Automatic production line of chamfering machine

An automatic production line and chamfering machine technology, applied in metal processing machinery parts, milling machine equipment details, maintenance and safety accessories, etc., can solve the problems of complex operation methods, high production costs, large floor space, etc., to achieve a wide range of applications , The effect of good processing quality and convenient adjustment and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below with reference to specific examples. The following examples are only descriptive and not restrictive, and the protection scope of the present invention cannot be limited by this.

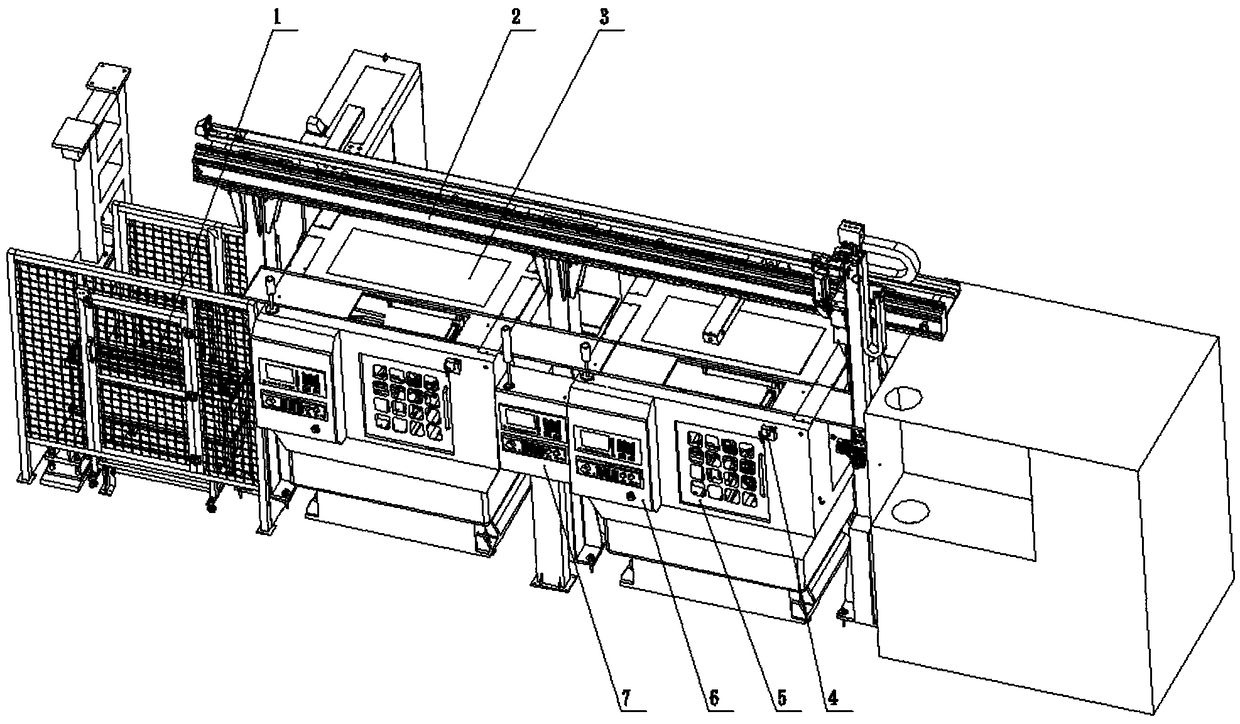

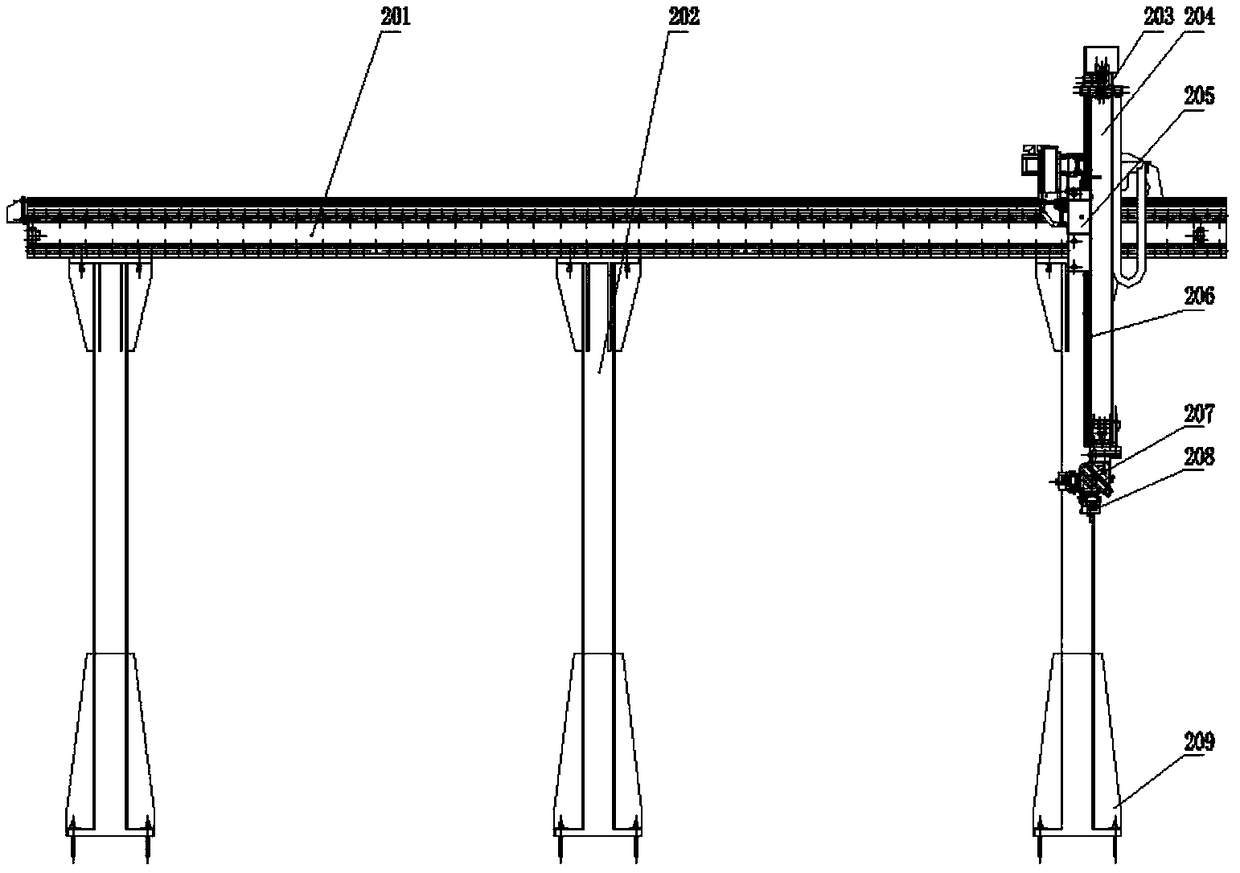

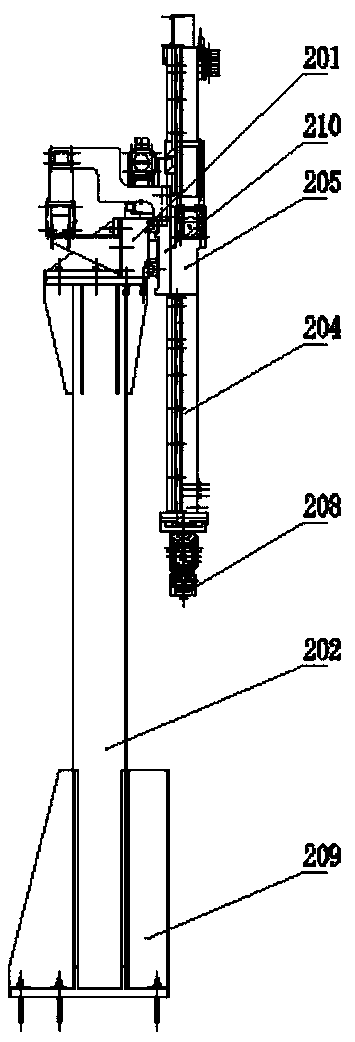

[0030] An automatic production line of chamfering machine, including three-axis chamfering machine 3, automatic line truss 2, workpiece horizontal movement slide table 1 and automatic line control box (not shown in the figure), workpiece horizontal movement slide table and automatic line truss left and right coaxial Place in order, place two three-axis chamfering machines on the left and right side by side in the automatic line truss;

[0031] The front end of the three-axis chamfering machine is equipped with a chamfering machine control panel 6, and the automatic line truss column between the two three-axis chamfering machines is equipped with a truss control panel 7 at the front end, which is convenient for the operator to set up; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com