Anti-jammed and anti-blocking wearproof ball valve

A wear-resistant ball and anti-blocking technology, applied in valve devices, cocks including cut-off devices, engine components, etc., can solve the problems of valve cavity deposition, blockage, switch jamming, etc., to solve valve jamming and ensure safety. , The effect of preventing medium deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is specifically described below by the embodiment, only for further illustrating the present invention, can not be interpreted as the limitation of protection scope of the present invention, the technical engineer of this field can make some non-essential improvements and improvements to the present invention according to the content of the above-mentioned invention Adjustment.

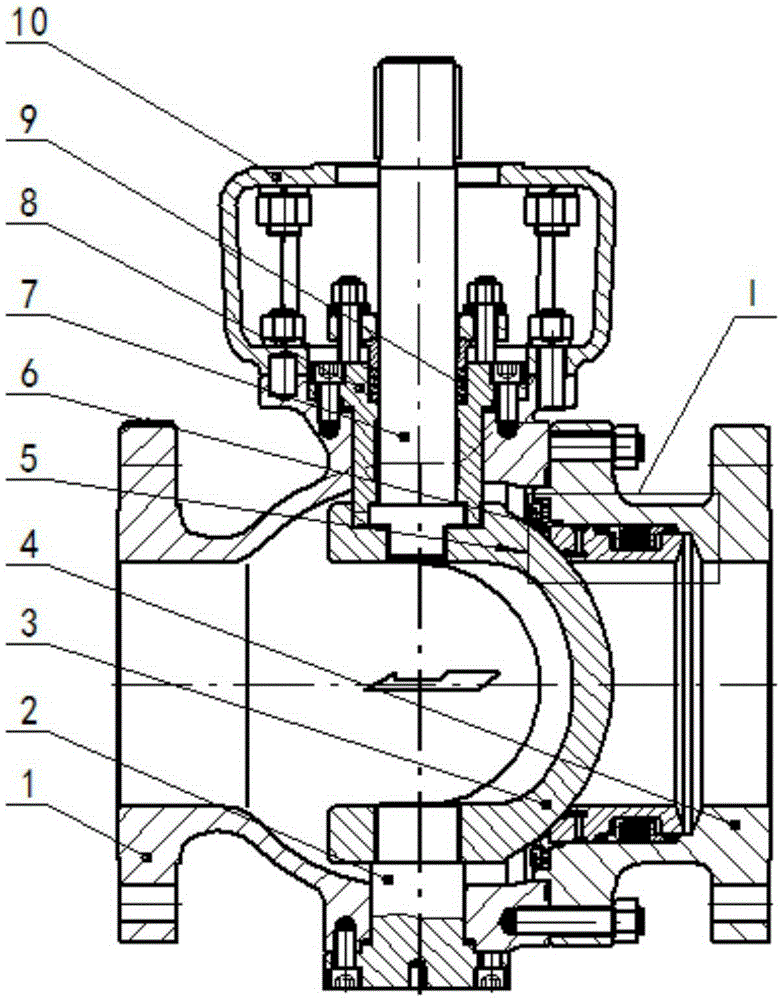

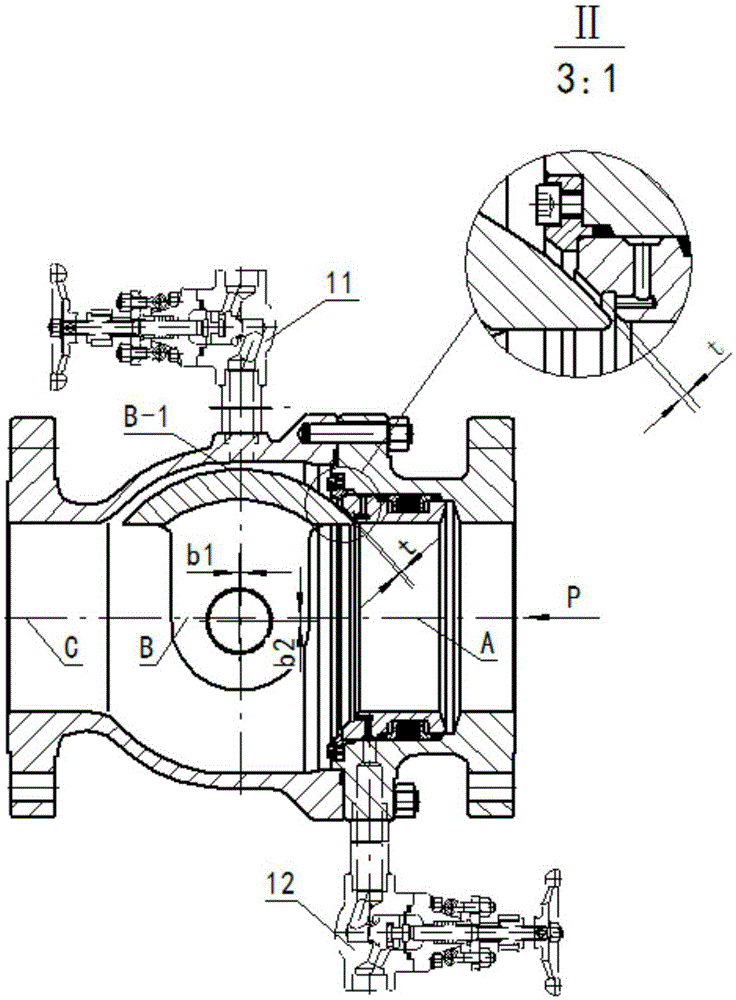

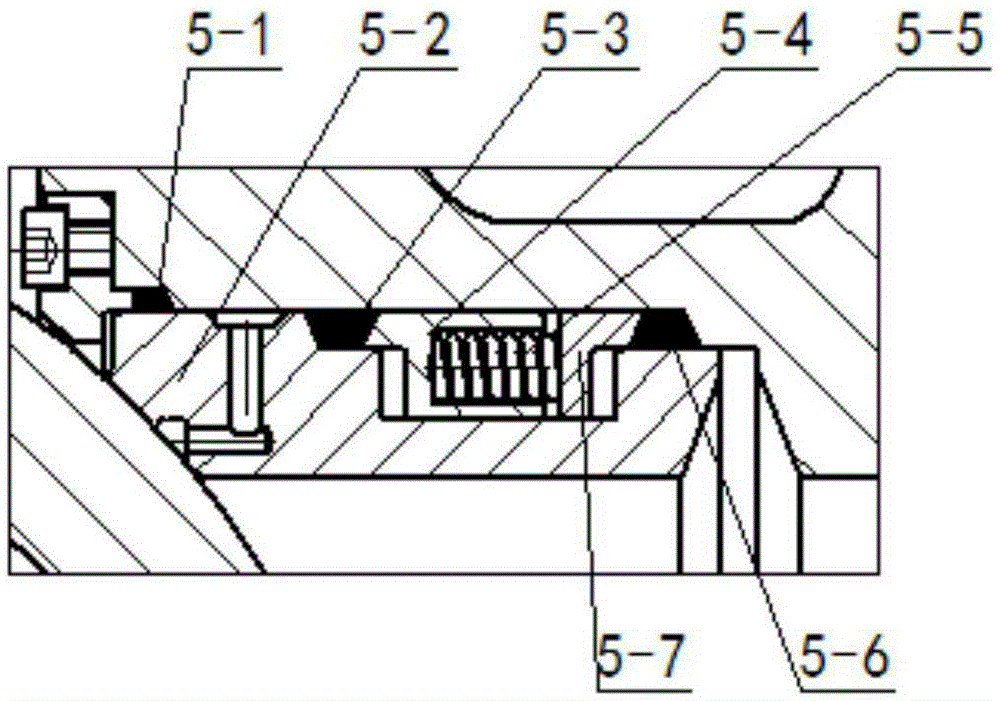

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, an anti-seize, anti-blocking and wear-resistant valve includes a valve body, a lower shaft 2, a valve core 3, a valve seat 5-2, a limiting plate 6, a valve stem 7, an upper shaft 8, packing 9 and a bracket 10 , the valve body includes a valve body main body 1 and a valve body side cover 4 detachably spliced left and right. Whole ball structure, the valve core 3 includes an upper connecting arm 31, a side ball panel 32 and a lower connecting arm 33, the upper connecting arm 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com