Preparation method and application of amorphous carbon-based composite negative electrode material containing metalloid lithium

A technology of amorphous carbon and negative electrode materials, applied in the direction of negative electrodes, battery electrodes, active material electrodes, etc., can solve the problems of reducing the overall energy density of lithium metal composite negative electrodes, the gap in cycle performance, and the easy generation of lithium dendrites, etc., to achieve improved The effect of cycle stability, good support and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Example 1: Preparation of pitch-based hard carbon negative electrode material containing metalloid lithium by electrochemical method

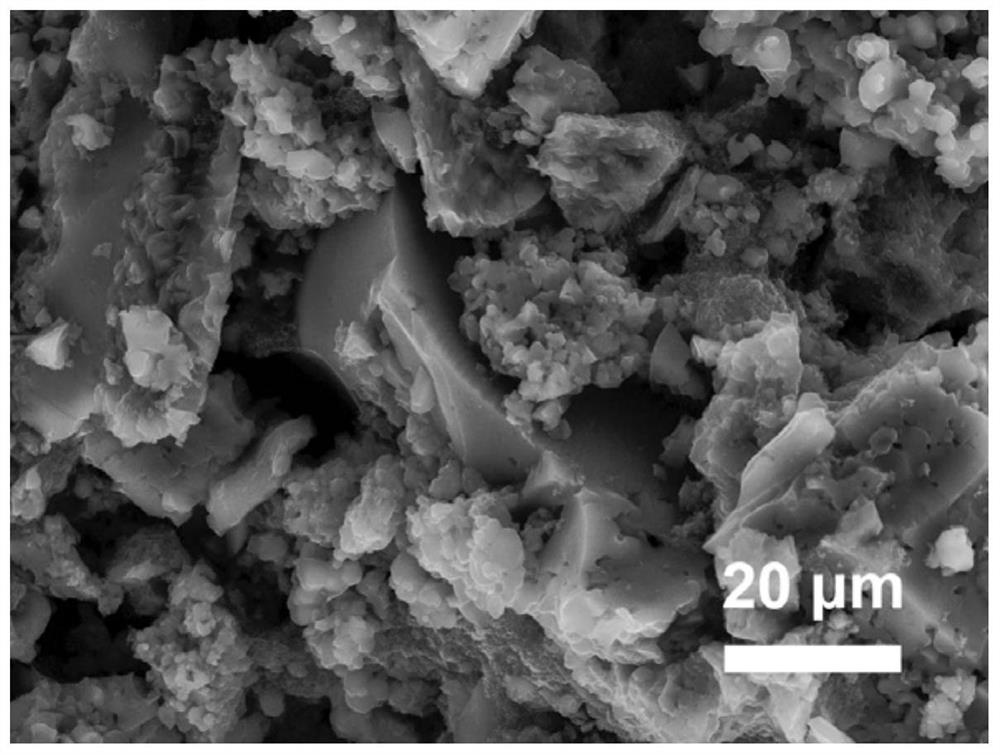

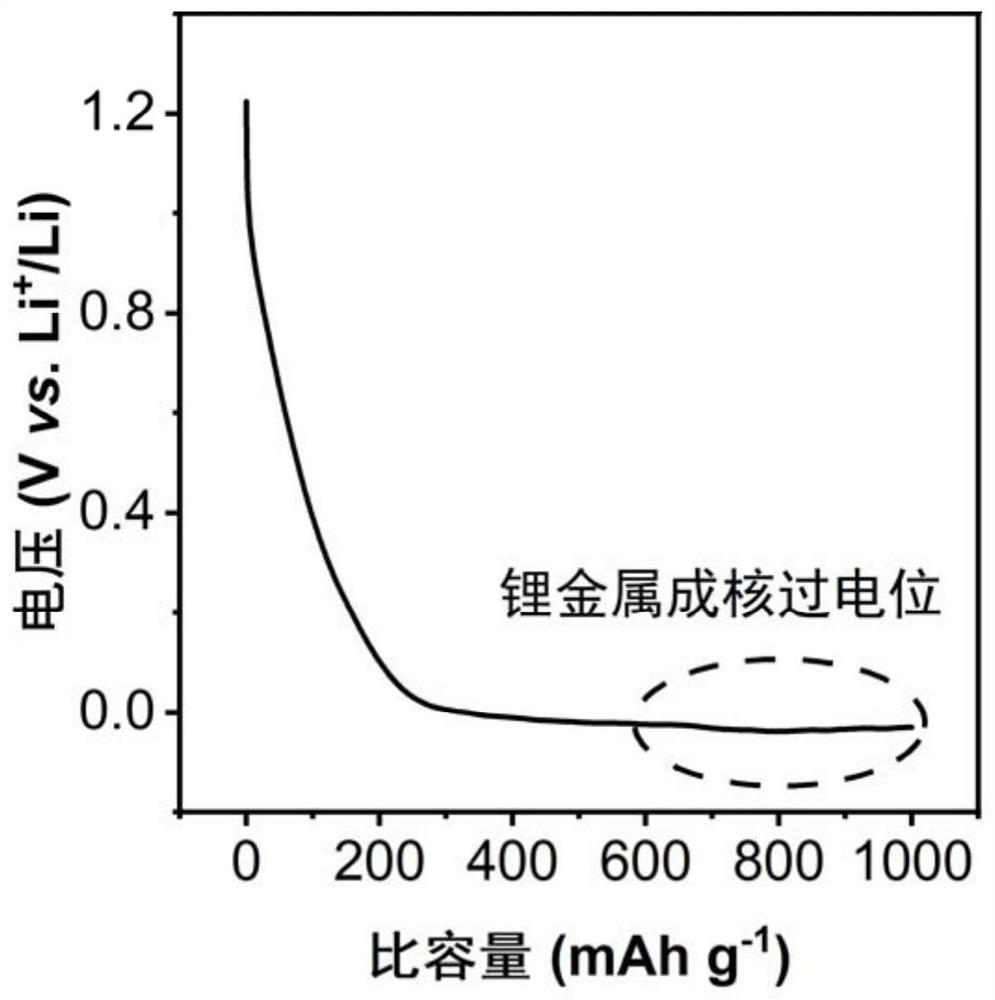

[0063] Pitch is calcined in air at 300°C and then at 1000°C in an inert atmosphere to obtain pitch-based hard carbon. In the hard carbon of this embodiment, the distance between carbon layers or the size of nanopores composed of disordered carbon is 0.39nm, the average particle size is 15 μm, and the specific surface area is 2m 2 g -1 , mix hard carbon, CMC, SBR and Super P conductive carbon black in a ratio of 90:3:3:4, coat it on copper foil, and use it as an amorphous carbon negative electrode after vacuum drying, such as figure 1 As shown, metal lithium sheet is used as counter electrode, Celgard 2325 is used as battery separator, EC+DEC+DMC(1:1:1vol)+5vol%FEC+1M LiPF 6 As the electrolyte, a lithium / carbon half-cell was prepared. By electrochemical lithiation, lithiation refers to: put the half-cell voltage below 0V, and use the ...

Embodiment 2

[0064] Example 2: Preparation of Kuraray hard carbon negative electrode material containing metalloid lithium by electrochemical method

[0065] In order to illustrate the universality of the preparation method of metalloid lithium, the hard carbon anode material was prepared with the commercial hard carbon material of Kuraray Company. The Kuraray hard carbon used in this example has a nanopore size of 0.38nm, an average particle size of 9μm, and a specific surface area of 4m 2 g -1 . Mix Kuraray hard carbon, CMC, SBR and Super P conductive carbon black in a ratio of 90:3:3:4, coat it on copper foil, and use it as the negative electrode of amorphous carbon after vacuum drying. Counter electrode, use Celgard 2325 as battery separator, EC+DEC+DMC(1:1:1vol)+5vol%FEC+1MLiPF 6 As an electrolyte, a lithium / carbon half-cell is prepared by electrochemical lithiation. Lithiation refers to: put the half-cell voltage below 0V, and use the maximum capacity before the nucleation over...

Embodiment 3

[0066] Embodiment 3: Preparation of soft carbon negative electrode material containing metalloid lithium by electrochemical method

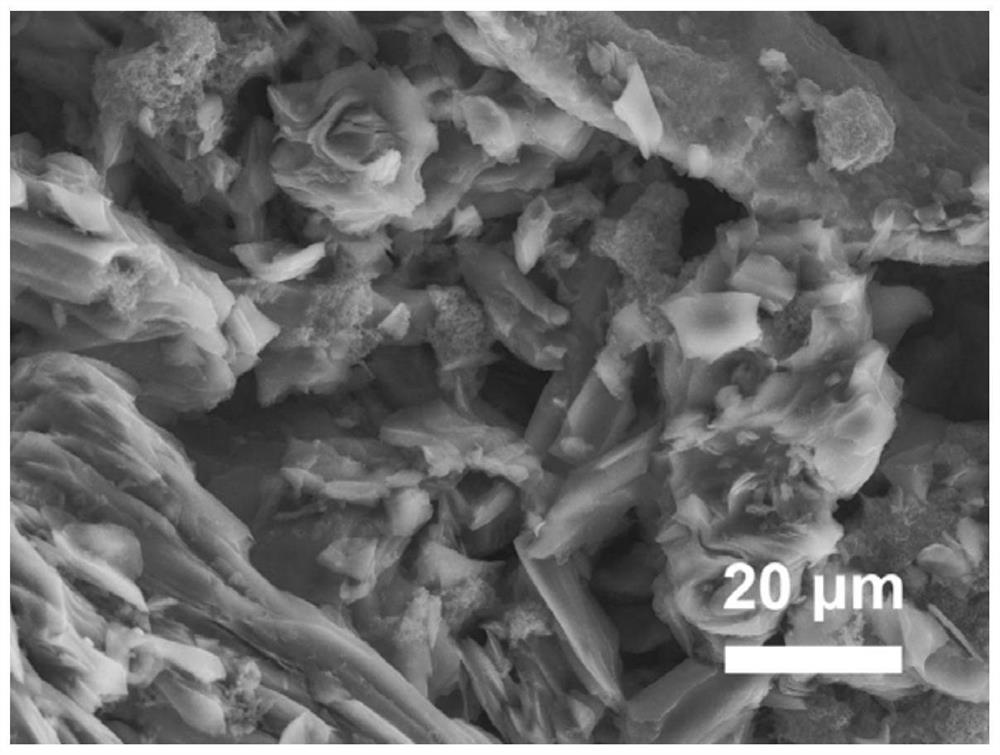

[0067] The pitch is calcined in an inert atmosphere at 300°C for 1 hour and then raised to 800°C for 2 hours to obtain pitch-based soft carbon. In the soft carbon of this embodiment, the distance between carbon layers or the size of nanopores composed of disordered carbon is 0.37nm, the average particle size is 12μm, and the specific surface area is 20m 2 g -1 . Mix pitch-based soft carbon, CMC, SBR, and Super P conductive carbon black in a ratio of 90:3:3:4, coat it on copper foil, and use it as an amorphous carbon negative electrode after vacuum drying, such as image 3 As shown, metal lithium sheet is used as counter electrode, Celgard 2325 is used as battery separator, EC+DEC+DMC(1:1:1vol)+5vol%FEC+1M LiPF 6 As the electrolyte, a lithium / carbon half-cell was prepared. By electrochemical lithiation, lithiation refers to: put the half-cell...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com