Silicon-based lithium ion battery negative electrode material and preparation method thereof

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low reversible specific capacity of amorphous silicon, improve cycle stability, facilitate industrial production, and have good crack resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Preparation of negative electrode materials for silicon-based lithium-ion batteries: At room temperature, add amorphous silicon particles into hydrofluoric acid solution with a molar concentration of 30mol / L, stir for 0.5h, then wash the product with deionized water, and collect the product by centrifugation ; Vacuum drying, the drying temperature is 40 ° C, the dried product is spread in a refractory container corundum porcelain boat, sintered at 650 ° C for 4 hours in an argon atmosphere, and the amorphous silicon-coated single crystal silicon can be obtained after cooling. composite material.

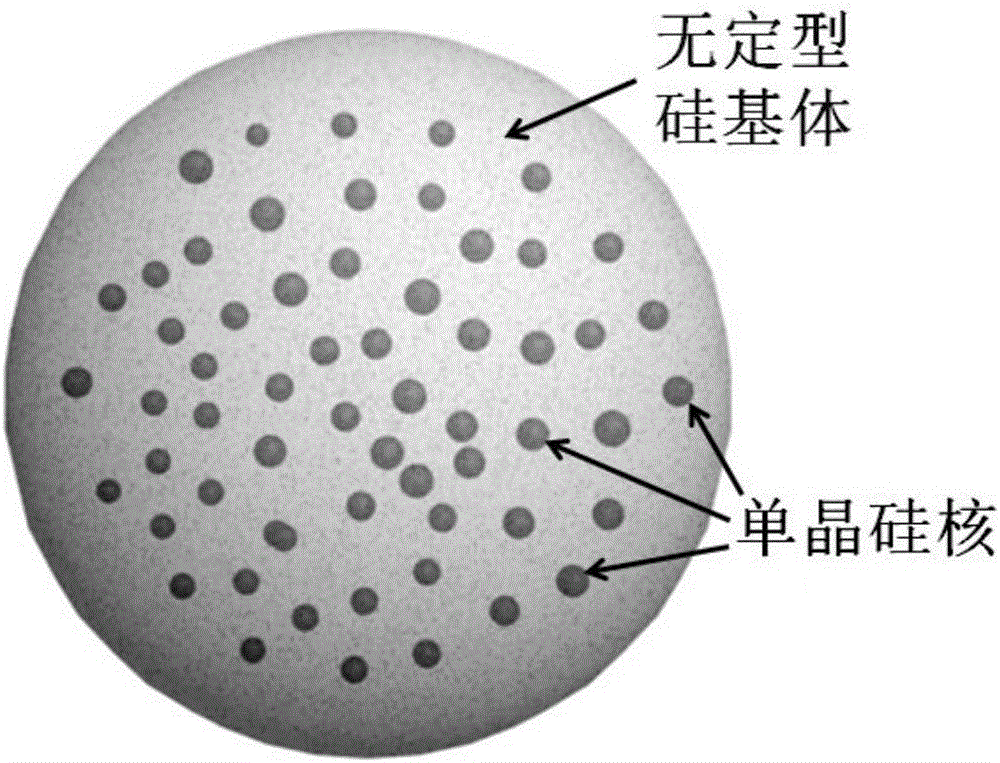

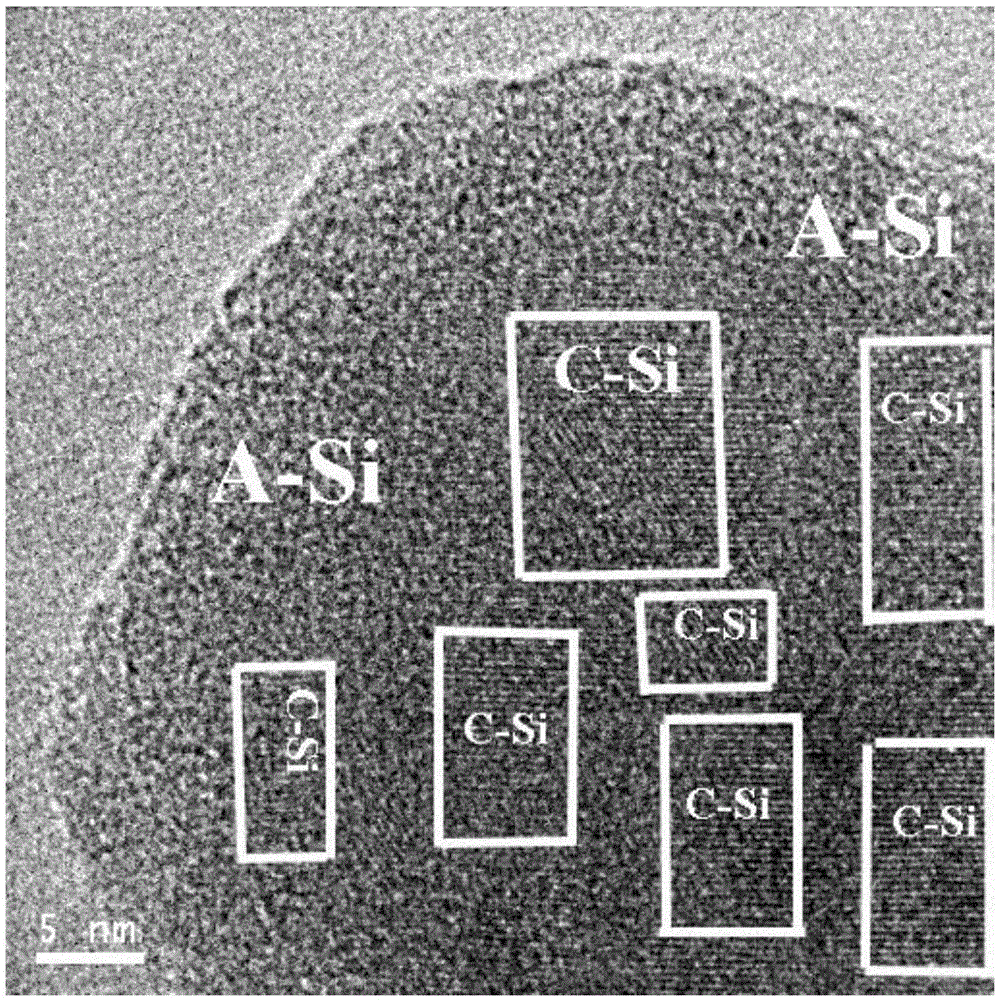

[0031] figure 1 It is a structural diagram of the silicon-based lithium-ion battery anode material obtained in Example 1, in which single crystal silicon (black) is embedded in an amorphous silicon matrix (gray).

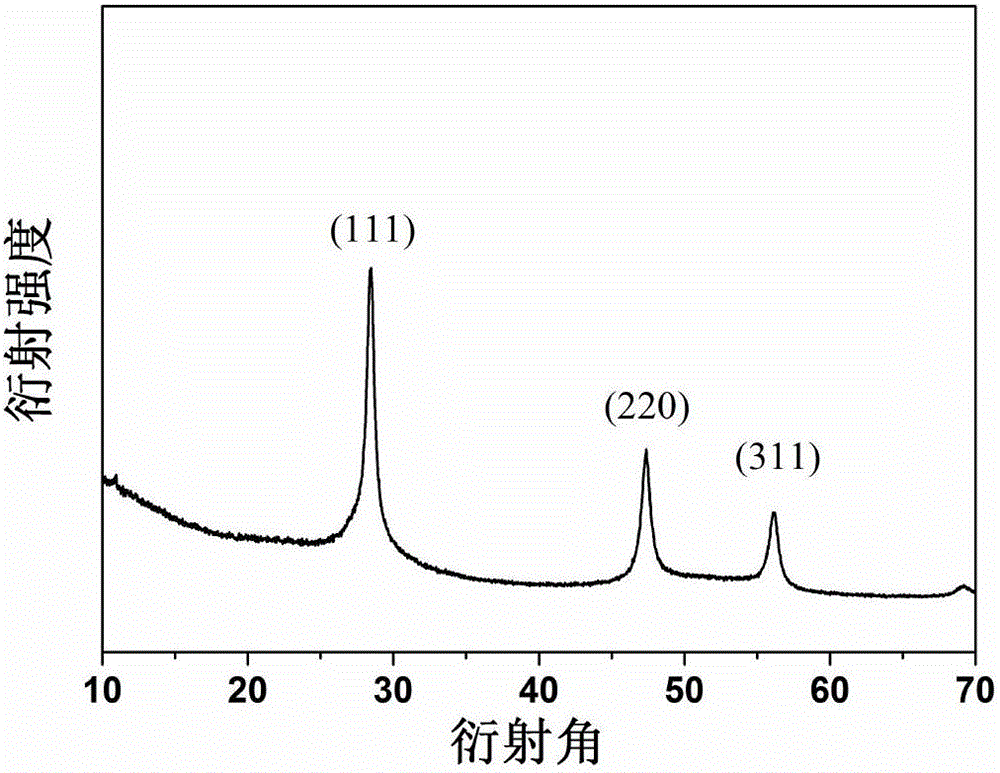

[0032] figure 2 It is the X-ray diffraction pattern of the silicon-based lithium-ion battery negative electrode material obtained in Example 1. The peak type can...

Embodiment 2

[0040]Negative electrode material preparation of silicon-based lithium-ion battery negative electrode material: Add amorphous silicon bulk material to 0.1mol / L sodium hydroxide solution at room temperature, let it stand for 5h, then wash the product with deionized water, and collect it by sedimentation product, remove the sodium hydroxide solution; blow dry with nitrogen, spread the dried product in a corundum porcelain boat in a refractory container, sinter at 500°C for 1h under an argon atmosphere, and obtain amorphous silicon-coated single crystal silicon after cooling block composites.

[0041] Image 6 The X-ray diffraction pattern of the silicon-based lithium-ion battery negative electrode material prepared in Example 2, the peak type can be compared with JCPDS 27-1402, and it is found that there are two broad peaks at 28° and 50°, which are speculated to be amorphous diffraction peaks of silicon ; and there are two narrow peaks at 47° and 56°, indicating the presence o...

Embodiment 3

[0044] Silicon-based lithium-ion battery anode material Anode material preparation: Add amorphous silicon wire to 1mol / L hydrofluoric acid solution at room temperature, stir for 1 hour, then wash the product with deionized water, collect the product by centrifugation; vacuum dry, The drying temperature is 100°C, spread the dried product in a corundum porcelain boat (other refractory containers can be used instead of the corundum porcelain boat), sinter at 1000°C for 10 hours in a neon atmosphere, and obtain amorphous silicon-coated single crystal after cooling Linear composites of silicon.

[0045] Figure 8 It is the X-ray diffraction pattern of the silicon-based lithium-ion battery negative electrode material prepared in Example 3. The peak type can be compared with JCPDS 27-1402. The peak type in the figure is narrower and the peak intensity is stronger, indicating that the crystallinity of silicon becomes higher.

[0046] Figure 9 The high-magnification TEM electron mic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com