Metastable-state tin-based alloy material and preparation method thereof

A tin-based alloy and alloy technology, applied in the field of preparation and application research, can solve the problem of material morphology, limited ability to control the size and phase composition, cannot be used for the preparation and development of metastable phase alloy materials, and it is difficult to apply catalysis and energy storage and other issues, to achieve the effect of improving cycle stability, wide application range, and improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

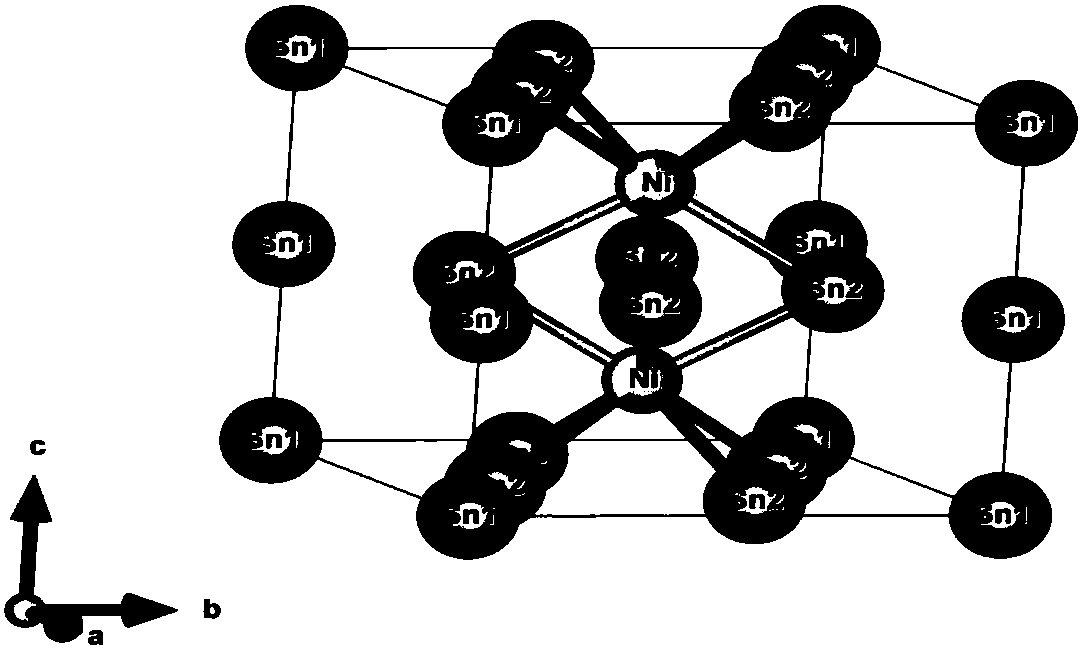

[0045] The MSn 5 The preparation methods of new tin-based alloy phases include: high-temperature reduction method, hydrothermal synthesis method, wet chemical method, high-temperature smelting method, mechanochemical reaction method (such as mechanical ball milling method, mechanical alloying method, etc.), sol-gel method, magnetic controlled sputtering etc.

[0046] In the selection of raw materials, high temperature reduction method, hydrothermal synthesis method, wet chemical method, sol-gel method and other methods are used to optimize the corresponding metal salt materials; mechanochemical reaction method (such as mechanical ball milling method, mechanical alloying method, etc.), magnetron For methods such as sputtering, the corresponding metal elemental materials are preferable.

[0047] The present invention adopts wet chemical method to prepare and obtain product, makes metastable state MSn by introducing seed crystal 5 Alloys are easier to form, which solves the dif...

Embodiment 1

[0050] Preparation of elemental Sn negative electrode material:

[0051] 1. Add 3.6g of polyvinylpyrrolidone (PVP, MW=360,000) and 0.6g of poly(2-ethyl-2 oxazoline) (PEtOx, MW=50,000) into a 250ml three-necked flask, and add 40ml of four gamma Alcohol (TEG), the mixture was heated to 130 °C under an inert atmosphere of high-purity Ar and stirred until completely dissolved.

[0052] 2. Disperse 0.59g of stannous sulfate into 16ml of tetraethylene glycol at room temperature, then add SnSO 4 The TEG solution was added dropwise into a three-necked flask and stirred for 15 min. Disperse 1 g of sodium borohydride into 30 ml of tetraethylene glycol, then add fresh NaBH 4 The TEG solution was slowly added dropwise into a three-necked flask to obtain a black suspension.

[0053] 3. Stir for 1 h under an inert atmosphere, centrifuge, wash, and dry in a vacuum oven at 60° C. overnight to obtain the product.

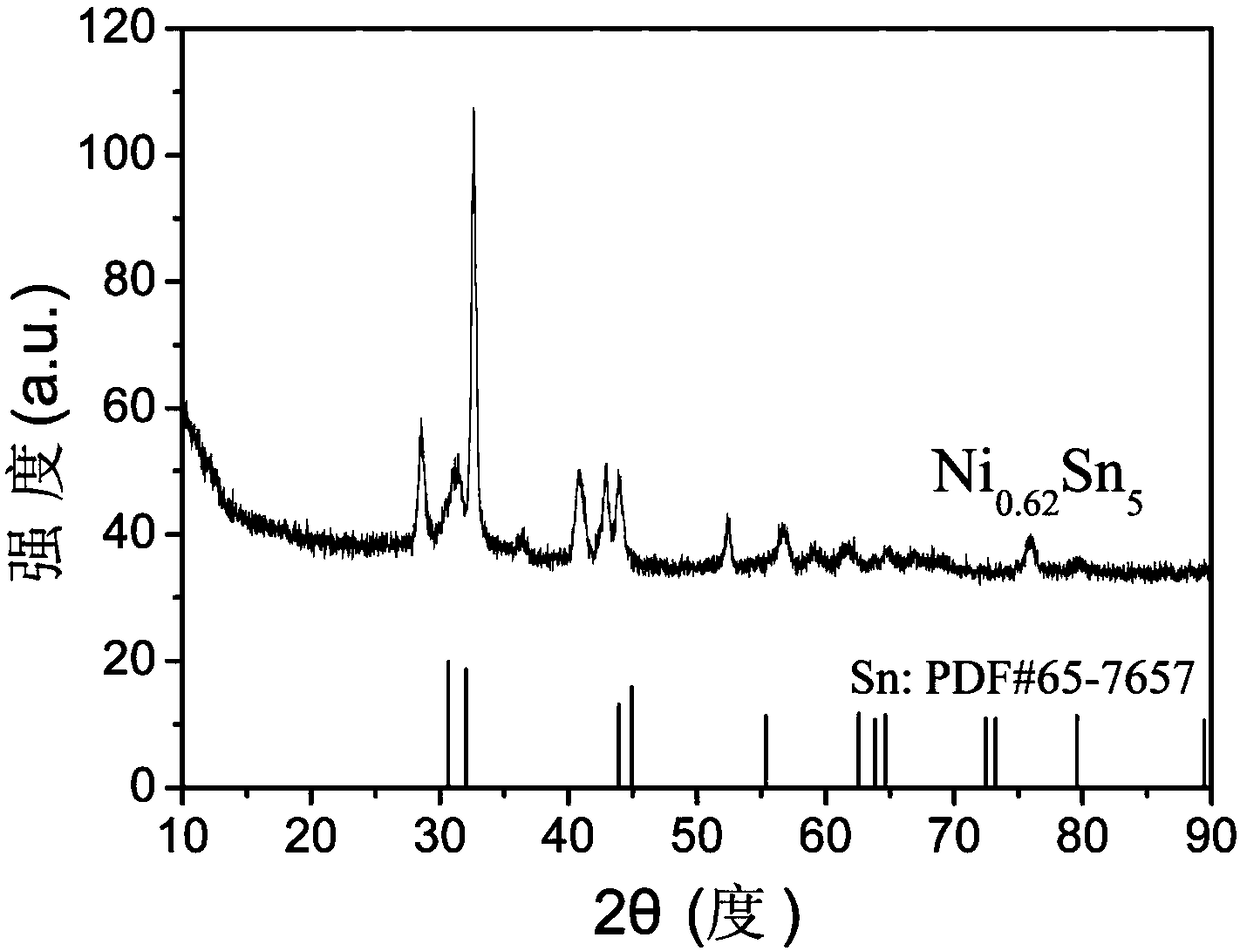

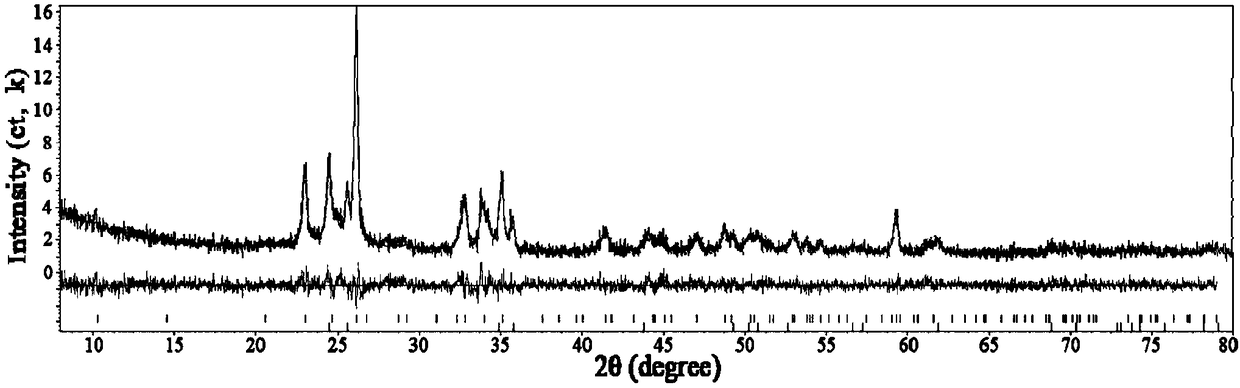

[0054] The crystal structure and morphology of the elemental Sn material pr...

Embodiment 2

[0059] NiSn 5 Preparation of binary alloy new phase materials:

[0060] 1. Add 3.6g of polyvinylpyrrolidone (PVP, MW=360,000) and 0.6g of poly(2-ethyl-2 oxazoline) (PEtOx, MW=50,000) into a 250ml three-necked flask, and add 40ml of four gamma Alcohol (TEG), the mixture was heated to 130 °C under an inert atmosphere of high-purity Ar and stirred until completely dissolved.

[0061] 2. Disperse 0.59g of stannous sulfate into 16ml of tetraethylene glycol at room temperature, then add SnSO 4 The TEG solution was added dropwise into a three-necked flask and stirred for 15 min. Disperse 1 g of sodium borohydride into 30 ml of tetraethylene glycol, then add fresh NaBH 4 The TEG solution was slowly added dropwise into a three-necked flask to obtain a black suspension, and the temperature was raised to 205° C., and the stirring was continued for 15 minutes.

[0062] 3. Disperse 2mg of ferric chloride into 5ml of tetraethylene glycol, and then add FeCl 3 The TEG solution was added ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com