Patents

Literature

38results about How to "Increase the specific capacity of lithium storage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

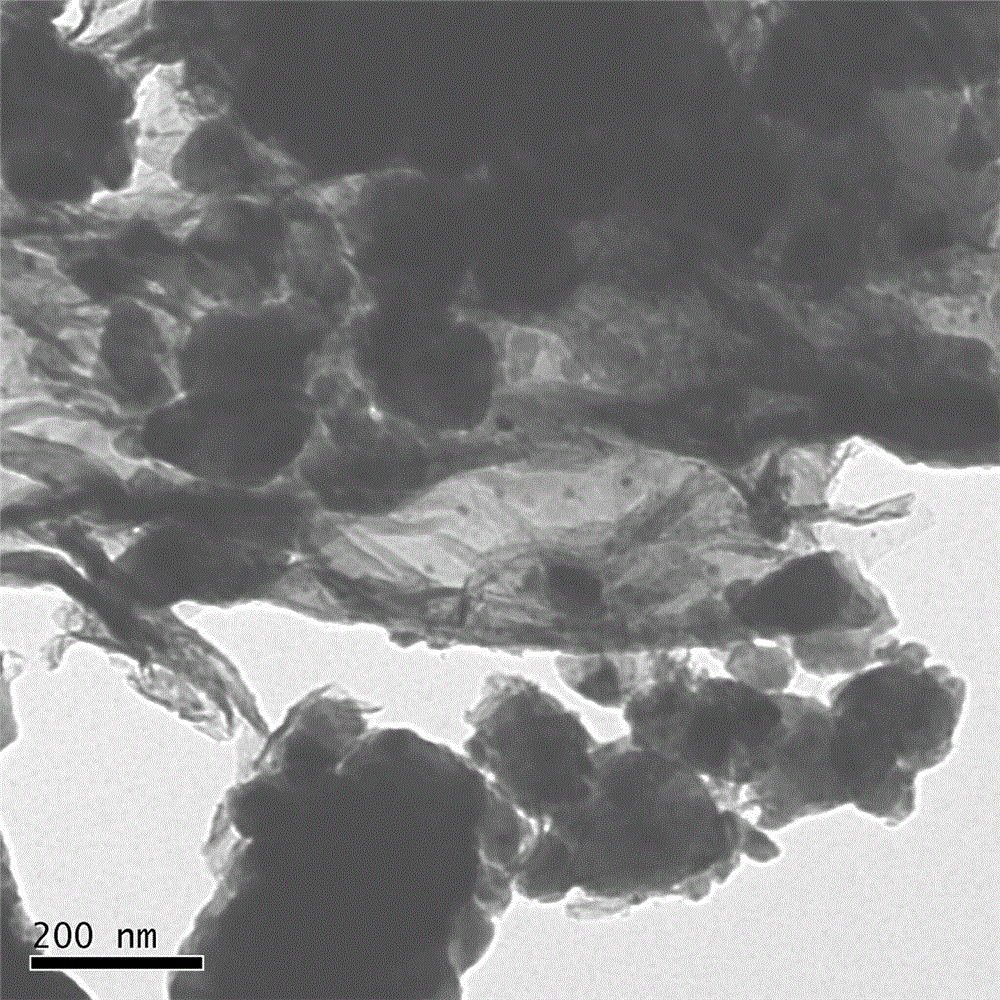

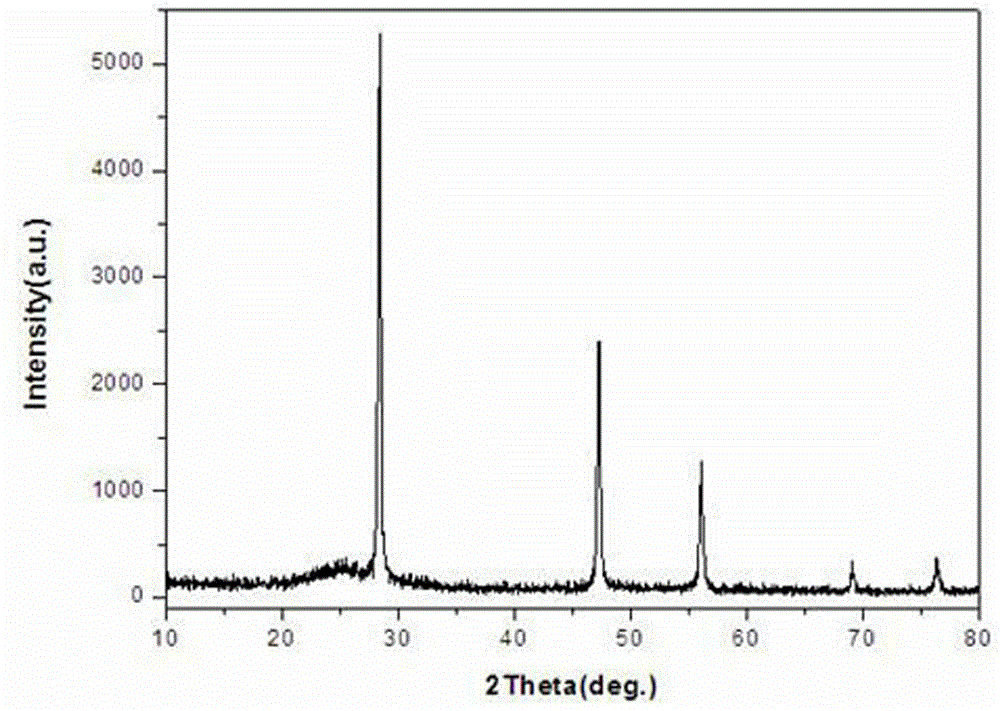

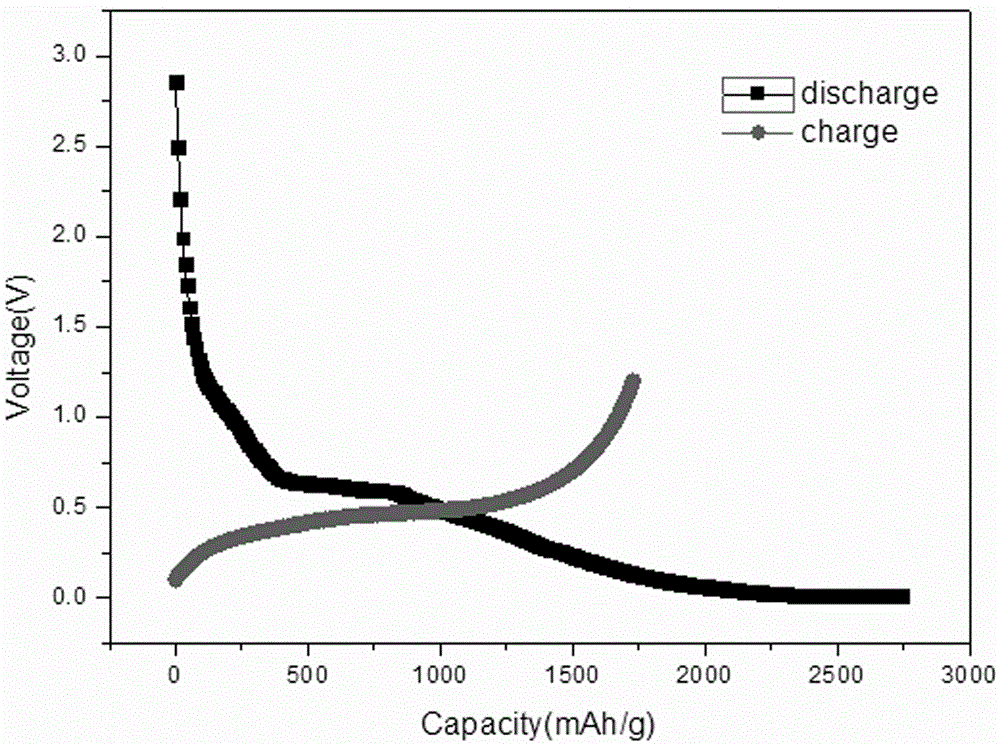

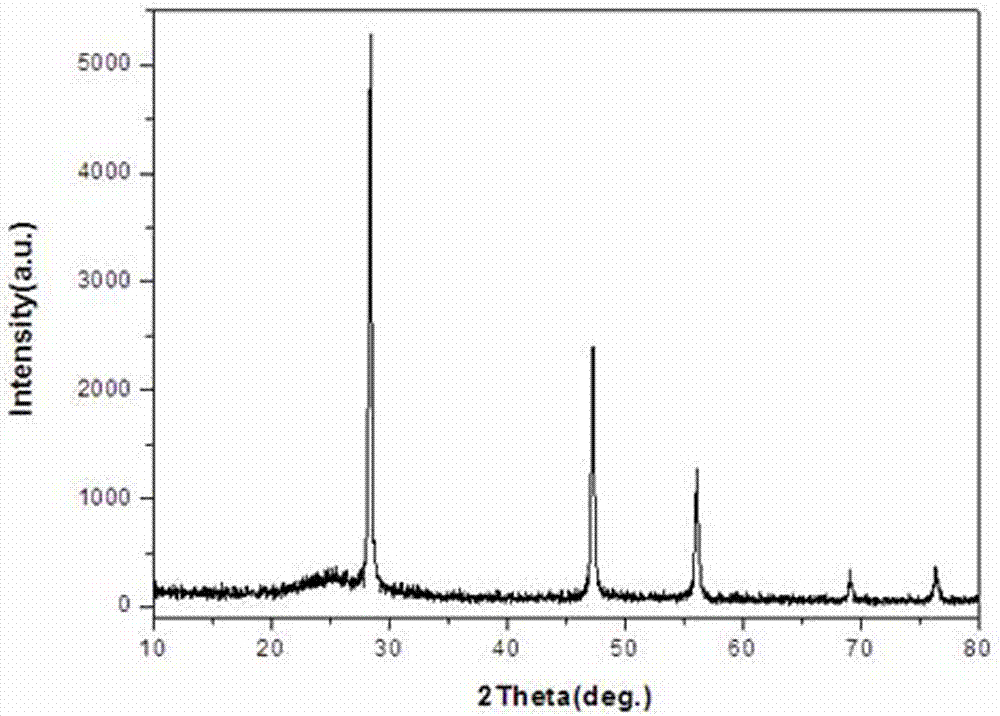

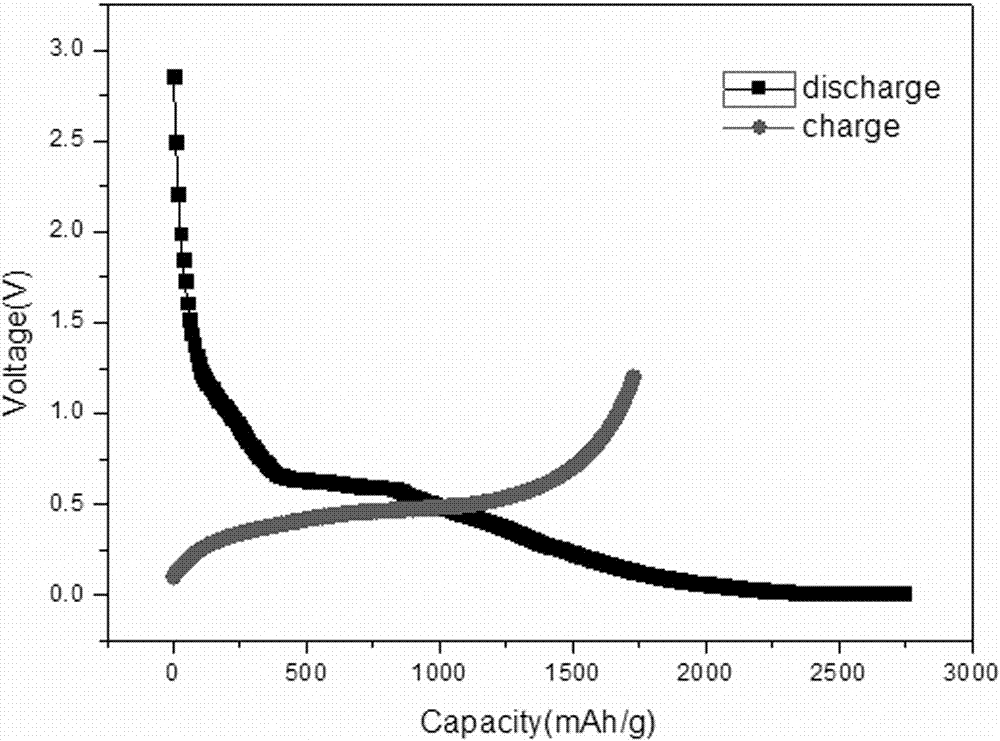

Silicon cathode material coated with graphene and preparation method thereof

InactiveCN104916826AWide variety of sourcesLow priceCell electrodesSecondary cellsOperabilitySilicon particle

The invention relates to the technical field of lithium-ion cathode material, in particular to silicon cathode material coated with graphene and a preparation method of the silicon cathode material coated with the grapheme. The preparation method comprises the following steps: A, preparing oxidized graphene suspension liquid; B, preparing nanometer silicon particle suspension liquid; and C, preparing silicon cathode material coated with grapheme. The preparation method adopts the electrostatic self-assembly synthetic technology and is wide in source of raw material, low in price, simple in synthetic method, easy for control of process conditions, strong in operability and good in repeatability. The silicon cathode material coated with grapheme is high in specific capacity and good in cycle performance and rate capability, wherein the specific discharge capacity for the first time under the electric current density of 0.01-1.2V, 200mA / g can reach 2746mAh / g, and the specific discharge capacity after 100 times of cycles can maintain 803.8mAh / g.

Owner:MCNAIR TECH +1

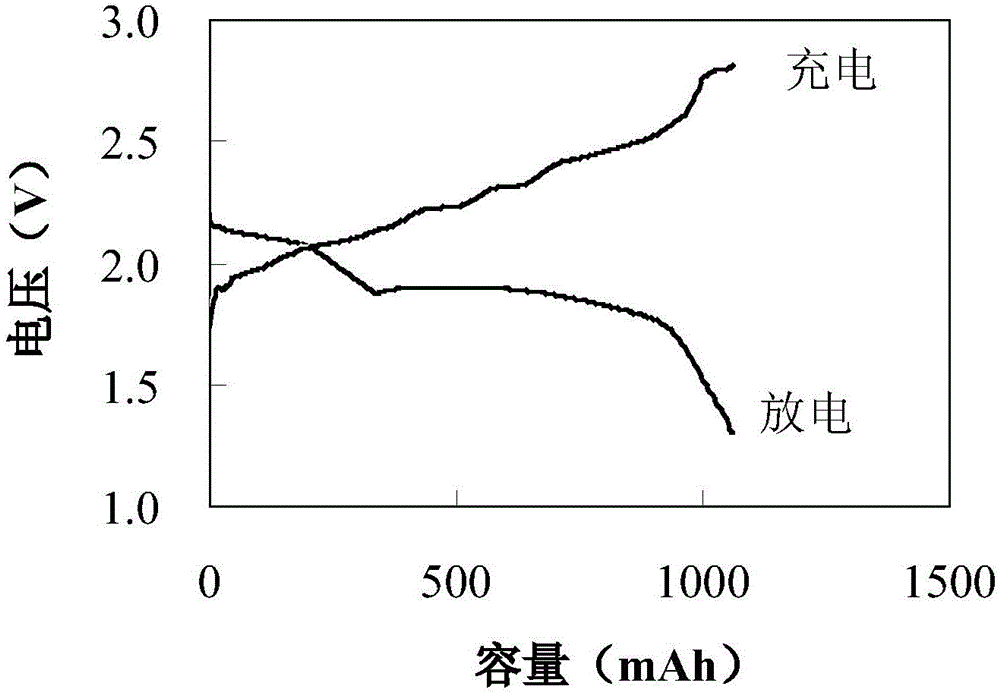

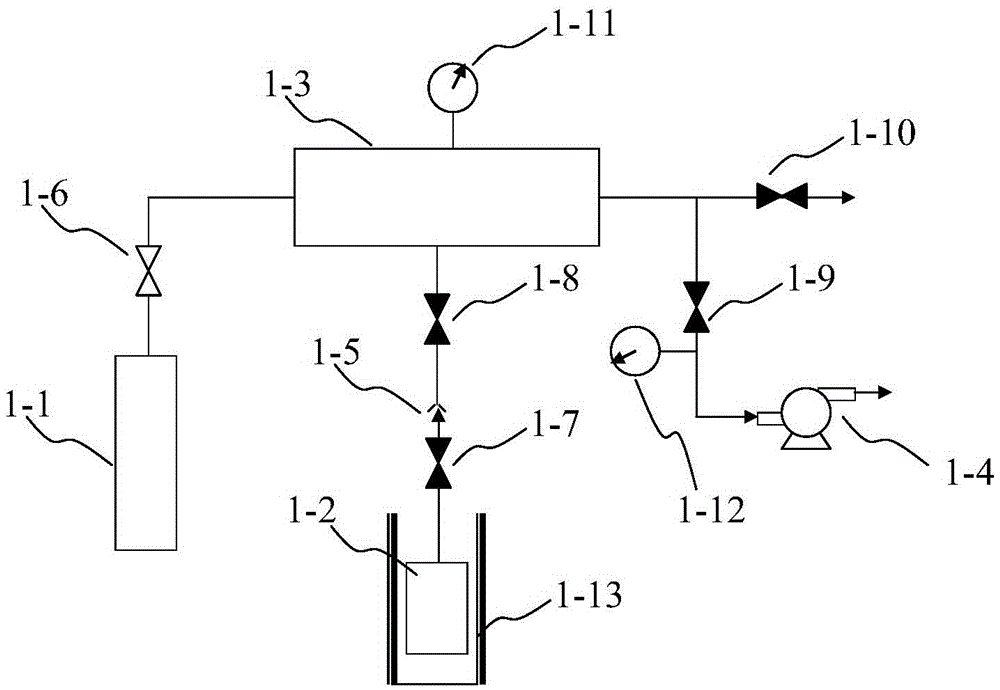

Preparation method of lithium sulfur battery membrane electrode

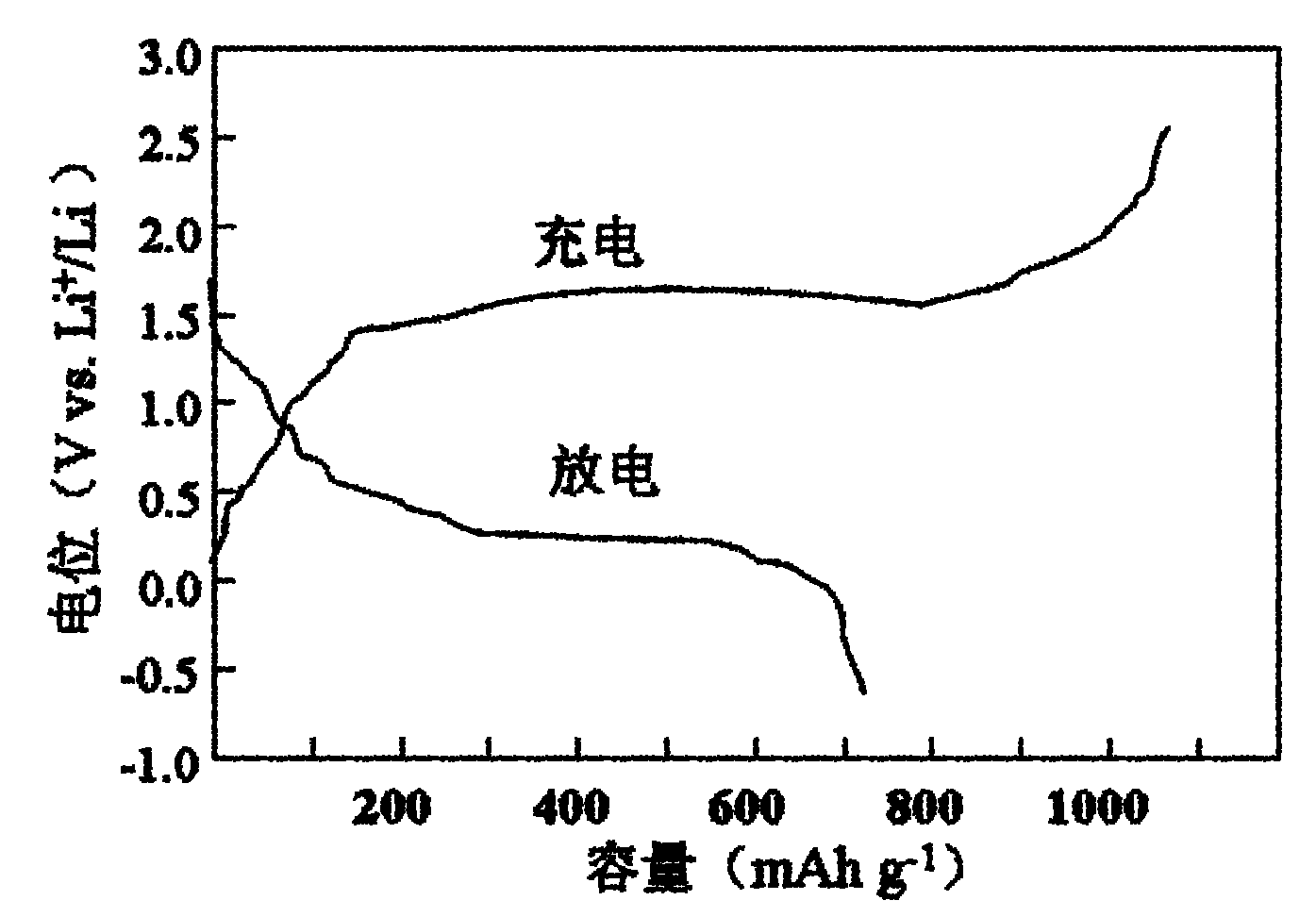

InactiveCN104157909AImprove performanceEliminates the possibility of a reactionFinal product manufactureElectrolyte accumulators manufactureLithium–sulfur batteryInternal resistance

The invention relates to the technical field of a lithium sulfur battery, and aims at providing a preparation method of a lithium sulfur battery membrane electrode. The preparation method of the lithium sulfur battery membrane comprises the following steps: preparing a carbon material with nano ferrous sulfide being dispersed on the surface of a carbon carrier, and then preparing a positive electrode material by utilizing the carbon material; respectively preparing a positive electrode and a negative electrode as well as a lithium ion exchange membrane, and finally pressing the positive electrode, the negative electrode and the lithium ion exchange membrane into the lithium sulfur battery membrane electrode. The prepared lithium sulfur battery membrane electrode is good in conductivity, low in internal resistance, good in electrode reaction reversibility, good in chemical stability and thermal stability, low in price, easy to prepare, pollution-free, simple in battery manufacturing process, favorable for mass production and capable of effectively reducing the production cost.

Owner:ZHEJIANG UNIV

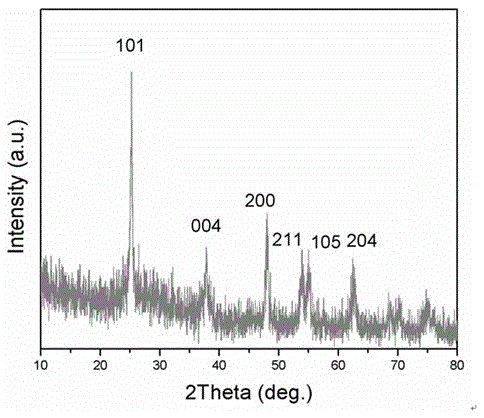

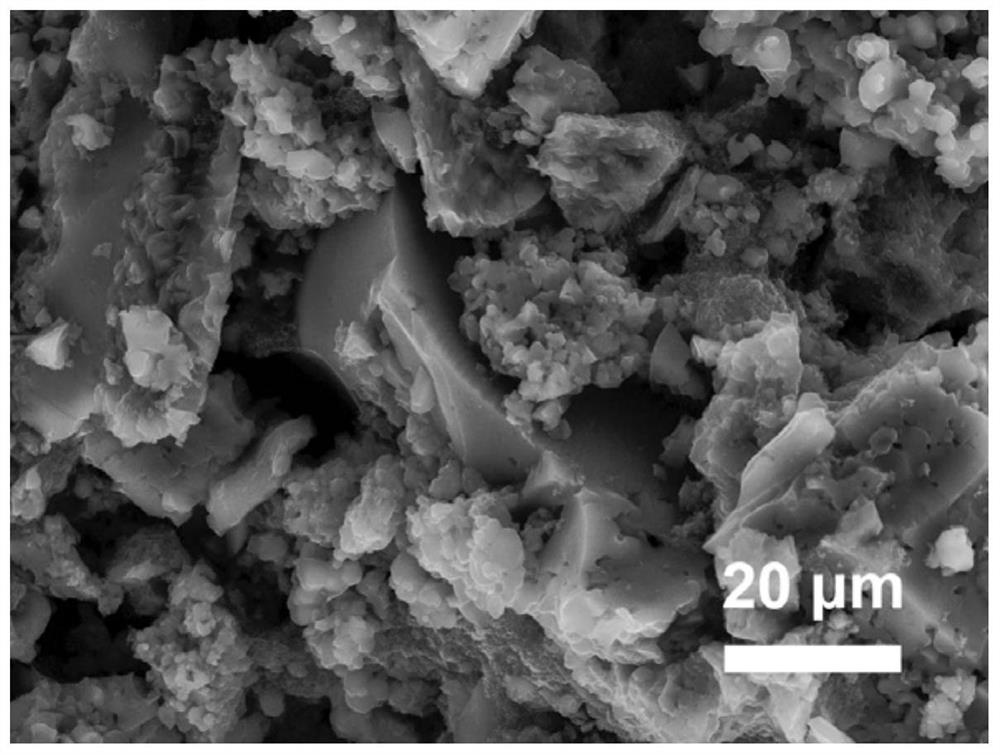

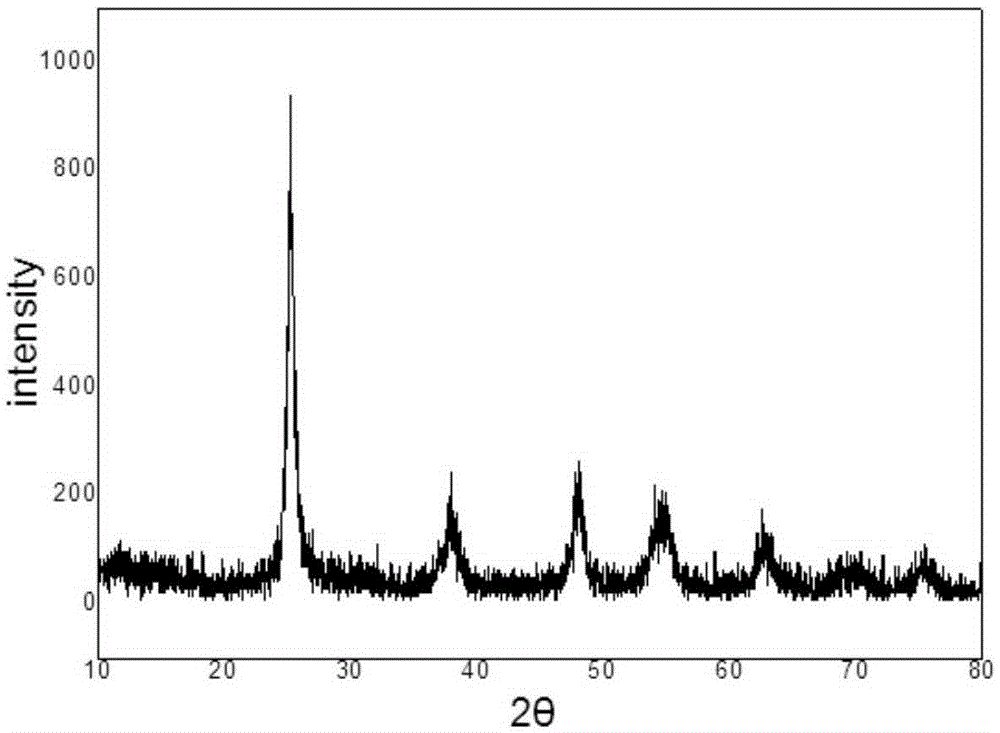

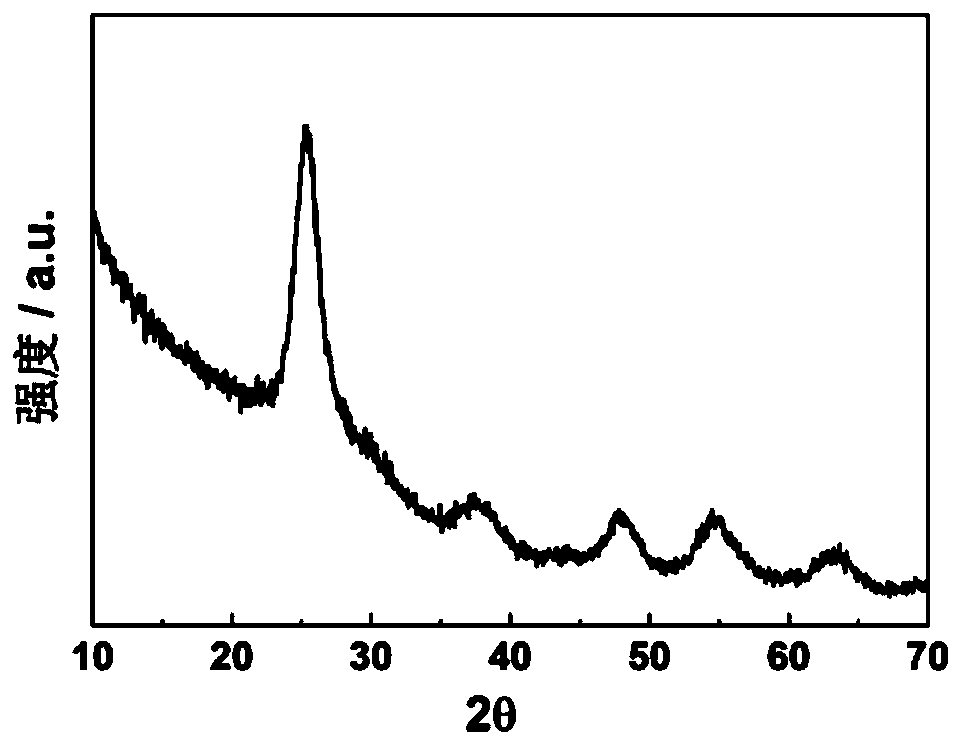

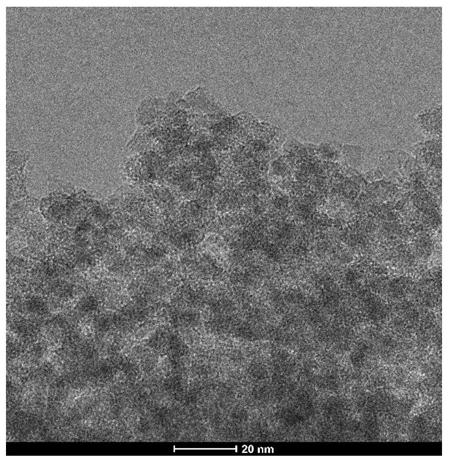

Method for preparing titanium dioxide nanosheet coated graphene anode material of lithium ion battery

InactiveCN105576212ARaise the ratioGood prospects for application developmentNegative electrodesSecondary cellsDiethylenetriamineSolvothermal reaction

The invention provides a method for preparing a titanium dioxide nanosheet coated graphene anode material of a lithium ion battery. The method comprises the following steps: a, preparing graphene oxide suspension: preparing graphite oxide by adopting a hummer method, and ultrasonically peeling graphite oxide in isopropanol to form graphene oxide suspension; and b, preparing the titanium dioxide nanosheet coated graphene material: adding a certain amount of diethylenetriamine into the graphene oxide suspension, uniformly stirring, adding butyl titanate, uniformly stirring, putting in a closed reaction kettle to perform solvothermal reaction, washing a solvothermal reaction product by using ethanol, drying, and processing at high temperature under the protective atmosphere so as to obtain the titanium dioxide nanosheet coated graphene anode material. By means of the preparation method disclosed by the invention, aggregation and overlapping in the reducing process of graphene can be effectively prevented; therefore, the electronic conductivity of the titanium dioxide nanosheet coated graphene anode material of the lithium ion battery is increased; and a research thought is provided for seeking the novel anode material of the lithium ion battery.

Owner:MCNAIR TECH +1

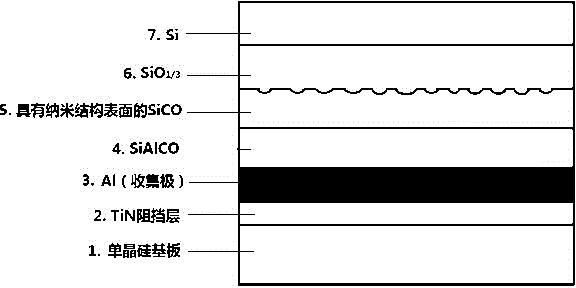

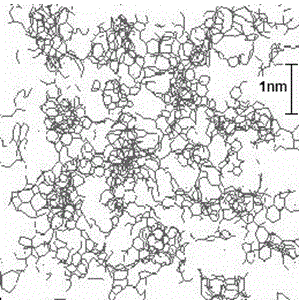

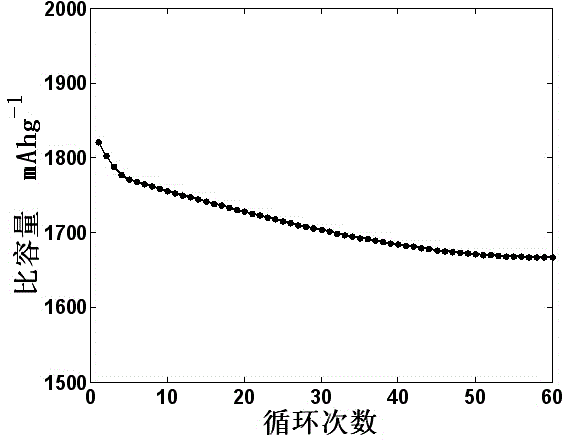

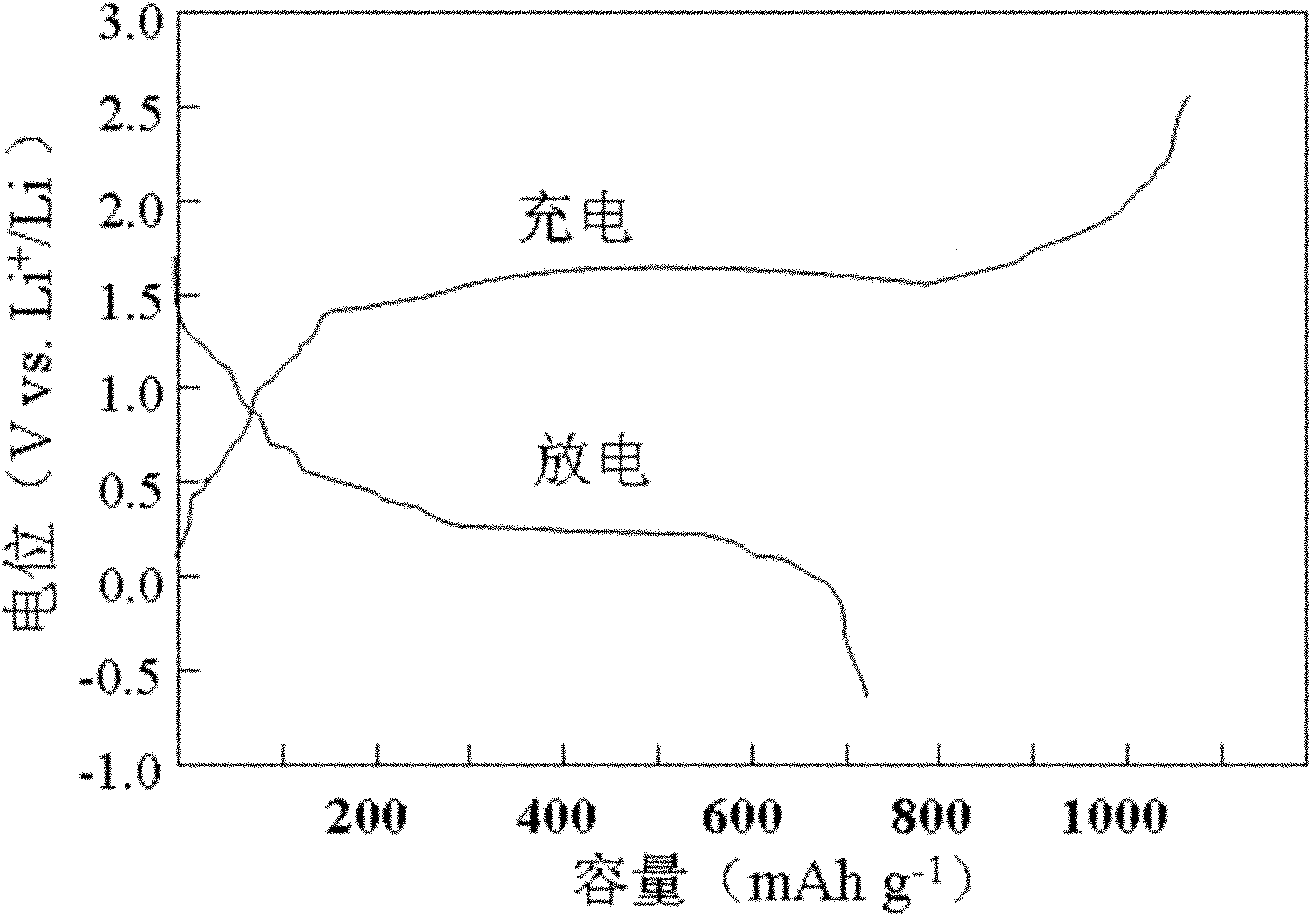

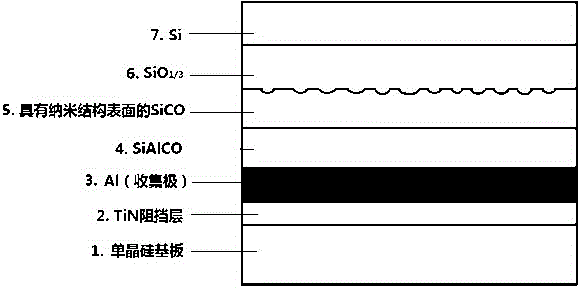

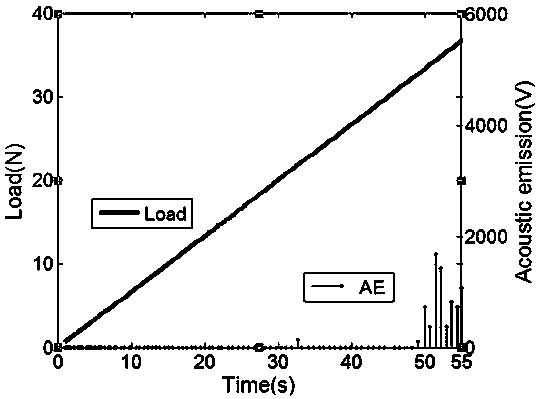

Lithium battery SiCO-Si gradient thin film electrode system and preparing method thereof

ActiveCN104993115AGood adhesionLow costCell electrodesLi-accumulatorsThin membraneMonocrystalline silicon

The invention discloses a lithium battery SiCO-Si gradient thin film electrode system. The system comprises a monocrystalline silicon substrate, wherein the monocrystalline silicon substrate is provided with a TiN barrier layer, an Al thin film layer, a SiAlCO thin film layer, a SiCO thin film layer, a SiO[1 / 3] thin film layer and a Si thin film layer from bottom to top in sequence. According to the system, by combining the two potential negative electrode materials, namely SiCO and silicon, through gradient design of specific capacity and mechanical property, the advantages of the two materials are comprehensively realized, and the disadvantages of the two materials are complemented. The thin film system prepared with the magnetic control sputtering method and target materials such as silicon, aluminum and graphite has the advantages of being high in adhesiveness, low in cost, controllable in constituent, low in temperature and the like. Through nanocrystallization of the SiCO surface, lithium diffusion and interface bonding strength are further improved, and the novel thin film electrode system with excellent electrochemical property and interface mechanical property is obtained finally. Furthermore, the method for preparing the SiCO nanometer surface with the chemical corrosion method has the advantages that the process is simple and quick, no expensive instrument is needed, raw materials are rich and cheap, and nanotopography is controllable.

Owner:WENZHOU UNIVERSITY

Preparation and application of conductive carbon film-coated calcium nitride compound serving as anode material of lithium battery

InactiveCN102082267ALow costGood thermal stabilityCell electrodesSecondary cellsCarbon filmNitrogen atmosphere

The invention relates to preparation and application of an anode material of a lithium battery and aims to provide preparation and the application of a conductive carbon film-coated calcium nitride compound serving as the anode material of the lithium battery. The preparation method comprises the following steps of: after calcium metal is molten, spraying into polyethylene glycol liquid by using high purity nitrogen, and performing a reaction of the calcium fog drops and nitrogen in an nitriding atmosphere to obtain Ca3N2 microspheres so as to obtain a carbon-coated calcium nitride material primary product; and after filtering out a carbon-coated calcium nitride material, calcining for 2 to 3 hours again in the high purity nitrogen atmosphere and carrying out refining to obtain carbon-coated Ca3N2, or calcining for 2 to 3 hours again in vacuum to obtain a carbon-coated Ca3N2-Ca2N mixture. In the invention, a conductive carbon film is formed on the surface of Ca3N2 or Ca3N2-Ca2N, is favorable for stability of an electrode structure, has high heat stability and low cost, is easy to prepare and has no pollution. The conductive carbon film prepared by a spraying method has the advantages of uniform thickness and high conductivity. The electrode polarization is reduced. The speed and the capacity of the lithium battery are improved.

Owner:ZHEJIANG UNIV

Nano silicon alloy based composite negative pole material and preparation method thereof

ActiveCN106058201AGood effectAddress volume expansionNegative electrodesSecondary cellsNano siliconMicrosphere

The invention discloses a nano silicon alloy based composite negative pole material. The nano silicon alloy based composite negative pole material has a three-shell layer structure, wherein a core layer is a nano carbon material coated nano silicon alloy core layer, and a three-shell layer is of a three-shell layer structure and is a conductive polymer film layer which is prepared by taking Fe3O4 nano-microspheres as sacrificial templates. The invention further discloses a preparation method of the nano silicon alloy based composite negative pole material. According to the preparation method, firstly, a nano silicon alloy material is prepared by a ball milling method and is subjected to wet grinding with a nano carbon material, then, hot coating is carried out so as to form the nano carbon material coated nano silicon alloy core layer, and then, the conductive polymer film layer with the three-shell layer structure is formed on the surface of the core layer by using a sacrificial Fe3O4 microsphere template method, so that the volume expansion of the nano silicon alloy material is effectively buffered. The nano silicon alloy based composite material disclosed by the invention has the advantages of high specific capacity, excellent cycle performance and rate performance, high tap density, and the like. The preparation method of the negative pole material, provided by the invention, is simple, environmentally friendly and pollution-free.

Owner:威海南海碳材料有限公司 +1

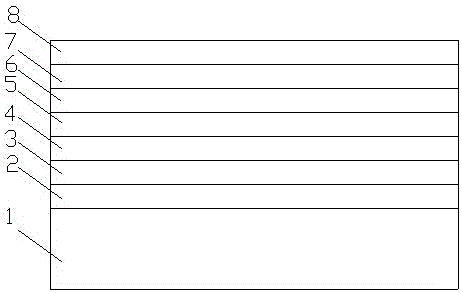

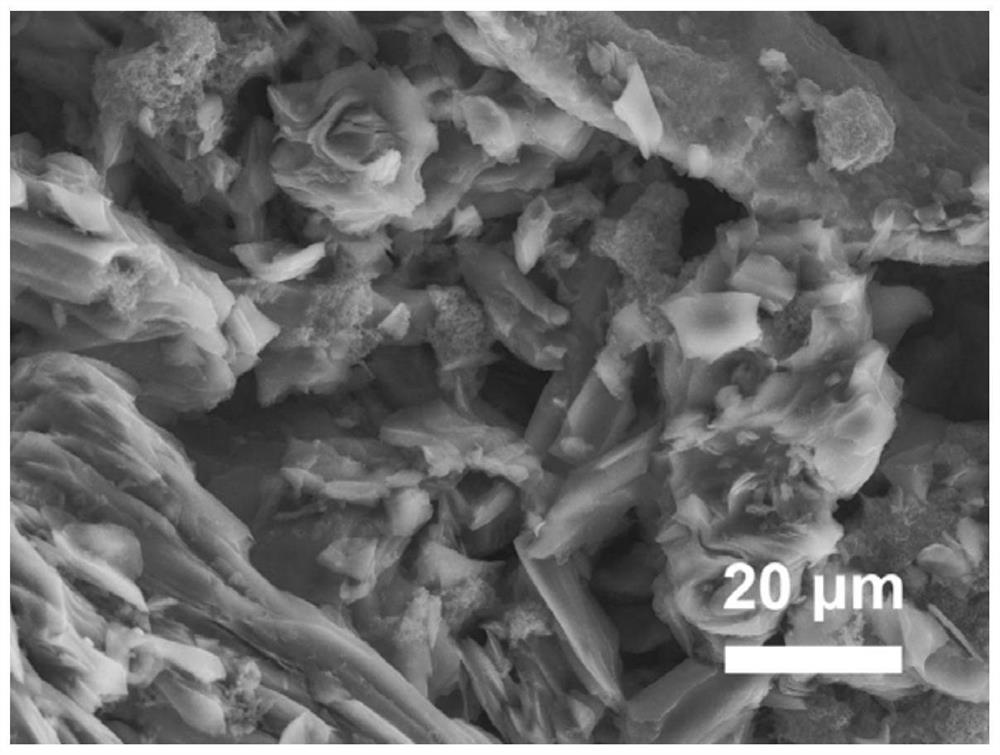

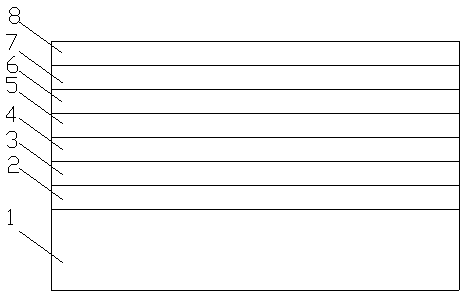

SiCO-carbon nanotube composite film electrode for lithium battery

ActiveCN106803570AHigh bonding strengthFast charging and dischargingNon-aqueous electrolyte accumulator electrodesVapour deposition manufacturingComposite filmCarbon nanotube

The invention discloses an SiCO-carbon nanotube composite film electrode for a lithium battery. The SiCO-carbon nanotube composite film electrode comprises a single-crystal silicon-based plate (1), wherein a TiN barrier layer (2), a Cu film layer (3), a CuO film layer (4), a SiCO film layer A (5), an Ni catalysis layer (6), a carbon nanotube layer (7) and an SiCO film layer B (8) are sequentially arranged on the single-crystal silicon-based plate (1). By adopting the SiCO-carbon nanotube composite film electrode, not only is the circulation stability of the electrode effectively improved, but also the thickness of a single film layer can be greatly reduced, a relatively large thickness of a film system can be achieved, and thus the electrochemical property of a material in high-magnification power charge / discharge can be improved.

Owner:WENZHOU UNIVERSITY

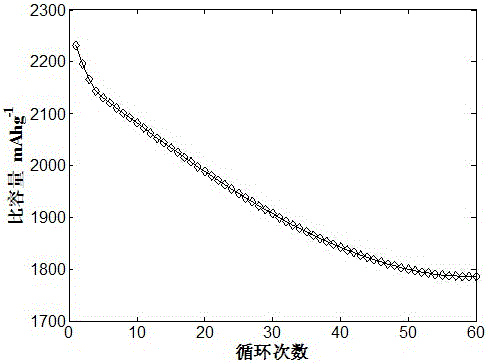

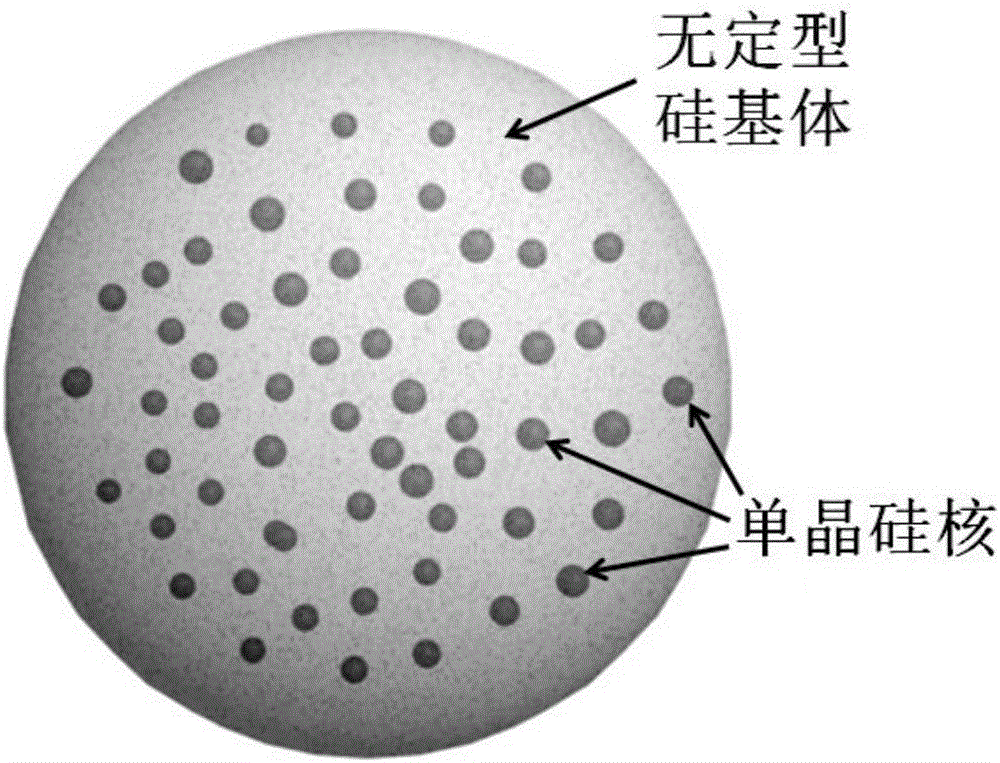

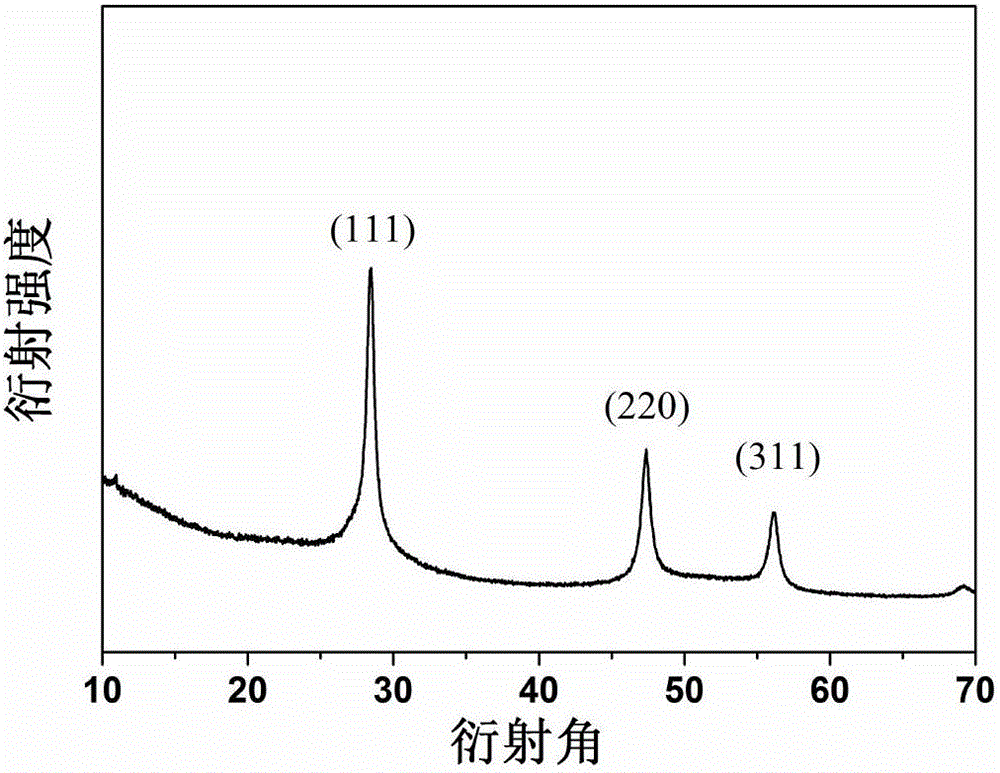

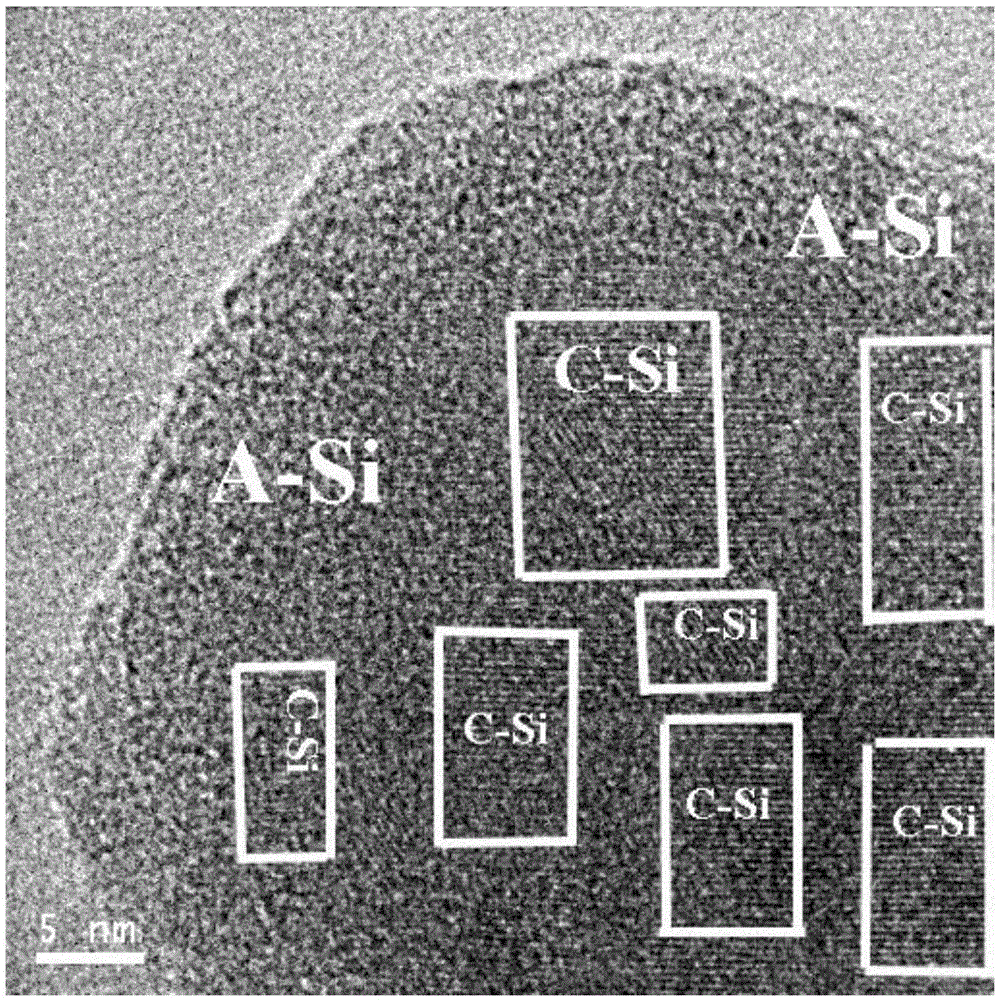

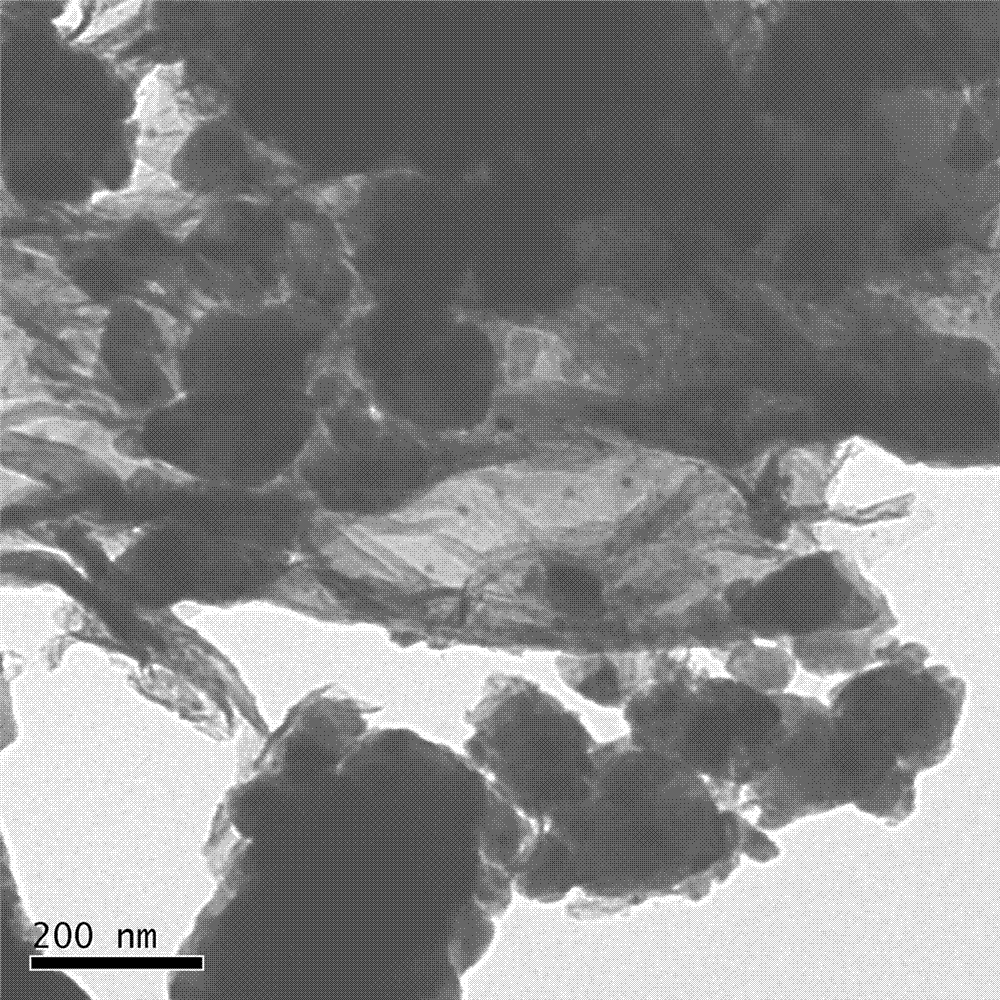

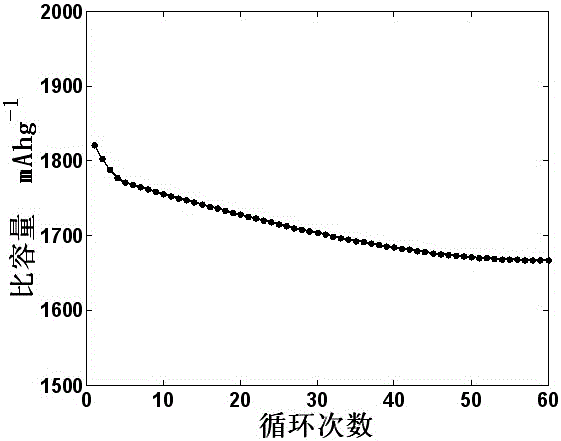

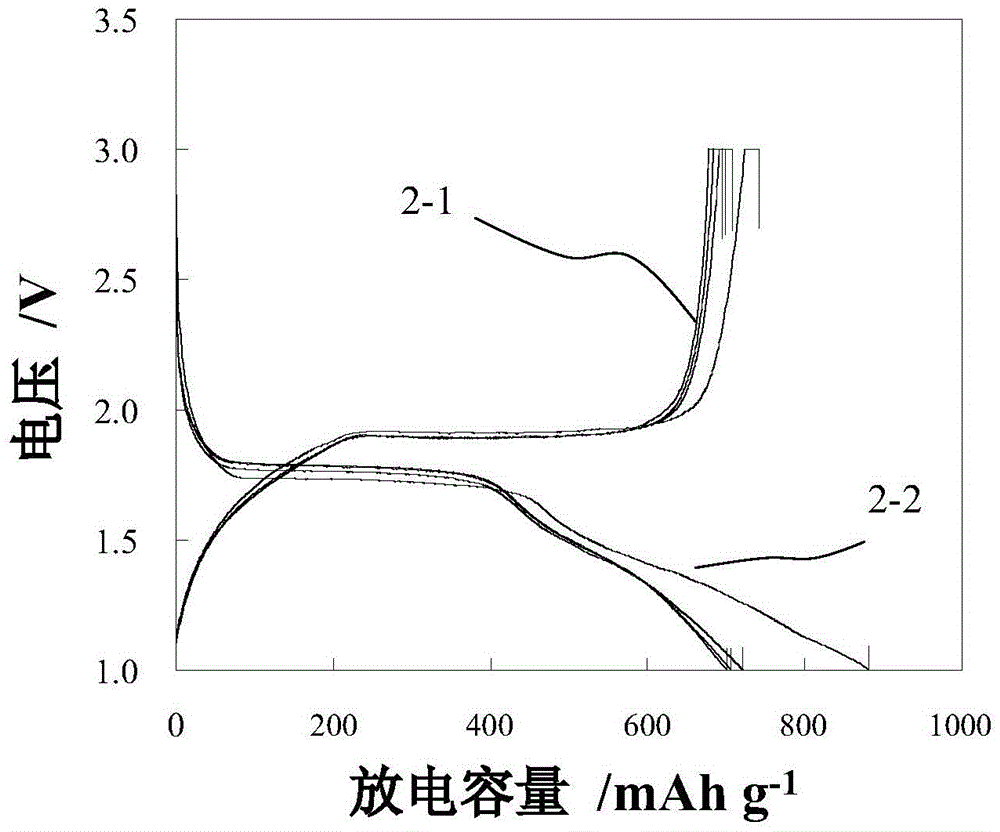

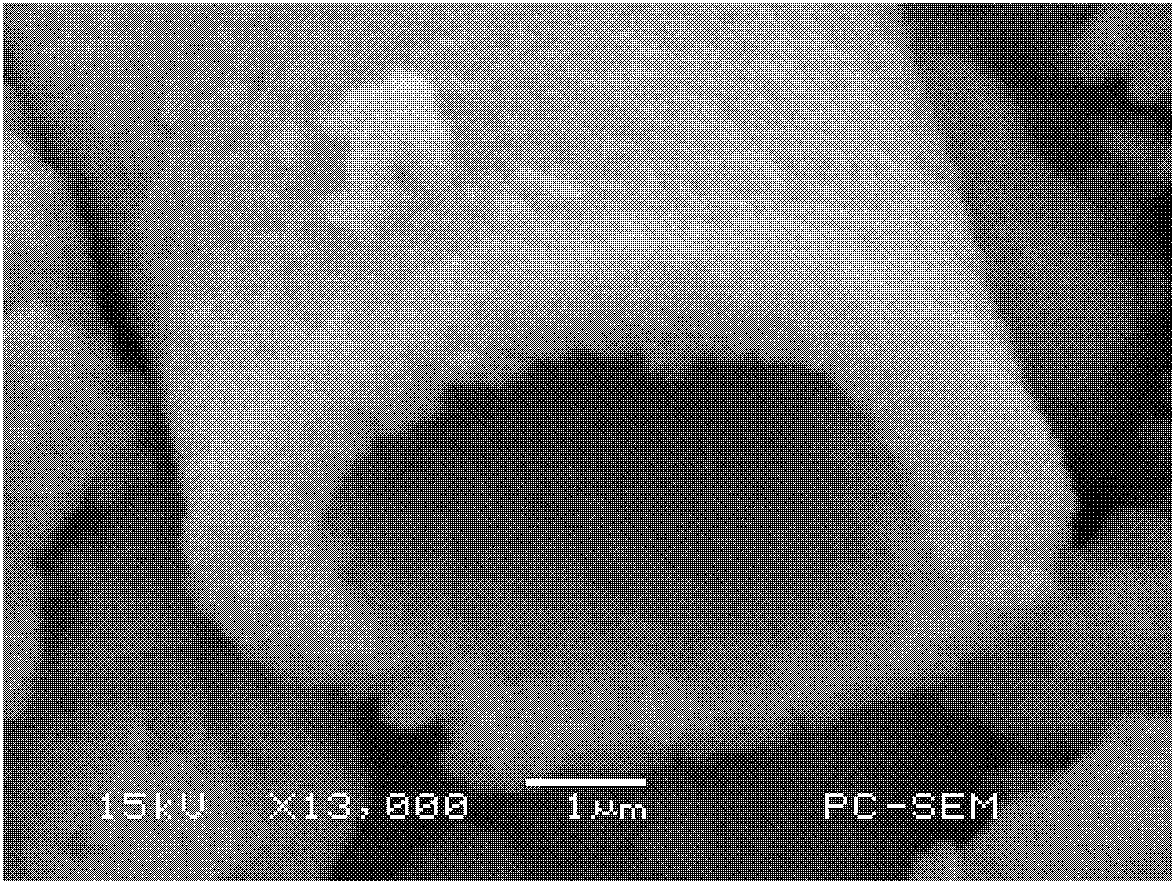

Silicon-based lithium ion battery negative electrode material and preparation method thereof

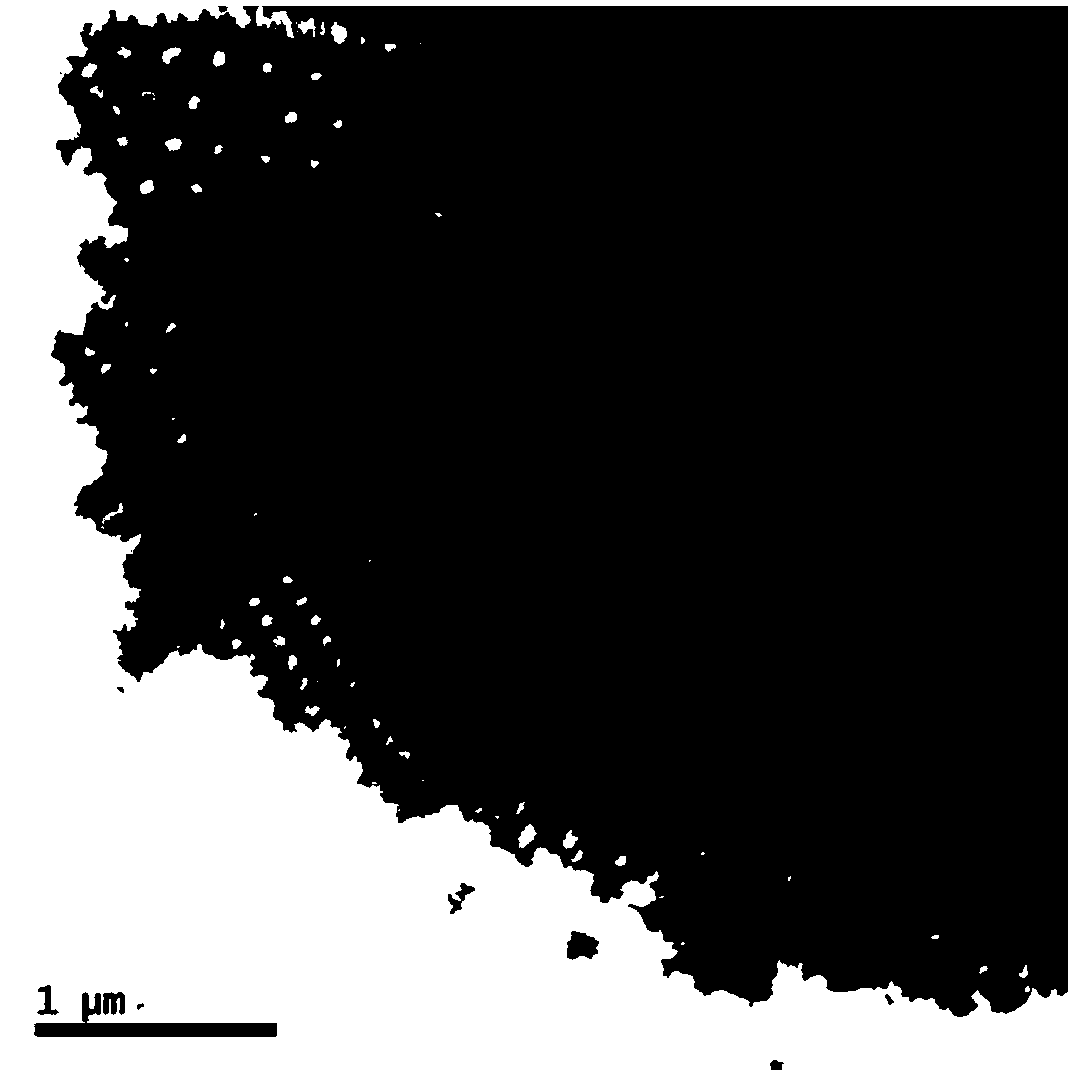

ActiveCN106299318AIncrease the specific capacity of lithium storageImprove cycle stabilityCell electrodesSecondary cellsAmorphous siliconSilicon oxide

The invention discloses a silicon substrate lithium ion battery negative electrode material and a preparation method thereof. The negative electrode material comprises an amorphous silicon substrate and a plurality of monocrystalline silicon cores, wherein the monocrystalline silicon cores are embedded in the amorphous silicon substrate and are covered by the amorphous silicon. The preparation method comprises the following steps: firstly, removing a silicon oxide layer on the outer surface of the amorphous silicon by adopting a chemical etching method; calcining the amorphous silicon material at high temperature under inert atmosphere; realizing the nucleation and growth of monocrystalline silicon in the amorphous silicon material; controlling the calcining time and the calcining temperature, thereby realizing the regulation for the inner silicon core size. The first specific discharge capacity of the compound material is above 1500mAh / g and the specific discharge capacity after 35 times of repeated charging and discharging circulation still can be kept above 1150mAh / g.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

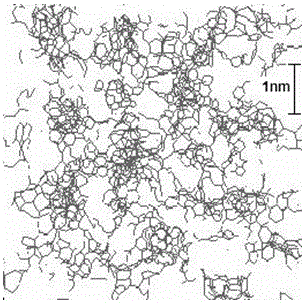

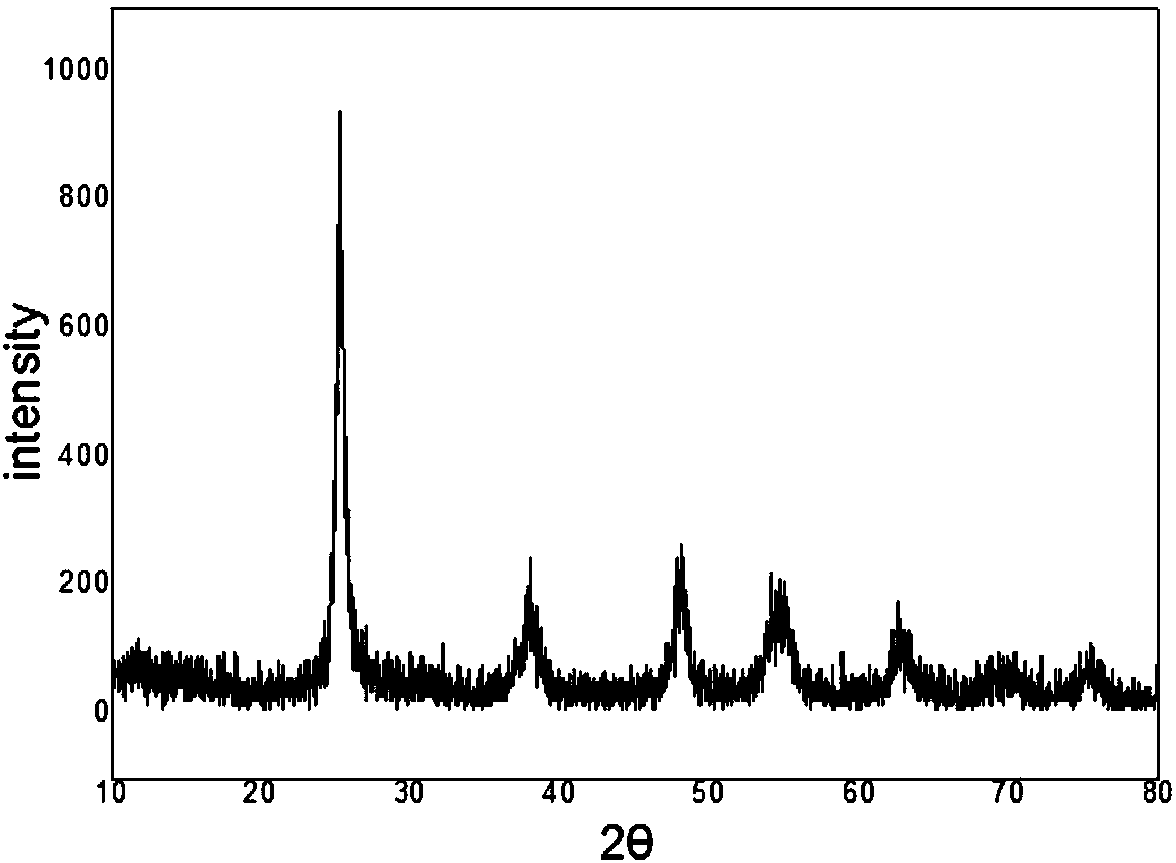

A kind of graphene coated silicon negative electrode material and preparation method thereof

InactiveCN104916826BWide variety of sourcesLow priceCell electrodesSecondary cellsOperabilitySilicon particle

The invention relates to the technical field of lithium-ion cathode material, in particular to silicon cathode material coated with graphene and a preparation method of the silicon cathode material coated with the grapheme. The preparation method comprises the following steps: A, preparing oxidized graphene suspension liquid; B, preparing nanometer silicon particle suspension liquid; and C, preparing silicon cathode material coated with grapheme. The preparation method adopts the electrostatic self-assembly synthetic technology and is wide in source of raw material, low in price, simple in synthetic method, easy for control of process conditions, strong in operability and good in repeatability. The silicon cathode material coated with grapheme is high in specific capacity and good in cycle performance and rate capability, wherein the specific discharge capacity for the first time under the electric current density of 0.01-1.2V, 200mA / g can reach 2746mAh / g, and the specific discharge capacity after 100 times of cycles can maintain 803.8mAh / g.

Owner:MCNAIR TECH +1

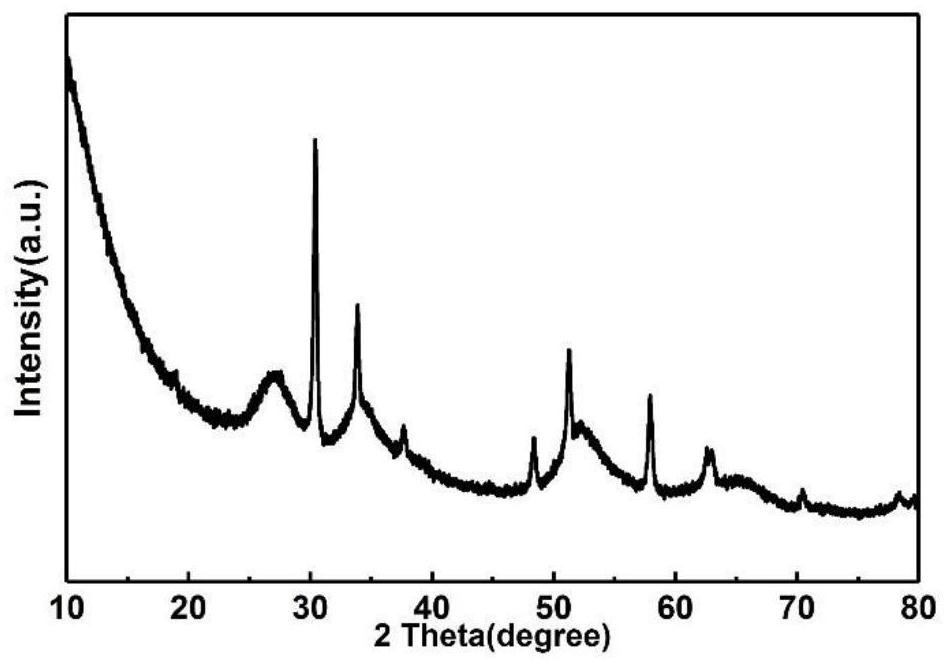

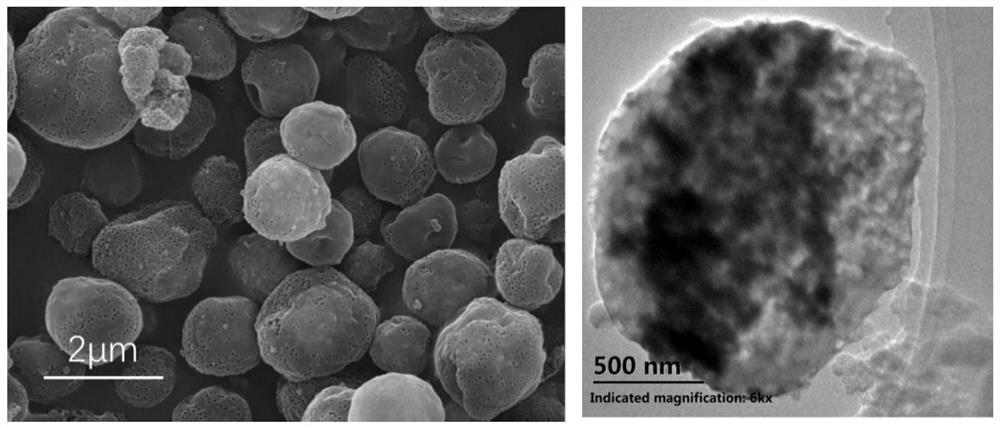

Tin oxide-hard carbon composite negative electrode material, and preparation method and application thereof

InactiveCN112331836ASimple preparation processEasy to operateElectrode thermal treatmentNegative electrodesCarbon compositesGraphite

The invention relates to a preparation method of a tin oxide-hard carbon composite negative electrode material. The preparation method comprises the following steps: mixing and stirring a phenolic monomer, an aldehyde monomer, tin salt, a sacrificial template agent and water to prepare a precursor solution; granulating the precursor solution by a spray drying method to obtain precursor particles;and calcining the precursor particles to obtain the tin oxide-hard carbon composite negative electrode material. The tin oxide-hard carbon composite negative electrode material is prepared according to the preparation method. The invention discloses an application of a tin oxide-hard carbon composite negative electrode material in a lithium ion battery. The preparation method has the beneficial effects that hard carbon and tin oxide with high specific capacity are compounded by using the spray drying method, so that the test specific capacity of the lithium ion battery is improved and is muchhigher than that of a commercial graphite material; and the cycling stability of the lithium ion battery is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

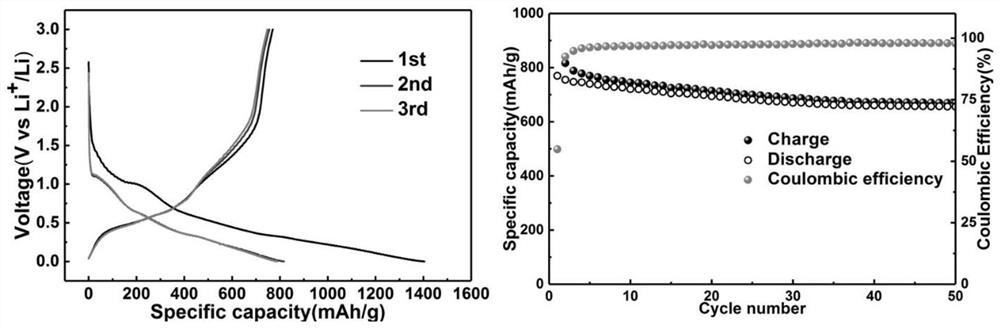

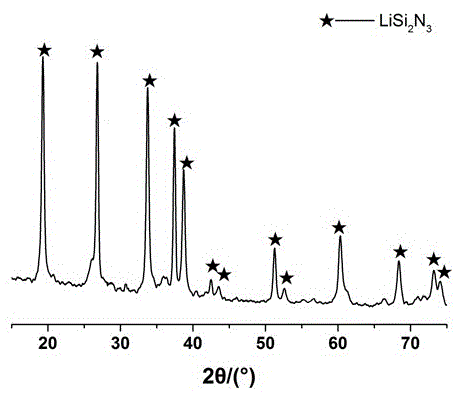

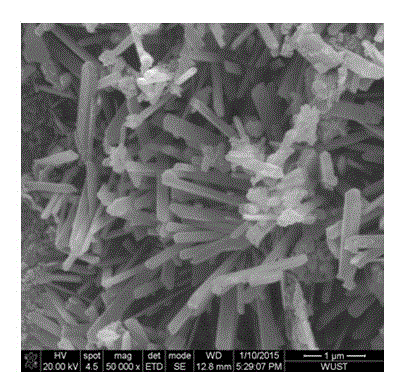

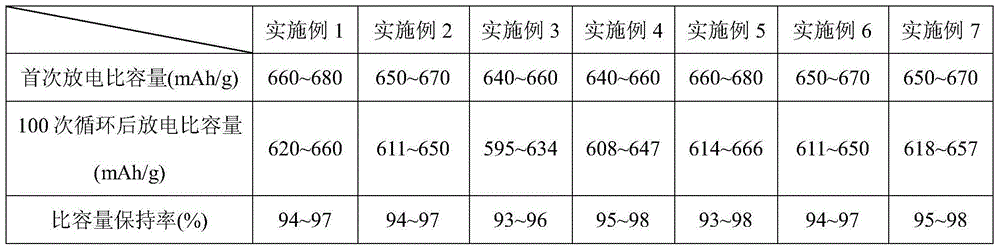

Lithium ion battery anode material LiSi2N3 and method for preparing material

ActiveCN104638250AImprove liquidityIncreased diffusion rateCell electrodesLithiumReaction temperature

The invention relates to a lithium ion battery anode material LiSi2N3 and a method for preparing the material. The technical scheme is as follows: the method comprises the following steps that 10-30wt% of elementary-substance silicon powder, 25-45wt% of trimeric cyanamide, 35-55wt% of a lithium precursor and 0.5-15wt% of halide powder are uniformly mixed to prepare a mixture; the mixture is placed in a tubular electric furnace, and heated up to 900-1200 DEG C at the heating rate of 2-10 DEG C / min under nitrogen atmosphere, and the temperature is kept for 2-6 hours; the prepared product is repeatedly washed by de-ionized water and titrated by respectively using AgNO3 and Ca(NO3)2 solutions until no white precipitates appear; and finally the prepared product is dried for 10-24 hours at 110 DEG C and thus the lithium ion battery anode material LiSi2N3 is prepared. The preparation method is low in reacting temperature and cost, easy to control, high in productivity, and applied to industrial production; the prepared lithium ion battery anode material LiSi2N3 is high in activity, large in specific surface area, high in purity and specific capacity, and steady in performance.

Owner:SUZHOU ZIGUANG WEIYE LASER TECH CO LTD

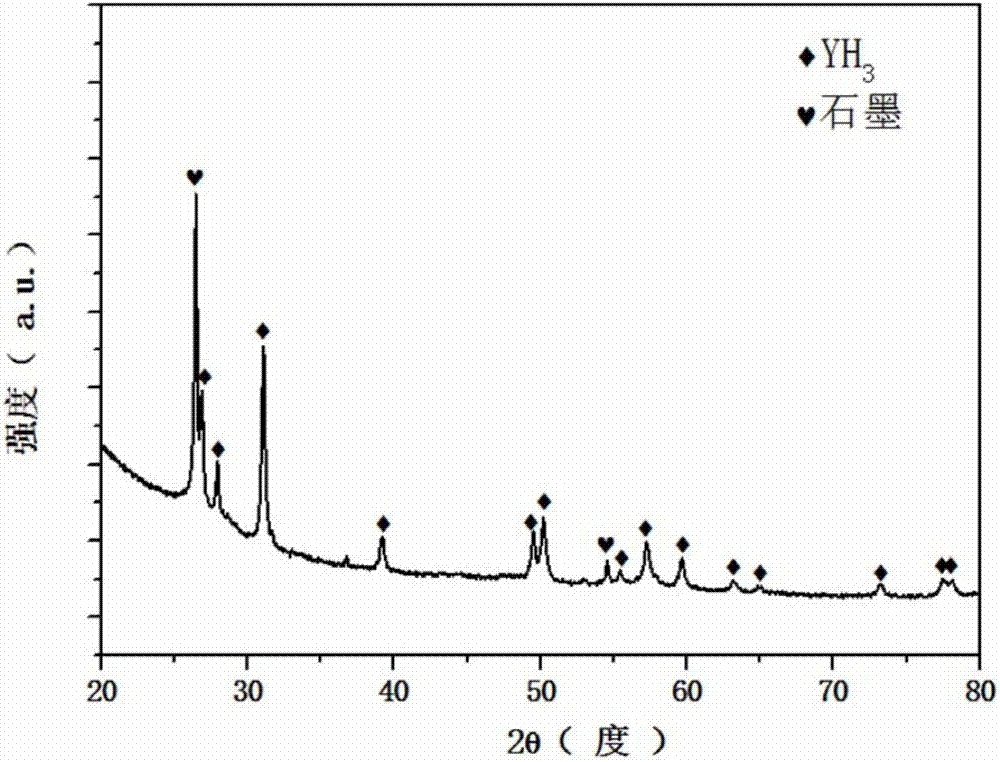

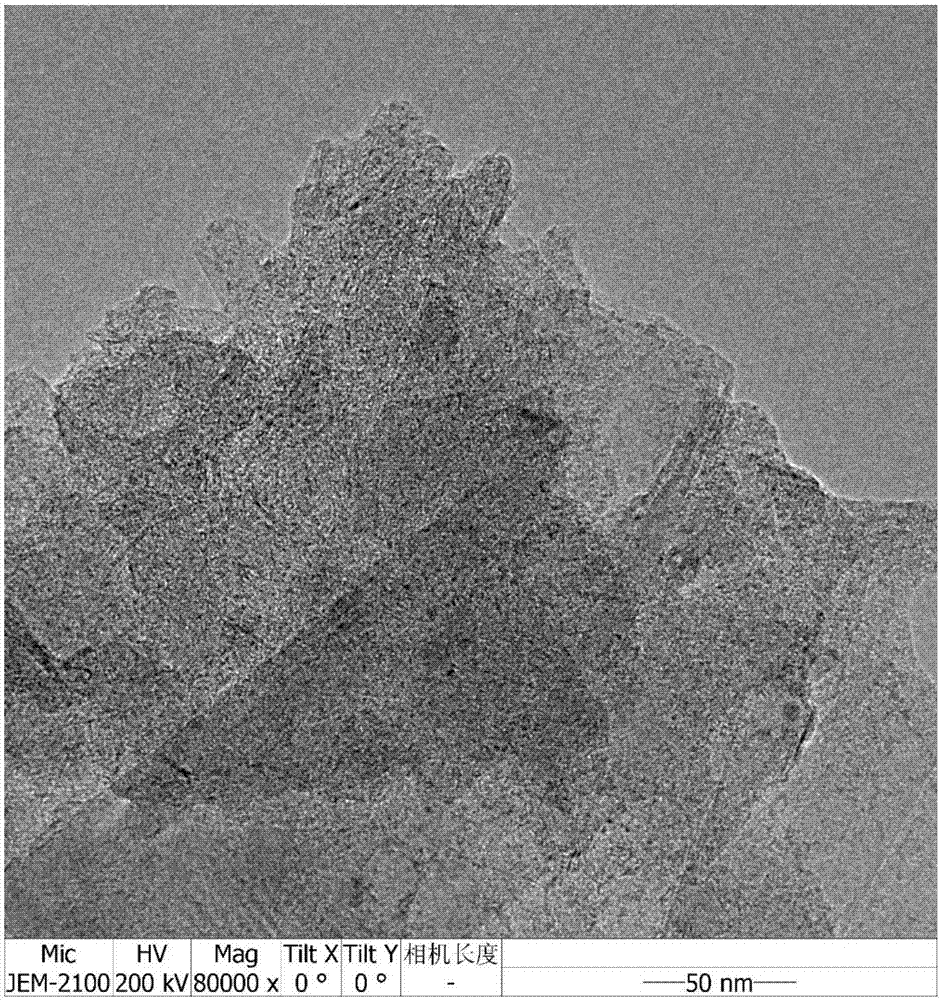

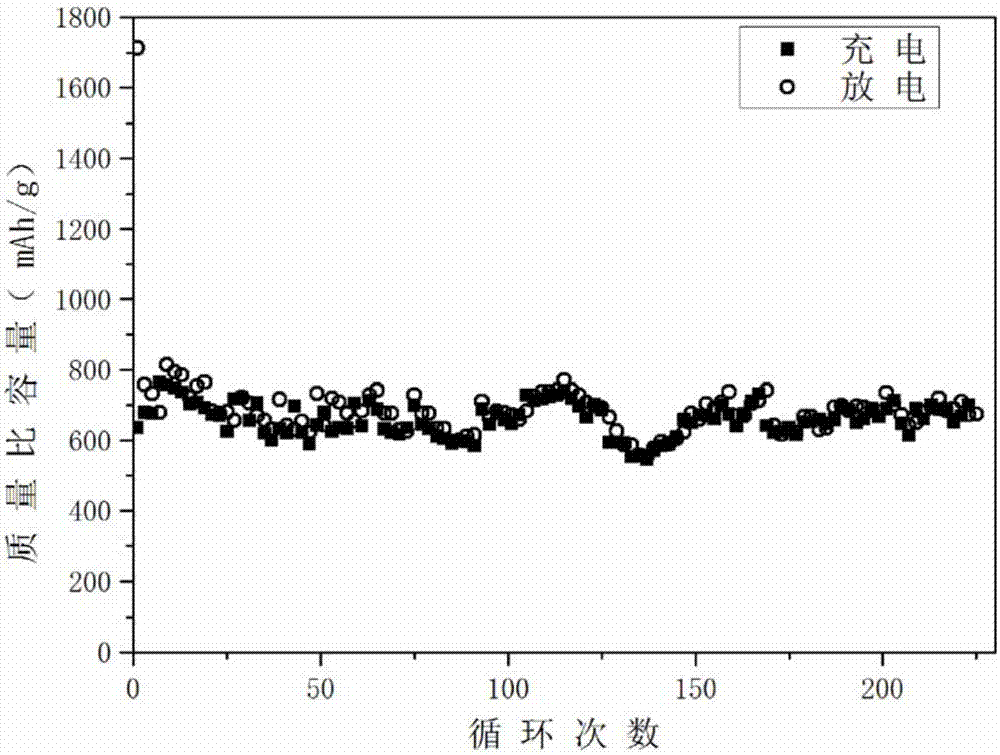

Rare earth hydride-carbon nano composite material and preparation method and application thereof

ActiveCN106941155AHigh purityWell mixedMaterial nanotechnologyCell electrodesLithiumRoom temperature

The present invention provides a rare earth hydride-carbon nano composite material and a preparation method and application thereof, a rare earth hydride is prepared by high temperature and high pressure, and the rare earth hydride and a carbon material are uniformly mixed in a certain proportion at room temperature by low rotation speed ball milling. The method is simple and quick, high in yield, low in cost, easy to enlarge, the reaction product is mixed evenly, particle size is small, purity is high, and the reaction product has a specific synergistic effect and has high lithium storage specific capacity. The rare earth hydride-carbon nano composite material has remarkable advantages, and has great industrial application prospects.

Owner:PEKING UNIV

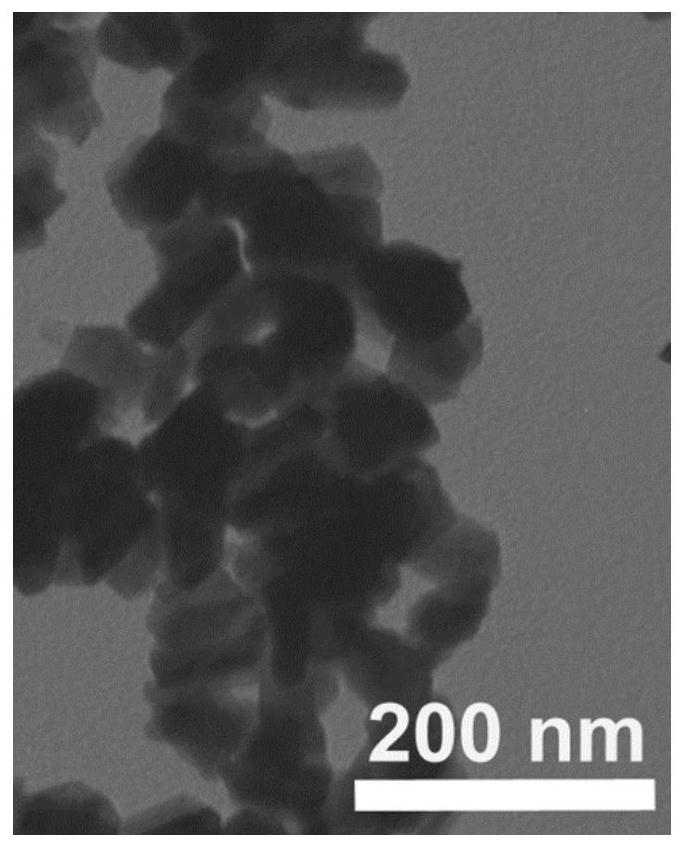

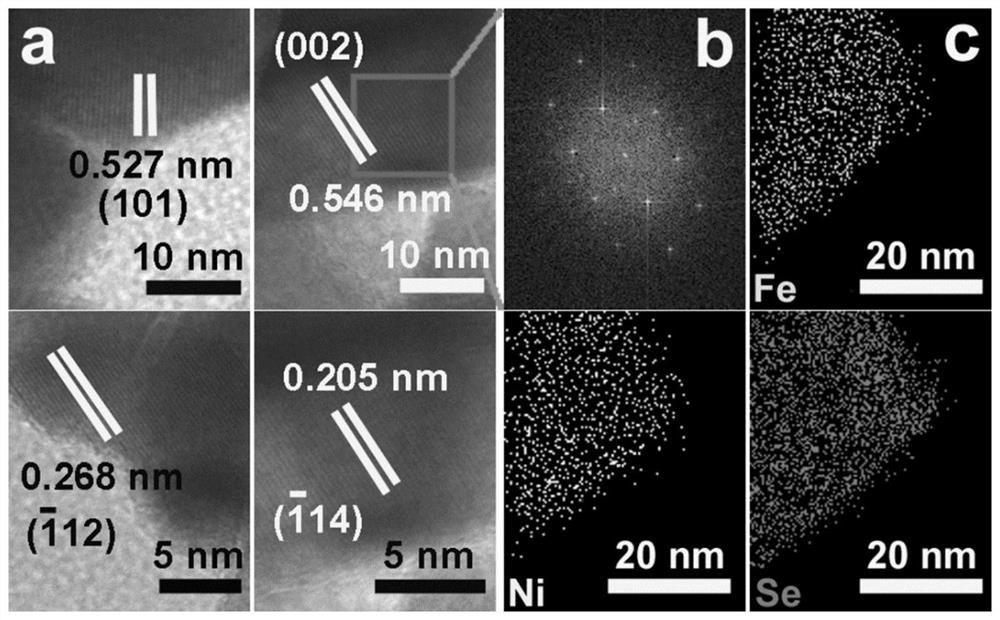

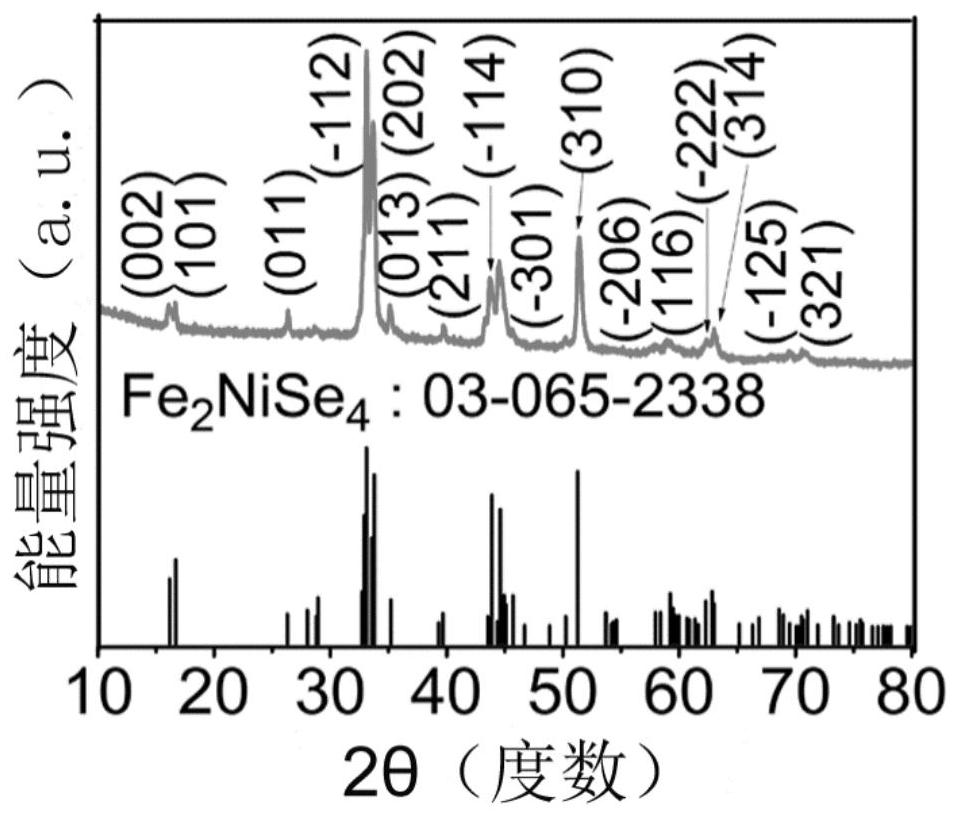

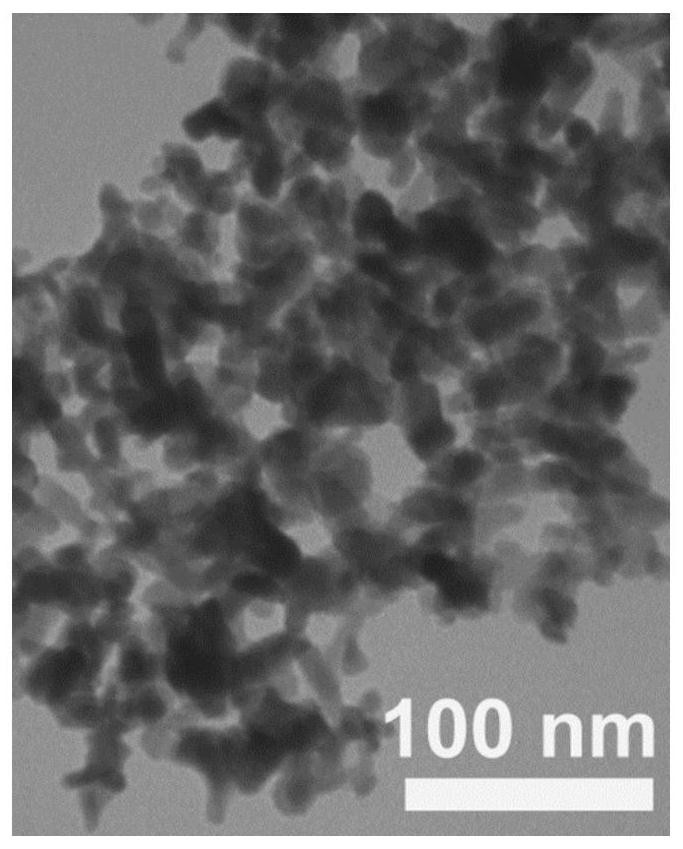

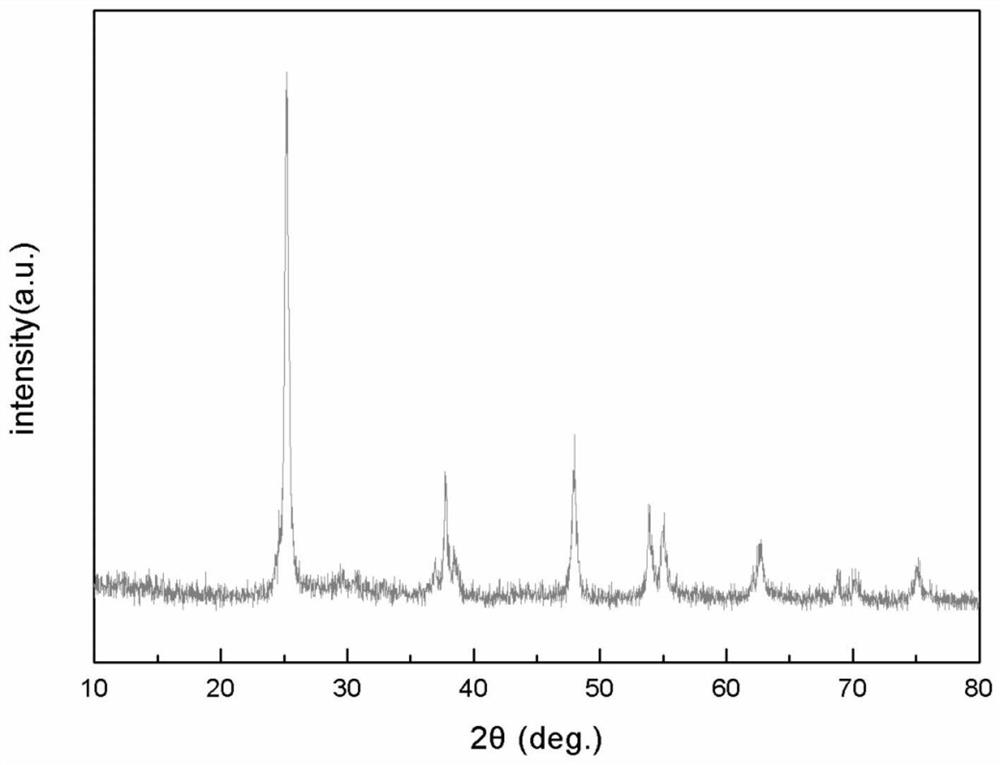

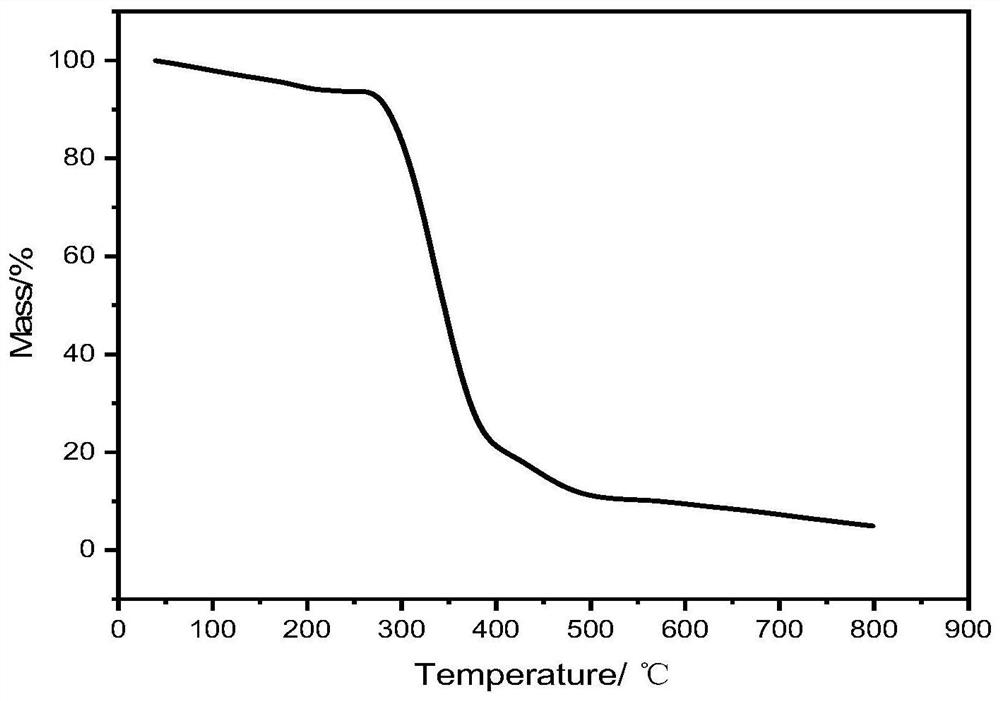

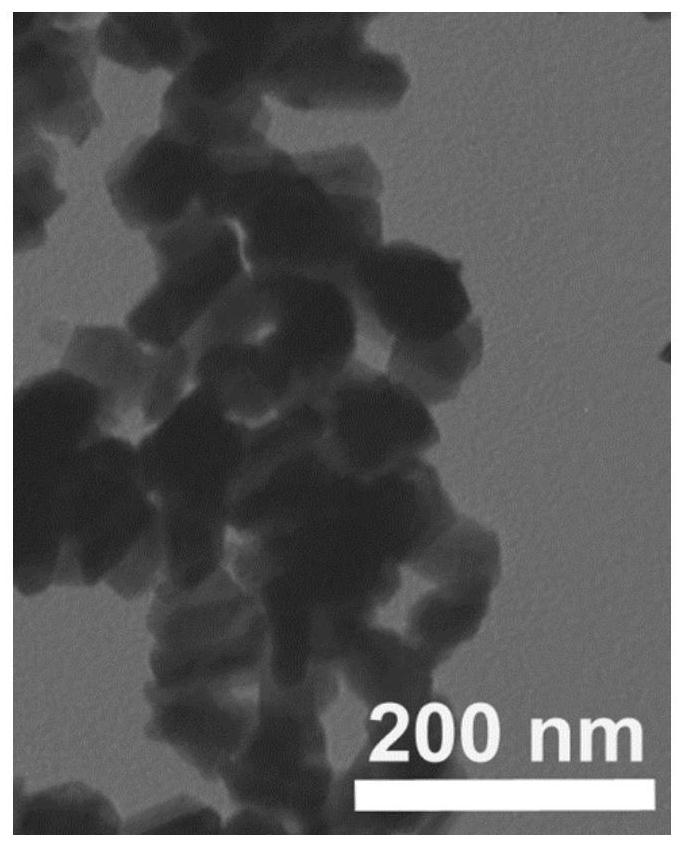

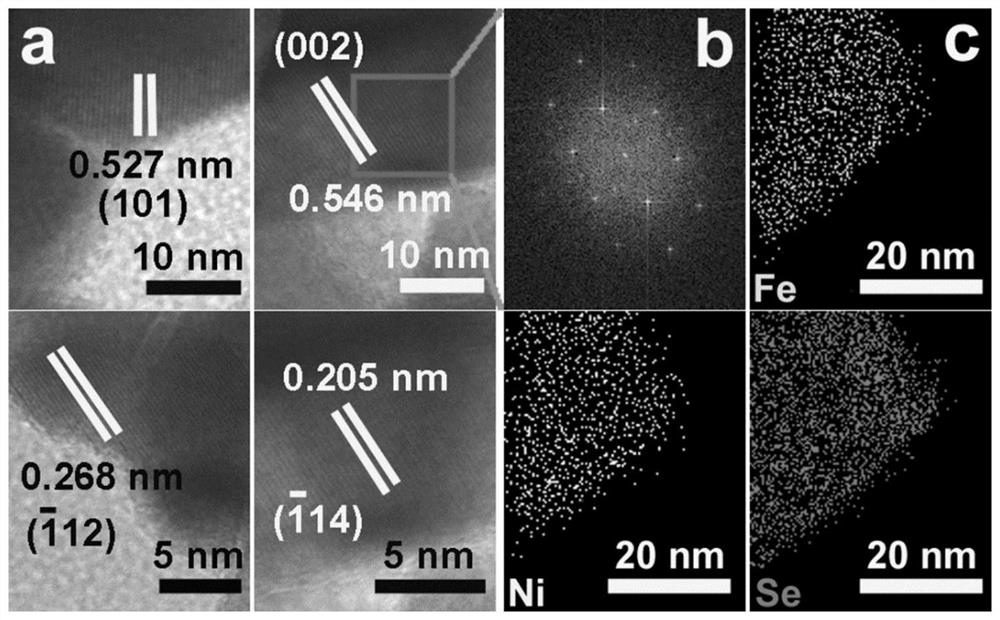

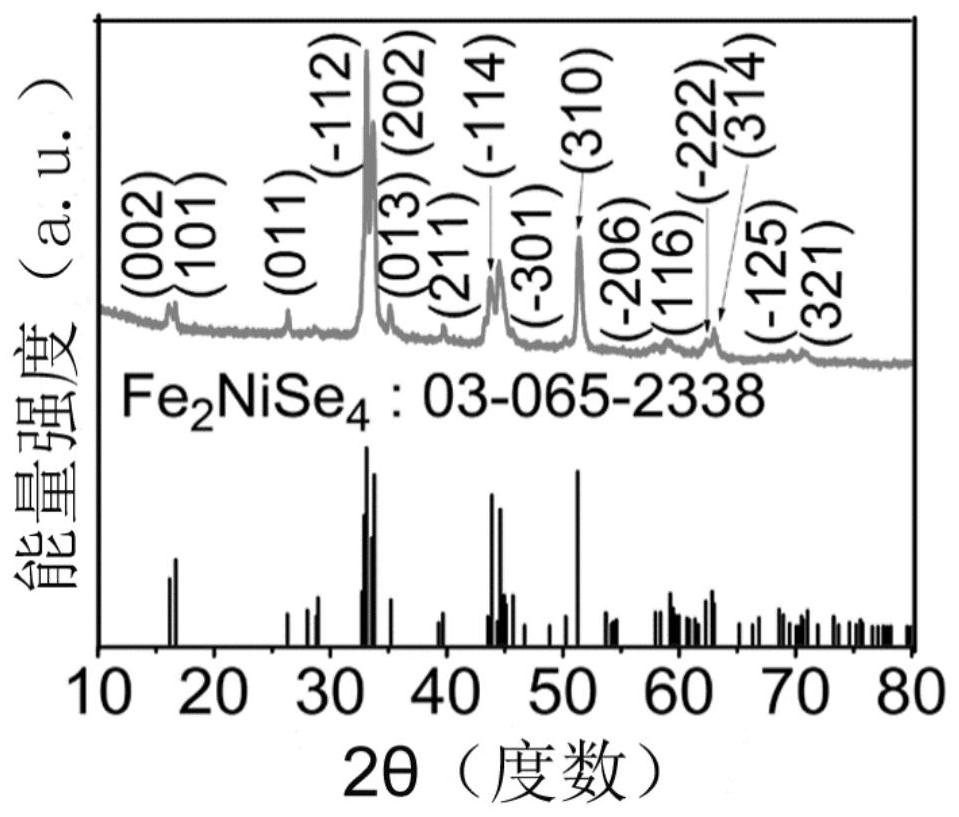

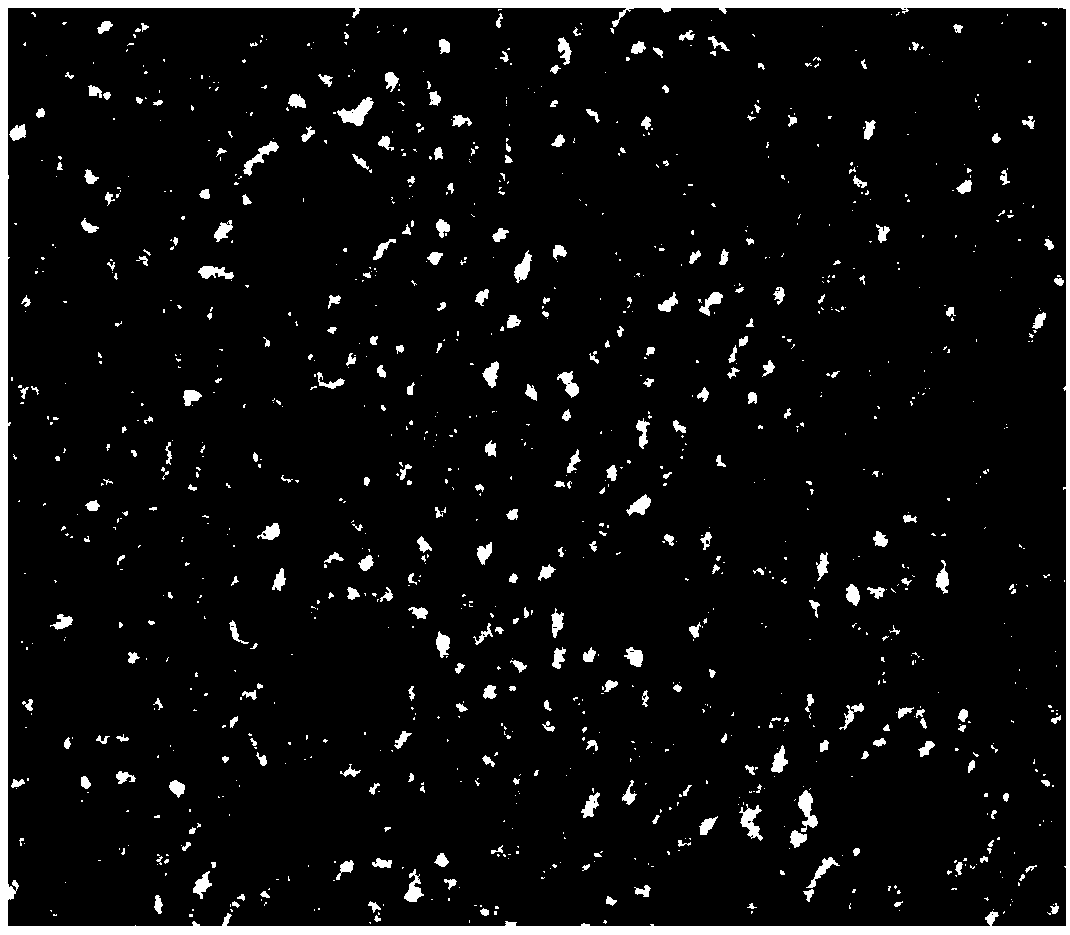

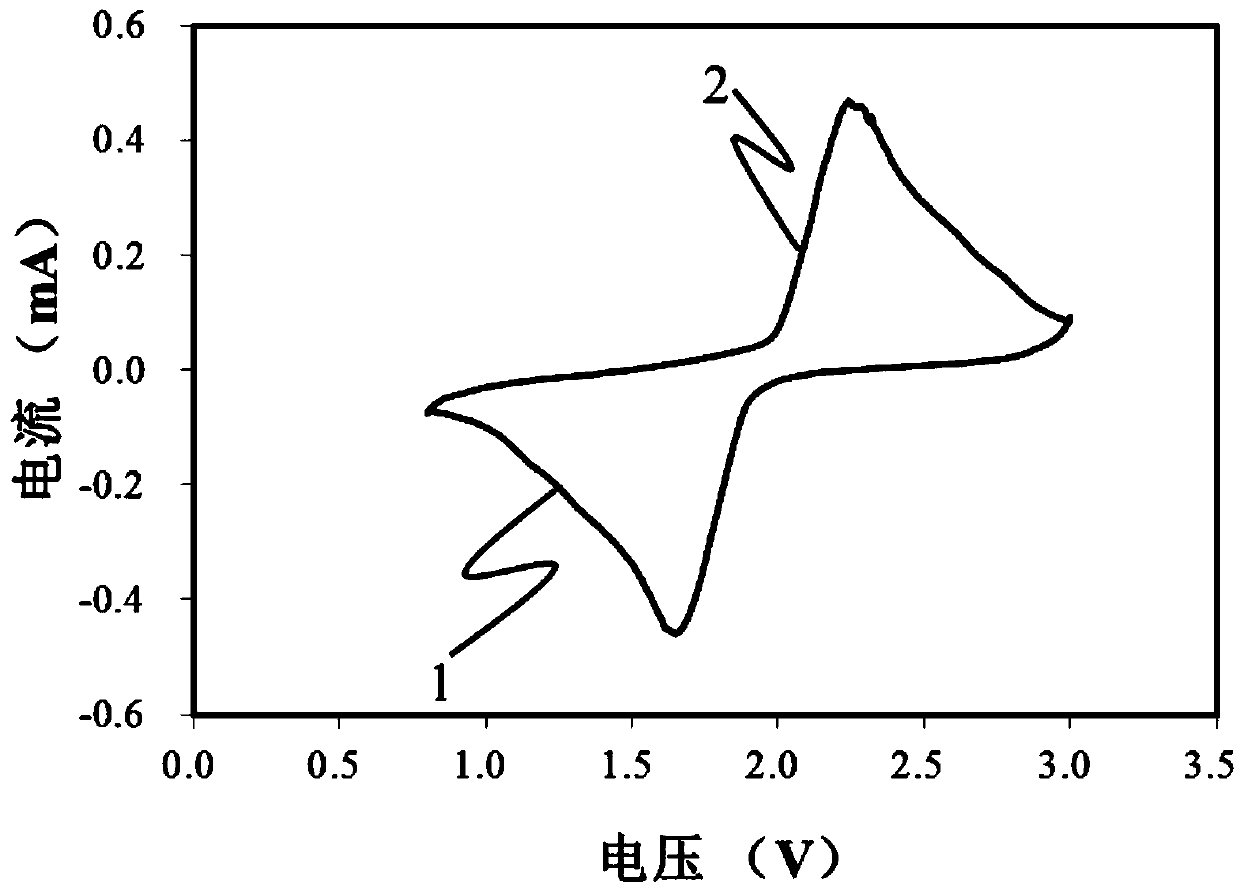

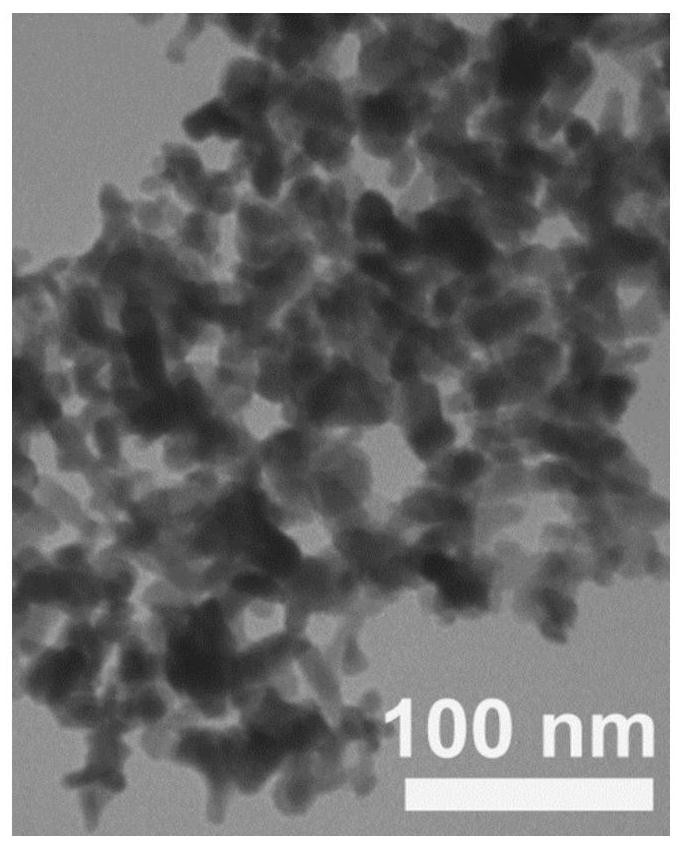

Iron-nickel bimetal selenide nanomaterial and preparation method thereof, and lithium ion battery

ActiveCN111924809AHigh crystallinityEasy to operateMaterial nanotechnologyCell electrodesPhysical chemistryLithium-ion battery

The invention provides an iron-nickel bimetal selenide nanomaterial and a preparation method thereof, and a lithium ion battery. The preparation method of the iron-nickel double-metal selenide nanomaterial provided by the invention comprises the step of carrying out a heating reaction on ferric acetylacetonate, nickel acetylacetonate and dibenzyl diselenide in a solvent to form the Fe2NiSe4 nanomaterial. According to the method, specific precursor sources, namely ferric acetylacetonate, nickel acetylacetonate and dibenzyl diselenide, are adopted and subjectecd to a reaction in a solvent system, so the Fe2NiSe4 nanomaterial can be directly synthesized in one step; and thus, operation is greatly simplified, and the crystallinity and purity of the Fe2NiSe4 nanomaterial can be effectively improved. When the Fe2NiSe4 nanomaterial prepared by the method is used as a negative electrode material of the lithium ion battery, the specific lithium storage capacity, the rate capability and the cycle performance of the battery can be improved.

Owner:UNIV OF SCI & TECH OF CHINA

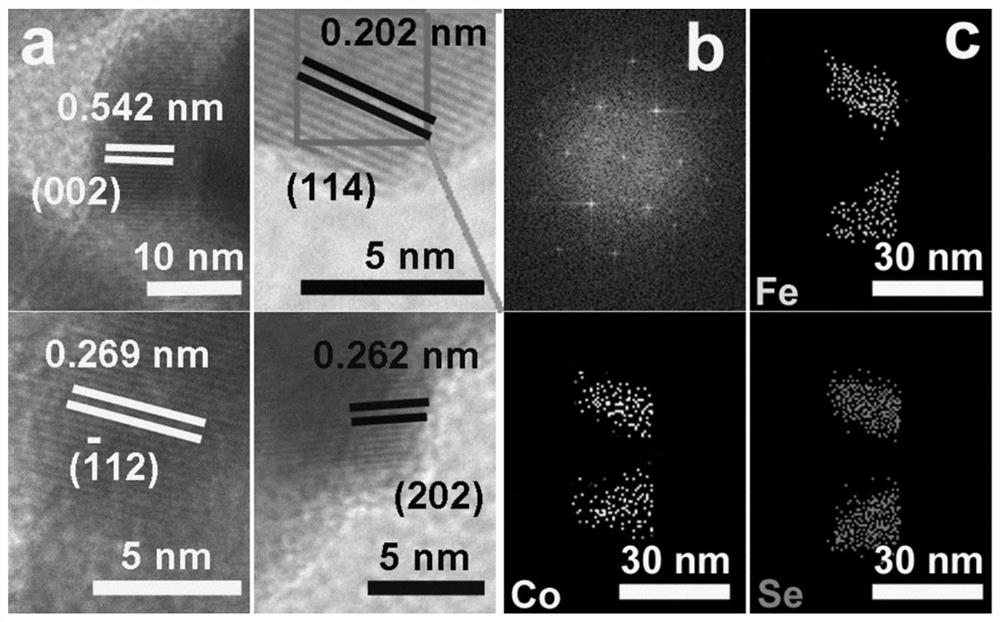

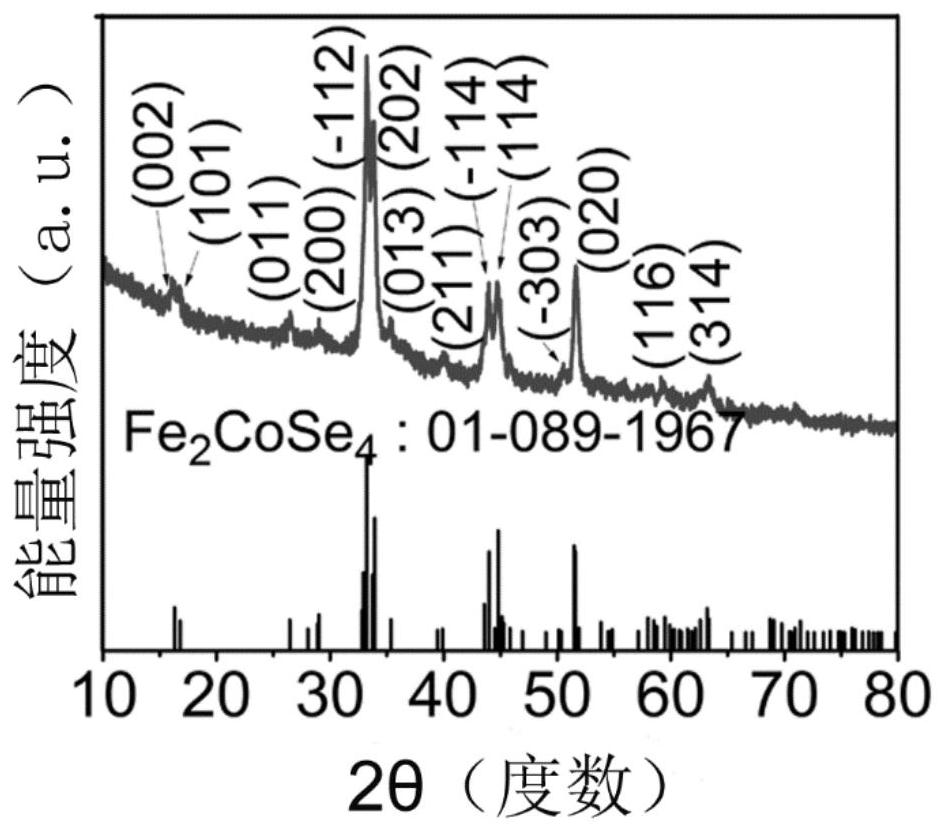

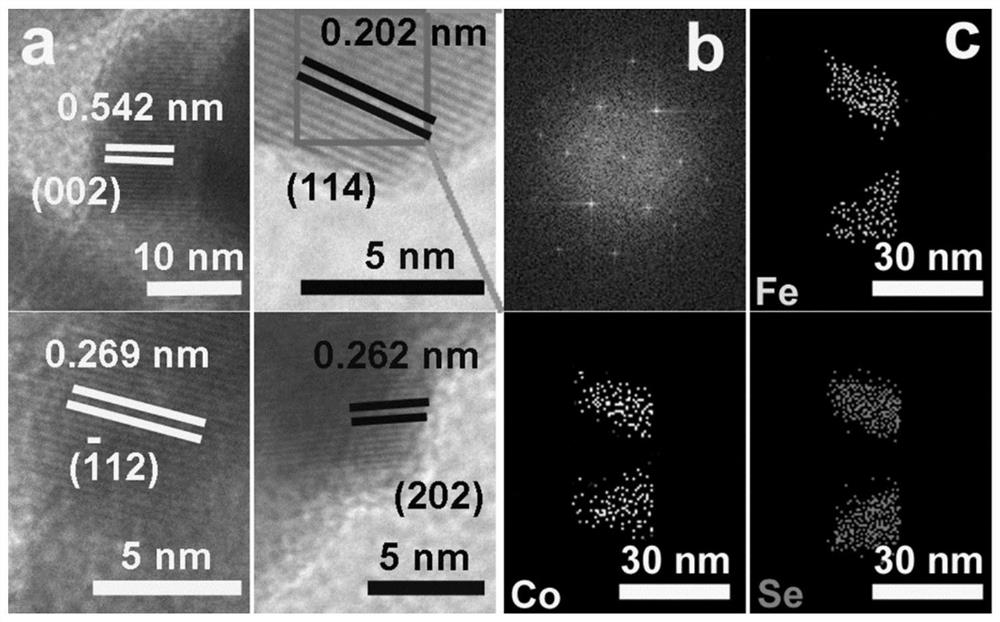

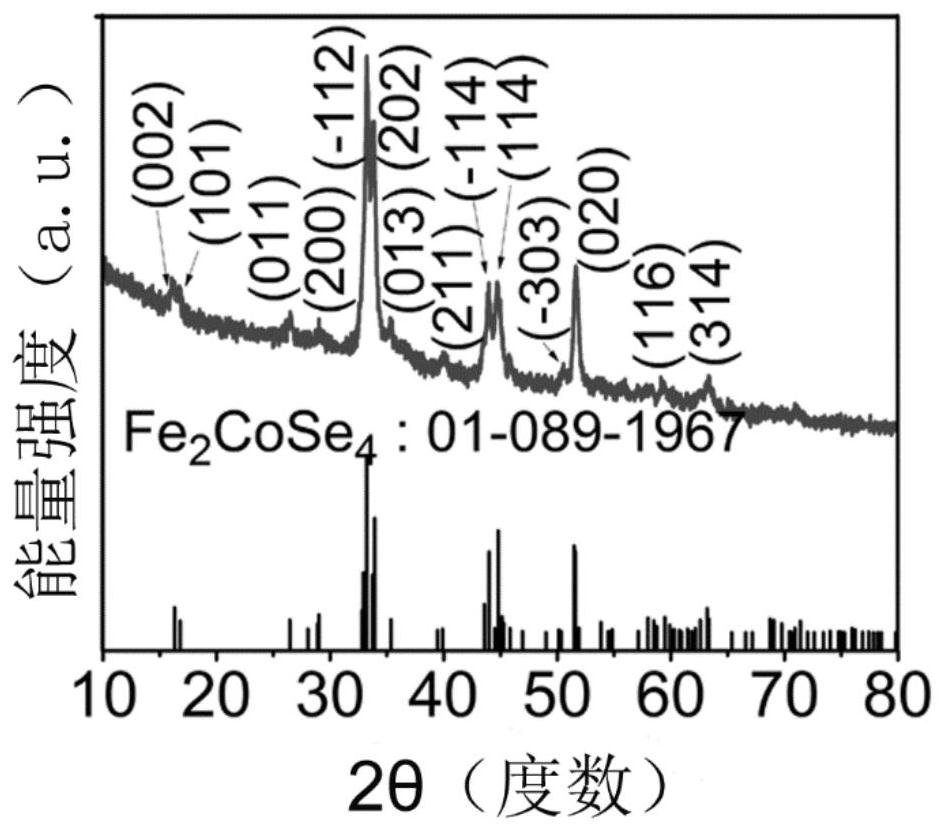

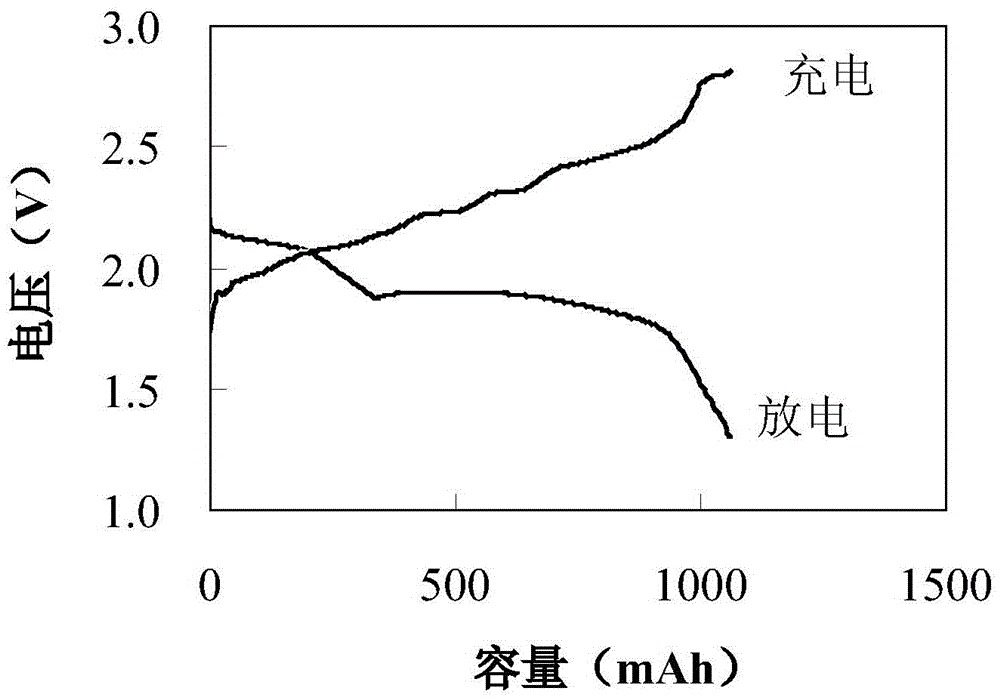

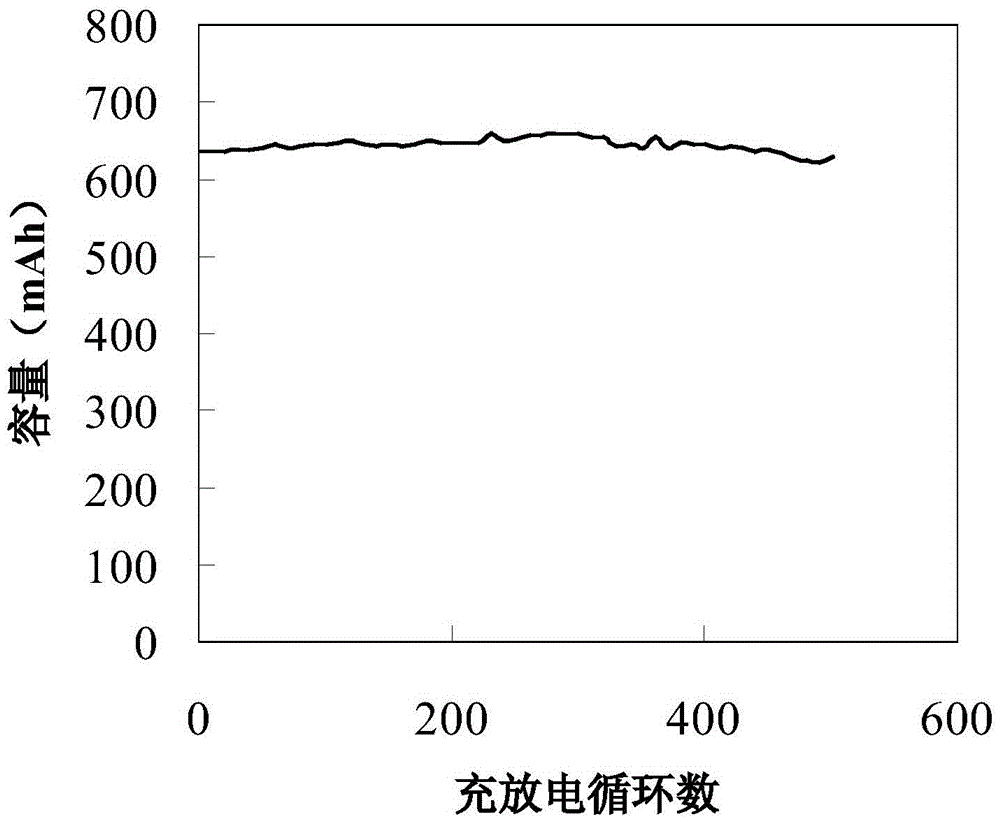

Iron-cobalt bimetal selenide nanomaterial and preparation method thereof, and lithium ion battery

ActiveCN111924810AHigh crystallinityHigh purityMaterial nanotechnologyCell electrodesPhysical chemistryLithium-ion battery

The invention provides an iron-cobalt bimetal selenide nanomaterial and a preparation method thereof, and a lithium ion battery. The preparation method of the iron-cobalt double-metal selenide nanomaterial comprises the following step: carrying out a heating reaction on ferric acetylacetonate, cobalt acetylacetonate and dibenzyl diselenide in a solvent to form the Fe2CoSe4 nanomaterial. Accordingto the method, specific ferric acetylacetonate, nickel acetylacetonate and dibenzyl diselenide are used as precursor sources and undergo a reaction in a solvent system, so the Fe2CoSe4 nanomaterial can be directly synthesized in one step; and thus, operation is greatly simplified, and the crystallinity and purity of the Fe2CoSe4 nanomaterial can be effectively improved. When the Fe2CoSe4 nanomaterial prepared by the method is used as a negative electrode material of the lithium ion battery, the specific lithium storage capacity, the rate capability and the cycle performance of the battery canbe improved.

Owner:UNIV OF SCI & TECH OF CHINA

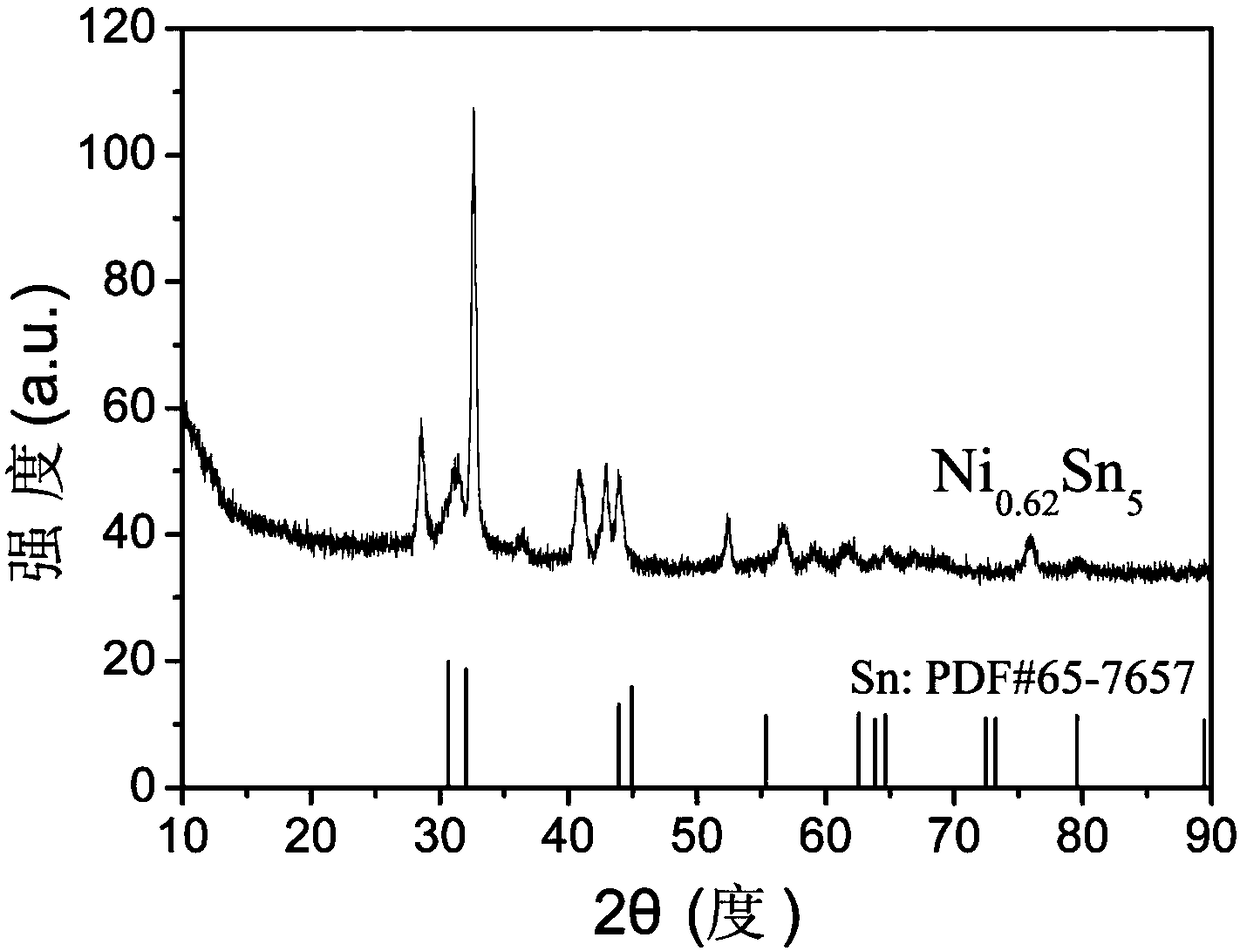

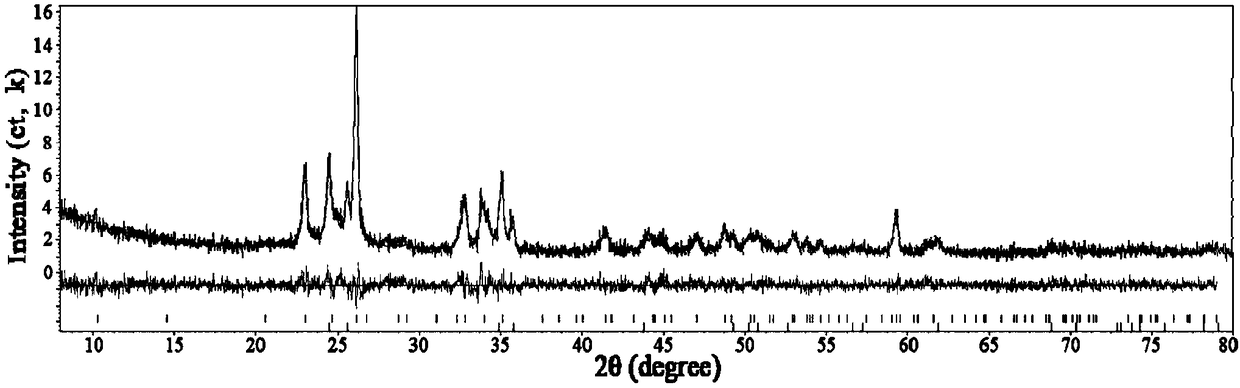

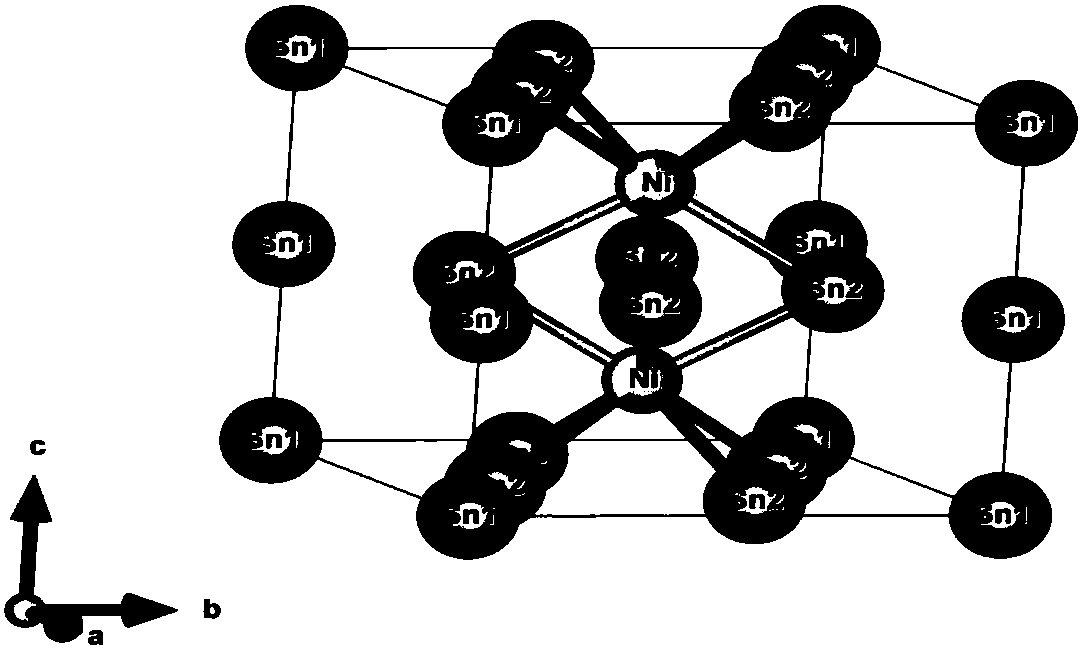

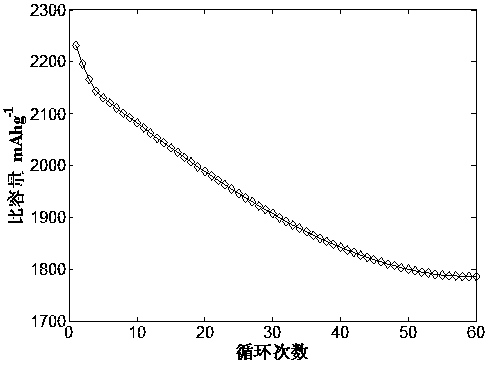

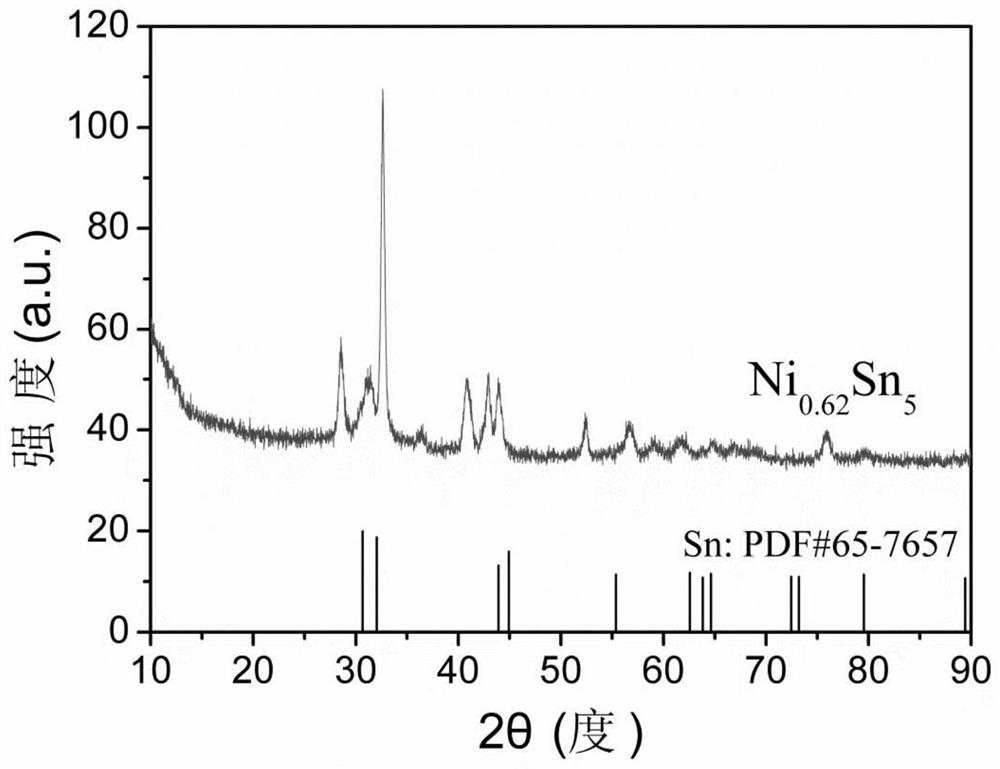

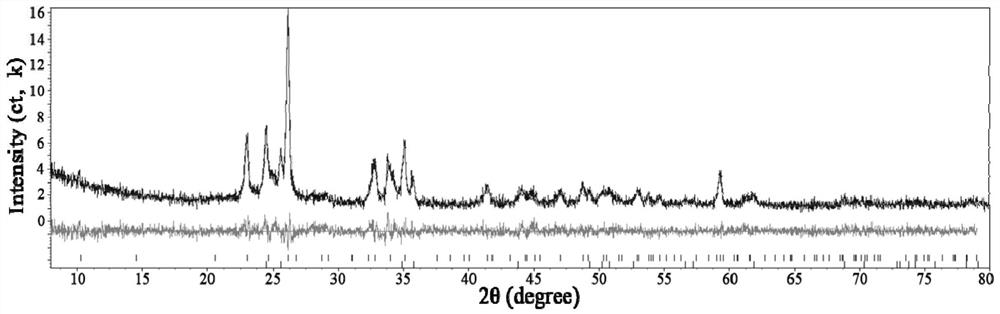

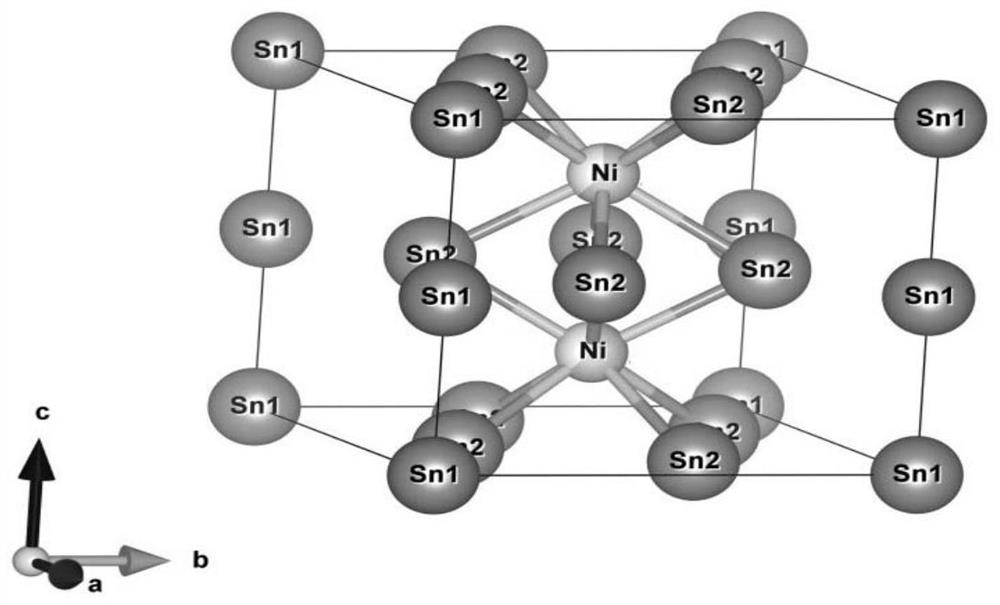

Metastable-state tin-based alloy material and preparation method thereof

ActiveCN108172774AExtended Phase DiagramImprove cycle stabilityCell electrodesSecondary cellsLithiumAlloy

The invention discloses a metastable-state tin-based alloy material and a preparation method thereof. The material mainly comprises two metal elements of Sn and Ni and also possibly comprises elementssuch as Fe, and Co, the metastable-state tin-based alloy material with a main phase being MSn5 is formed, and M is Ni, Fe<0.5>Ni<0.5> and Co<0.5>Ni<0.5>. By introducing a crystal seed during the synthesis process, a tin-based alloy new phase taking tin and nickel as main and difficult to synthesize by a traditional method is induced to be formed, and the method provides a new method and idea forsynthesis of other metastable-state materials particularly the metastable-state tin-based alloy material. The MSn5 alloy material can be used as a lithium / sodium ion battery active negative electrodematerial, Sn agglomeration can be suppressed due to the existence of non-active M metal, and the cycle stability of the material is improved.

Owner:ZHEJIANG UNIV

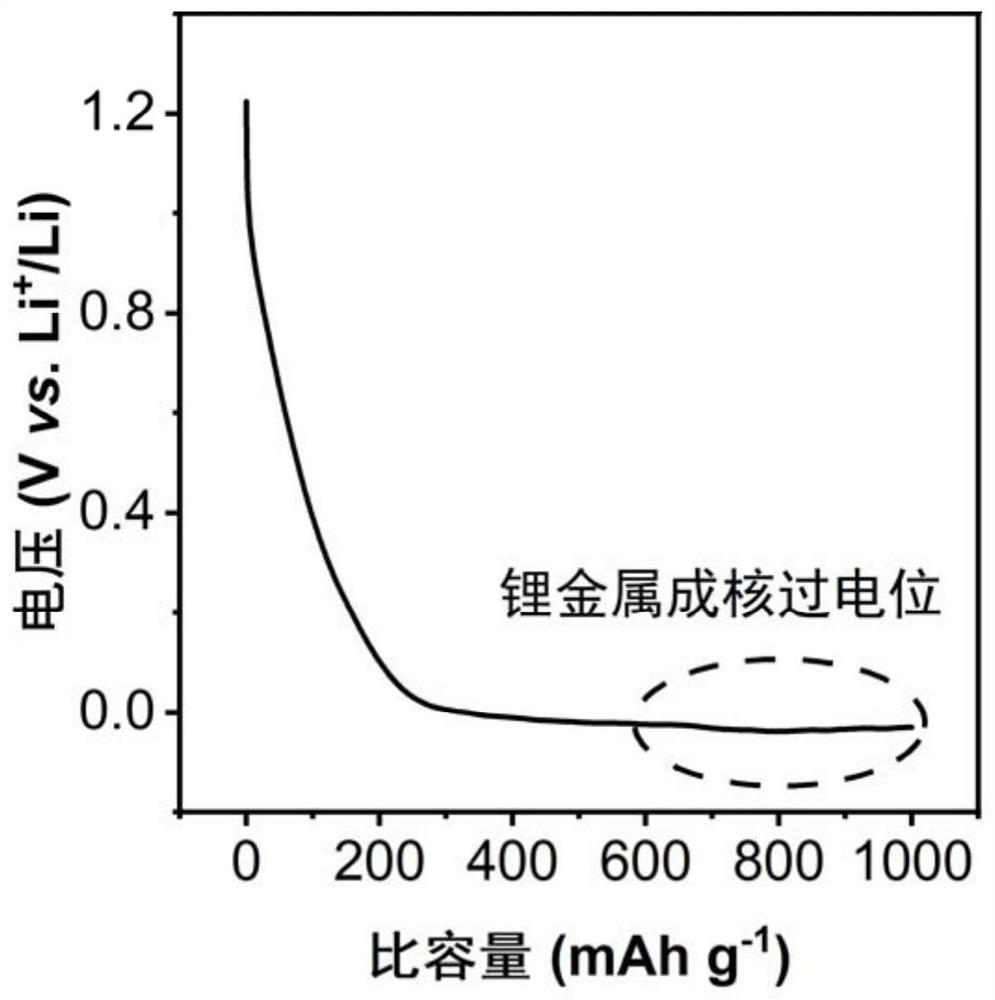

Preparation method and application of amorphous carbon-based composite negative electrode material containing metalloid lithium

ActiveCN113903891AImprove conductivityImprove cycle stabilitySecondary cellsNegative electrodesMetallic lithiumElectrolytic agent

The invention provides a preparation method and application of an amorphous carbon-based composite negative electrode material containing metalloid lithium. An amorphous carbon electrode is prepared from amorphous carbon, a binder and a conductive agent, the amorphous carbon electrode is used as a negative electrode, and lithiation is performed on the amorphous carbon negative electrode, so that the amorphous carbon-based composite negative electrode material is obtained, and the amorphous carbon-based composite negative electrode material contains metalloid lithium. The amorphous carbon-based composite negative electrode disclosed by the invention is used as the negative electrode of an energy storage battery and has excellent conductivity, and nano-scale pores formed by disordered carbon in the amorphous carbon-based composite negative electrode provide a special confinement space for the reversible storage of metalloid lithium, so that the reaction of an electrolyte and metal lithium can be effectively reduced, and the cycling stability of the negative electrode is remarkably improved.

Owner:BEIJING UNIV OF CHEM TECH

A kind of lithium battery sico-si gradient thin film electrode system and preparation method

ActiveCN104993115BHigh bonding strengthBuffer volume expansionCell electrodesLi-accumulatorsNanotopographyMechanical property

The invention discloses a lithium battery SiCO-Si gradient thin film electrode system. The system comprises a monocrystalline silicon substrate, wherein the monocrystalline silicon substrate is provided with a TiN barrier layer, an Al thin film layer, a SiAlCO thin film layer, a SiCO thin film layer, a SiO[1 / 3] thin film layer and a Si thin film layer from bottom to top in sequence. According to the system, by combining the two potential negative electrode materials, namely SiCO and silicon, through gradient design of specific capacity and mechanical property, the advantages of the two materials are comprehensively realized, and the disadvantages of the two materials are complemented. The thin film system prepared with the magnetic control sputtering method and target materials such as silicon, aluminum and graphite has the advantages of being high in adhesiveness, low in cost, controllable in constituent, low in temperature and the like. Through nanocrystallization of the SiCO surface, lithium diffusion and interface bonding strength are further improved, and the novel thin film electrode system with excellent electrochemical property and interface mechanical property is obtained finally. Furthermore, the method for preparing the SiCO nanometer surface with the chemical corrosion method has the advantages that the process is simple and quick, no expensive instrument is needed, raw materials are rich and cheap, and nanotopography is controllable.

Owner:WENZHOU UNIVERSITY

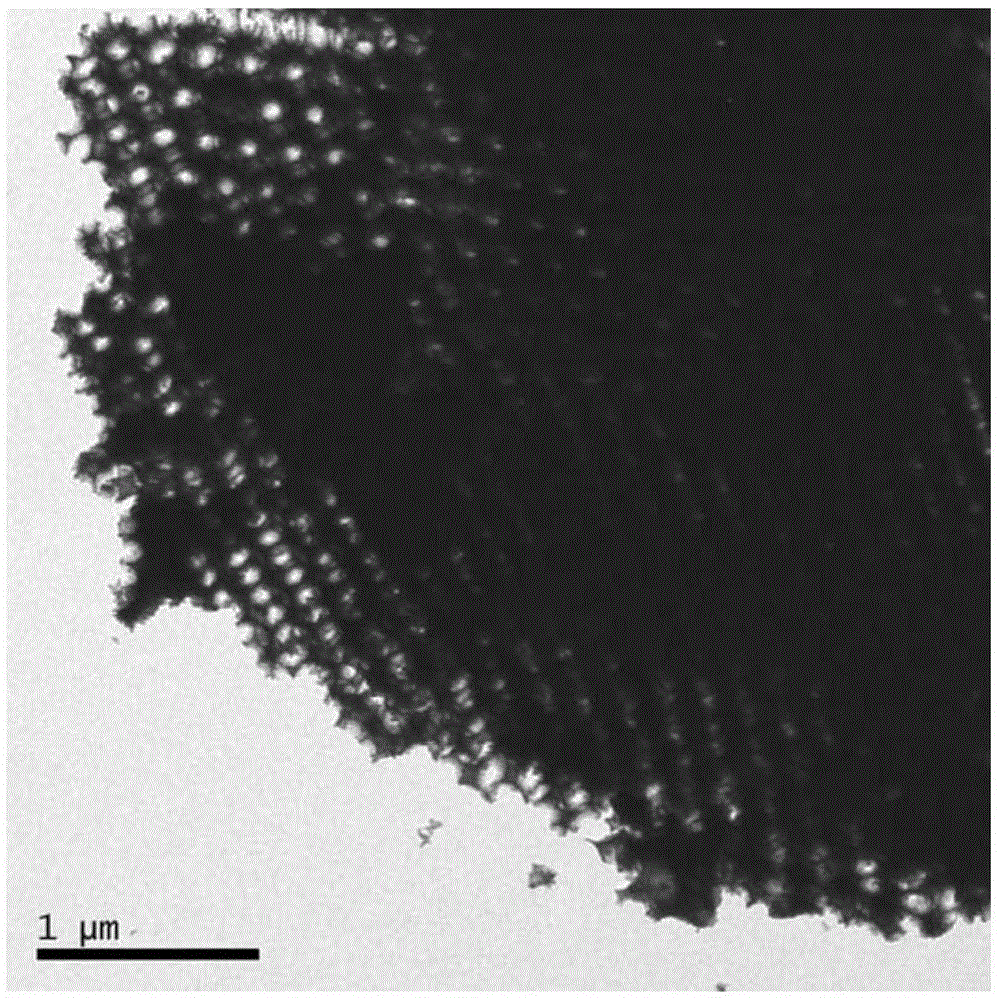

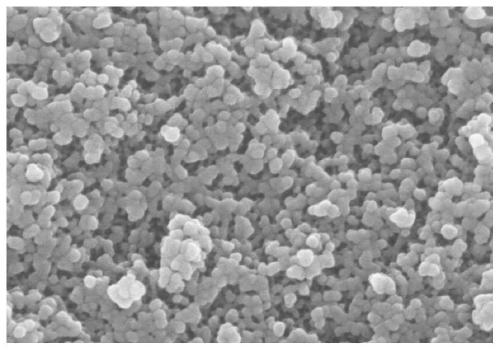

Ordered macroporous titanium dioxide and preparation method thereof

InactiveCN105304886AEasily hydrolyzedAvoid hydrolysisCell electrodesSecondary cellsCarboxylic acidSolvent

The invention relates to the technical field of electrochemical materials, in particular to a preparation method for an ordered macroporous titanium dioxide, which includes the following steps: titanium halide and hydrolytic titanate are respectively added into absolute ethanol and uniformly agitated, so that titanium dioxide precursor solvent is obtained; carboxylic acid type polystyrene spheres are dispersed into absolute ethanol, so that carboxylic acid type polystyrene sphere suspension is obtained; the titanium dioxide precursor solvent and the carboxylic acid type polystyrene sphere suspension are mixed together and dried in an oven, so that titanium dioxide precursor is obtained, the titanium dioxide precursor is calcined under high temperature, and thereby the ordered macroporous titanium dioxide is obtained. The template method is adopted by the preparation method, the process conditions are simple and easy to control, operability is high, and repeatability is good; the produced product has an ordered macroporous structure, which enlarges the specific surface area of the titanium dioxide and is favorable for the increase of the specific lithium storage capacity of the product and the permeation of electrolyte, consequently, the electronic conductivity of the ordered macroporous titanium dioxide used as a lithium ion electrode material is increased, and moreover, safety is high.

Owner:MCNAIR TECH +1

Preparation method of lithium-ion type perfluorosulfonic acid resin coated aluminum-lithium alloy material

InactiveCN104157864BImprove securityEvenly filledCell electrodesSecondary cellsOxidation resistantSodium-ion battery

The invention relates to the technical field of a lithium ion battery, and aims at providing a preparation method of a lithium-ion perfluorinated sulfonic acid resin cladding aluminum-lithium alloy material. The preparation method comprises the following steps: preparing a tetrahydrofuran solution of lithium aluminum hydride, preparing a macroporous carbon material, adding the macroporous carbon material to the tetrahydrofuran solution of the lithium aluminum hydride to prepare a macroporous carbon supported lithium aluminum hydride composite material and further to obtain a macroporous carbon supported aluminum-lithium composite material; preparing a Li<+> perfluorinated sulfonic acid resin solution, and preparing the macroporous carbon supported Li<+> perfluorinated sulfonic acid resin cladding aluminum-lithium alloy composite material by virtue of the Li<+> perfluorinated sulfonic acid resin solution and the macroporous carbon supported aluminum-lithium composite material. The prepared lithium-ion perfluorinated sulfonic acid resin cladding aluminum-lithium alloy material has the advantages that organic electrolyte is safer when being applied to the battery; the electrode reaction reversibility is good; the chemical stability and thermal stability are good; the price is low, and easiness in preparation can be realized; no pollution is caused; safety of the lithium ion battery can be improved by virtue of oxidation resistance.

Owner:ZHEJIANG UNIV

A kind of ordered macroporous titanium dioxide and its preparation method

InactiveCN105304886BLarge specific surface areaIncrease the specific capacity of lithium storageCell electrodesSecondary cellsElectrolytic agentEngineering

Owner:MCNAIR TECH +1

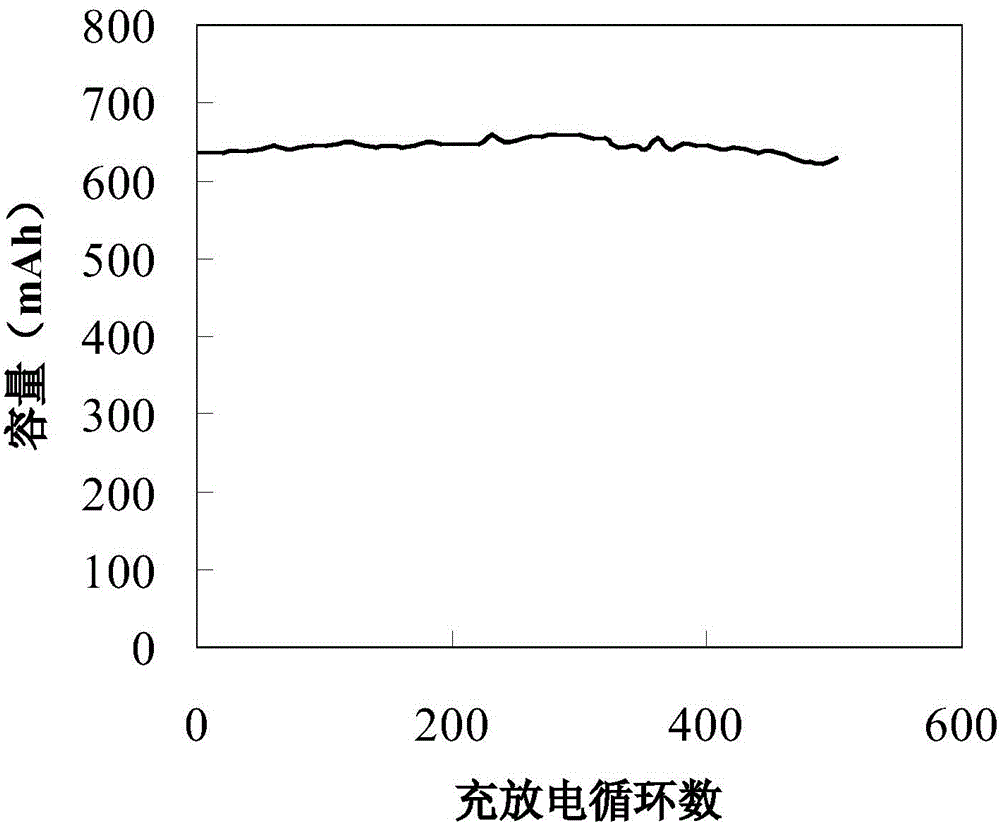

A carbon-wrapped titanium dioxide airgel lithium-ion battery negative electrode material and preparation method thereof

InactiveCN108155356BImprove performanceImprove electrochemical activityMaterial nanotechnologyCell electrodesSupercritical dryingOrganosolv

The invention relates to a preparation method of a carbon-coated titanium dioxide aerogel lithium ion battery anode material and belongs to the fields of nano material preparation and electrochemicalmaterials. The preparation method comprises the following steps: mixing a titanium source, a hydrochloric acid water solution and absolute ethanol according to a certain mol ratio to obtain a first reaction solution; mixing the first reaction solution with a certain amount of a hydrous ethanol solution, and allowing the mixed solution to stand and age to obtain xerogel; mixing an organic carbon precursor and an organic solvent according to a certain mol ratio to obtain a second reaction solution; mixing and heating the obtained xerogel and the second reaction solution, and after reaction ends,performing supercritical drying with carbon dioxide to obtain organic compound titanium dioxide aerogel; and performing high-temperature heat treatment on the aerogel under an inert gas condition toobtain the carbon-coated titanium dioxide aerogel. The carbon-coated titanium dioxide aerogel prepared by the preparation method still maintains high specific capacity of 133mAh / g after 3000 times ofcirculation under 10C high current density, and the carbon-coated titanium dioxide aerogel can serve as a high-performance lithium ion battery anode material.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

Preparation method of lithium titanate with special morphology

Owner:HUNAN ZOOMWE NEW ENERGY TECH CO LTD

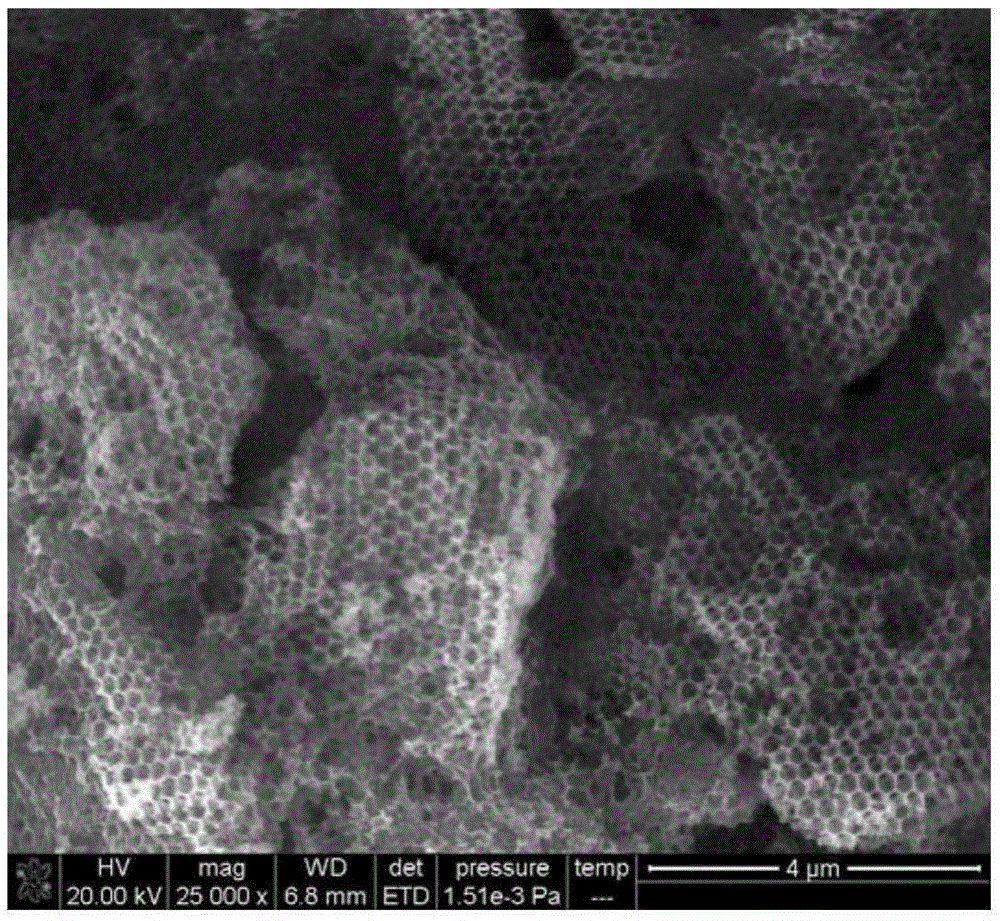

Preparation method and application of a kind of cobalt trioxide nano hollow sphere inlaid carbon flake-like composite material

InactiveCN106058174BImprove conductivityPromote circulationMaterial nanotechnologyCell electrodesNew energyCoupling

The invention relates to a preparation method and application of a flower-shaped composite material formed by carbon plates in which cobaltosic oxide is embedded in a hollow nano sphere mode, and belongs to the technical field of a novel functional material and new energy. By use of the flower-shaped composite material fusing a cobaltosic oxide nano hollow structure with a carbon plate structure, organic coupling of multiple levels of structures is achieved, and the preparation method is simple and reliable. A carbon plate not only improves electrical conductivity of the composite material, but also plays a part in fixing hollow cobaltosic oxide nano spheres as a matrix. As a lithium ion cathode material, the carbon plate structure greatly shortens a transmission distance of the electrolyte and lithium ions, and the cobaltosic oxide hollow structure is beneficial for improving of lithium storage specific capacity and buffering of volume expansion of the oxide in the charging and discharging process, and thus, as a lithium ion battery cathode material, the composite material is helpful in developing a lithium ion battery with high specific capacity and excellent cycle performance. The invention provides a good design strategy for preparing the high-performance lithium ion battery cathode material.

Owner:DALIAN UNIV OF TECH

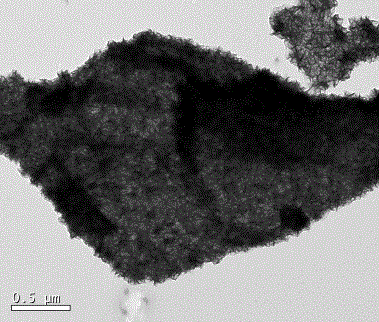

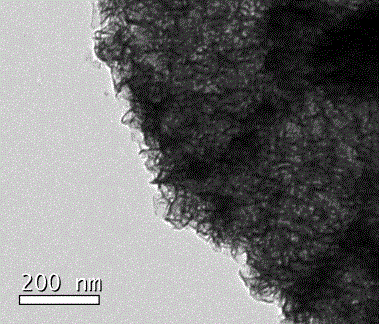

Nano titanium dioxide/graphene negative electrode material and preparation method thereof

ActiveCN113675384AIncrease the specific capacity of lithium storageExcellent electronic conductivityMaterial nanotechnologySecondary cellsFluoboric acidGraphite oxide

The invention discloses a nano titanium dioxide / graphene negative electrode material and a preparation method thereof, and belongs to the field of electrochemical materials. According to the preparation method of the nano titanium dioxide / graphene negative electrode material, titanium dioxide with nano morphology is generated on graphene oxide through in-situ assembly of a hydrothermal method, meanwhile, dominant crystal faces are selectively generated by titanium dioxide through addition of fluoroborate, the particle size morphology of titanium dioxide in the prepared material composition is effectively limited, the prepared material is uniformly dispersed and free of agglomeration, the contact resistance is reduced, and the permeation of electrolyte is facilitated, and a final product has high capacity and excellent rate discharge performance; and the preparation method is simple to operate and high in repeatability. The invention also discloses the nano titanium dioxide / graphene negative electrode material prepared by the method and a lithium ion battery further prepared from the nano titanium dioxide / graphene negative electrode material.

Owner:广州明美新能源股份有限公司

A kind of iron-nickel double metal selenide nanomaterial, its preparation method and lithium ion battery

ActiveCN111924809BHigh crystallinityEasy to operateMaterial nanotechnologyCell electrodesPhysical chemistryLithium-ion battery

The invention provides an iron-nickel double metal selenide nanometer material, a preparation method thereof and a lithium ion battery. The preparation method of the iron-nickel double metal selenide nanomaterial provided by the invention comprises: heating and reacting iron acetylacetonate, nickel acetylacetonate and dibenzyl diselenide in a solvent to form Fe 2 NiSe 4 nanomaterials. The present invention adopts specific precursor sources-iron acetylacetonate, nickel acetylacetonate and dibenzyl diselenide to react in a solvent system to directly synthesize Fe in one step. 2 NiSe 4 nanomaterials, which greatly simplifies the operation and can effectively improve the Fe 2 NiSe 4 Crystallinity and purity of nanomaterials. Fe obtained by the present invention 2 NiSe 4 Nanomaterials are used as anode materials for lithium-ion batteries, which can improve the lithium storage specific capacity, rate performance and cycle performance of the battery.

Owner:UNIV OF SCI & TECH OF CHINA

Preparation method of gel polymer lithium ion battery

InactiveCN106784547BGood chemical stabilityIncrease the specific capacity of lithium storageCell electrodesFinal product manufactureHigh energyNitrogen gas

The invention relates to the preparation technology of a gel lithium ion battery, and aims to provide a preparation method for a gel-state polymer lithium ion battery. The preparation method comprises the steps of performing ball milling and mixing on glucose monohydrate, melamine, metaboric acid and NaCl-KCl eutectic salt, and heating the mixture in a nitrogen atmosphere for three times and then cooling to the room temperature; cleaning off salt content by deionized water and performing vacuum drying; performing mixing and grinding on obtained graphene-loaded nanometer boron and acetylene black, and Nafion-PEO co-mixed resin solution, and mixing the mixture into paste shape to coat foamed nickel; drying in the shade and pressing and shaping to obtain a negative electrode; performing arrangement on a positive electrode, a diaphragm and the negative electrode in sequence and performing pressing and shaping, and then carrying out heat treatment in a nitrogen atmosphere to obtain a film electrode, and immersing the film electrode in an electrolyte for 2h to obtain a cell; and assembling a button type gel-state polymer lithium ion battery by the cell. By adoption of the preparation method, a free-state electrolyte does not exist, so that the safety of the lithium ion battery can be remarkably improved, the electrode structural stability can be improved, high-current discharge can be promoted, and a safe and reliable high-energy power battery can be provided for an electric vehicle.

Owner:ZHEJIANG UNIV

A kind of iron-cobalt bimetallic selenide nanomaterial, its preparation method and lithium ion battery

ActiveCN111924810BHigh crystallinityEasy to operateMaterial nanotechnologyCell electrodesPhysical chemistryLithium-ion battery

The invention provides an iron-cobalt double metal selenide nanometer material, a preparation method thereof and a lithium ion battery. The preparation method of the iron-cobalt double metal selenide nanomaterial provided by the invention comprises: heating and reacting iron acetylacetonate, cobalt acetylacetonate and dibenzyl diselenide in a solvent to form Fe 2 CoSe 4 nanomaterials. The present invention uses specific iron acetylacetonate, nickel acetylacetonate and dibenzyldiselenide as precursor sources, reacts in a solvent system, and can directly synthesize Fe in one step. 2 CoSe 4 nanomaterials, which greatly simplifies the operation and can effectively improve the Fe 2 CoSe 4 Crystallinity and purity of nanomaterials. Fe obtained by the present invention 2 CoSe 4 Nanomaterials are used as anode materials for lithium-ion batteries, which can improve the lithium storage specific capacity, rate performance and cycle performance of the battery.

Owner:UNIV OF SCI & TECH OF CHINA

A kind of preparation method of lithium-sulfur battery membrane electrode

InactiveCN104157909BImprove performanceEliminates the possibility of a reactionFinal product manufactureElectrolyte accumulators manufactureInternal resistanceLithium–sulfur battery

The invention relates to the technical field of lithium-sulfur batteries, and aims to provide a method for preparing membrane electrodes of lithium-sulfur batteries. The preparation method of the membrane electrode of the lithium-sulfur battery comprises the steps of: preparing a carbon material with nanometer ferrous sulfide dispersed on the surface of the carbon carrier, and then using the carbon material to prepare a positive electrode material; then preparing the positive electrode and the negative electrode, and the lithium ion exchange membrane respectively, Finally, the positive electrode, negative electrode and lithium ion exchange membrane are pressed into a lithium-sulfur battery membrane electrode. The lithium-sulfur battery membrane electrode prepared by the invention has: good electrical conductivity, very low internal resistance; good electrode reaction reversibility; good chemical stability and thermal stability; cheap and easy to prepare; pollution-free; battery manufacturing The process is simple, conducive to large-scale production, and can effectively reduce production costs.

Owner:ZHEJIANG UNIV

A kind of sico-carbon nanotube composite film electrode for lithium battery

ActiveCN106803570BHigh bonding strengthFast charging and dischargingNon-aqueous electrolyte accumulator electrodesVapour deposition manufacturingThin film electrodeComposite film

The invention discloses a SiCO-carbon nanotube composite film electrode for a lithium battery, which is characterized in that it comprises a single crystal silicon substrate (1), on which a TiN barrier layer (2), Cu Thin film layer (3), CuO thin film layer (4), SiCO thin film layer A (5), Ni catalyst layer (6), carbon nanotube layer (7) and SiCO thin film layer B (8). The invention can not only effectively improve the cycle stability of the electrode, but also greatly reduce the thickness of the single layer film, and can obtain a larger thickness of the thin film system, thereby improving the electrochemical performance of the material during high-rate charge and discharge.

Owner:WENZHOU UNIV

A metastable tin-based alloy material and its preparation method

ActiveCN108172774BExtended Phase DiagramImprove cycle stabilityCell electrodesSecondary cellsSodium-ion batteryAlloy

The invention discloses a metastable-state tin-based alloy material and a preparation method thereof. The material mainly comprises two metal elements of Sn and Ni and also possibly comprises elementssuch as Fe, and Co, the metastable-state tin-based alloy material with a main phase being MSn5 is formed, and M is Ni, Fe<0.5>Ni<0.5> and Co<0.5>Ni<0.5>. By introducing a crystal seed during the synthesis process, a tin-based alloy new phase taking tin and nickel as main and difficult to synthesize by a traditional method is induced to be formed, and the method provides a new method and idea forsynthesis of other metastable-state materials particularly the metastable-state tin-based alloy material. The MSn5 alloy material can be used as a lithium / sodium ion battery active negative electrodematerial, Sn agglomeration can be suppressed due to the existence of non-active M metal, and the cycle stability of the material is improved.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com