Lithium ion battery anode material LiSi2N3 and method for preparing material

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of unsuitability for industrial production, high raw material prices, high synthesis temperature, etc., achieve low cost, improve lithium storage specific capacity, and react The effect of low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of negative electrode material LiSi of lithium ion battery 2 N 3 and its preparation method. Mix 15-25wt% elemental silicon powder, 25-35wt% melamine, 40-50wt% lithium source and 10-15wt% halide powder to prepare a mixture; then put the mixture into a tubular electric furnace In a nitrogen atmosphere, the temperature was raised to 900-1000°C at a rate of 2-5°C / min, and kept at a temperature of 4-6 hours; 3 and Ca(NO 3 ) 2 Titrate the solution until no white precipitate appears; finally dry at 110°C for 10 to 24 hours to obtain the lithium-ion battery negative electrode material LiSi 2 N 3 .

[0028] In this embodiment: the lithium source is lithium fluoride; the halide powder is a mixture of 50-60 wt% sodium chloride and 40-50 wt% potassium fluoride.

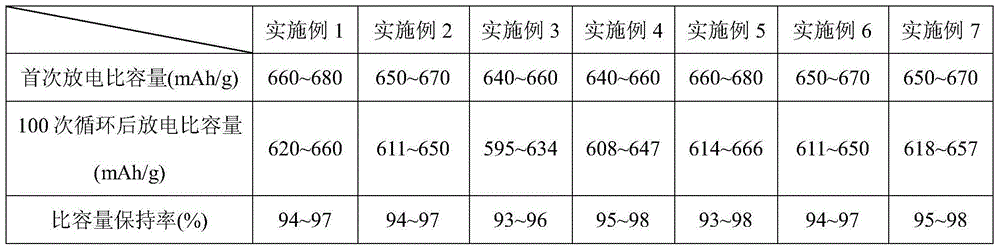

[0029] Lithium-ion battery anode material LiSi prepared by the present embodiment 2 N 3 It has high activity, large specific surface area, high purity, high specific capacity and stable performance. The cr...

Embodiment 2

[0031] A kind of negative electrode material LiSi of lithium ion battery 2 N 3 and its preparation method. Mix 15-25wt% elemental silicon powder, 25-35wt% melamine, 40-50wt% lithium source and 10-15wt% halide powder to prepare a mixture, and then put the mixture into a tubular electric furnace In a nitrogen atmosphere, the temperature was raised to 1100-1200°C at a rate of 2-5°C / min, and the temperature was kept for 2-4 hours; then the obtained product was repeatedly washed with deionized water until the AgNO 3 and Ca(NO 3 ) 2 Titrate the solution until no white precipitate appears; finally dry at 110°C for 10 to 24 hours to obtain the lithium-ion battery negative electrode material LiSi 2 N 3 .

[0032] In this embodiment: the lithium source is a mixture of 50-70 wt% lithium fluoride and 30-50 wt% lithium chloride; the halide powder is sodium chloride.

[0033] Lithium-ion battery anode material LiSi prepared by the present embodiment 2 N 3It has high activity, large...

Embodiment 3

[0035] A kind of negative electrode material LiSi of lithium ion battery 2 N 3 and its preparation method. Mix 10-20wt% elemental silicon powder, 35-45wt% melamine, 35-45wt% lithium source and 0.5-5wt% halide powder to prepare a mixture; then put the mixture into a tubular electric furnace In a nitrogen atmosphere, the temperature was raised to 1100-1200°C at a rate of 5-10°C / min, and the temperature was kept for 2-4 hours; then the obtained product was repeatedly washed with deionized water until the AgNO 3 and Ca(NO 3 ) 2 Titrate the solution until no white precipitate appears; finally dry at 110°C for 10 to 24 hours to obtain the lithium-ion battery negative electrode material LiSi 2 N 3 .

[0036] In this embodiment: the lithium source is lithium chloride; the halide powder is sodium fluoride.

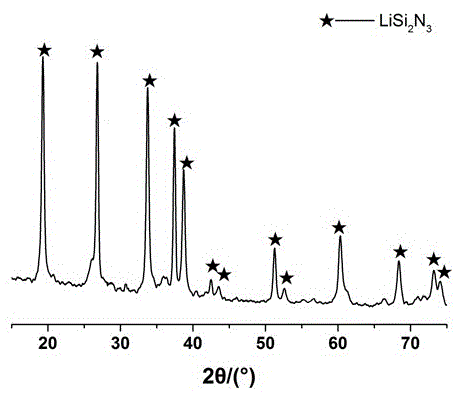

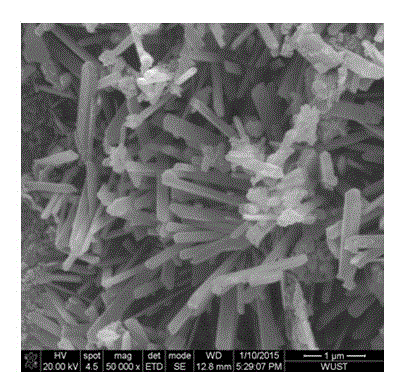

[0037] figure 1 It is a lithium ion battery negative electrode material LiSi prepared by the present invention 2 N 3 The XRD pattern, figure 2 yes figure 1 The lithium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com