Nano titanium dioxide/graphene negative electrode material and preparation method thereof

A nano-titanium dioxide and graphene negative electrode technology, applied in the field of electrochemical materials, can solve the problems of lack of channels, easy to agglomerate, reduce the charge-discharge capacity and cycle rate of lithium-ion batteries, etc., and achieve good penetration, high repeatability, Effect of excellent electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

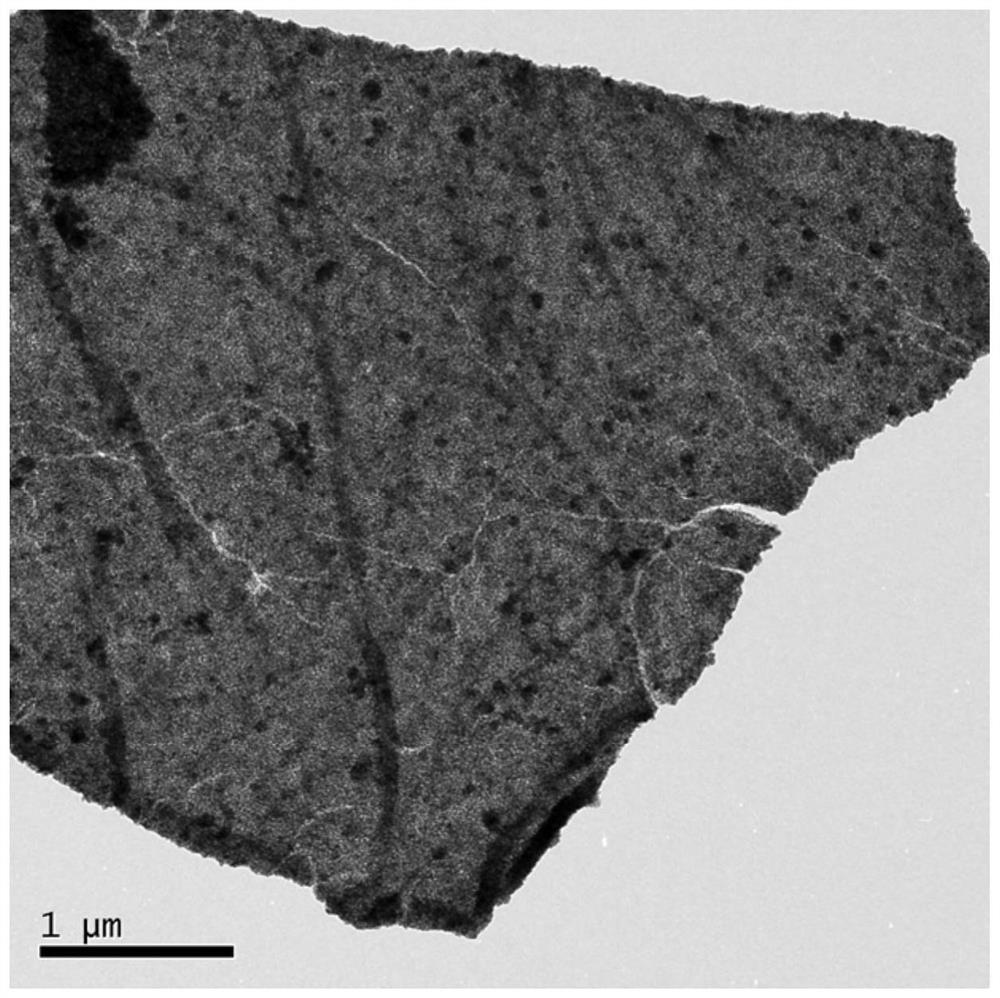

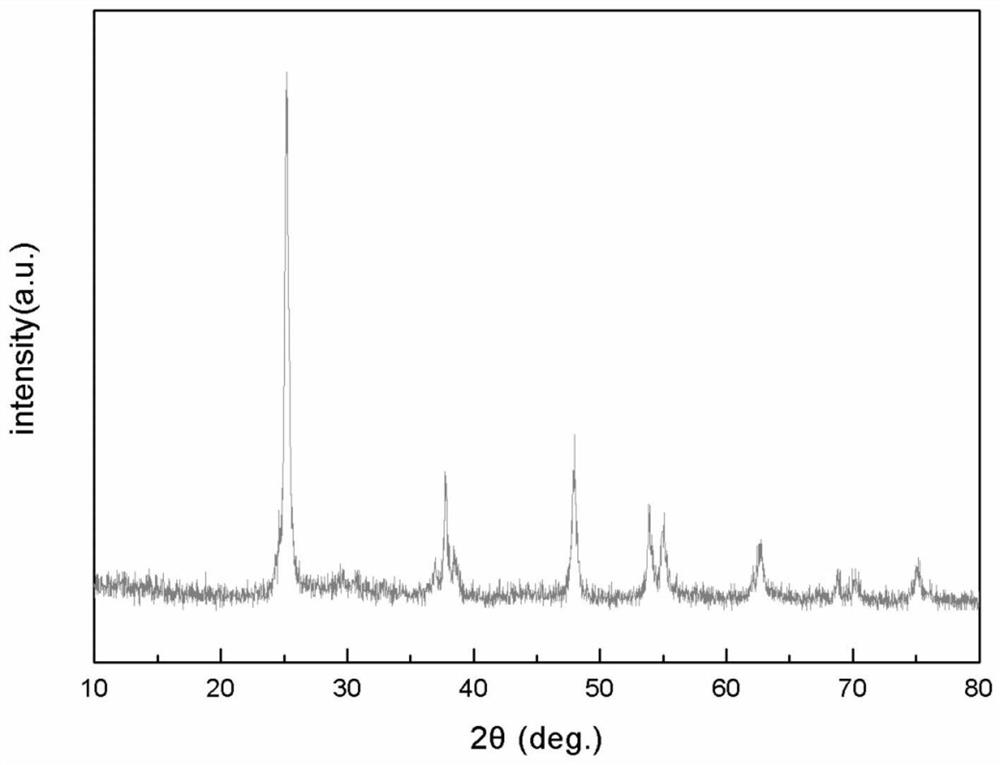

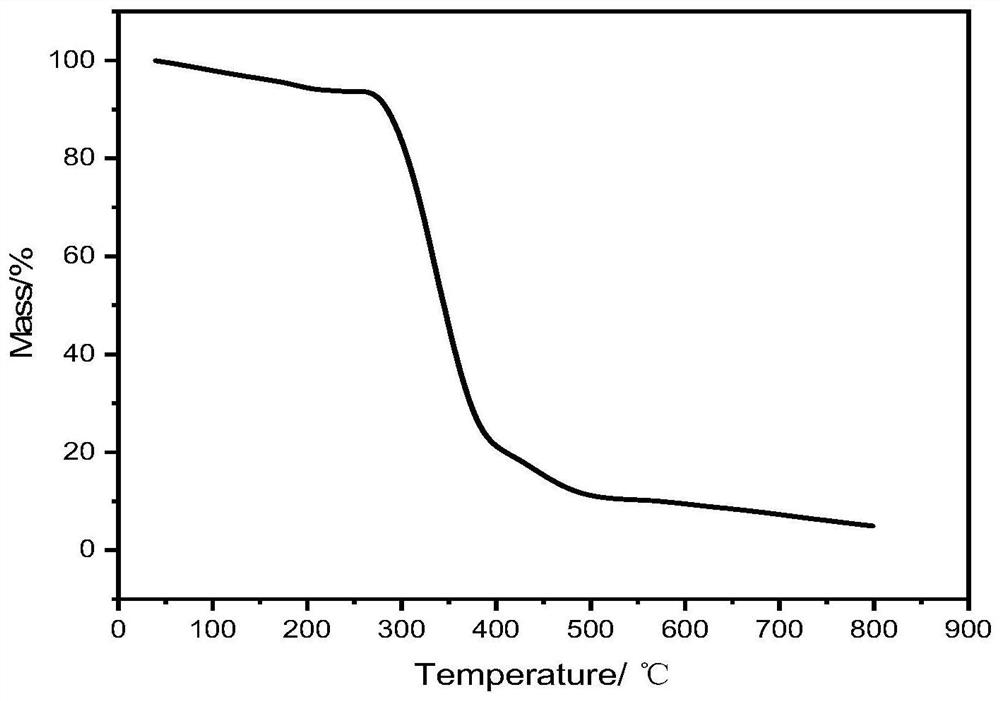

[0047] A kind of embodiment of the preparation method of nano titanium dioxide / graphene negative electrode material of the present invention, comprises the following steps:

[0048] (1) Add 0.27mL ammonia water, 5mL butyl titanate and 0.25g sodium fluoroborate successively to the graphene oxide suspension in the ice bath, mix and stir evenly, continue the ice bath for 15min, and obtain the precursor solution A; the graphene oxide The preparation method of the suspension is as follows: prepare graphite oxide by the Hummer method, sonicate 16mg of graphite oxide in 80mL of ethanol with a 250W ultrasonic instrument for 3h to form a graphene oxide suspension, and ice-bath for 30min;

[0049] (2) Put the precursor solution A obtained in step (1) in a 100mL closed reaction kettle, and perform a solvothermal reaction at 90°C for 10 hours to obtain the precursor B;

[0050] (3) The precursor B in step (2) was washed with ethanol, dried, then placed under a nitrogen atmosphere, and sub...

Embodiment 2

[0055] A kind of embodiment of the preparation method of nano titanium dioxide / graphene negative electrode material of the present invention, comprises the following steps:

[0056] (1) Add 0.35mL ammonia water, 7mL butyl titanate and 0.15g sodium fluoroborate successively to the graphene oxide suspension in the ice bath, mix and stir evenly, and continue the ice bath for 15min to obtain the precursor solution A; the graphene oxide The preparation method of the suspension is as follows: prepare graphite oxide by the Hummer method, sonicate 30 mg of graphite oxide in 80 mL of ethanol with a 250 W ultrasonic instrument for 3 h to form a graphene oxide suspension, and ice-bath for 30 min;

[0057] (2) Put the precursor solution A obtained in step (1) in a 100mL closed reaction kettle, and perform a solvothermal reaction at 90°C for 10 hours to obtain the precursor B;

[0058] (3) The precursor B in step (2) was washed with ethanol, dried, then placed under a nitrogen atmosphere, ...

Embodiment 3

[0062] A kind of embodiment of the preparation method of nano titanium dioxide / graphene negative electrode material of the present invention, comprises the following steps:

[0063] (1) Add 0.3mL ammonia water, 7.5mL butyl titanate and 0.2g sodium fluoroborate successively to the graphene oxide suspension in the ice bath, mix and stir evenly, and continue the ice bath for 15min to obtain the precursor solution A; the graphite oxide The preparation method of the olefin suspension is: adopt the Hummer method to prepare graphite oxide, 20mg of graphite oxide is used in 80mL ethanol with a 250W ultrasonic instrument for 3h to form a graphene oxide suspension, and ice bath for 30min;

[0064] (2) Put the precursor solution A obtained in step (1) in a 100mL closed reaction kettle, and perform a solvothermal reaction at 90°C for 10 hours to obtain the precursor B;

[0065] (3) The precursor B in step (2) was washed with ethanol, dried, then placed under a nitrogen atmosphere, and sub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com