SiCO-carbon nanotube composite film electrode for lithium battery

A carbon nanotube composite, thin-film electrode technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, electrode manufacturing, etc. Chemical properties and mechanical properties, good adhesion, controllable components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

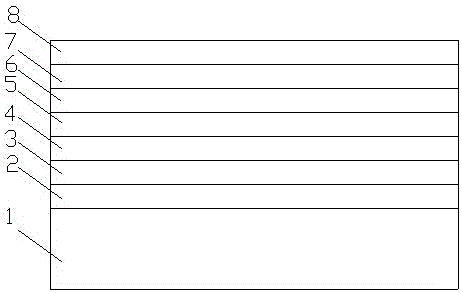

[0027] Example. A kind of SiCO-carbon nanotube composite film electrode for lithium battery, constitutes as follows figure 1 As shown, a single crystal silicon substrate 1 is included, and a TiN barrier layer 2, a Cu thin film layer 3, a CuO thin film layer 4, a SiCO thin film layer A5, a Ni catalyst layer 6, a carbon nanotube layer 7 and SiCO thin film layer B8.

[0028] The thickness of the TiN barrier layer 1 is 95-105nm.

[0029] The thickness of the Cu thin film layer 2 is 290-310 nm, and the thickness of the CuO thin film layer 4 is 95-105 nm.

[0030] The thickness of the SiCO thin film layer A5 is 190-210 nm; the thickness of the Ni catalyst layer 6 is 45-55 nm; the thickness of the carbon nanotube layer 7 is 95-105 nm; the SiCO thin film layer B8 The thickness is 190-210 nm.

[0031] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com