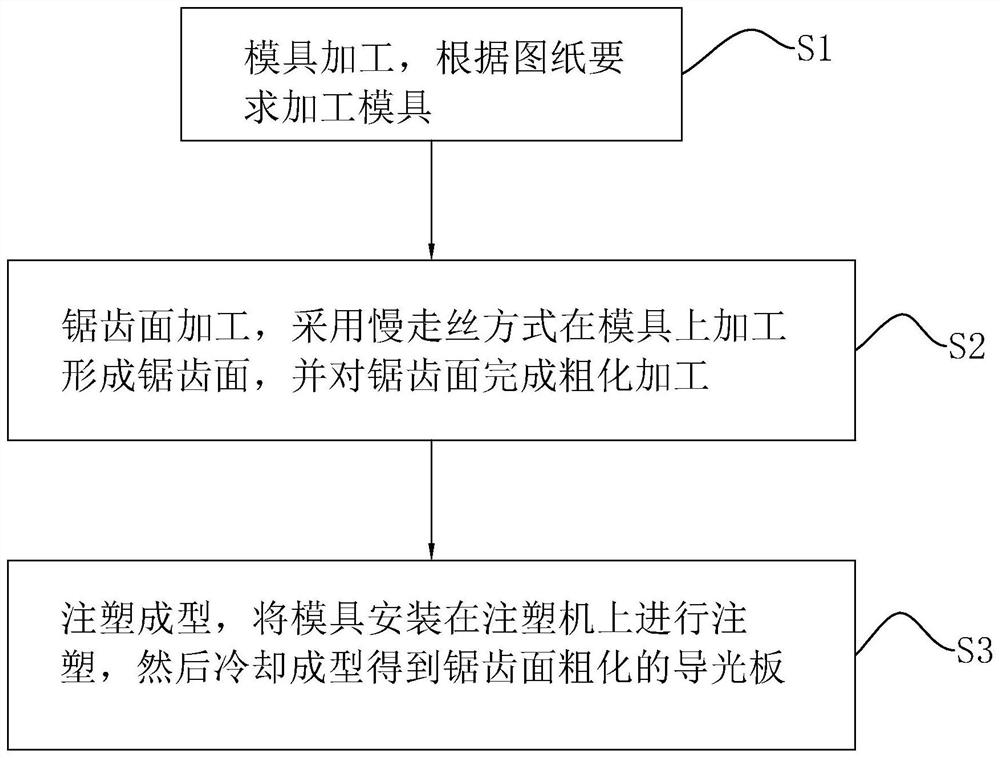

[0035] refer to figure 2 , a sawtooth process for solving the yellowing of the backlight LED side disclosed by the present invention, comprising the following steps:

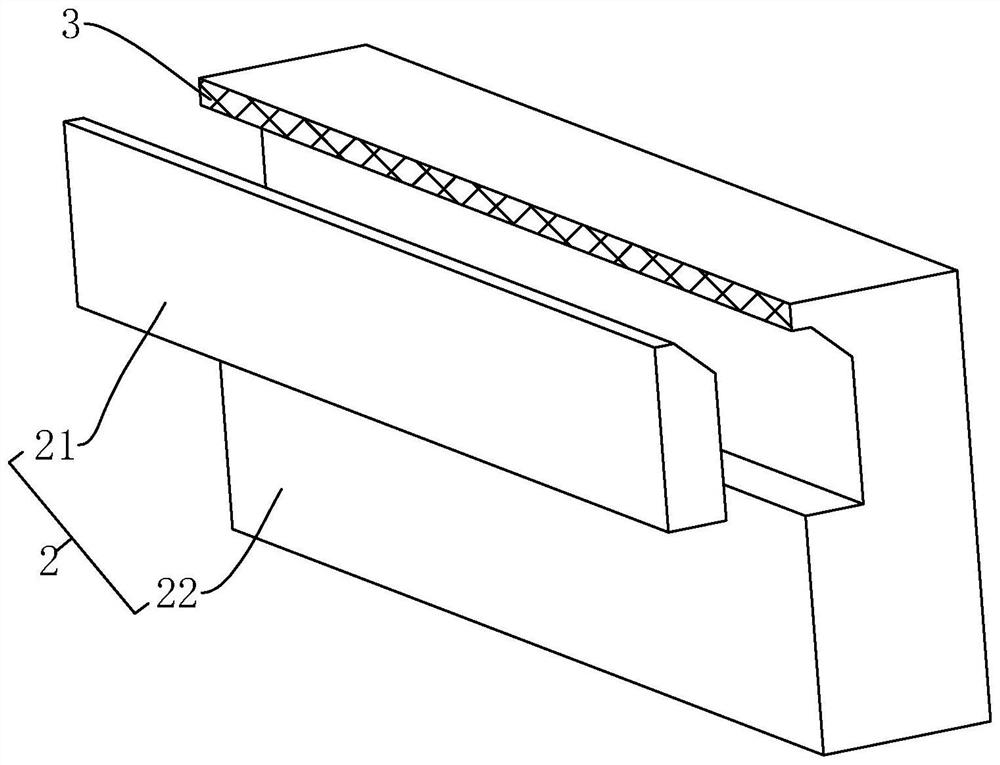

[0036] Step S1: Mold 1 is processed, and the mold 1 is processed according to the drawings. Among them, the mold 1 includes the serrated insert 2. Firstly, the serrated insert 2 is processed into the shape by slow wire walking. Refer to image 3 and 4 , the sawtooth insert 2 consists of two parts: block A21 and block B22. The length, width and height of block B22 leave a margin of 0.1 mm, and then use a grinder to grind off the margin on the surface of block B22 to obtain the size required by the drawing. A21 directly cuts out the size and shape. By cutting out the block A21, leave room for the machining of the serrated surface 3.

[0037] Step S2: Process the sawtooth surface 3 on the bl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com