Ordered macroporous titanium dioxide and preparation method thereof

A titanium dioxide and order technology, which is applied in the field of order macroporous titanium dioxide and its preparation, can solve the problems of low rate capacity, limited use, poor conductivity, etc., and achieve the effect of simple synthesis method, improved electronic conductivity and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

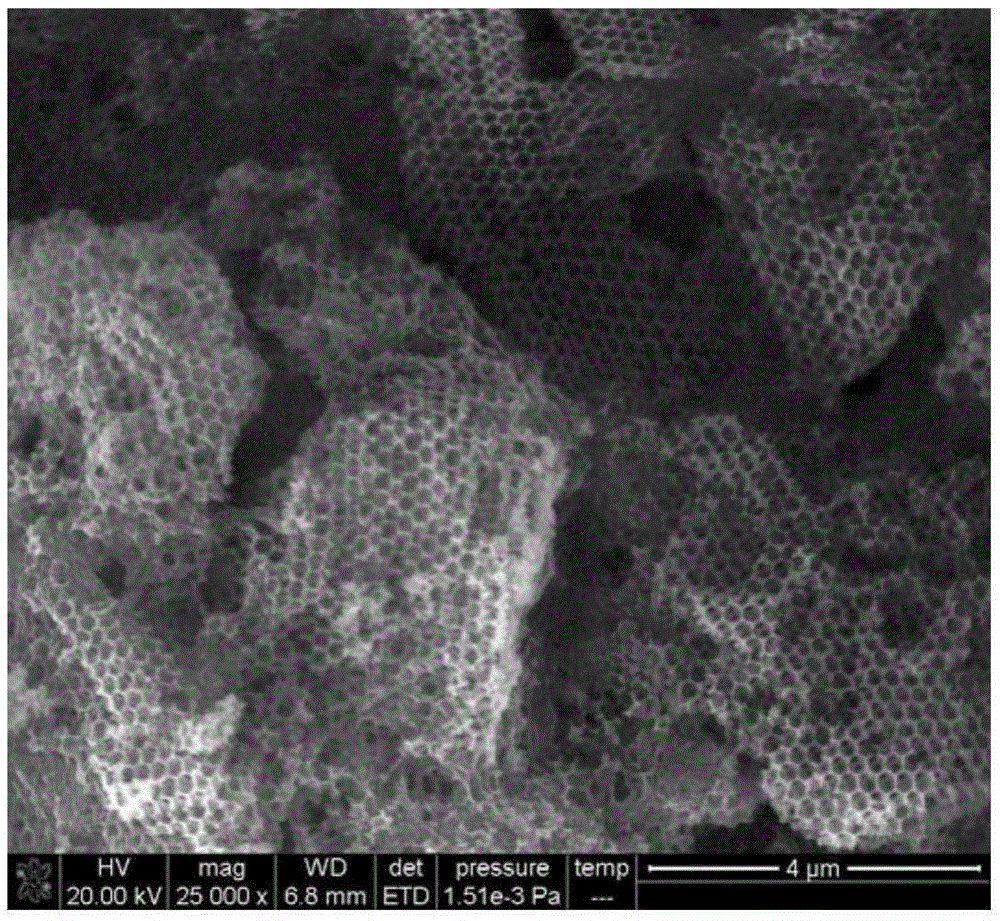

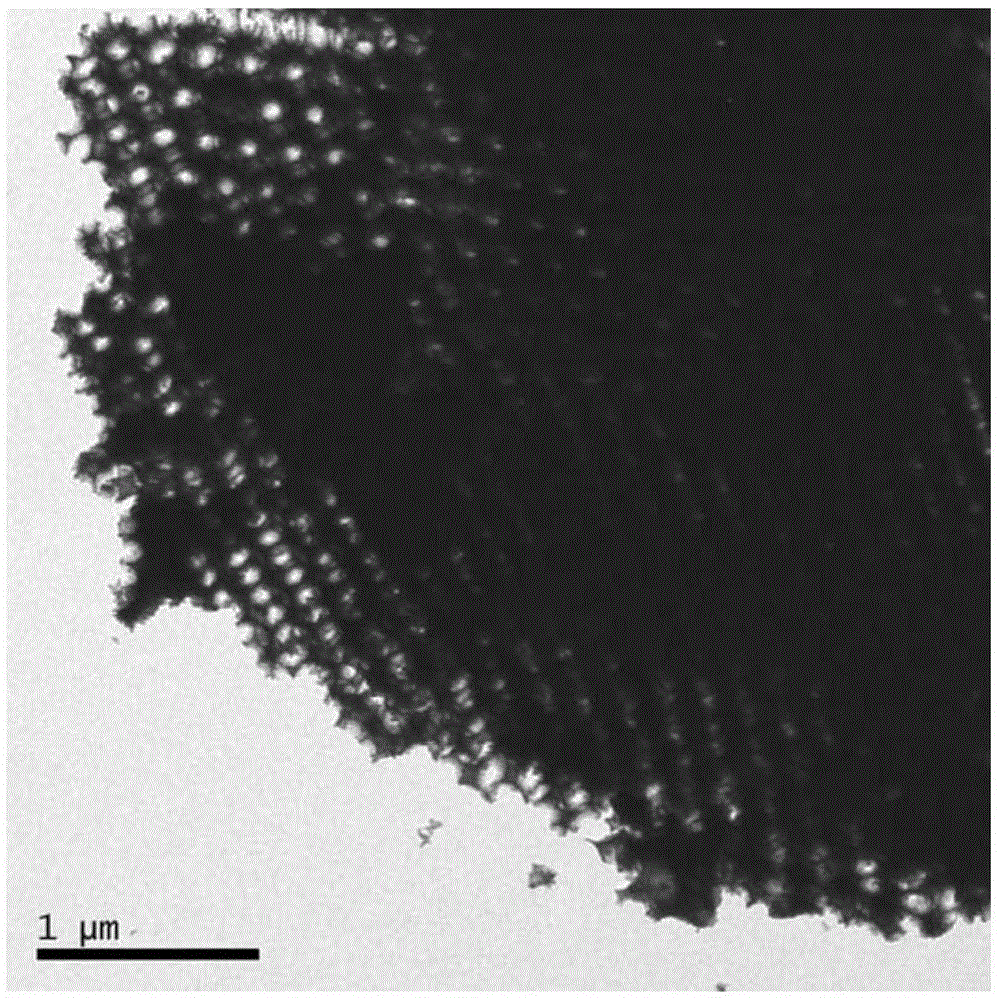

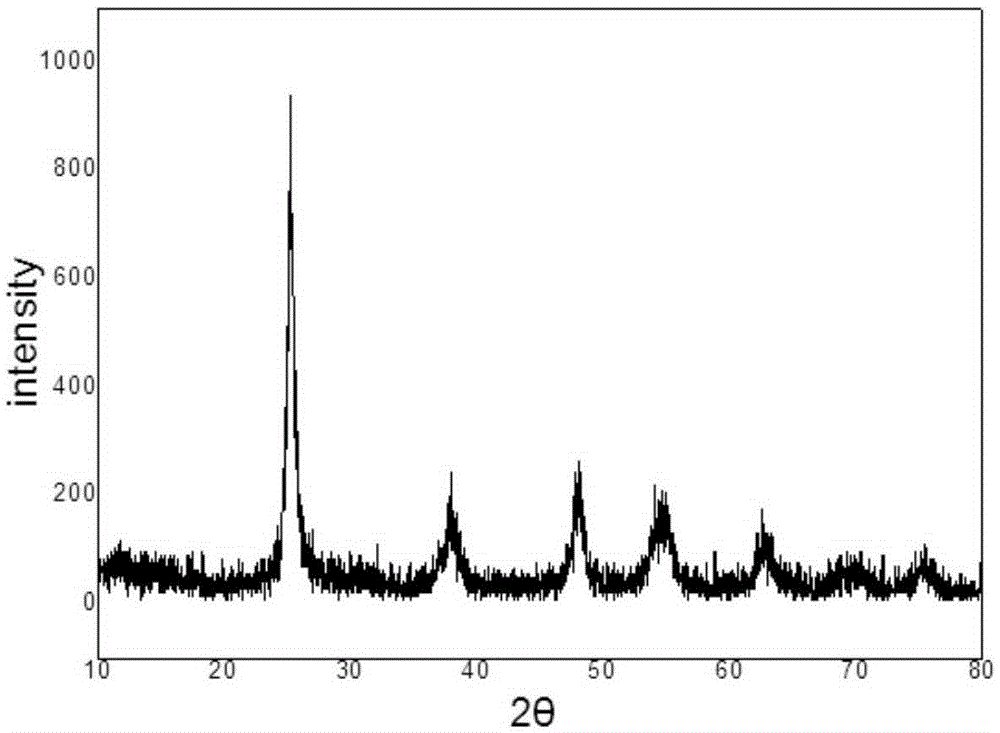

[0028] The preparation method of ordered macroporous titanium dioxide comprises the following steps:

[0029] (1) Preparation of titanium dioxide precursor solution: add 1.0 g of titanium tetrachloride to 50 g of absolute ethanol, stir evenly, then add 0.7 g of titanium tetraisopropoxide while stirring, and stir evenly to obtain a titanium dioxide precursor solution;

[0030] (2) Preparation of PS-COOH sphere suspension: disperse 1.0 g of PS-COOH spheres in 250 W ultrasonic for 2 hours in 10 g of absolute ethanol to obtain PS-COOH sphere suspension, wherein the diameter of PS-COOH spheres is about 200 nanometers;

[0031] (3) Preparation of ordered macroporous titanium dioxide: Mix the titanium dioxide precursor solution and PS-COOH ball suspension together, stir evenly to obtain suspension C, let it stand at room temperature for 36 hours, and dry it in a blast oven at 65°C for 48 hours, The dried product was placed in the center of a high-temperature tube furnace, and the tem...

Embodiment 2

[0042] The preparation method of ordered macroporous titanium dioxide comprises the following steps:

[0043] (1) Preparation of titanium dioxide precursor solution: 0.5 g of titanium tetrachloride was added to 40 g of absolute ethanol, stirred evenly, then 1.5 g of titanium tetraisopropoxide was added while stirring, and stirred evenly to obtain a titanium dioxide precursor solution;

[0044] (2) Preparation of PS-COOH ball suspension: disperse 1.3g of PS-COOH ball in 250W ultrasonic for 2 hours in 15g of absolute ethanol to obtain PS-COOH ball suspension, wherein the diameter of PS-COOH ball is about 100 nanometers;

[0045] (3) Preparation of ordered macroporous titanium dioxide: Mix the titanium dioxide precursor solution and PS-COOH ball suspension together, stir evenly to obtain suspension C, let it stand at room temperature for 36 hours, and dry it in a blast oven at 65°C for 48 hours, The dried product was placed in the center of a high-temperature tube furnace, and th...

Embodiment 3

[0049] The preparation method of ordered macroporous titanium dioxide comprises the following steps:

[0050] (1) Preparation of titanium dioxide precursor solution: 0.8g of titanium tetrachloride was added to 45g of absolute ethanol, stirred evenly, then 1.3g of titanium tetraisopropoxide was added while stirring, and stirred evenly to obtain a titanium dioxide precursor solution;

[0051] (2) Preparation of PS-COOH ball suspension: disperse 1.2g of PS-COOH ball with 250W ultrasonic wave for 1.5 hours in 13g of absolute ethanol to obtain PS-COOH ball suspension, wherein the diameter of PS-COOH ball is 500nm;

[0052] (3) Preparation of ordered macroporous titanium dioxide: Mix the titanium dioxide precursor solution and PS-COOH ball suspension together, stir evenly to obtain suspension C, let it stand at room temperature for 36 hours, and dry it in a blast oven at 65°C for 48 hours, The dried product was placed in the center of a high-temperature tube furnace, and the tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com