Method for producing natural gas and fabricated wall plate through food and kitchen waste and production line

A kind of kitchen waste and assembled technology, which is applied in the direction of biochemical equipment and methods, solid waste removal, gas production bioreactor, etc., can solve the problems of non-treatment and utilization, endangering human health, easy corruption and deterioration, etc. , to achieve the effect of light weight, high economic added value, energy and building materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiment of the present invention is illustrated below in conjunction with accompanying drawing:

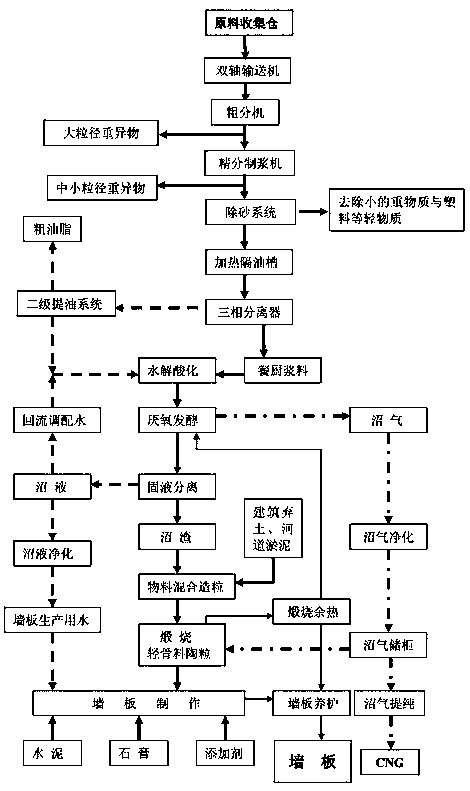

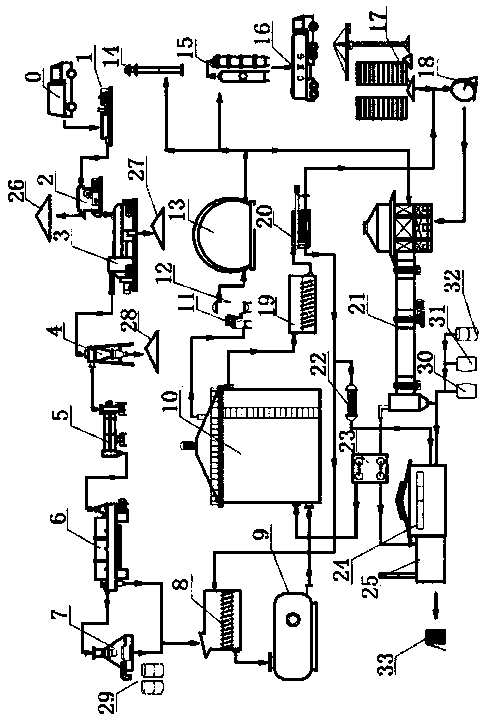

[0026]Its production methods include pretreatment, anaerobic fermentation, biogas purification, solid-liquid separation, biogas slurry purification, calcined ceramsite and wallboard production. The pretreatment is to pour the kitchen waste into the raw material collection bin, drain and send it to the rough separator through the biaxial conveyor, and the coarse separator separates the heavy foreign matter with large particle size from the system; the homogeneous material mainly composed of organic matter enters the fine separator Separation pulping machine, fine separation pulping machine separates small and medium particle size heavy foreign matter out of the system, and at the same time breaks the material into slurry material mainly slurry material; then enters the desanding system to remove small heavy matter and Light substances such as plastics and finely shredded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com