High-frequency induction heat-treatment system with IGBT (Insulated Gate Bipolar Translator)

A heat treatment system and high-frequency induction technology, applied in the direction of improving energy efficiency and process efficiency, can solve the problems of IGBT switching loss, complex process adjustment, narrow frequency range, etc., to achieve high electrothermal efficiency, simple process adjustment, frequency wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

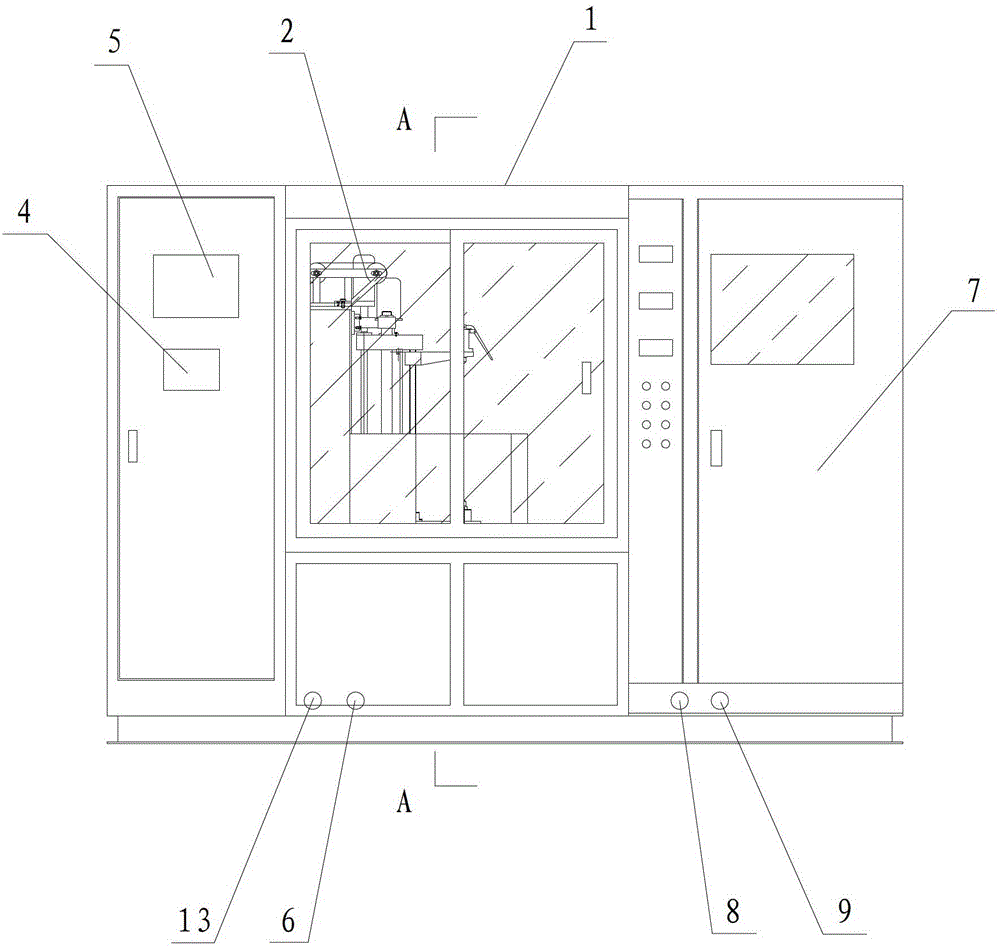

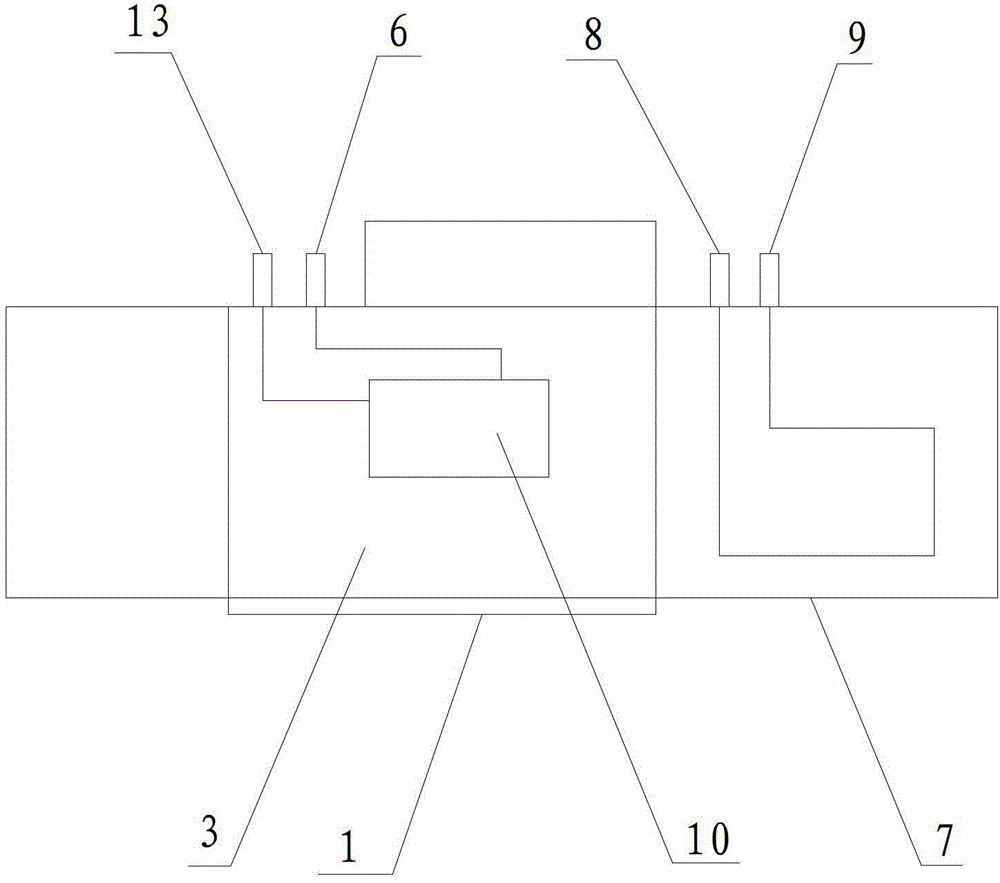

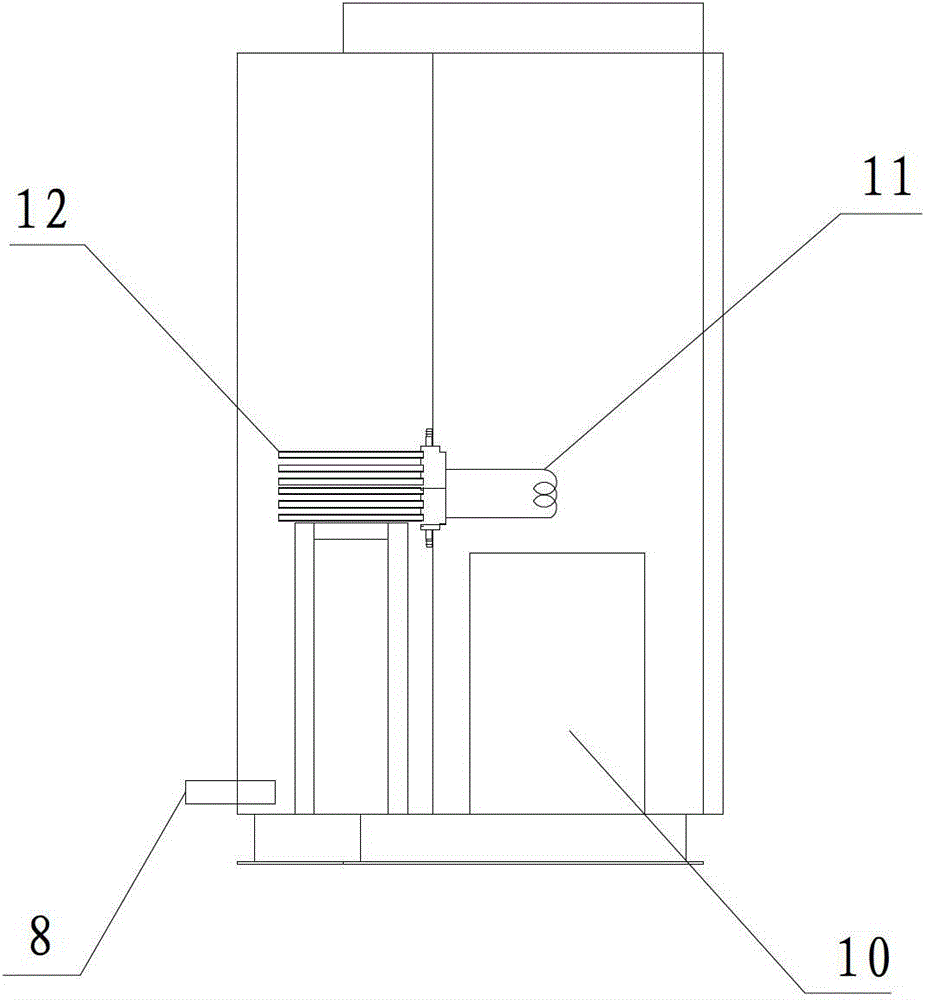

[0024] Such as Figure 1-4 As shown, a kind of IGBT high-frequency induction heat treatment system described in the embodiment of the present invention includes a body 1, a mechanical transmission system 2 and a circulating water cooling system 3 are provided inside the body 1, and a working The working condition management system 4 is provided with a touch screen control system 5, the bottom of the working condition management system 4 is provided with a workpiece coolant inlet 13 and a workpiece coolant outlet 6, and the right side of the body 1 is provided with an IGBT sensor The heating power supply 7 and the bottom of the IGBT induction heating power supply 7 are provided with a power supply cooling liquid inlet 8 and a power supply cooling liquid outlet 9 . The circulating water cooling system 3 includes a water tank 10 connected to the workpiece cooling liquid inlet 13 and the workpiece cooling liquid outlet 6 . An output induction coil 11 is arranged above the water t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com