Polypyrrole-coated sulfur-doped cobalt-based carbon nanocage material, preparation method and application thereof

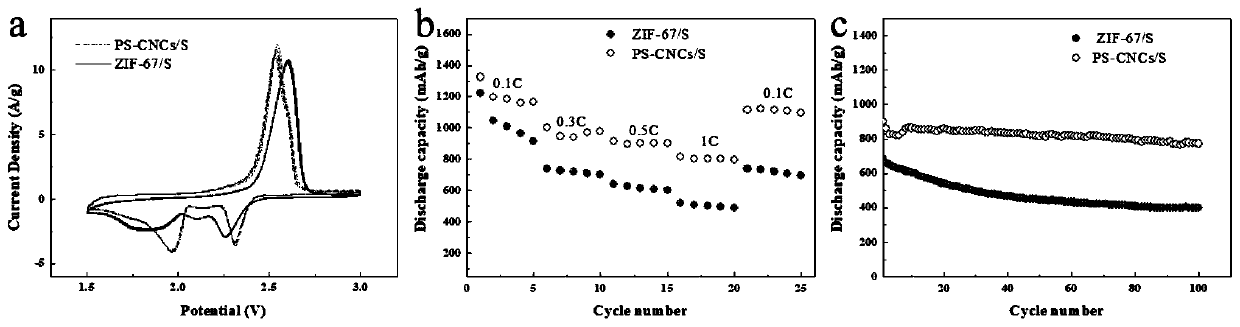

A technology of carbon nanocage and sulfur doping, applied in the direction of active material electrodes, electrical components, battery electrodes, etc., can solve the problems of reduced utilization of active materials, capacity loss, unfavorable electron transfer, etc., to improve interaction and cycle performance, the effect of suppressing the shuttle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A preparation method of polypyrrole-coated sulfur-doped cobalt-based carbon nanocage material, specifically comprising the following steps:

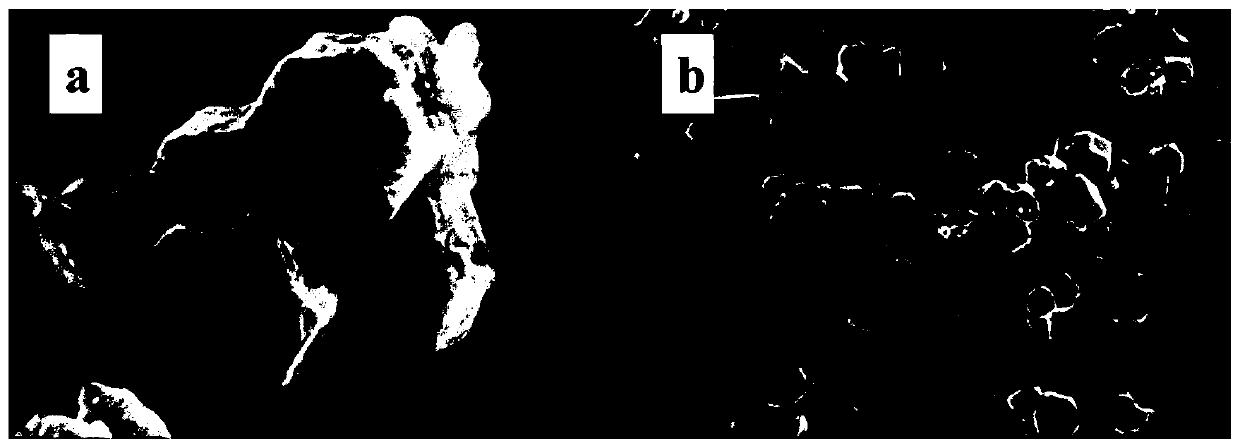

[0039] (1) Preparation of precursor ZIF-67

[0040] Weigh 600 mg of cobalt nitrate hexahydrate and 1.5 g of 2-methylimidazole and dissolve them in 25 mL of methanol solution, stir evenly with a magnetic force, slowly pour the 2-methylimidazole solution into the cobalt nitrate solution, and let it stand at room temperature for reaction After centrifugation for 24 hours, it was dried at a constant temperature of 60°C to obtain cobalt-based ZIF-67 as a precursor;

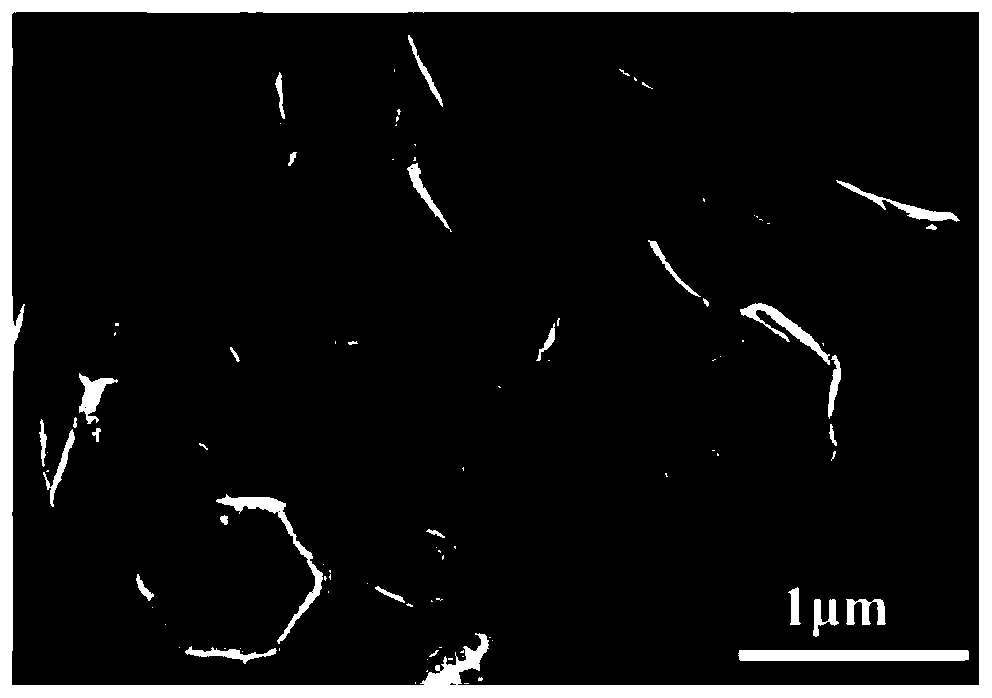

[0041] (2) Preparation of sulfur-doped cobalt-based carbon nanocages (S-CNCs)

[0042] Weigh 90 mg of the above-prepared precursor and dissolve it in 30 mL of absolute ethanol. After ultrasonic treatment, add 60 mg of thioacetamide (TAA) and continue ultrasonication for 30 minutes. After putting it into the reaction kettle, react in an oven at 120 ° C for 2 h, and natural...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com