Preparation method and application of nitrogen-doped CoB alloy

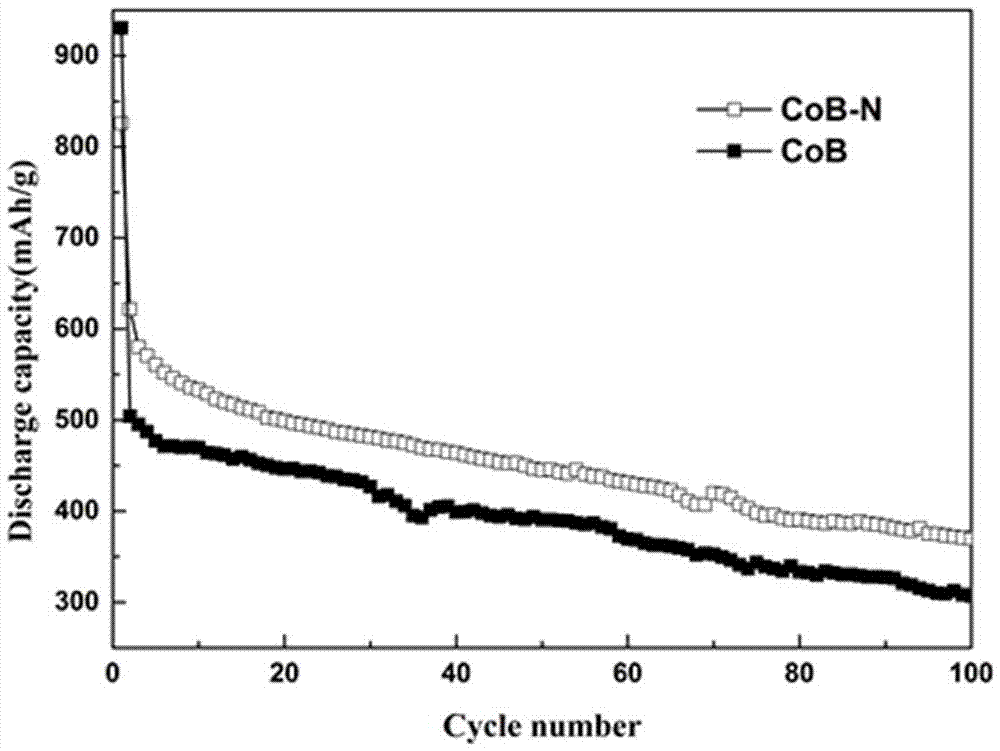

A nitrogen doping and alloying technology, applied in hybrid capacitor electrodes, electrical components, battery electrodes, etc., can solve the problems of poor cycle stability, low electrochemical capacity, easy particle agglomeration, etc., and achieve uniform distribution and high electrochemical capacity. , the effect of good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] A kind of preparation method of nitrogen-doped CoB alloy, concrete steps are as follows:

[0029] In step (1), 10 g of cobalt chloride and 3 g of urea were dissolved in 60 mL of water to obtain a mixed solution of cobalt chloride and urea;

[0030] In step (2), 8 g of sodium borohydride was dissolved in 30 mL of water to obtain a sodium borohydride solution, and the sodium borohydride solution was added dropwise to the step at a rate of 1.5 mL / min at 25 °C and under ultrasonic conditions. In the mixed solution described in (1), after the dropwise addition, continue to maintain it at 25 °C for 20 minutes to obtain a black suspension;

[0031] Step (3), after filtering the black suspension in step (2), wash the precipitate with distilled water and absolute ethanol three times respectively, put it in a vacuum drying oven, and dry it at 60°C for 12 h to obtain nitrogen Doped CoB alloy.

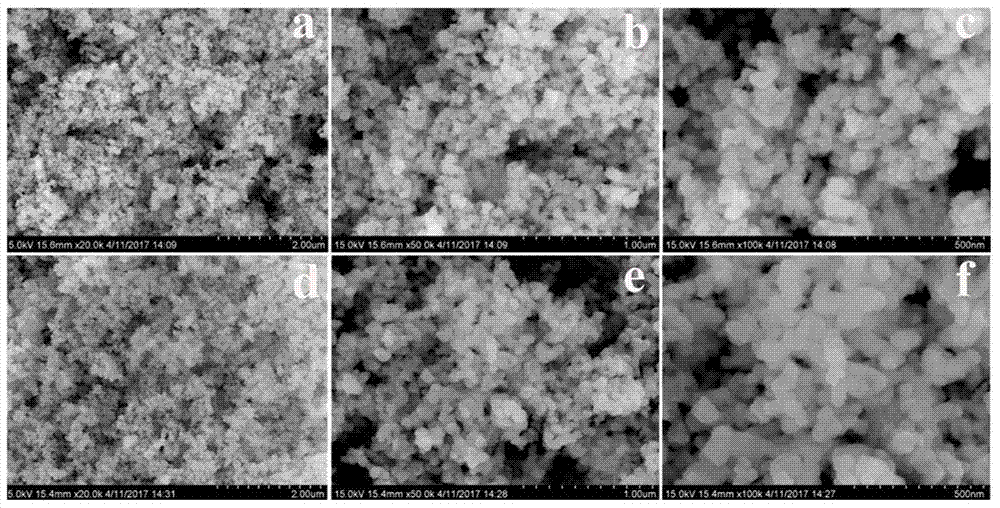

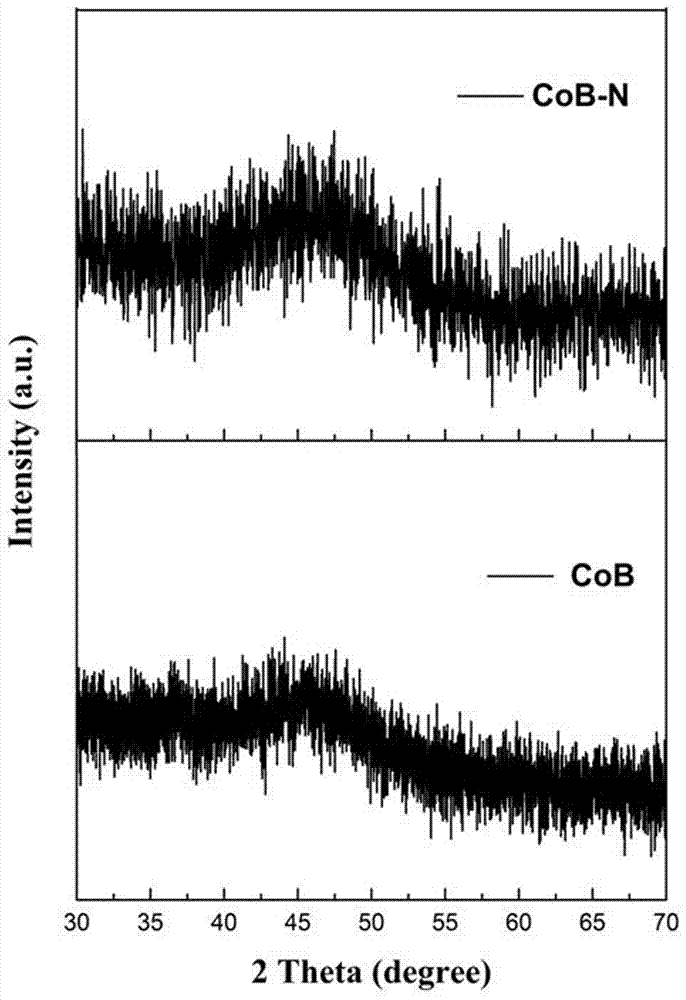

[0032] In order to verify the excellent performance of the CoB alloy prepared in this...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com