Electronic jet drying cylinder dryer

A dryer and drying cylinder technology, applied in dryers, drying, progressive dryers and other directions, can solve the problems of difficult to guarantee product quality, low production efficiency, and high production costs, reducing floor space, Ease of maintenance and upkeep, the effect of reduced steel usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

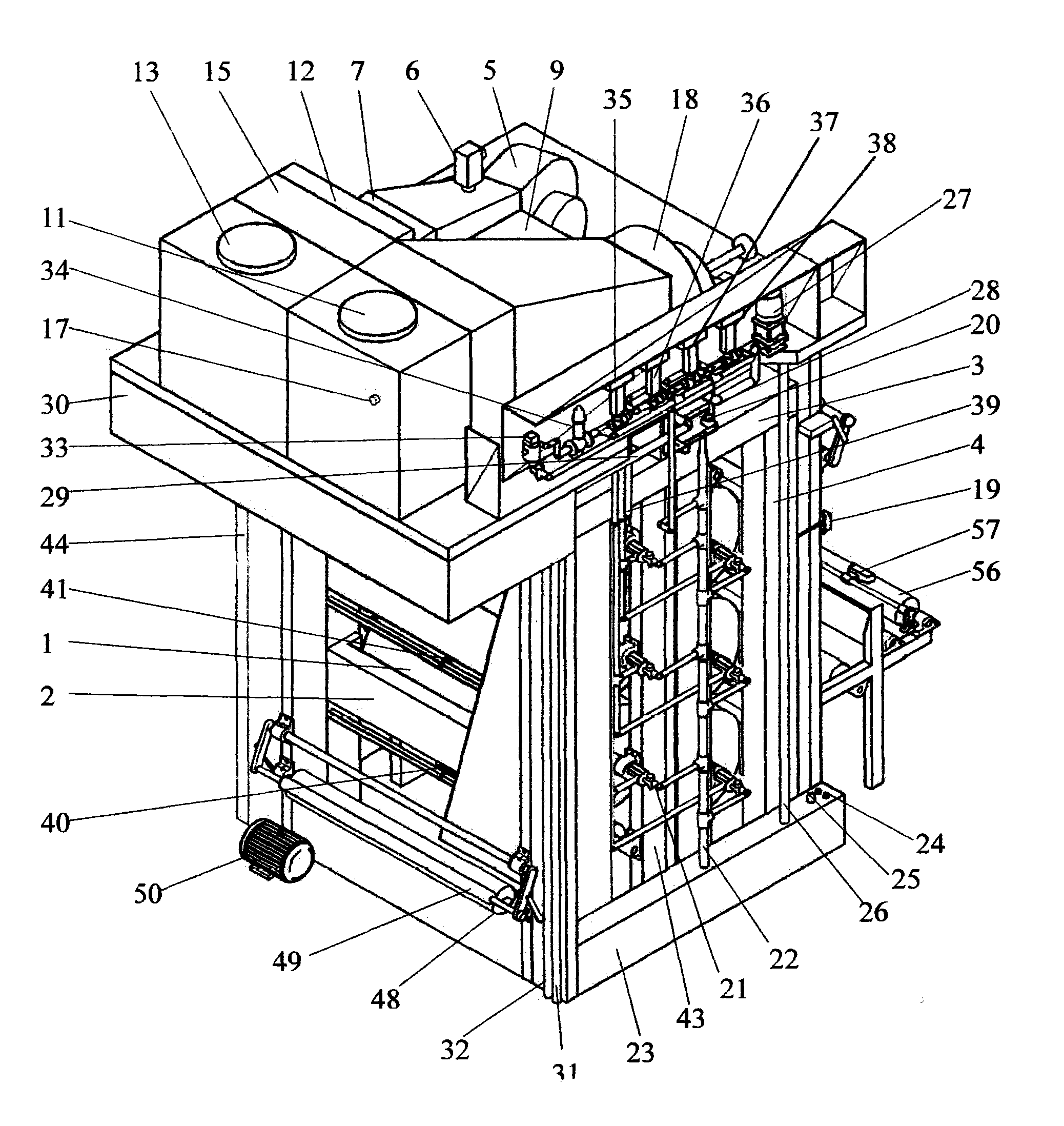

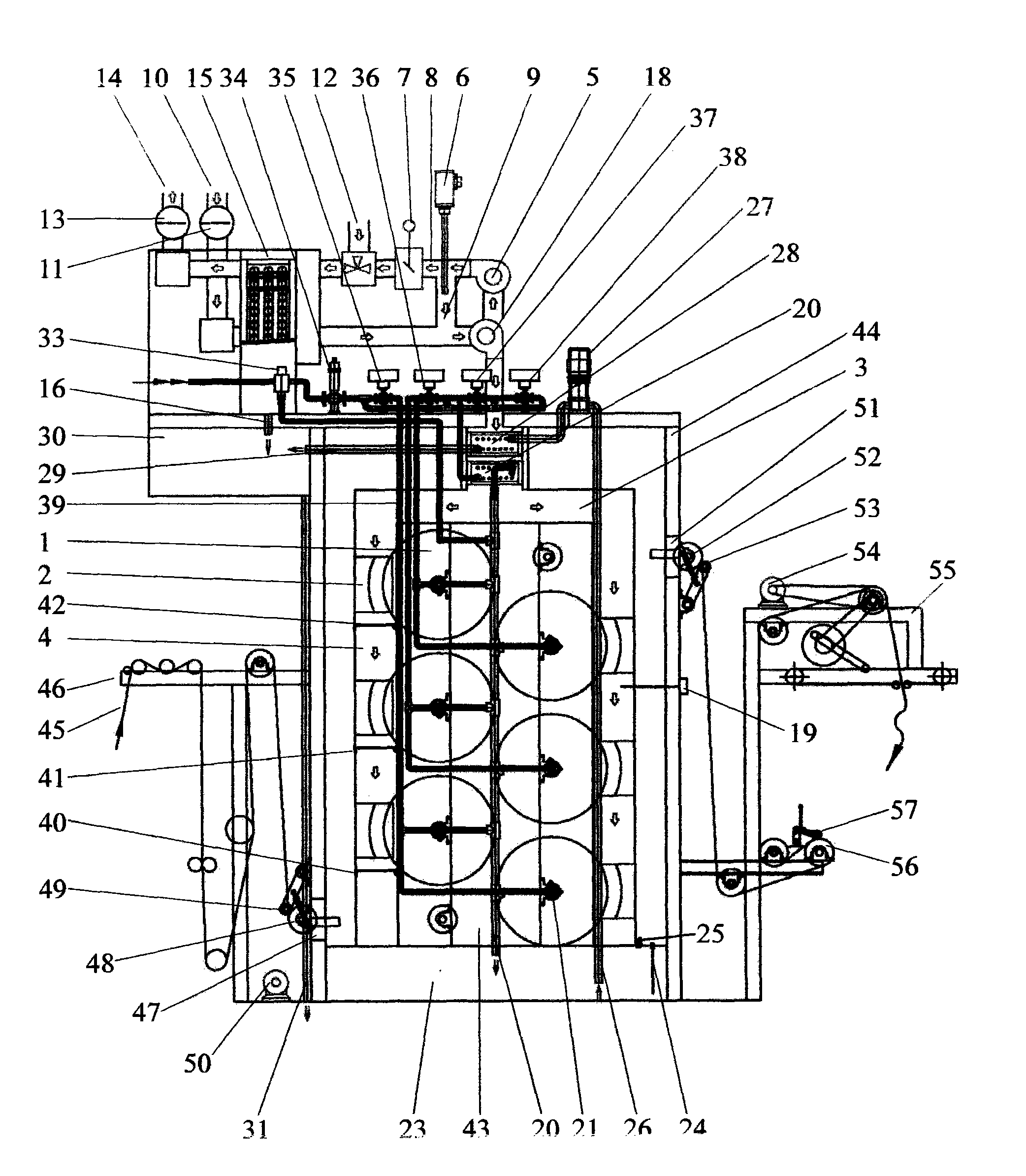

[0039] For the convenience of reading, in figure 1 Among them, the wallboard on one side of the heat-insulating and heat-preserving drying room 44 is removed, and the wallboard above the cloth inlet 47 is only drawn partly by oblique cutting; figure 2 Among them, the waste gas heat recovery part installed on the roof of the heat-insulating and heat-preserving drying room 44 is represented by a schematic diagram. The specific implementation will be described below in conjunction with the accompanying drawings.

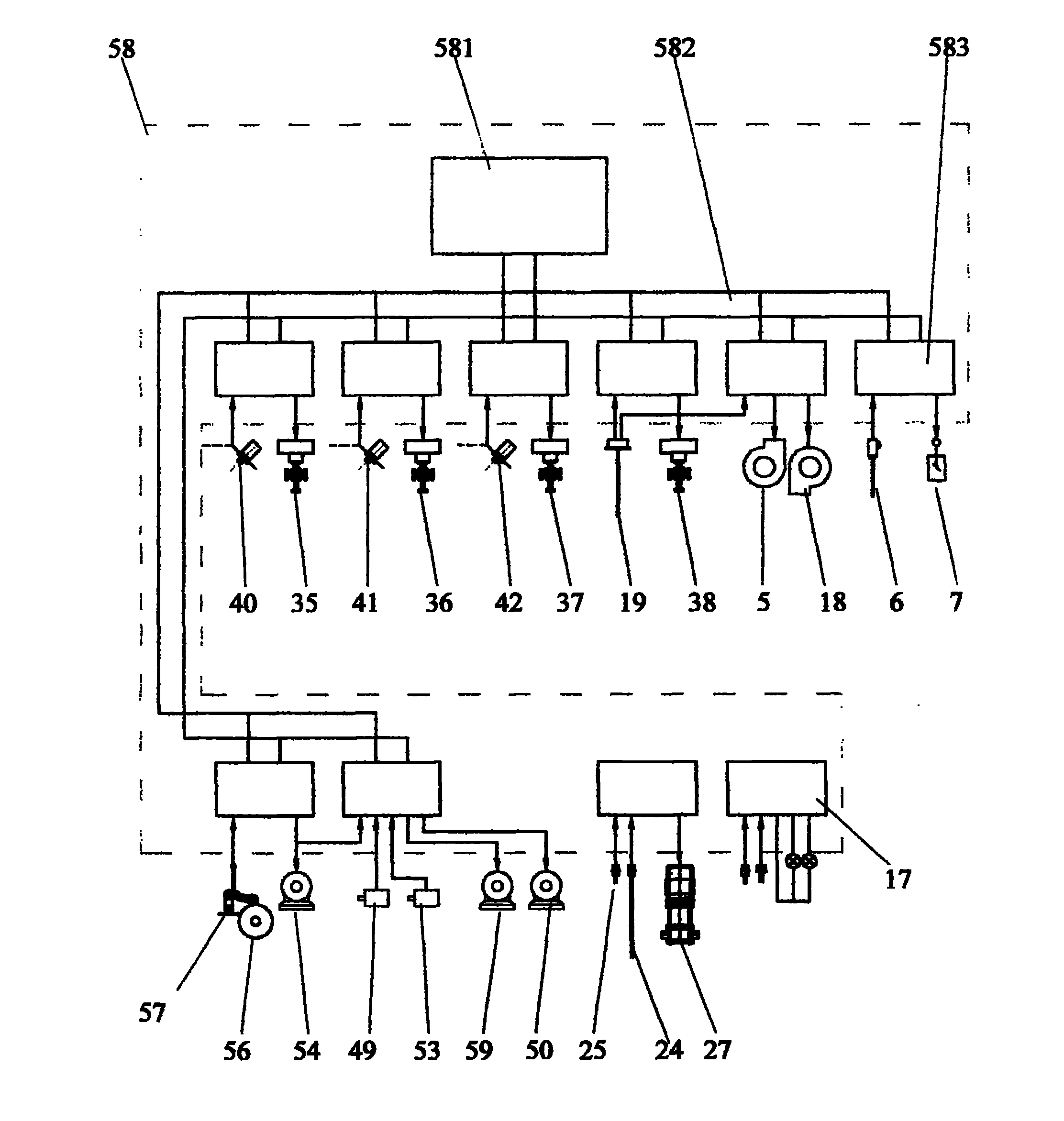

[0040] see figure 1 , figure 2 , image 3 , use channel steel or other profiled steel, make drying cylinder column 43 and be used to install the steel frame of air jet pipeline 4, air jet duct 3, cloth inlet roller 48, cloth outlet roller 52, thermal insulation oven 44. According to FZ 92065-2006, select 6 siphon drainage stainless steel welded flat plate dryers with an outer diameter of φ800mm as the standard dryer 1, divide them into two rows of 3 in each row, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com