A carbon-wrapped titanium dioxide airgel lithium-ion battery negative electrode material and preparation method thereof

A lithium-ion battery, titanium dioxide technology, applied in battery electrodes, secondary batteries, nanotechnology for materials and surface science, etc., can solve the problems of inability to achieve precise control of structure and composition, complex synthesis methods, etc., to achieve improved battery life The effect of chemical activity, simple preparation process and process, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

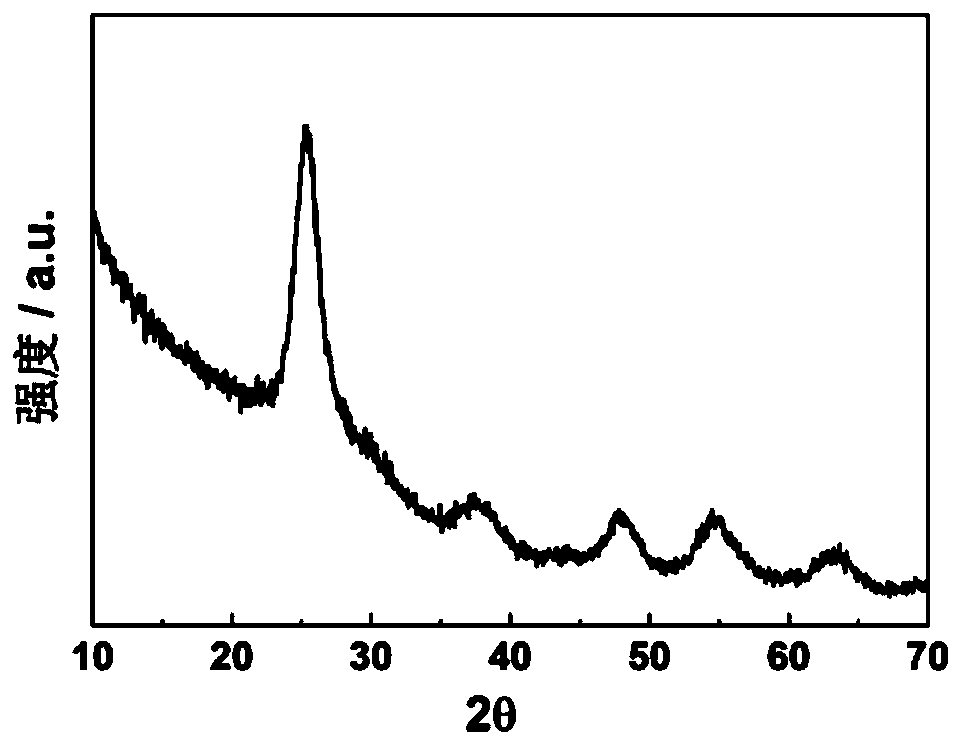

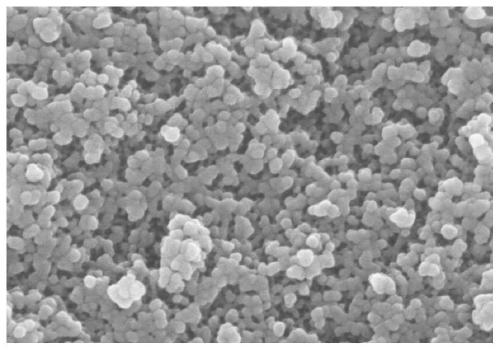

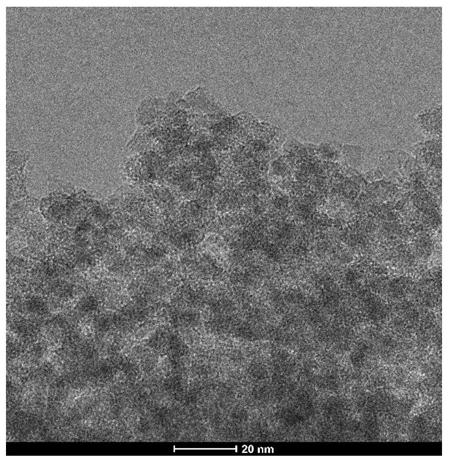

[0039] 4.4 g of tetrabutyl titanate and 0.2 ml of hydrochloric acid were added to 20 ml of ethanol, and the first reaction solution was obtained after uniform stirring. 1.5 ml of deionized water was added to 20 ml of ethanol, and after stirring, an aqueous ethanol solution was obtained. The upper aqueous ethanol solution is slowly added to the first reaction solution, stirred at room temperature, then the sol is poured into a petri dish, and aged at 30° C. for 24 hours to obtain a colorless transparent titanium dioxide gel. 1 g of bisphenol A diglycidyl ether was added to 10 ml of tetrahydrofuran, and the second reaction solution was obtained after uniform stirring. The upper titanium dioxide gel and the second reaction solution are mixed and put into a reaction tank, and are allowed to stand under heating at 70° C. for 24 hours to obtain a light yellow transparent dry gel. The dry gel is cooled and supercritically dried with carbon dioxide to obtain a light yellow transparent...

Embodiment 2

[0046] 4.0 g of tetrabutyl titanate and 0.1 ml of hydrochloric acid were added to 20 ml of ethanol, and the first reaction solution was obtained after uniform stirring. Add 2 ml of deionized water to 20 ml of ethanol and stir well to obtain an aqueous ethanol solution. The upper aqueous ethanol solution is slowly added to the first reaction solution, stirred at room temperature, then the sol is poured into a petri dish, and aged at 25° C. for 24 hours to obtain a colorless transparent titanium dioxide gel. 1 g of bisphenol A diglycidyl ether was added to 15 ml of tetrahydrofuran, and the second reaction solution was obtained after uniform stirring. The upper titanium dioxide gel and the second reaction solution are mixed and put into a reaction tank, and are allowed to stand under heating at 80° C. for 12 hours to obtain a light yellow transparent dry gel. The dry gel is cooled and supercritically dried with carbon dioxide to obtain a light yellow transparent aerogel. Finally...

Embodiment 3

[0048] 5.5 g of tetrabutyl titanate and 0.2 ml of hydrochloric acid are added to 20 ml of ethanol, and the first reaction solution is obtained after uniform stirring. Add 3.8 ml of deionized water to 30 ml of ethanol, and stir well to obtain an aqueous ethanol solution. The upper aqueous ethanol solution is slowly added to the first reaction solution, stirred at room temperature, then the sol is poured into a petri dish, and aged at 25° C. for 20 hours to obtain a colorless transparent titanium dioxide gel. Add 2 g of bisphenol A diglycidyl ether to 15 ml of tetrahydrofuran, and stir uniformly to obtain a second reaction solution. The upper titanium dioxide gel and the second reaction solution are mixed and put into a reaction tank, and are allowed to stand under heating at 70° C. for 20 hours to obtain a light yellow transparent dry gel. The dry gel is cooled and supercritically dried with carbon dioxide to obtain a light yellow transparent aerogel. Finally, the aerogel was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com