Preparation method of gel polymer lithium ion battery

A lithium-ion battery and polymer technology, applied in the field of preparation of gel lithium-ion batteries, can solve the problems of poor performance, serious discharge polarization, poor conductivity, etc., achieve high ability to absorb electrolyte, improve safety, The effect of electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Example 1: Preparation of NaCl-KCl eutectic salt

[0048] Add NaCl (45g) and KCl (55g) into a ball mill jar, mill at a speed of 700rpm for 1 hour, take it out and put it in a crucible, heat it in air at 700°C for 2 hours, and cool it to 25°C to obtain NaCl-KCl eutectic salt.

Embodiment 2

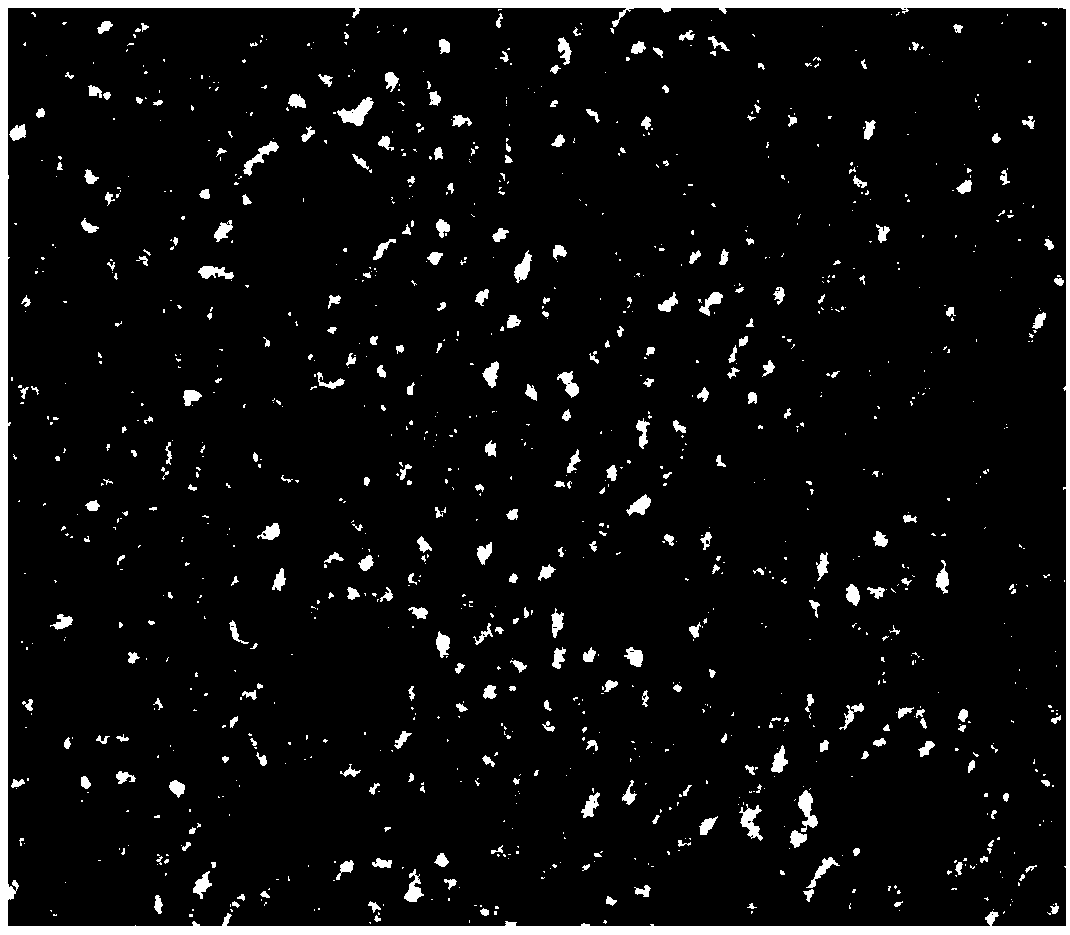

[0049] Example 2: Preparation of graphene-loaded nano-boron

[0050] Take the NaCl-KCl eutectic salt (30g) prepared in Example 1, add glucose monohydrate, melamine, metaboric acid and NaCl-KCl eutectic salt in a ball mill tank at a mass ratio of 4:2:1:300, and rotate 700rpm ball milling and mixing for 2 hours to prepare the precursor of graphene-loaded nano-boron-lithium;

[0051] After heating up to 110°C for 2 hours under nitrogen atmosphere, vacuumize and heat up to 440°C for 8 hours, then heat up to 900°C for 2 hours, three times at a heating rate of 10°C / min, and then cool to room temperature to obtain salt-containing Graphene supports nano boron. The salt content was washed away with deionized water, and then vacuum-dried to obtain nano-boron supported on graphene.

Embodiment 3

[0052] Example 3: Preparation of Nafion-PEO blended resin solution

[0053] 5g of PEO (polyethylene oxide) was added to 95g of a proton-type perfluorosulfonic acid resin solution with a mass content of 5wt% produced by DuPont Company of the United States, and stirred to dissolve to obtain a Nafion-PEO blended resin solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com