Patents

Literature

40results about How to "Good production demand" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

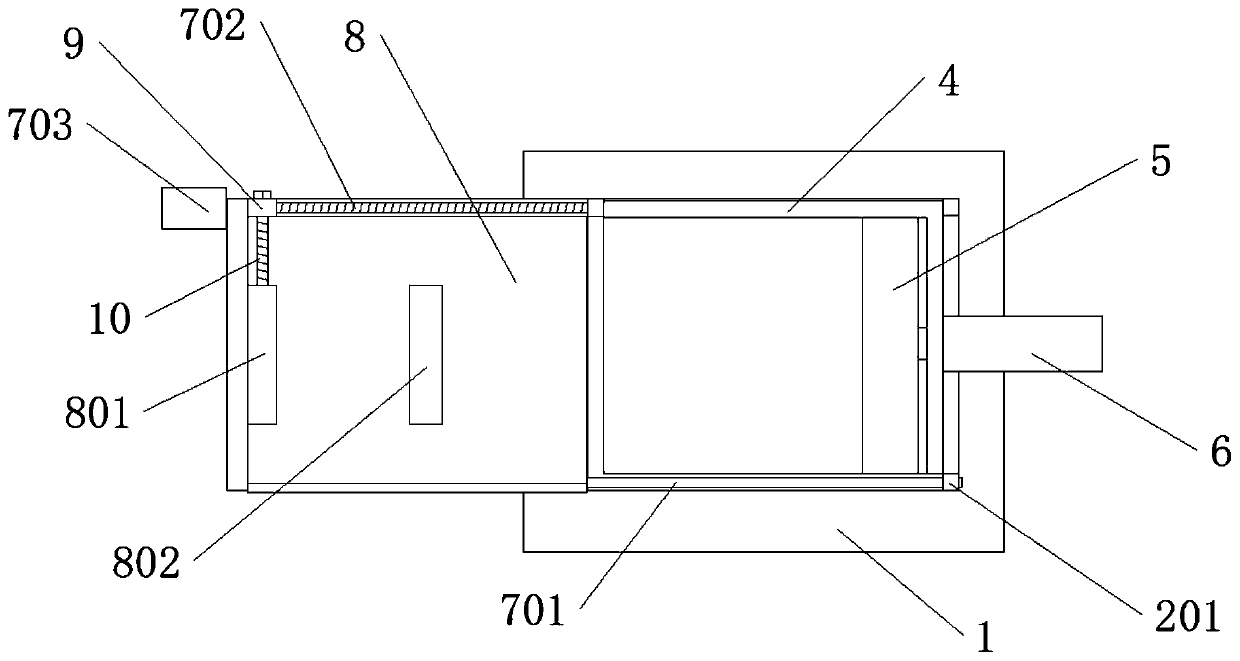

Electronic jet drying cylinder dryer

InactiveCN102183128AMeet production needsSatisfy productivityDrying gas arrangementsLiquid/gas/vapor removalTextile printerWaste heat recovery unit

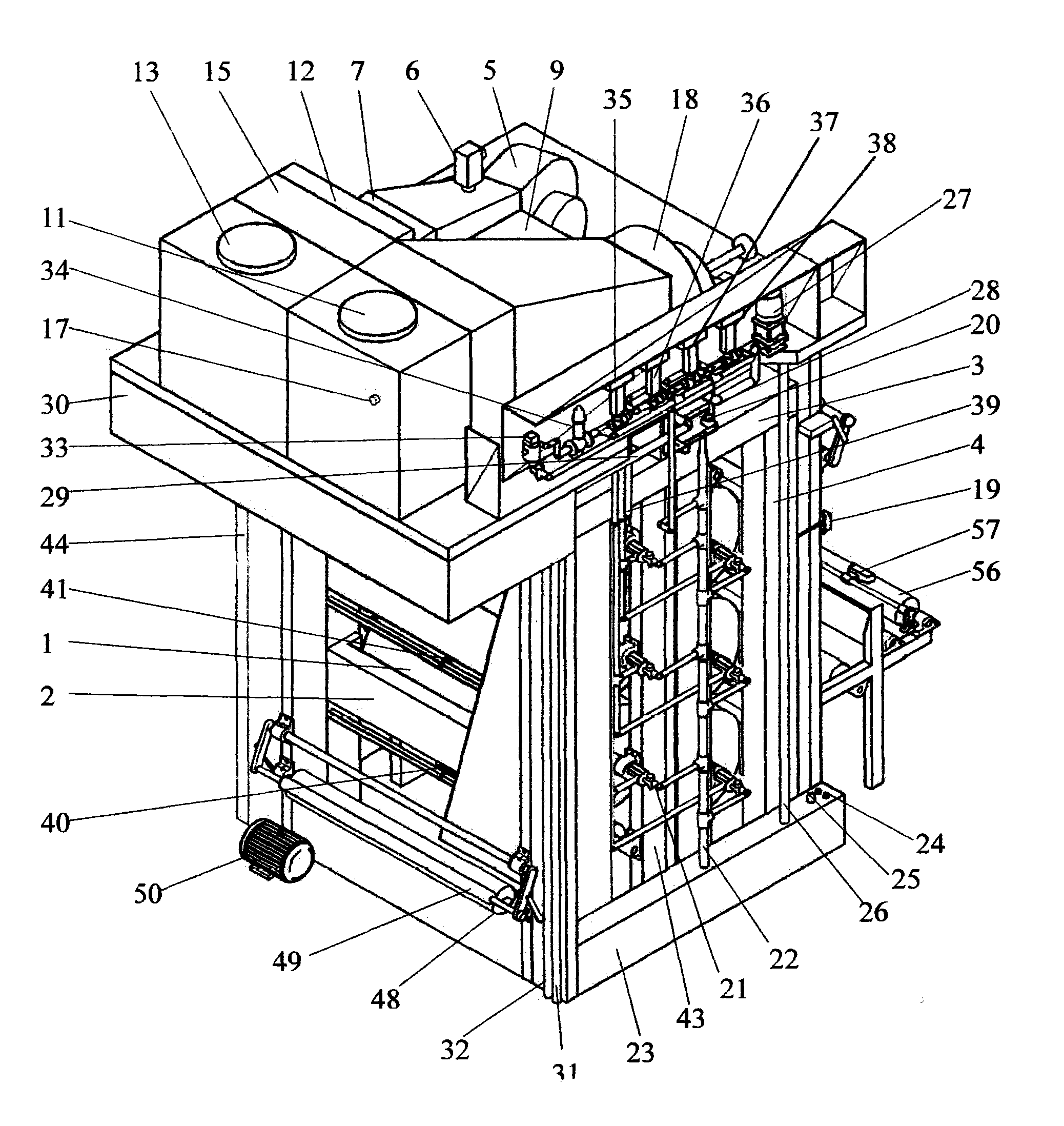

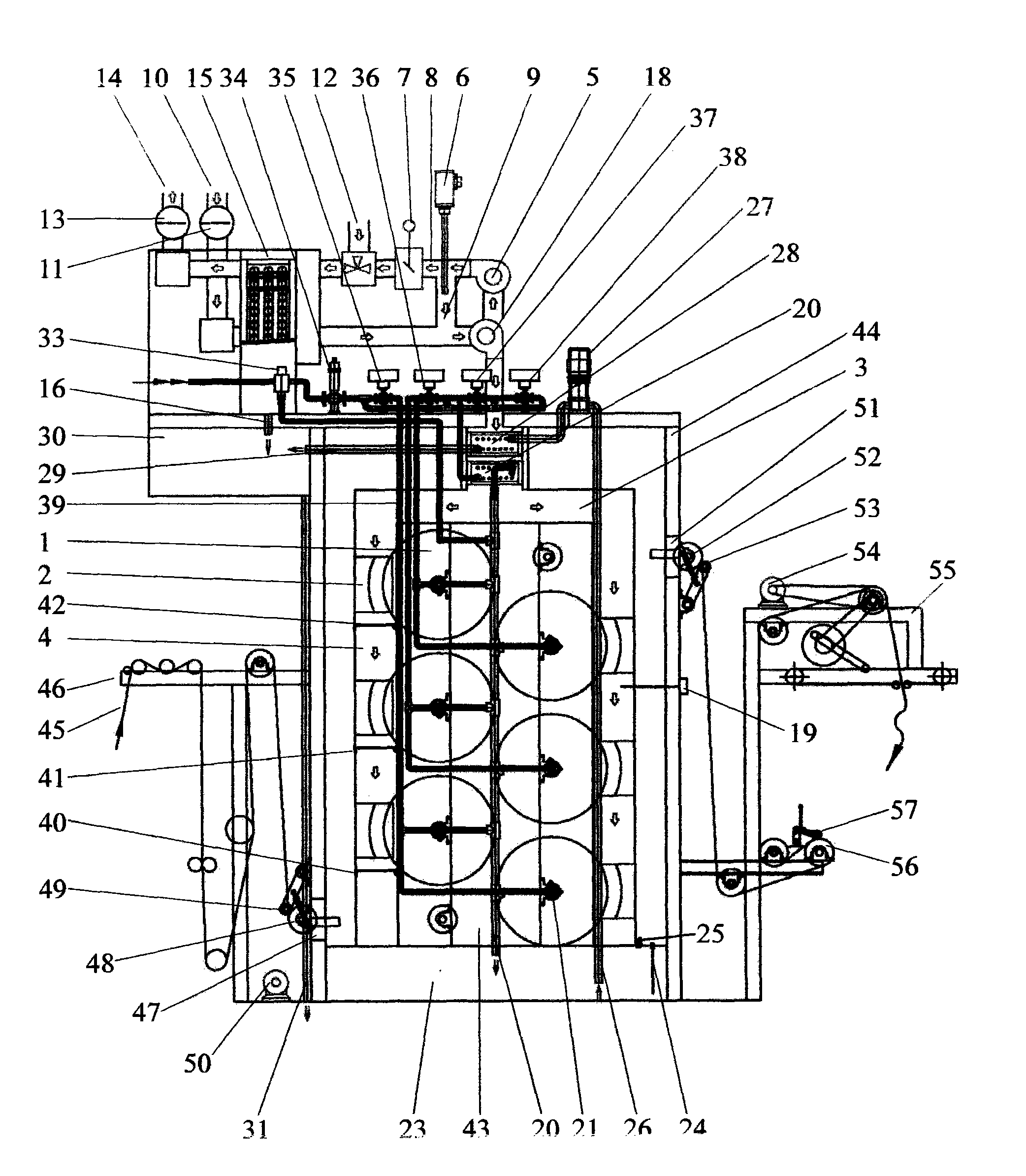

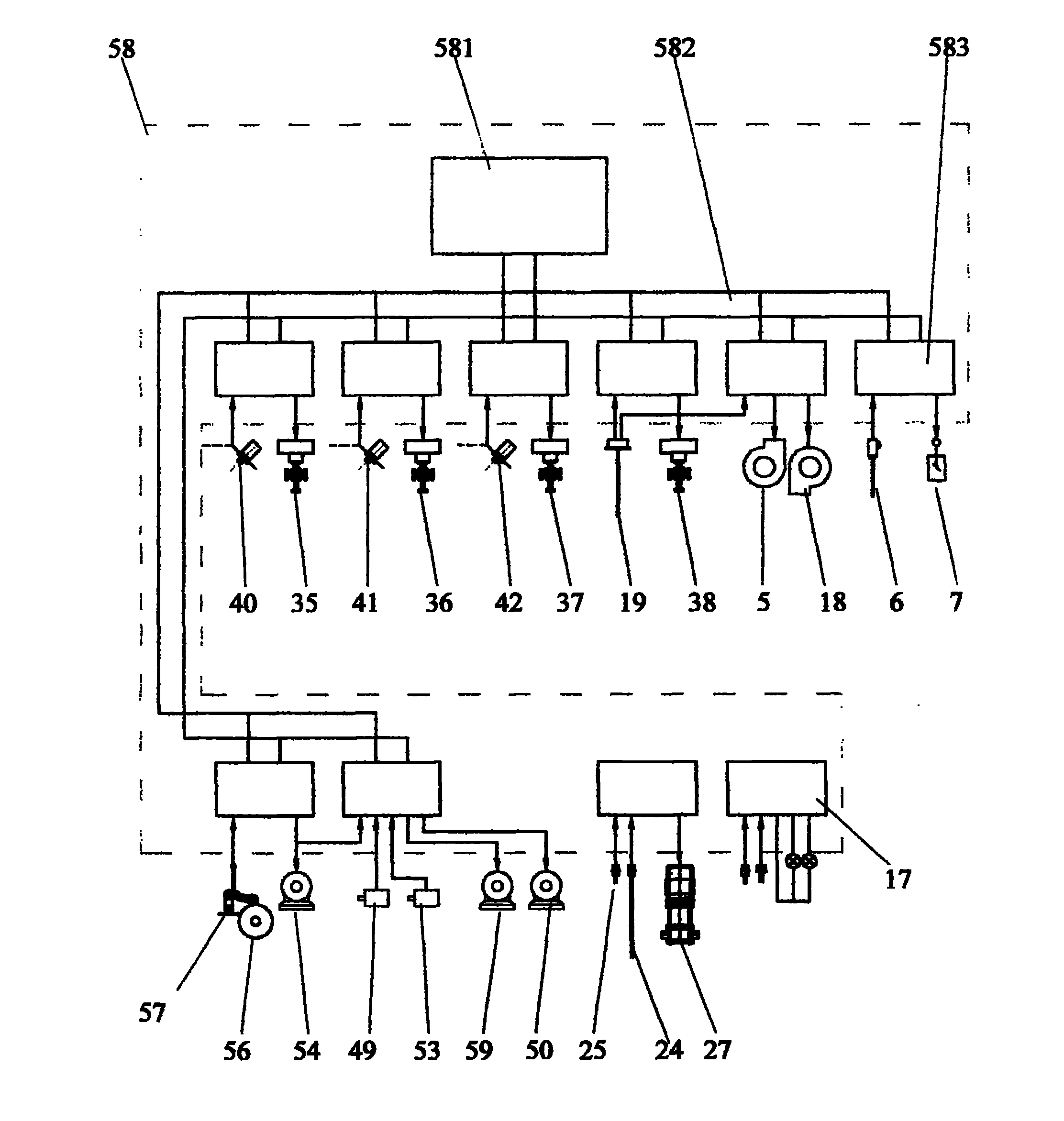

The invention discloses a textile printing and dyeing electronic jet drying cylinder dryer and a jet drying cylinder, waste gas heat recovery and condensate water recovery thereof and a method for setting a moisture regain reference roller. The electronic jet drying cylinder dryer consists of a heat insulating and preserving drying room, the jet drying cylinder, a heat recovery and jet system and an electronic information system, wherein exhaust air is divided into exhausted air and circulating air according to humidity of the exhaust air; heat of the exhausted air is recovered by fresh air; the fresh air is mixed with the circulating air; the heat of condensate water is then recovered and the condensate water is sprayed to a textile; heating is performed and drying conditions are improved; complete on-line detection and control are performed on temperature, tension and moisture regain of the textile and humidity, temperature and speed of an air flow; therefore, heat application efficiency and drying efficiency are increased, production cost is reduced and production requirement of high-grade textiles is met in a scientific, strict, careful and reliable drying mode. The electronic jet drying cylinder dryer can be used for substituting a drying cylinder dryer or is made by modifying the drying cylinder dryer; a waste gas heat recovery system and a condensate water recovery system are suitable for various heating production occasions; and by the method for setting the moisture regain reference roller, reliability and validity of moisture regain control are solved.

Owner:段新顺 +1

Preparation method of fluorocarbon compound liposome

InactiveCN102988294AImprove stabilitySmall particle sizeRespiratory disorderIn-vivo testing preparationsCholesterolOrganosolv

The invention relates to a preparation method of fluorocarbon compound liposome. The method comprises the following steps of a. dissolving 1-50 parts by weight of phospholipid and 0-50 parts by weight of cholesterol in 200 parts by weight of an organic solvent, and mixing uniformly under the assistance of ultrasonic; b. adding 10-50 parts by weight of fluorocarbon in the organic solvent with the phospholipid dissolved therein, and continuously mixing uniformly under the assistance of the ultrasonic; and c. dropwise-adding the solution obtained from the step b in 100-500 parts by weight of a salt solution, stirring the solution with a stirring rate of 500-2,500 revolutions per minute until the organic solvent is volatilized completely, the stirring time being 2 hours, and thus the fluorocarbon compound liposome is obtained. The prepared fluorocarbon compound liposome has good stability and small particle size. The method is simple, and is convenient for large-scale production. The prepared fluorocarbon compound liposome can have good applications in the aspects such as emergency oxygen supply drugs, acute blood supply, contrast agents, etc.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

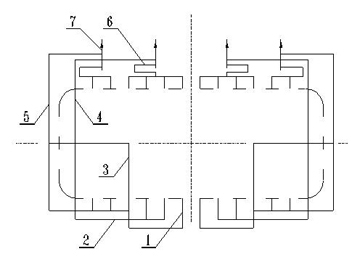

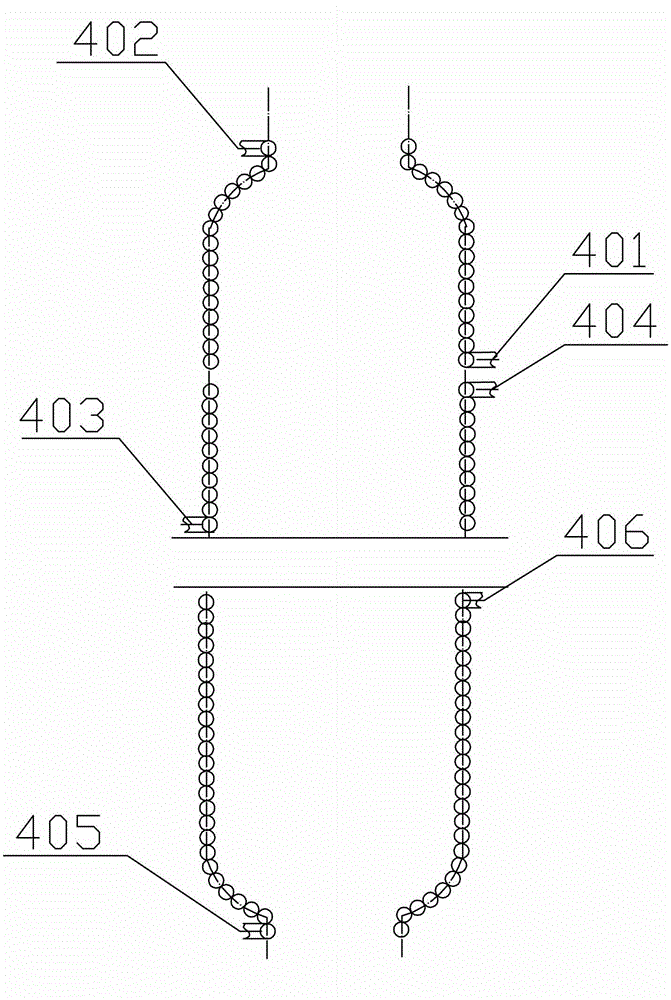

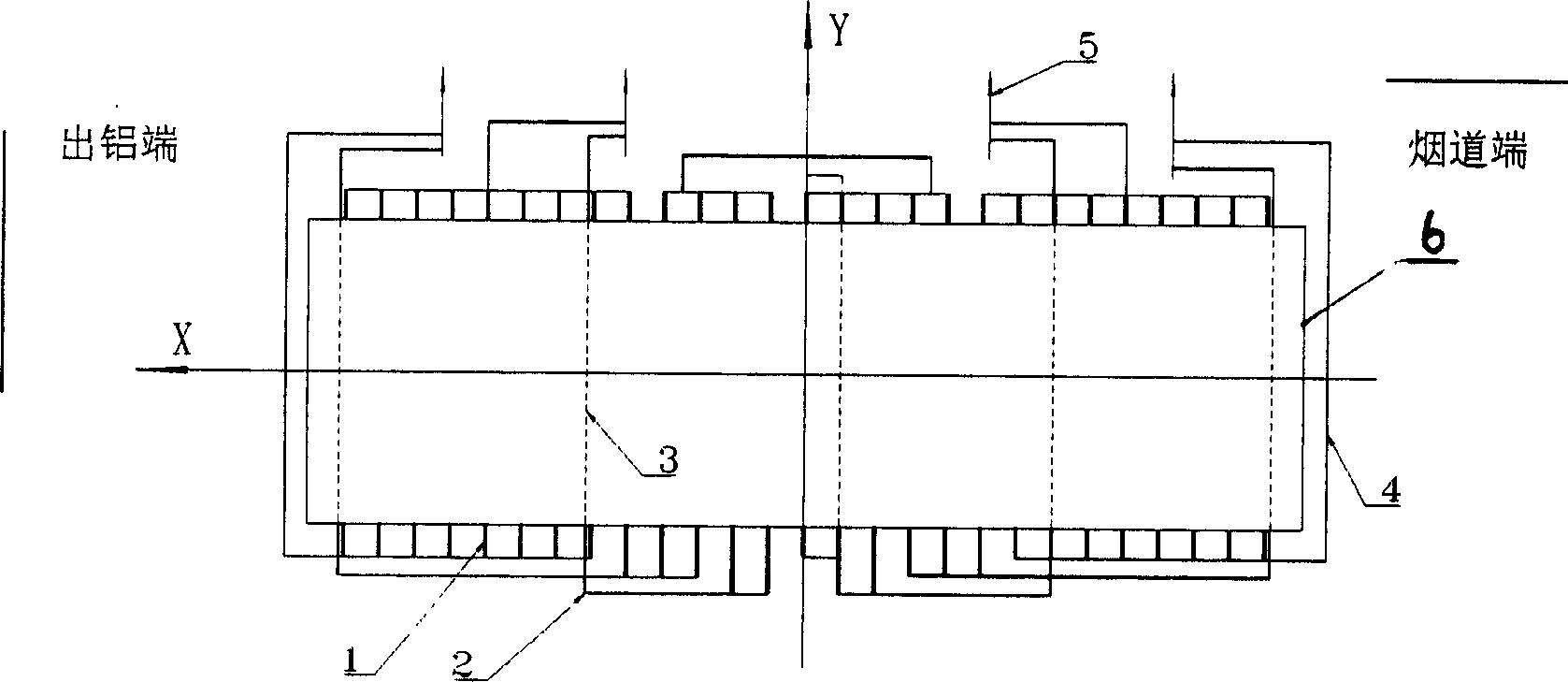

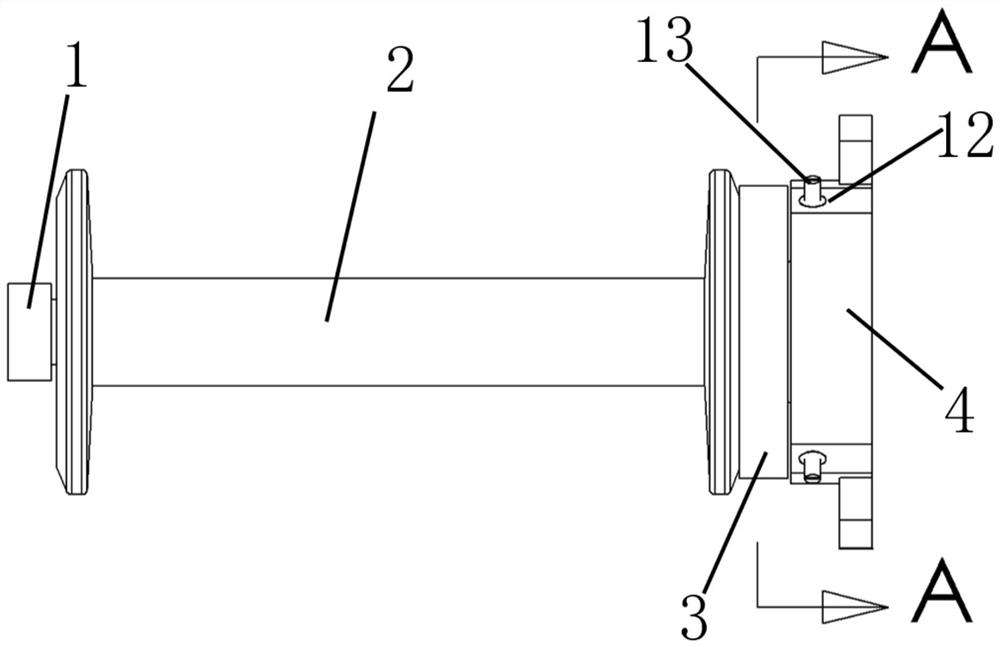

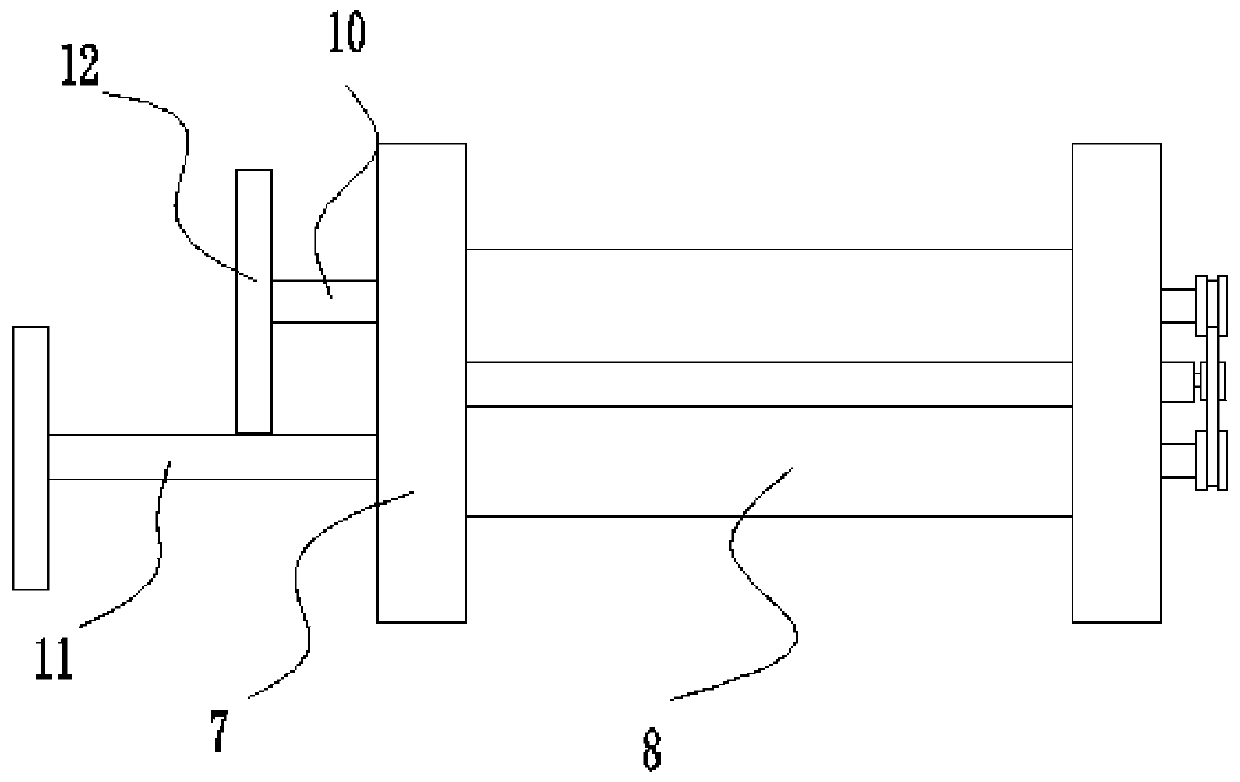

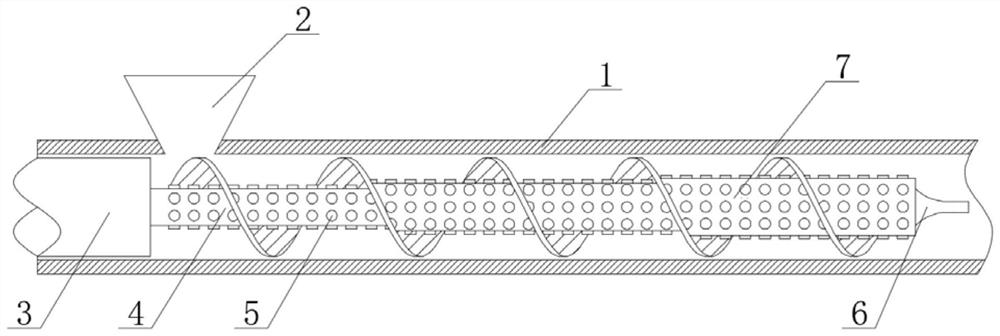

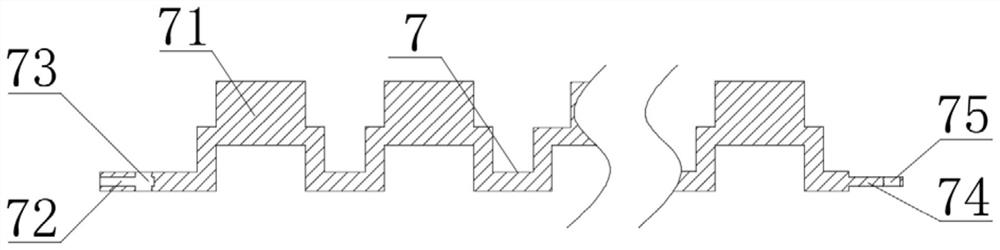

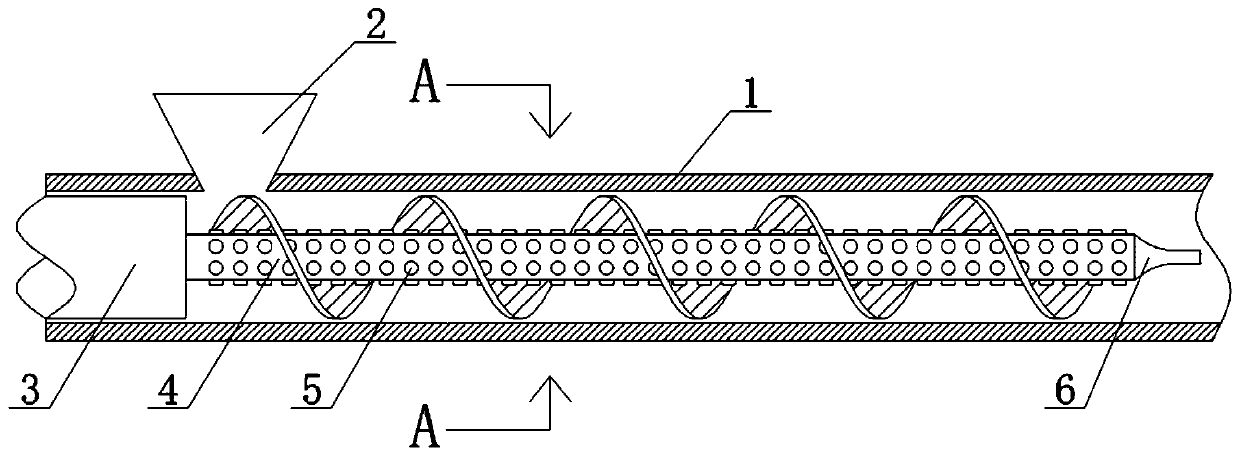

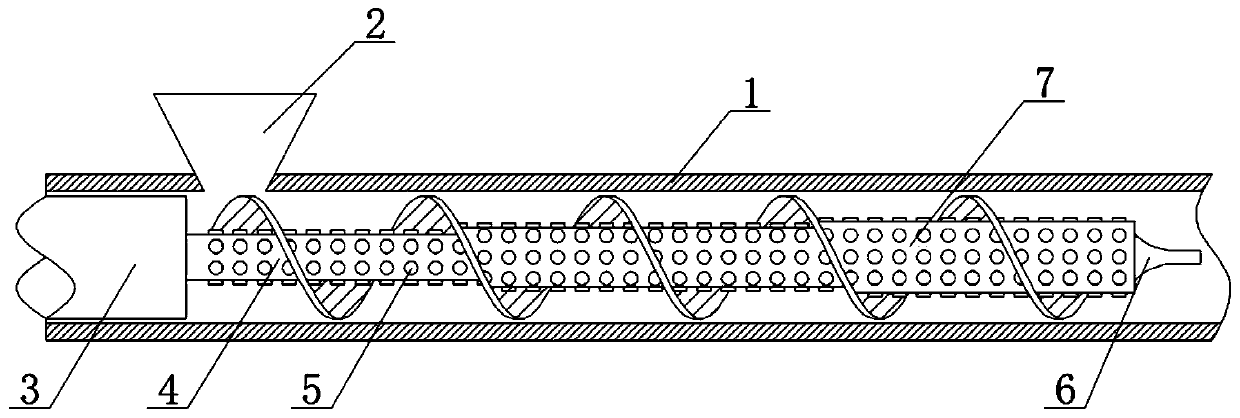

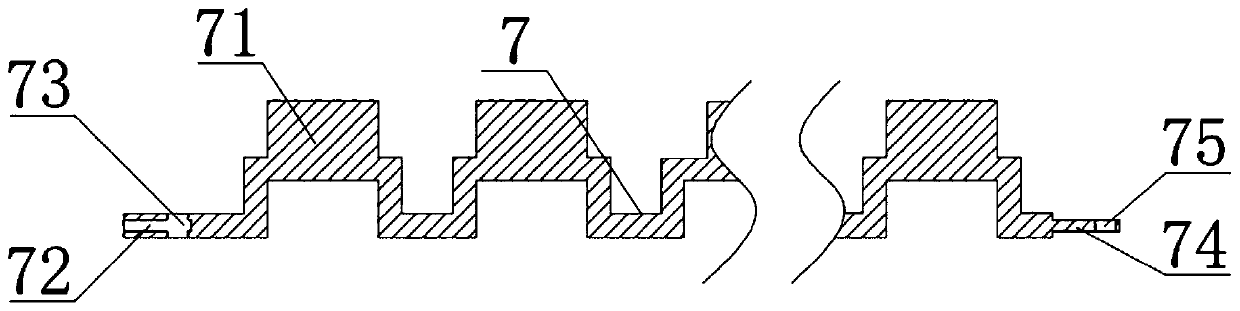

Method for configuring bus bar of aluminum electrolytic bath

InactiveCN101857960ASave bus consumptionGood design and production requirementsEmbedded systemElectricity

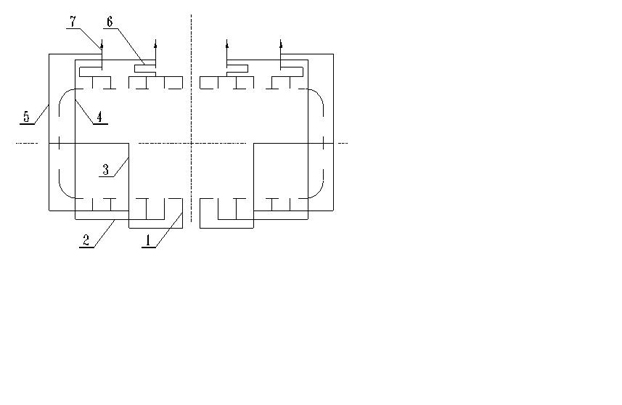

The invention discloses a method for configuring a bus bar of an aluminum electrolytic bath. The current in the electrolytic bath flows out from a power-in bus bar through a negative soft bus bar (1) to a zigzag bottom bus bar (3), a bottom through bus bar (4) and a side bus bar (5) respectively though a power-in negative bus bar, then enters a side bus bar through the zigzag bottom bus bar (3) and finally enters 4 pillar bus bars (7) of a downstream bath through the bottom through bus bar (4) and the side bus bar (5) respectively; and the current also flows out from a power-out bus bar through the negative soft bus bar (1) to the 4 pillar bus bars (7) of the downstream bath through a power-out negative bus bar (6). In the method, in an overall consideration of technology and economy and based on the configuration form of negative and positive pole numbers of the whole bath and the power-in way, a scheme for the magnetic field compensation of large aluminum electrolytic baths is more rationally designed to achieve a good magnetic field compensation effect and save the using amount of the bus bar around the baths so as to overcome the adverse factors in the conventional electrolytic baths.

Owner:GUIYANG AL-MG DESIGN & RES INST

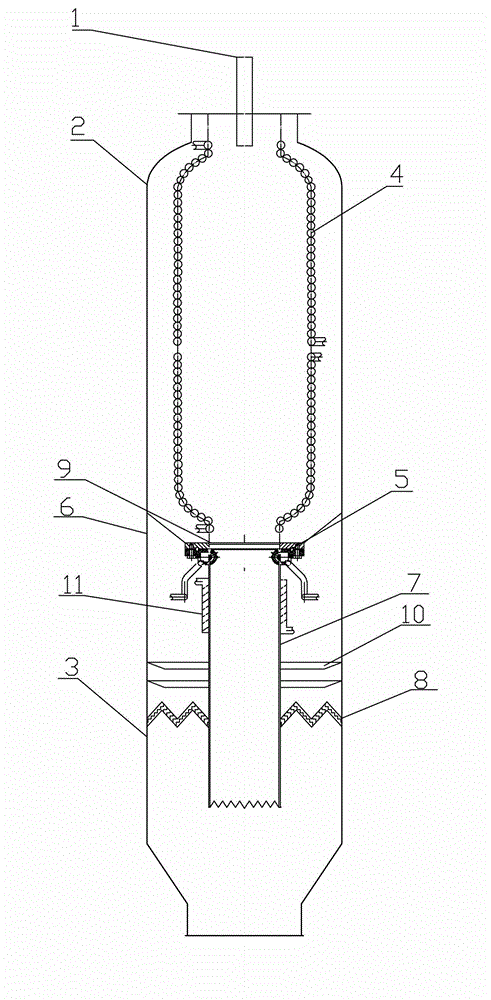

Multi-section water-cooling wall high-efficiency chilling gasification device

InactiveCN104560212AGood production demandEfficient use ofGasification processes detailsGasification apparatus detailsSlagEngineering

The invention relates to a multi-section water-cooling wall high-efficiency chilling gasification device. The multi-section water-cooling wall high-efficiency chilling gasification device comprises spray nozzles, a gasification chamber and a high-efficiency chilling device, wherein the gasification chamber is arranged on the upper part of the high-efficiency chilling device, and one or more spray nozzles are installed on a top flange of the gasification chamber; the gasification chamber is formed by one or more sections of water cooling walls, each water cooling wall is in a tabulation form or a tube winding form, a water outlet of each section of water cooling wall is arranged above the same section of water cooling wall, and the exterior of the water cooling wall is connected with a water supply device. The diameter of the gasification chamber is equivalent to that of the high-efficiency chilling device; each water cooling wall is connected with a slag opening of the gasification chamber in a plugging manner; a slag opening section is not provided with a water cooling wall; each spray nozzle is in a combined nozzle structure. A space is reserved for installing and overhauling the water cooling wall of a gasification furnace, the convenience is provided for examining the leakage and replacing each water cooling wall, and the real production requirement can be met.

Owner:水煤浆气化及煤化工国家工程研究中心

Five power-on bus distributing style with different current

ActiveCN1598068ATroubleshoot Magnetic FieldsHarm reductionBus-bar installationElectricityTransverse magnetic field

The invention discloses a 5-point generatrix configuration method of a large-area inequipotential electricity type. It is composed of the cathode soft generatrix, cathode generatrix, bottom generatrix, side generatrix, lower column generatrix and electrobath. The lower column generatrix is 5-piece configuration. The invention not only can make the current passing every column appropriate and effectively reduce the magnetic field in the slot and the transverse magnetic field, but also match with every slot paramete of the large-scale slot. Especially compared with the two columns, the center columune has low current and is benefit to reduce the danger caused by the middle level magnetic field in the electrobath to make the electrobath more stable.

Owner:GUIYANG AL-MG DESIGN & RES INST

Forming die with adjustable die cavity

Owner:苏州钧固精密模具有限公司

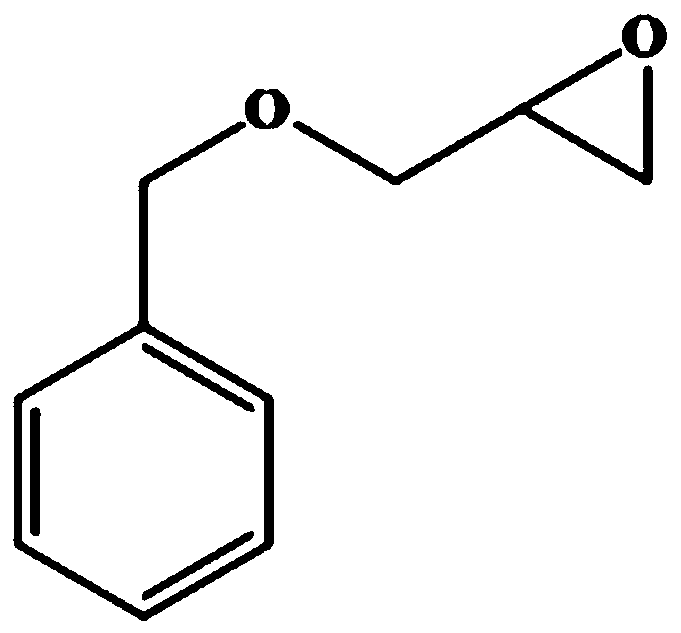

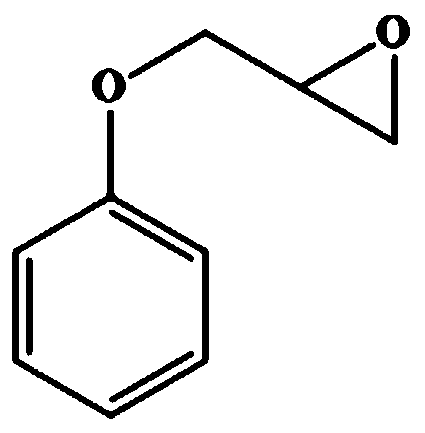

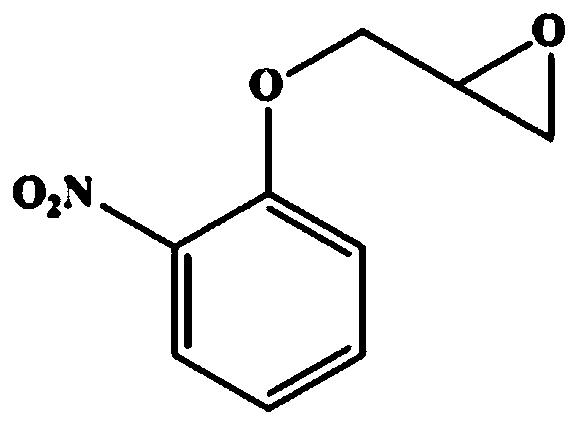

Halohydrin dehalogenase mutant for improving enantioselectivity and application thereof

ActiveCN110423740AHigh enantioselectivityImprove efficiencyBacteriaCarbon-halide lyasesArginineWild type

The invention relates to a halohydrin dehalogenase mutant for improving enantioselectivity and application thereof, and belongs to the technical field of enzyme engineering and biocatalysis. The halohydrin dehalogenase mutant is obtained by carrying out single-point mutation or combined mutation on 89th arginine, 137th valine, 178th proline, 179th asparagine and 187th phenylalanine in a sequence as shown in SEQ ID NO.1. Compared with wild type halohydrin dehalogenase, the mutant obtained by the invention obviously improves enantioselectivity (E value) during the preparation of (S)-o-nitrophenyl glycidyl ether, (R)-benzyl glycidyl ether and (R)-phenyl glycidyl ether, the maximum improvement is 44.6, 2.9 and 9.4 times of the original enzyme respectively, and has good industrial application prospect.

Owner:YANCHENG INST OF TECH

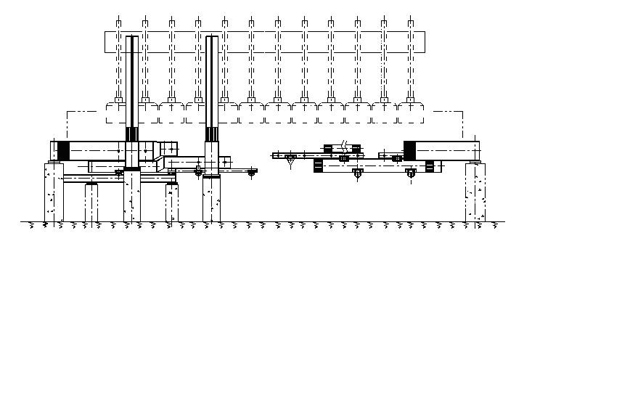

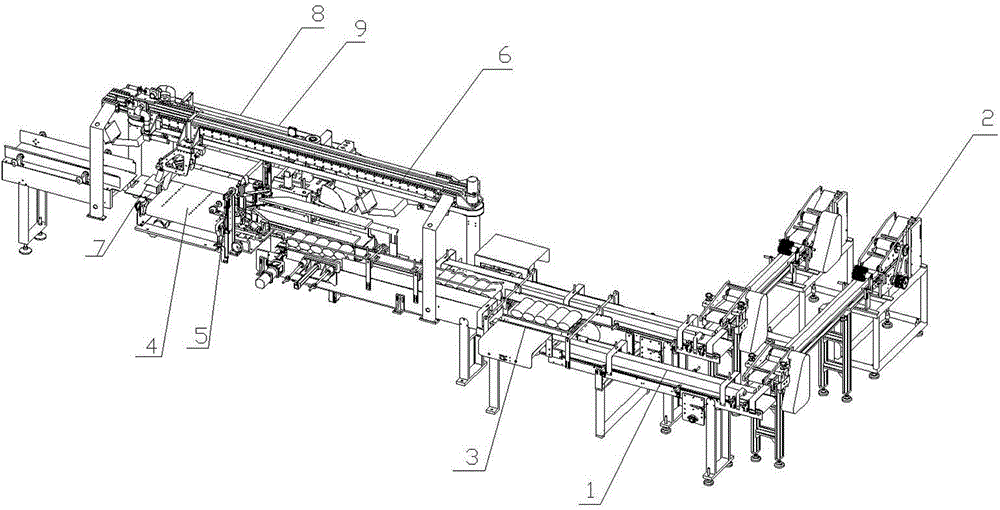

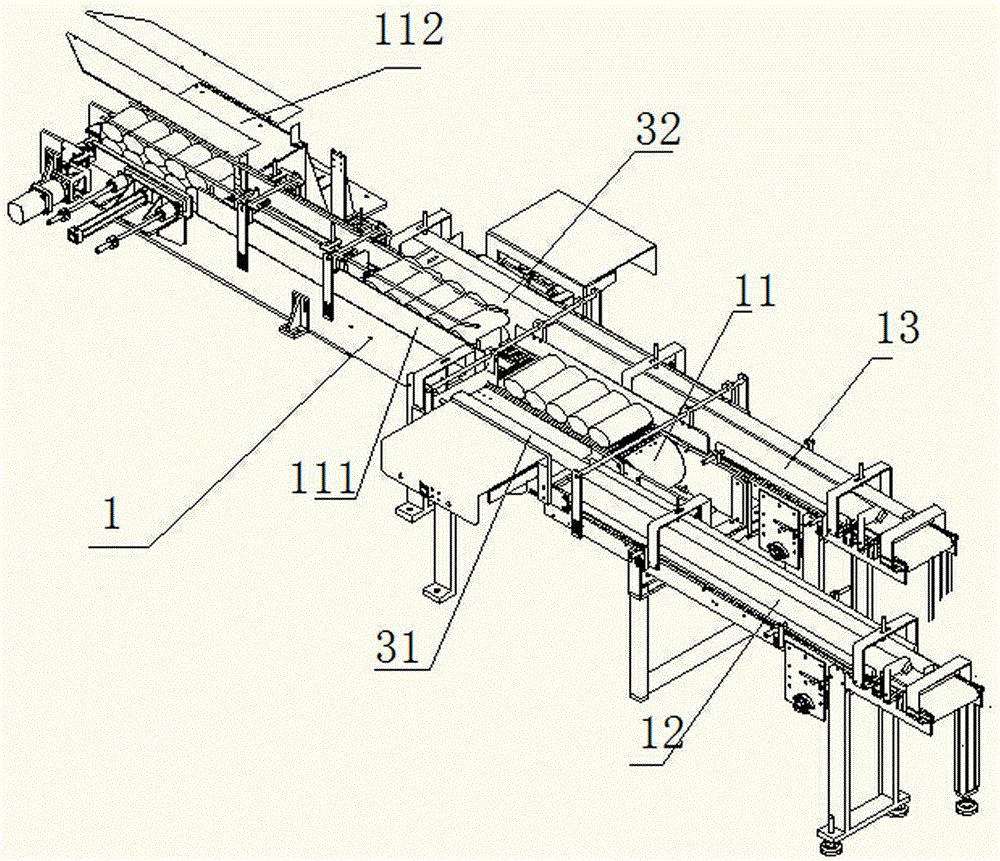

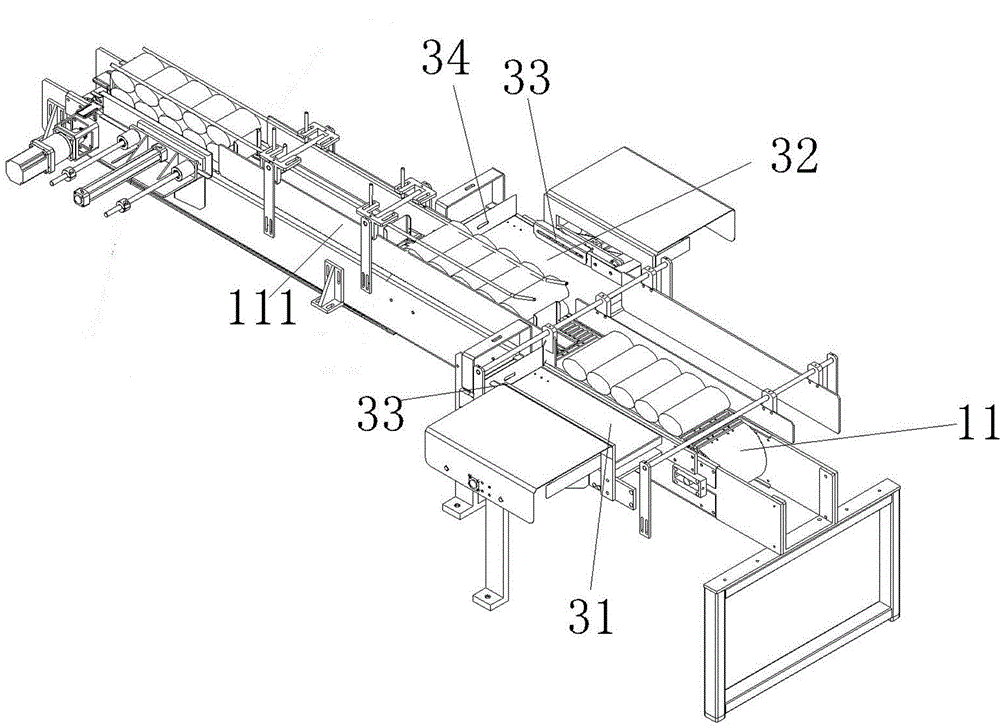

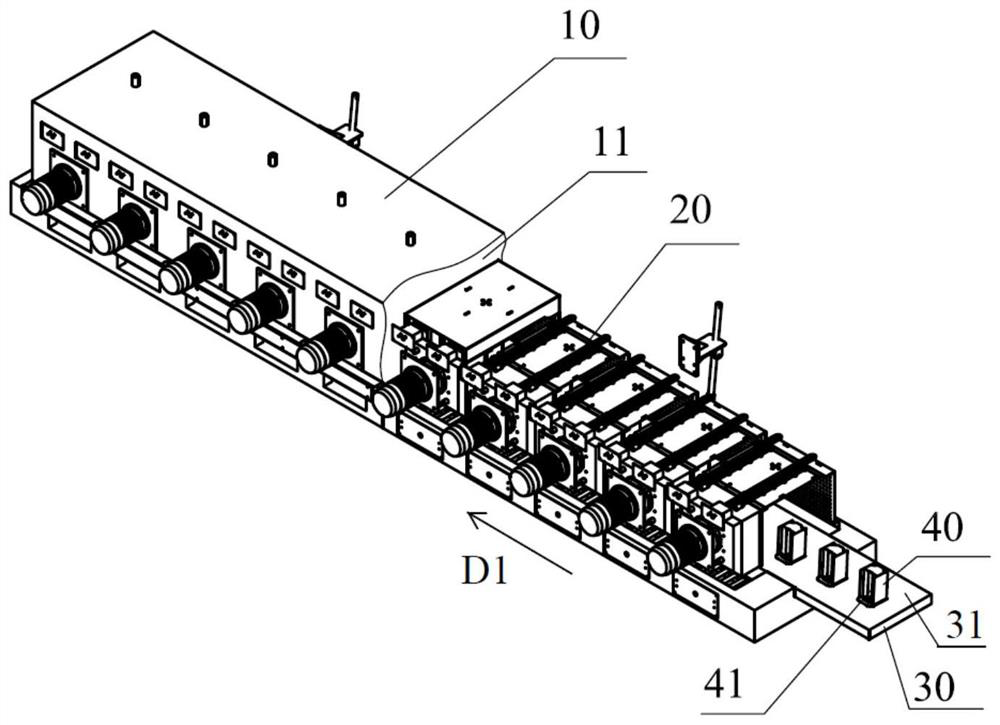

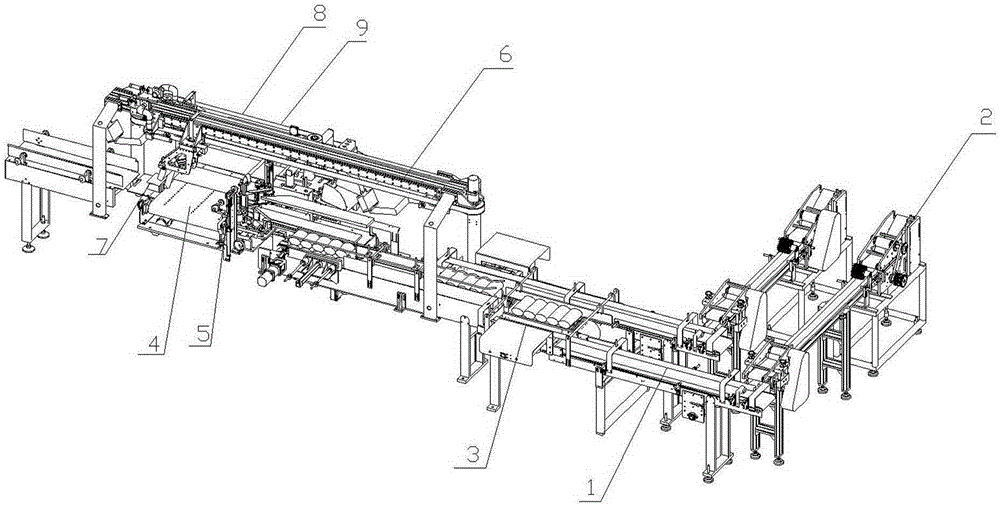

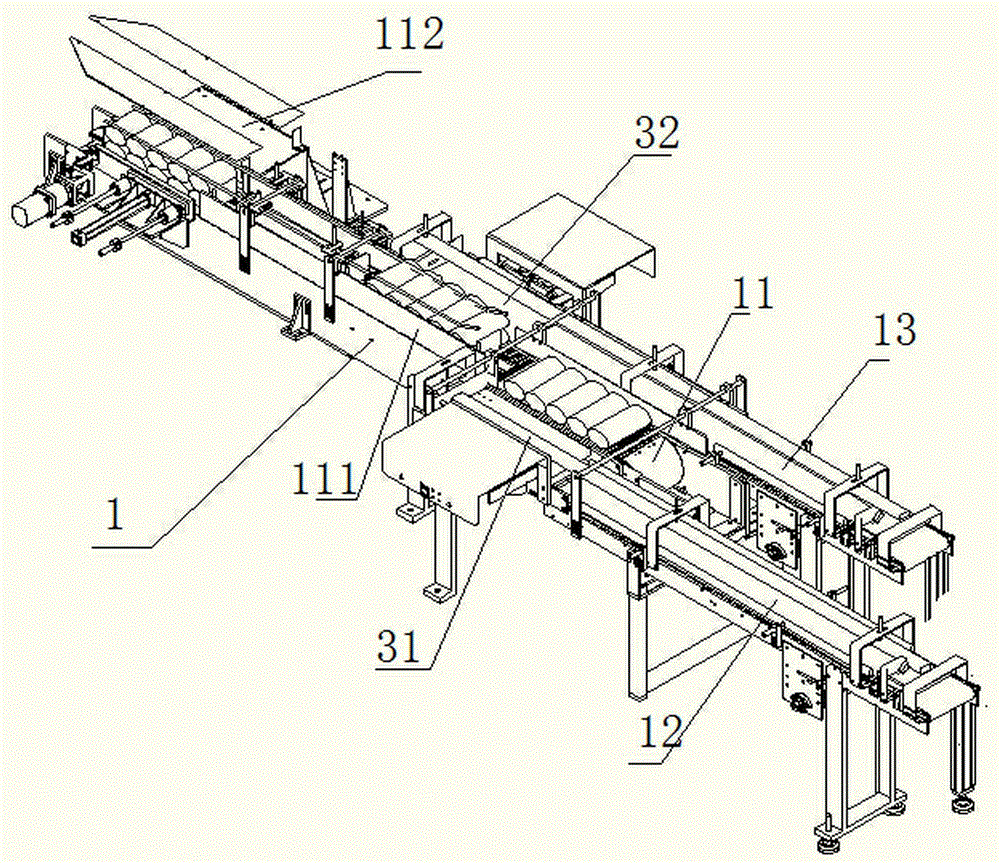

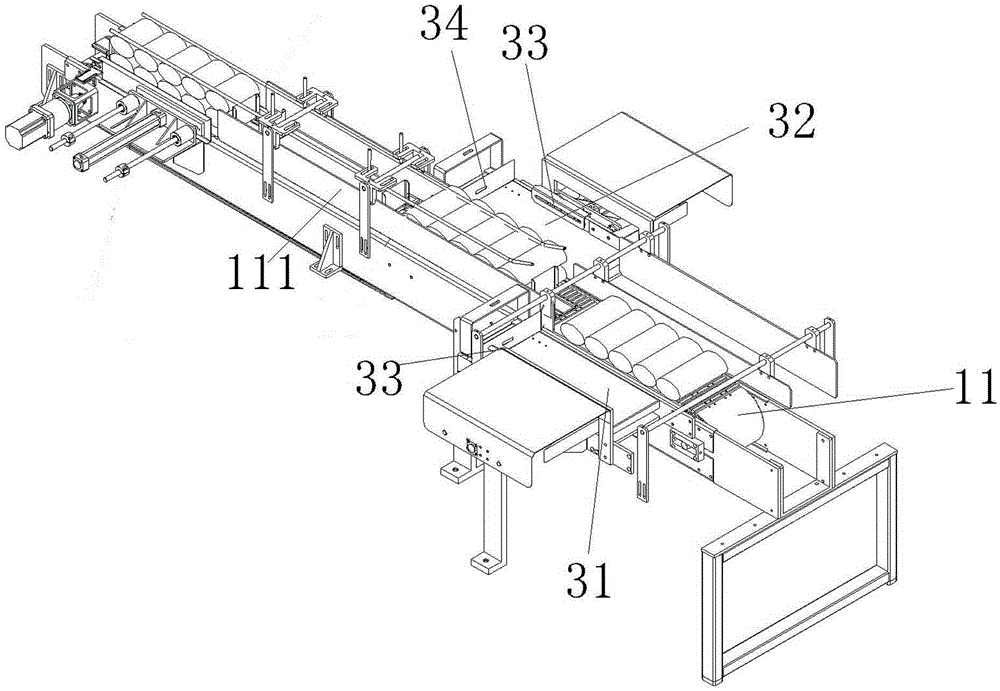

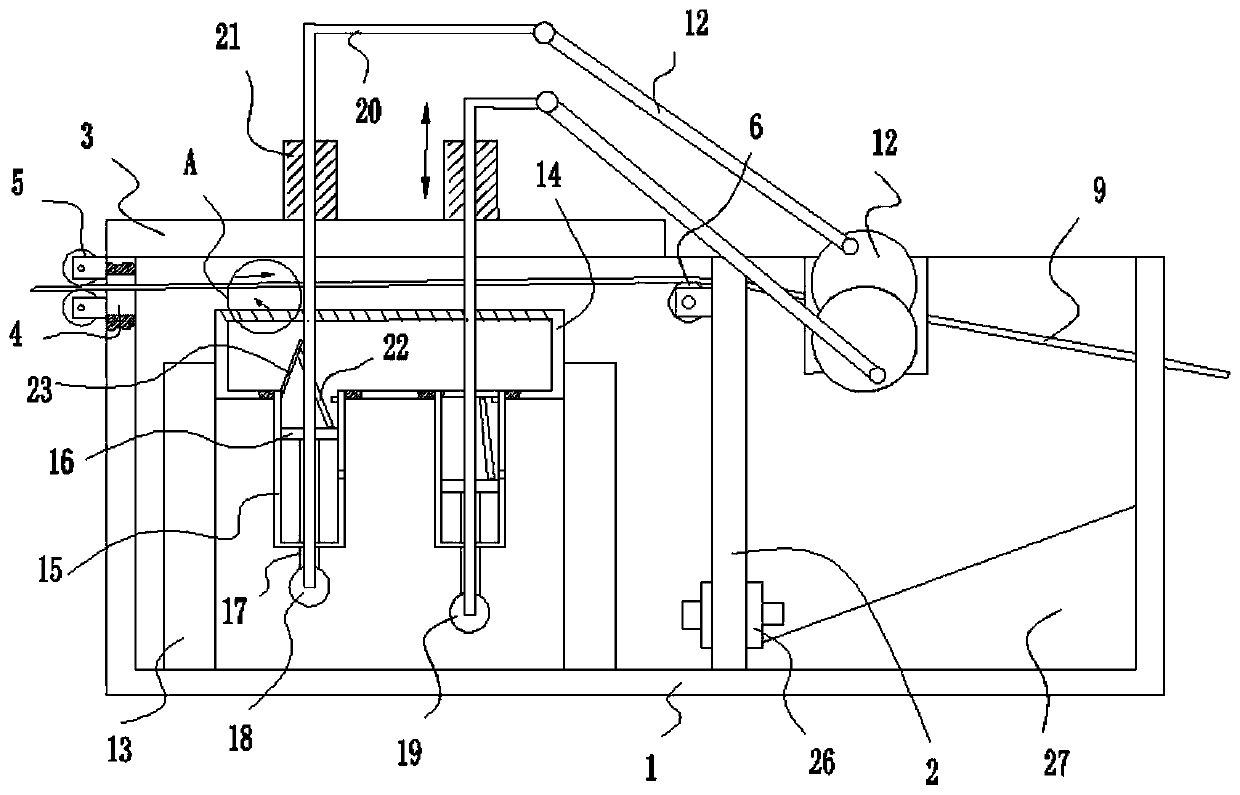

Flat roll packaging machine

ActiveCN104129529AGuarantee the quality of materialsIncrease productivityPackagingEngineeringPackaging machine

The invention discloses a flat roll packaging machine, and relates to the field of tissue packaging machines. The flat roll packaging machine comprises conveying devices, a film conveying device, a bag opening and supporting device, a package pushing device and a negative pressure forming device and further comprises flattening devices and a laminating device. The conveying devices comprise the first conveying device, the second conveying device and the third conveying device. The laminating device comprises a first pushing platform and a second pushing platform, the first pushing platform and the second pushing platform are provided with pushing air cylinders respectively, and the first pushing platform and the second pushing platform are arranged on the two sides of the first conveying device respectively. According to the flat roll packaging machine, flattening is conducted on a paper roll twice, the paper roll is flattened and formedcompletely, the situations of jumping and warping can be avoided, automatic laminating processing can be achieved, laminating packaging is completed automatically, and packaging operation is completed efficiently.

Owner:SHANGHAI SOONTRUE MACHINERY EQUIP

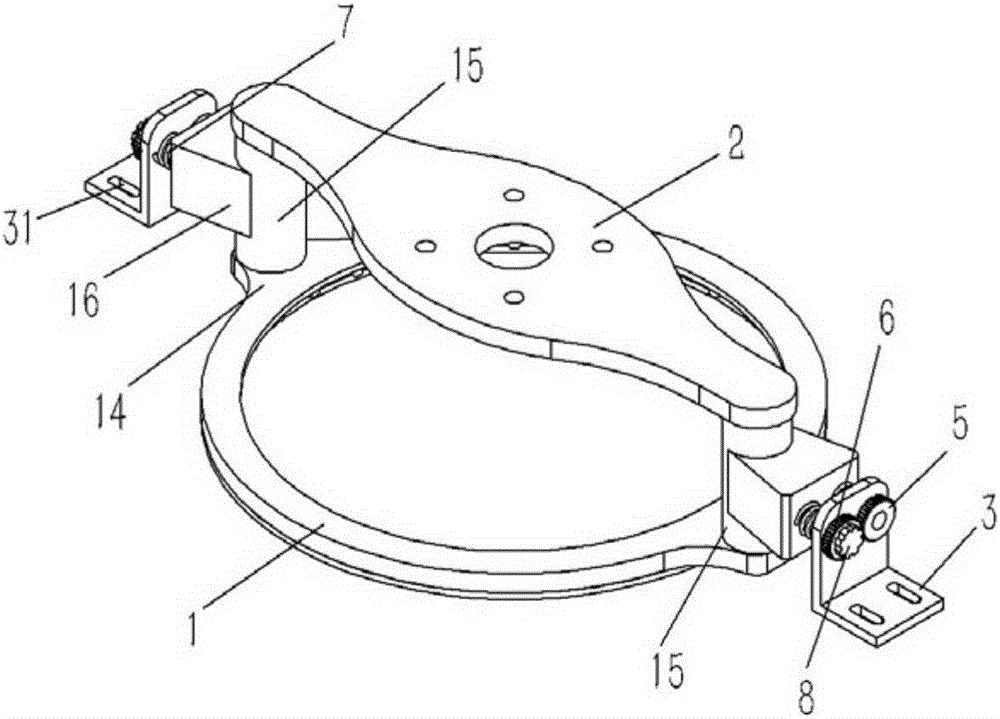

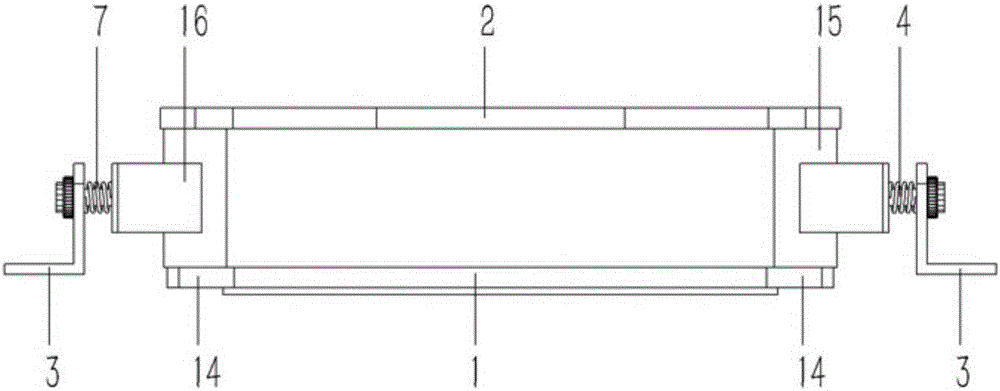

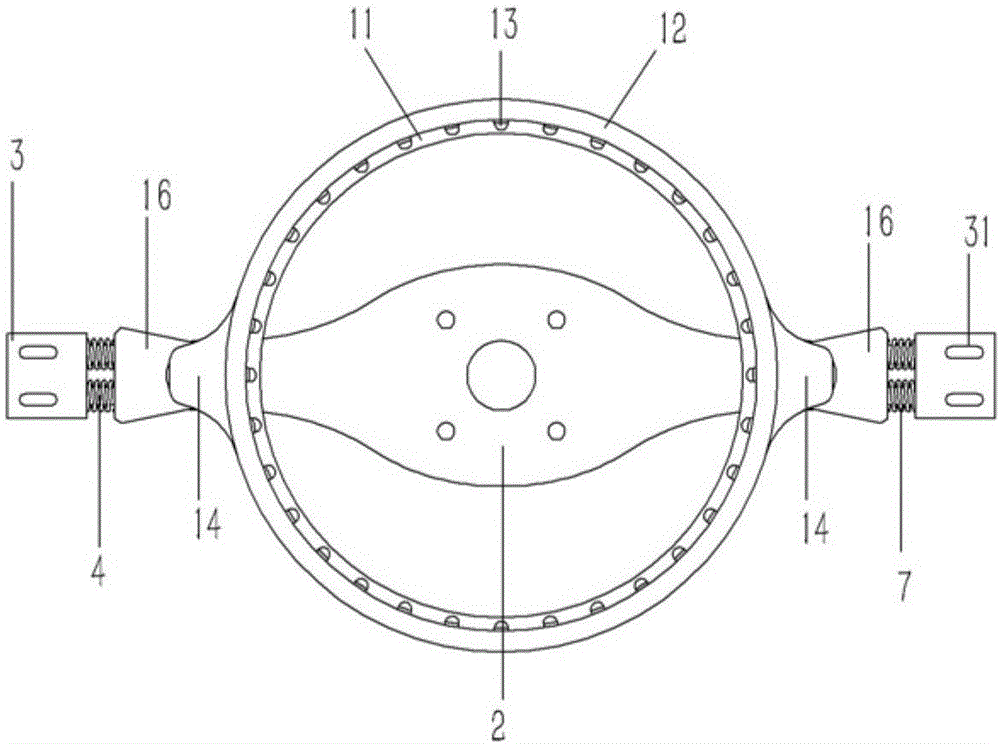

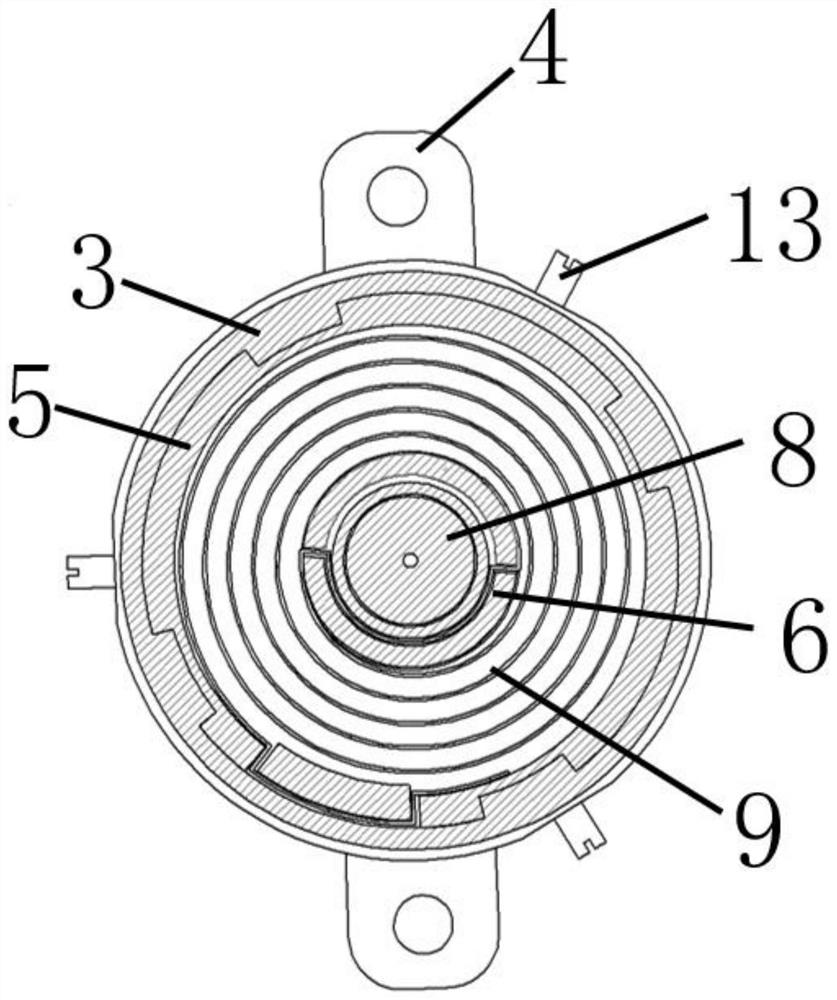

Aperture device capable of adjusting position on automation device

ActiveCN106383426AOptimize the installation structureRealize position adjustmentCamera diaphragmsProduction lineBolt connection

The invention discloses an aperture device capable of adjusting a position on an automation device. Support lugs are formed on two opposite sides of the aperture; a stand column is formed on each of the support lug; a camera installation support is fixed on the top ends of the stand columns; connection seats which are opposite are molded on the stand columns on two sides of the aperture; the outer side of the connection seat is provided with an L-shaped installation seat; the L-shaped installation seat consists of a horizontal part and a vertical part; two parallel studs are connected to the connection seat through bolt connection; a first gear and a second gear are fixed on vertical parts of ends of the two studs which pass through the installation seat; the first gear is meshed with the second gear; a pressure spring sleeves the stud; and the two ends of the pressure spring are pressed against the installation seat and the connection seat. The aperture device capable of adjusting the position on the automation device optimizes and improves installation structures of the industrial camera and the aperture, realizes position regulation of the industrial camera and the aperture, and brings convenience to production requirements of an industrial automation production line.

Owner:罗更荣

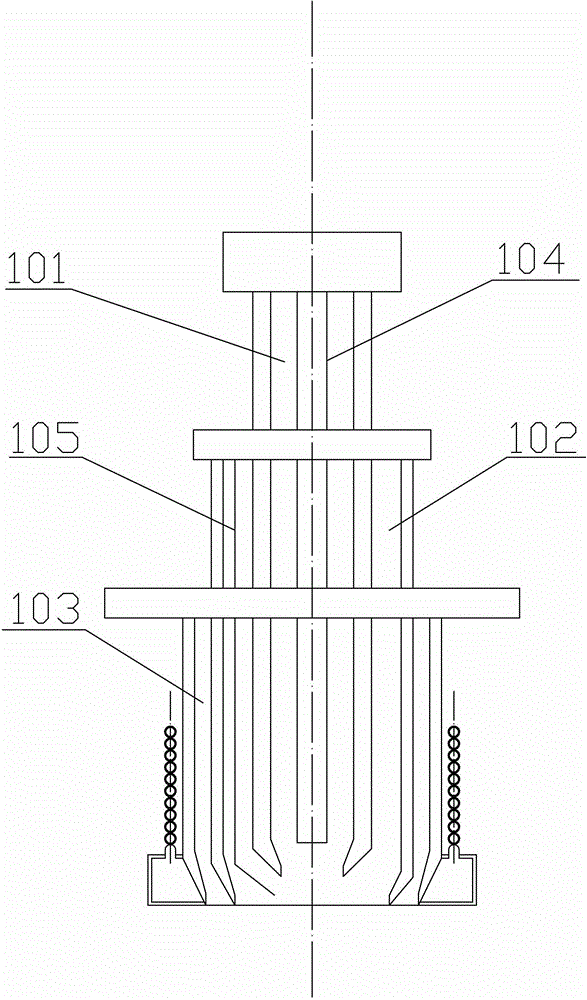

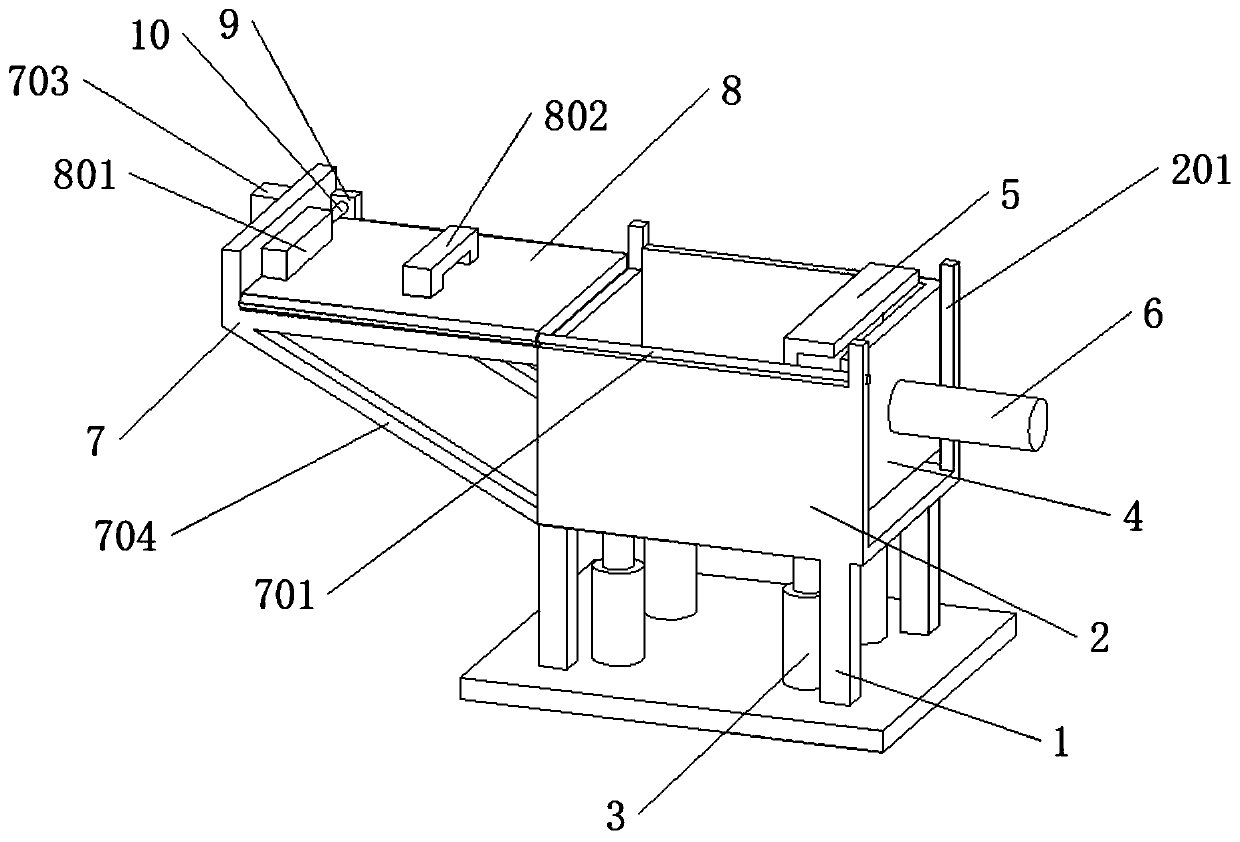

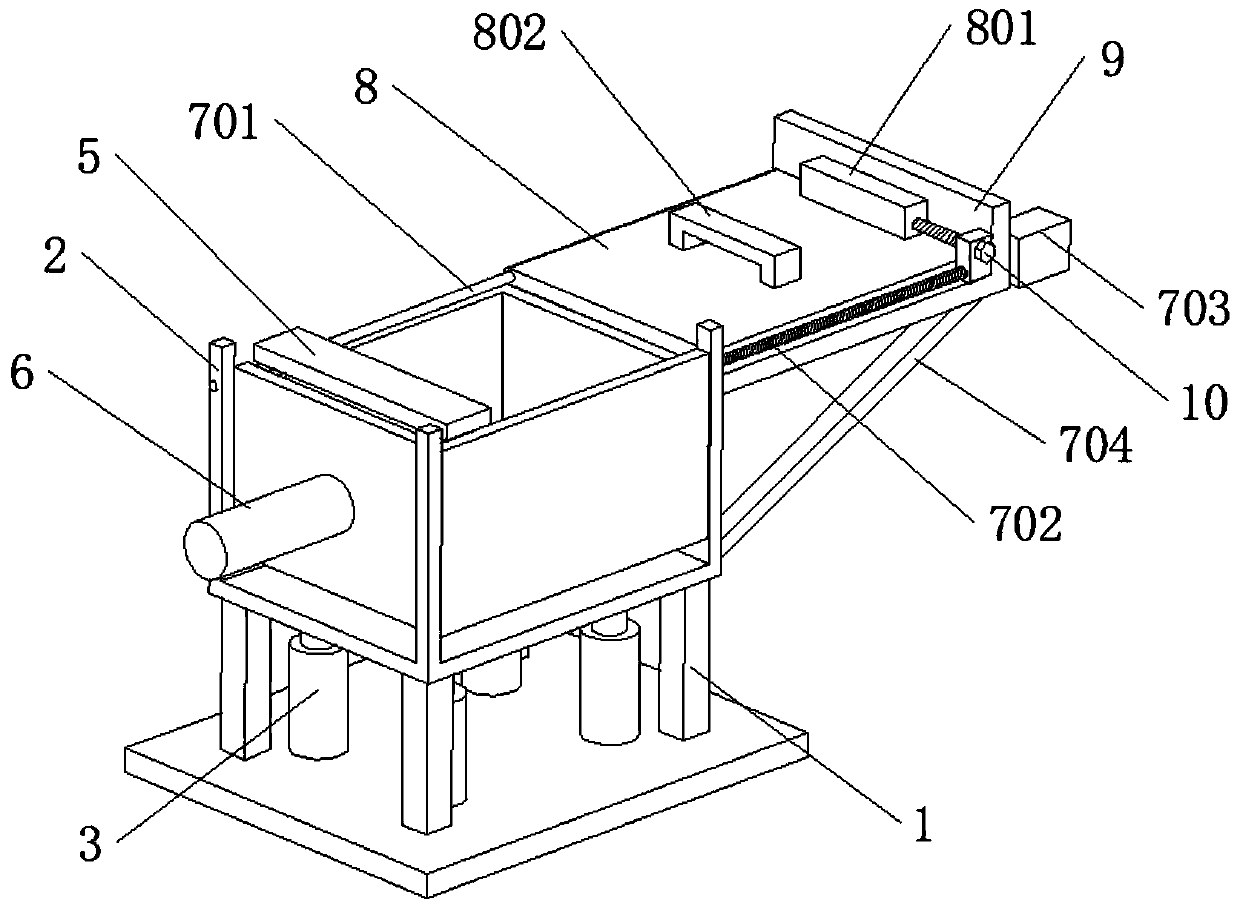

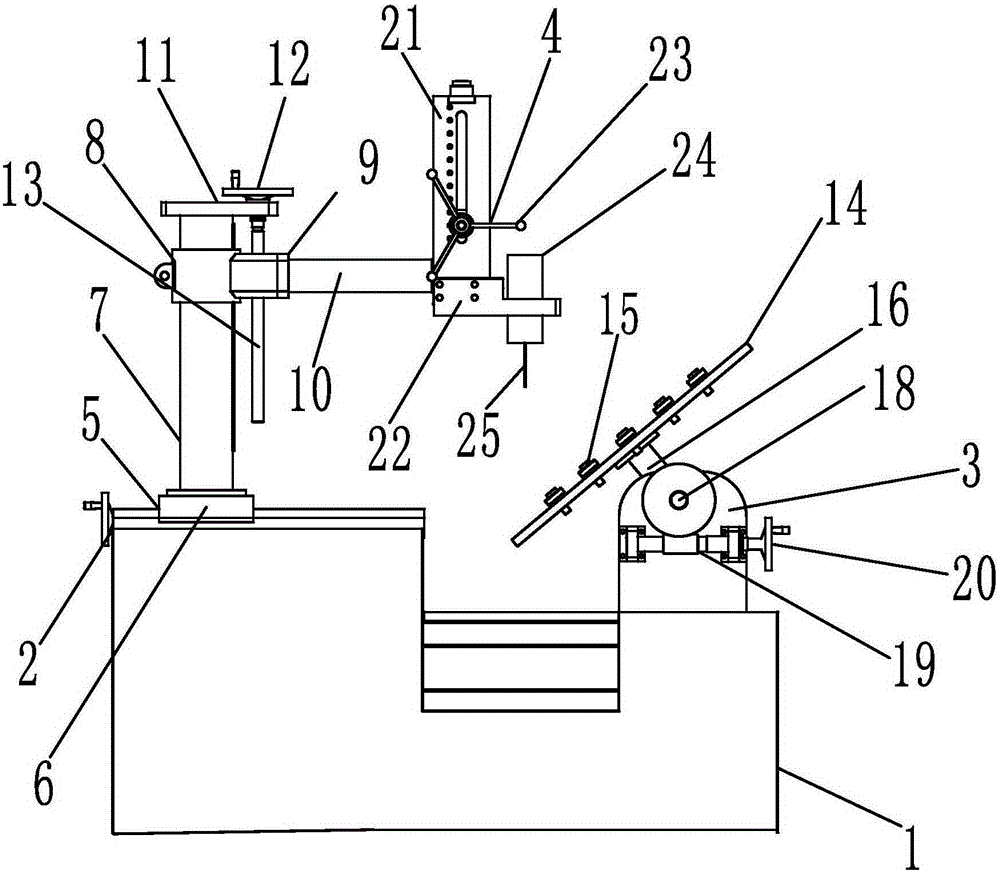

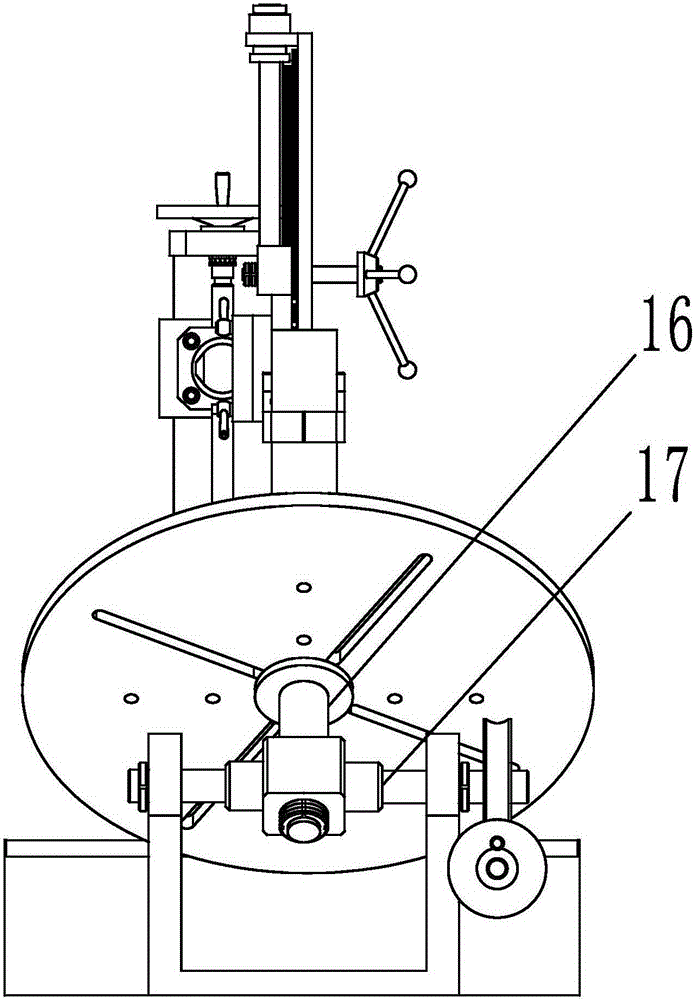

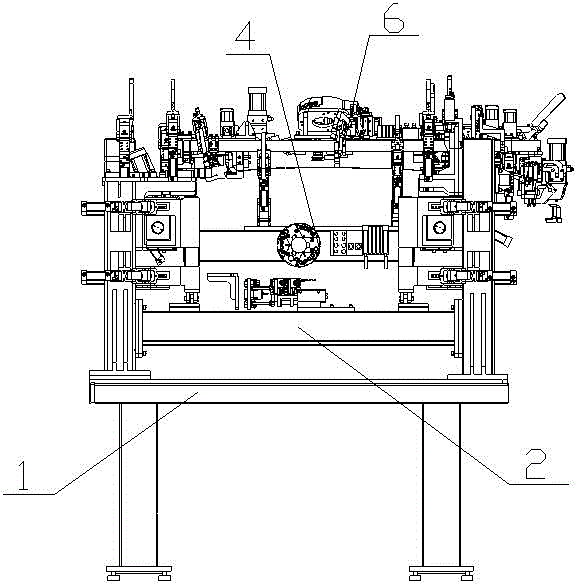

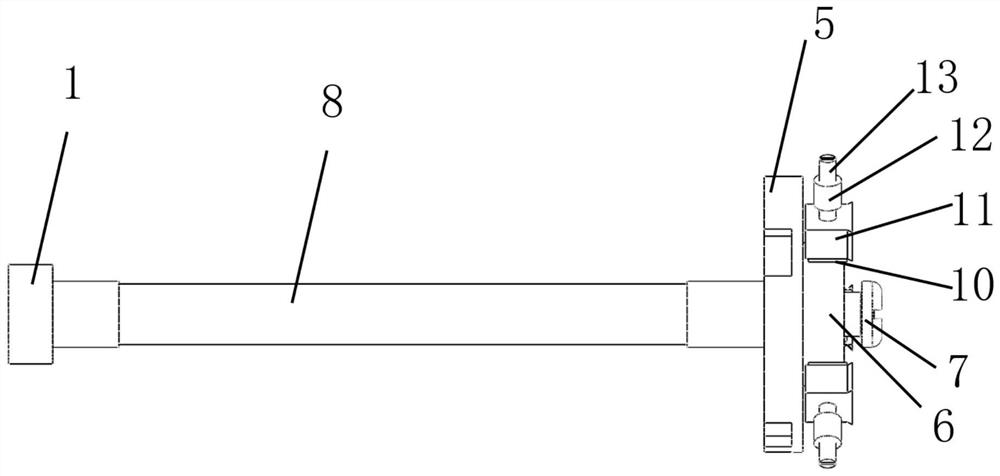

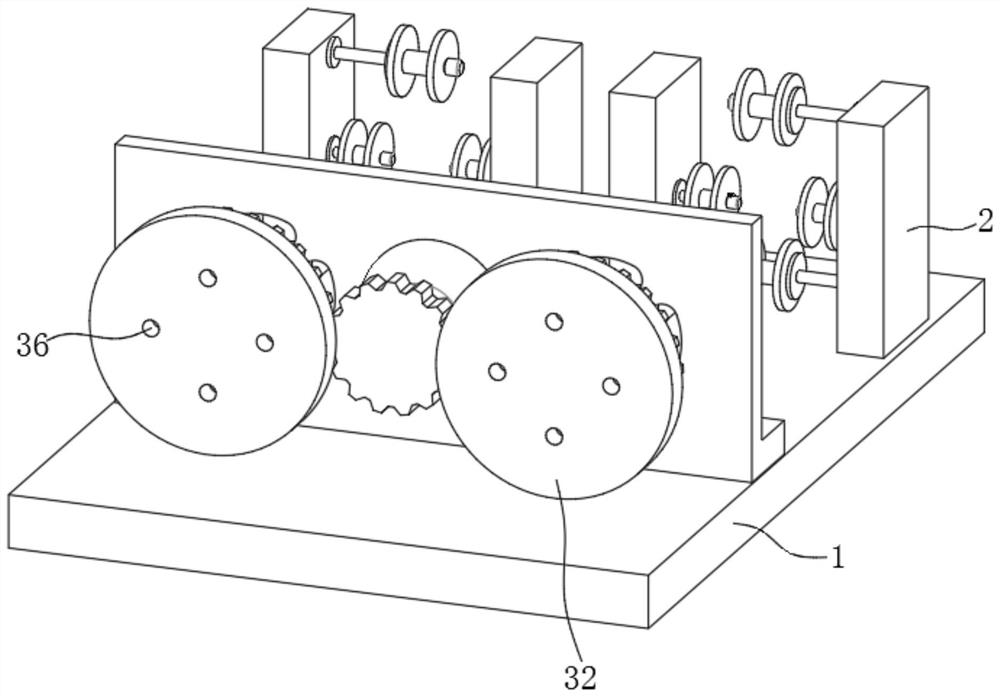

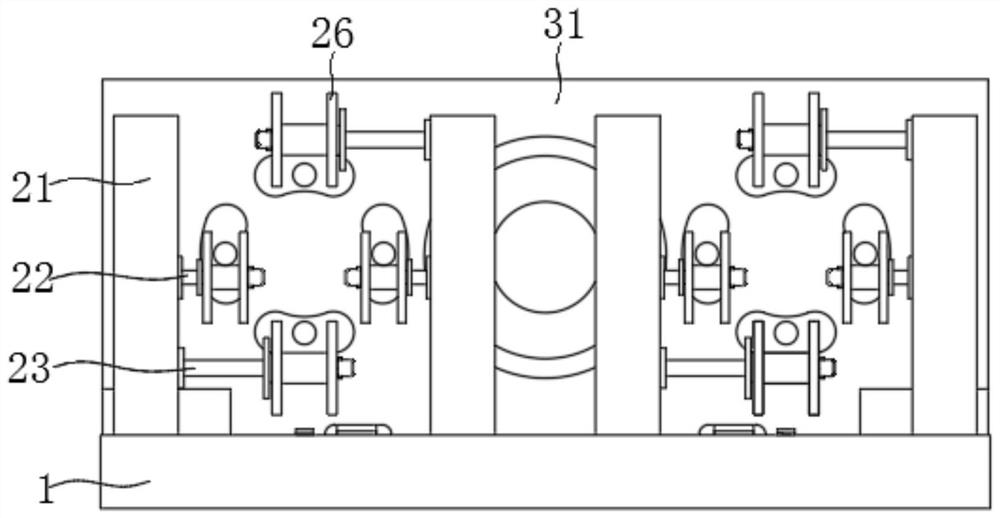

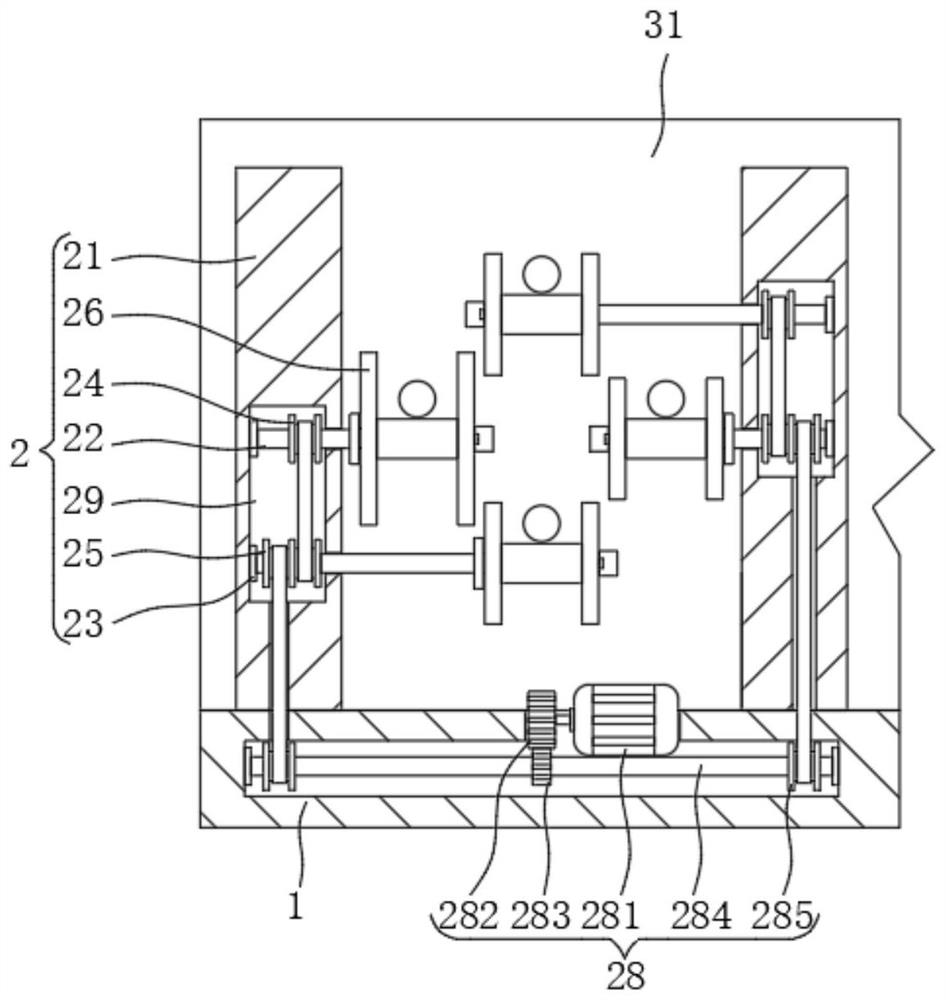

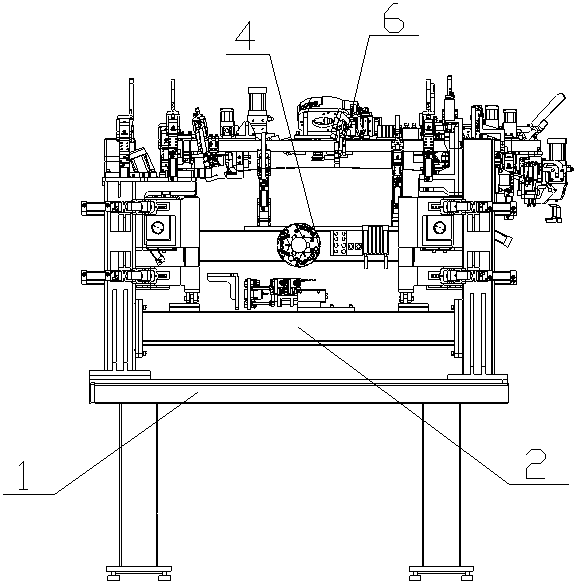

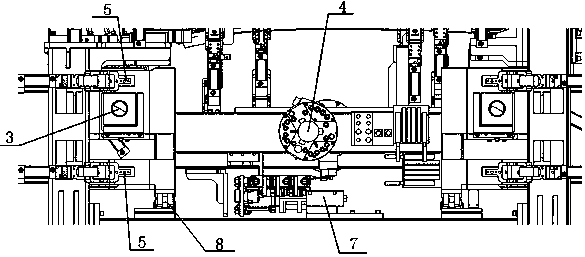

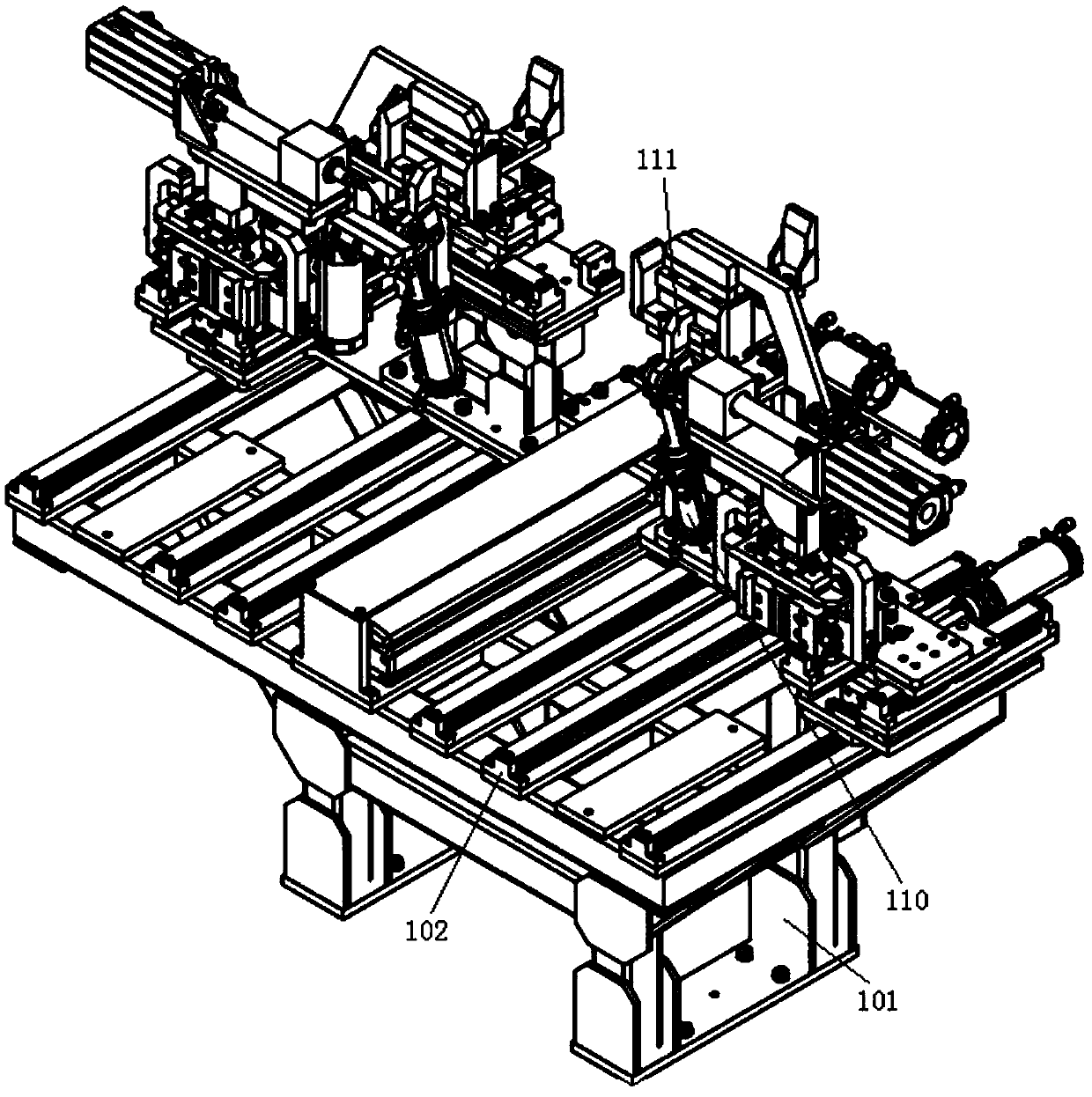

Special drilling machine for two-piece tire mold

InactiveCN105149644AReduce labor intensityWith rotation functionBoring/drilling machinesEngineeringUltimate tensile strength

The invention discloses a special drilling machine for a two-piece tire mold. The special drilling machine for the two-piece tire mold comprises a base, a guide rail system, a rotary workbench system and a spindle system. The special drilling machine for the two-piece tire mold is characterized in that the guide rail system is mounted at the upper left end of the base, the rotary workbench system is located at the upper right end of the base and lower than the guide rail system, and the spindle system is mounted on the guide rail system. By the adoption of the technical scheme, the special drilling machine for the two-piece tire mold has the beneficial effects of having the rotating function, the load bearing function and the layer depth and radian machining function, and being capable of fully meeting production requirements, simple in structure, convenient to install and maintain, capable of relieving the labor intensity of workers and improving production efficiency, and also capable of reducing production cost and increasing production benefits.

Owner:ZHUCHENG ZHIXIN MOLD EQUIP

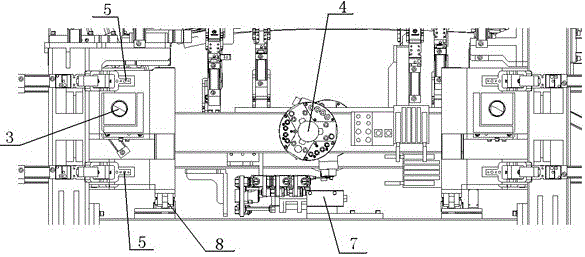

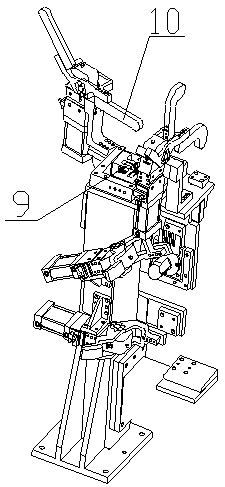

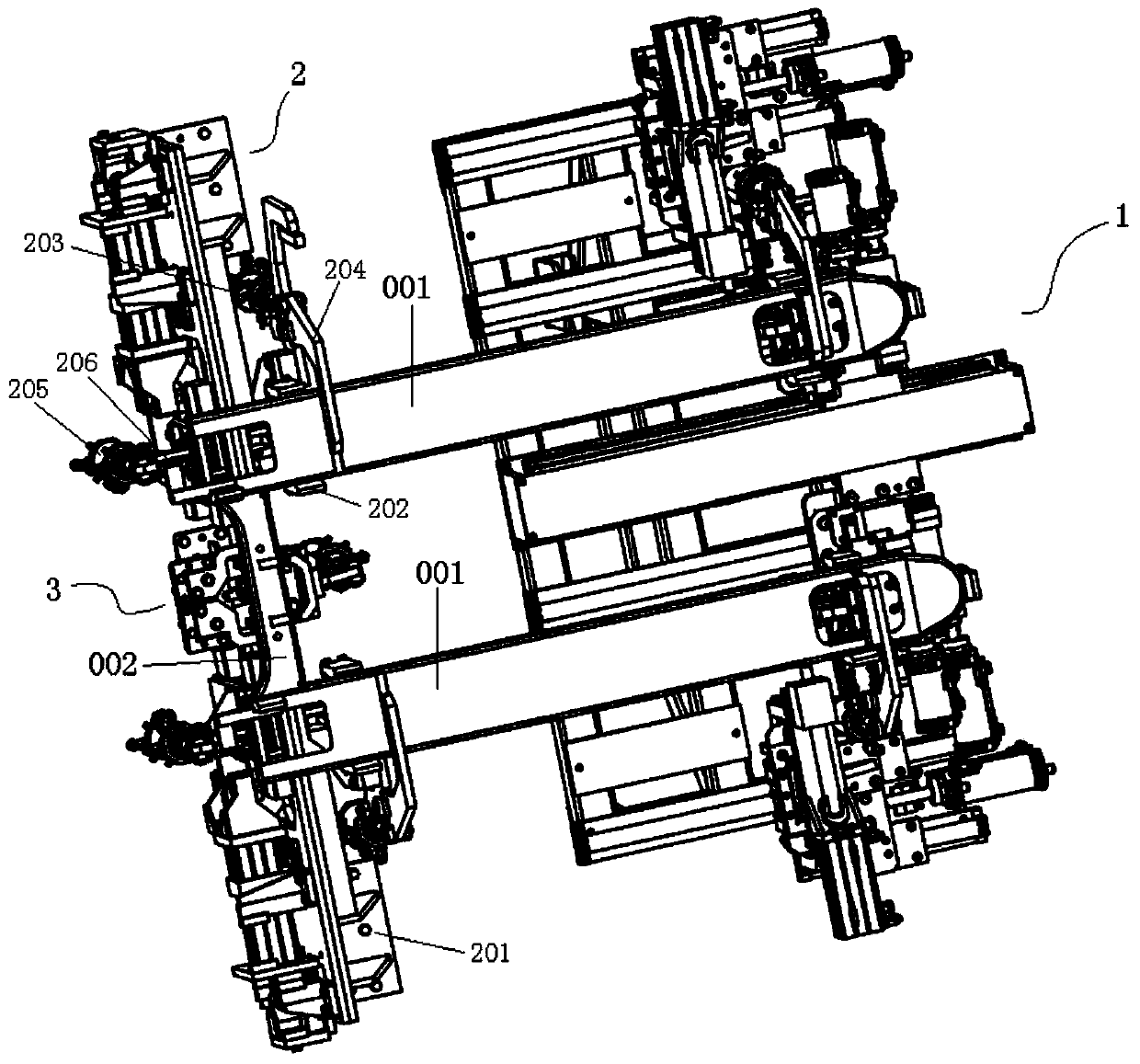

Flexible location mechanism of welding top cap of car body frame

ActiveCN106392418AHigh degree of flexibilityHigh precisionWelding/cutting auxillary devicesAuxillary welding devicesCar manufacturingMan machine

The invention provides a flexible location mechanism of a welding top cap of a car body frame. The flexible location mechanism of the welding top cap of the car body frame comprises a base. A slippage base is arranged on the base, a location pin is arranged on the slippage base, and side body location hand grabs are arranged on the slippage base and fixed by the location pin. Pressure arms are arranged on the two sides of the location pin and through the pressure arms, the slippage base in place is fixed. Top cap of location hand grabs are arranged on the top of the slippage base. The utility rate of space is high, floor space is small, the structure is single, and breakdown is little; flexible degree of the mechanism is high, switching time is short, and precision is high; and equipment and manpower investment cost for multi-vehicle manufacture are lowered. Complicated structure switch before is evaded, the flexible degree is high, the cost is low and the utility rate of each device is improved, so that man-machine harmony and product quality are both highly promoted. Under the circumstance of low cost, an enterprise can obtain good manufacture requirements through the high-quality mechanism, flexible manufacture requirement of automobile manufacture industry nowadays is met, and the flexible location mechanism of the welding top cap of the car body frame is sure to win general consent of market.

Owner:ANHUI RUIXIANG IND

Yarn feeder with adjustable yarn feeding speed

The invention discloses a yarn feeder with the adjustable yarn feeding speed. The yarn feeder comprises an end screw, a bobbin, a driven wheel cover, a bottom plate, a driven wheel, a driving wheel, a mandrel, a coil spring, a friction plate, embedded blocks and a locking screw; one end of the mandrel is fixed on the bottom plate, and the end screw is fixed at the other end of the mandrel; the driving wheel is located in the bottom plate and rotationally installed on the mandrel; the bobbin is rotationally connected with the mandrel; one end of the bobbin is limited by the end screw, and the other end of the bobbin is fixedly connected with the driven wheel cover; the driven wheel cover is located on the outer side of the driven wheel and fixedly connected with the driven wheel; the driven wheel is rotationally mounted on the mandrel; the coil spring is arranged in the driven wheel, one end of the coil spring is fixedly connected with the driven wheel, and the other end of the coil spring is fixedly connected with the driving wheel; the plurality of embedded blocks are fixed on the bottom plate, and internal threads are formed in the embedded blocks; the friction plate is arranged at the tail end of the locking screw; and the locking screw is matched with the internal threads of the embedded blocks, and the friction plate at the tail end can make contact with the driving wheel. The yarn feeding tension and the yarn feeding speed can be manually adjusted.

Owner:TIANJIN POLYTECHNIC UNIV

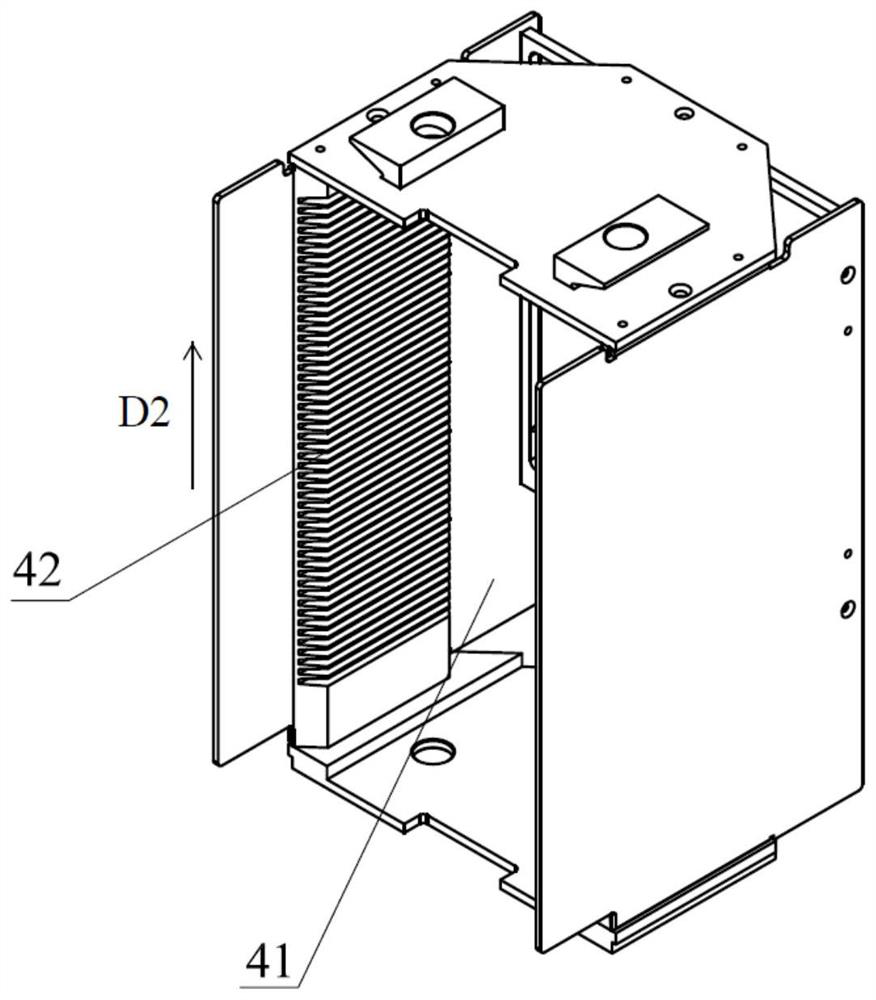

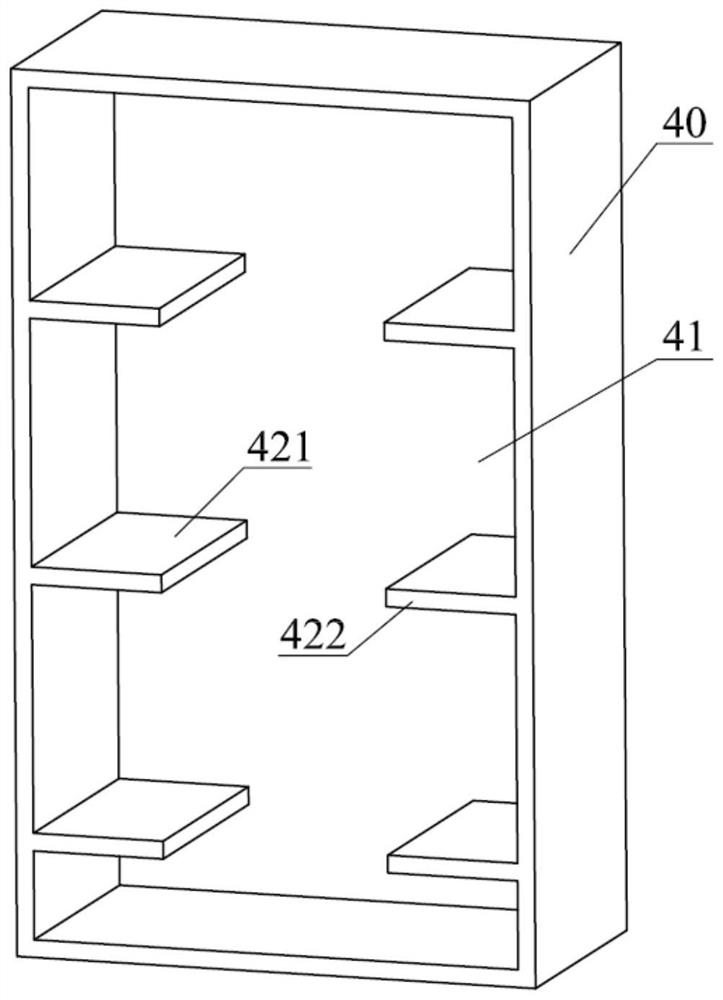

Curing device and drying equipment

InactiveCN112197561ASmall footprintAvoid scratchesDomestic cooling apparatusDrying gas arrangementsProcess engineeringMechanical engineering

The invention provides a curing device and drying equipment. The curing device comprises a shell, wherein a hollow heating cavity is formed in the shell, a heating assembly, wherein the heating assembly is arranged in the heating cavity, a conveying assembly, wherein the conveying assembly penetrates through the heating cavity in a first direction, and a conveying surface of the conveying assemblycan move in the first direction, and a containing piece, wherein the containing piece forms a hollow containing cavity, a plurality of partition pieces which are distributed at intervals in a seconddirection are arranged on the wall surface, adjacent to the containing cavity, of the containing piece, the second direction is basically perpendicular to the first direction, one end of each partition piece is connected with the wall surface, and the other end, opposite to the above-mentioned end, of each partition piece is a free end, and the containing piece is arranged on the conveying surfaceof the conveying assembly and moves in the first direction along with the conveying assembly. According to the curing device and the drying equipment, the corresponding occupied area can be effectively reduced.

Owner:CFDR SHENZHEN TECH CO LTD

100-400mm large-particle dolomite fettling method for large face of converter

InactiveCN111270043AImprove responseExtend your lifeManufacturing convertersProcess efficiency improvementSteelmakingDolomite

The invention belongs to the technical field of steelmaking, and particularly provides a 100-400mm large-particle dolomite fettling method for a large face of a converter. The 100-400mm large-particledolomite fettling method for the large face of the converter comprises the following steps that the step (1), after steel tapping operation of the converter is finished, converter slag which has a certain fluidity and is appropriate in alkalinity is selected, and slag splashing operation is not conducted after the steel tapping operation is finished; the step (2) large-particle dolomite is pouredinto the converter through a scrap steel bucket, specifically, the material size of the dolomite ranges from 100mm to 400mm; and the step (3) after the large-particle dolomite is added to the converter, the converter is immediately shaken to be about 88-95 degrees, and remains for 8-12 minutes, after the situation that the slag face is stable and does not roll over is observed, slag splashing andfurnace protection operation is conducted, and the residual slag in the converter is completely poured away or part of the furnace slag is reserved after the slag splashing operation is accomplished.

Owner:BENGANG STEEL PLATES

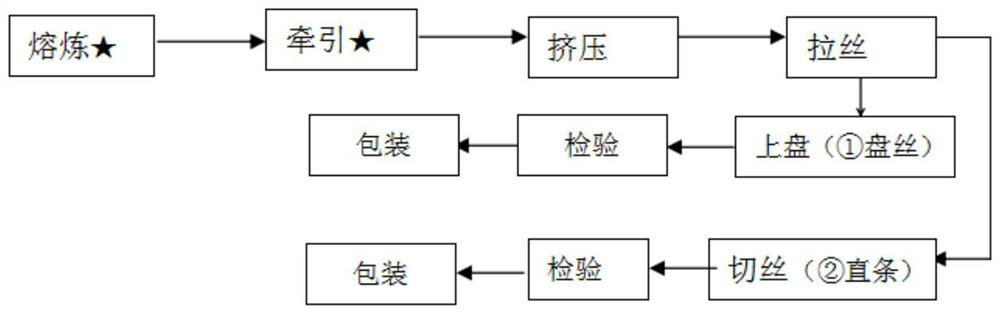

Tin brass welding wire and preparation method thereof

PendingCN112410609AComplete processing technologyEasy to processWelding/cutting media/materialsSoldering mediaNickel alloyCemented carbide

The invention provides a tin brass welding wire. The tin brass welding wire is prepared from the following components in percentage by weight: 59%-61% of copper, 0.8%-1.0% of tin, 0.15%-0.35% of silicon and the balance of zinc. According to the tin brass welding wire and a preparation method thereof, the defects in the prior art are overcome, the machining process is very complete, the machining effect is good, the production requirement can be met conveniently, and the tensile strength is high and is improved by 20%-30% compared with a welding wire machined through a common method; and the tin brass welding wire is high in hardness, can bear large pressure, can be widely applied to brazing, copper, steel, copper-nickel alloy, gray cast iron, inlaid hard alloy cutters and the like, and canalso be used as a surfacing material for low-pressure valve seal and light-load N-grinding surfaces, the performance of welding wire products can be improved through a reasonable proportion of Sn andSi in the tin brass welding tire, the fluidity, strength and corrosion resistance of the welding wire are improved through Sn, Si controls evaporation of zinc, and air holes are eliminated.

Owner:铜陵新鑫焊材有限公司

Annular rotary cotton yarn impurity removal equipment convenient to blank

PendingCN113682885AGood production demandImprove work efficiencyFilament handlingFibre cleaning/openingYarnStructural engineering

The invention provides annular rotary cotton yarn impurity removal equipment convenient to blank. The annular rotary cotton yarn impurity removal equipment convenient to blank comprises a base; and a winding structure, wherein the winding structure is arranged on the base, and the winding structure comprises a side plate, a first connecting rotating shaft, a second connecting rotating shaft, a first transmission wheel, a second transmission wheel, a winding wheel, a positioning rotating piece and a driving assembly. According to the annular rotary cotton yarn impurity removal equipment convenient to blank, which is provided by the invention, by arranging the winding structure, four batches of yarns can be wound at the same time, a traditional single winding mode is changed, the working efficiency of the equipment is greatly improved, the yarn production requirement is better met, each winding wheel is independently arranged, the winding wheels do not influence each other during winding, and the two groups of winding wheels are synchronously driven by the driving assembly, so that four batches of yarns can be synchronously wound, and the yarns are directly wound on the detachable winding wheels.

Owner:颍上鑫鸿纺织科技有限公司

Paint spraying device

ActiveCN113814089AImprove painting efficiencyGood production demandSpray boothsMachiningSupport plane

The invention discloses a paint spraying device, and relates to the technical field of pipe machining. The device comprises a supporting assembly; the supporting assembly comprises a supporting frame. A pair of side supporting beams are horizontally fixed on the supporting frame; and the ends, facing the same direction, of the supporting beams on the two sides are connected through a middle beam. A feeding assembly, a paint spraying assembly and a drying assembly are arranged between the supporting beams on the two sides side by side in the length direction. A material conveying assembly is arranged on the middle beam. Materials are taken from the feeding assembly through the material conveying assembly, then the materials are driven by the feeding assembly to sequentially pass through the paint spraying assembly and the drying assembly, paint spraying and drying are achieved, the structural design is reasonable, use is convenient and fast, paint spraying and drying can be conducted on multiple metal pipes, the paint spraying efficiency of the metal pipes is effectively improved, and the device has high market application value.

Owner:江苏克莱德激光技术有限责任公司

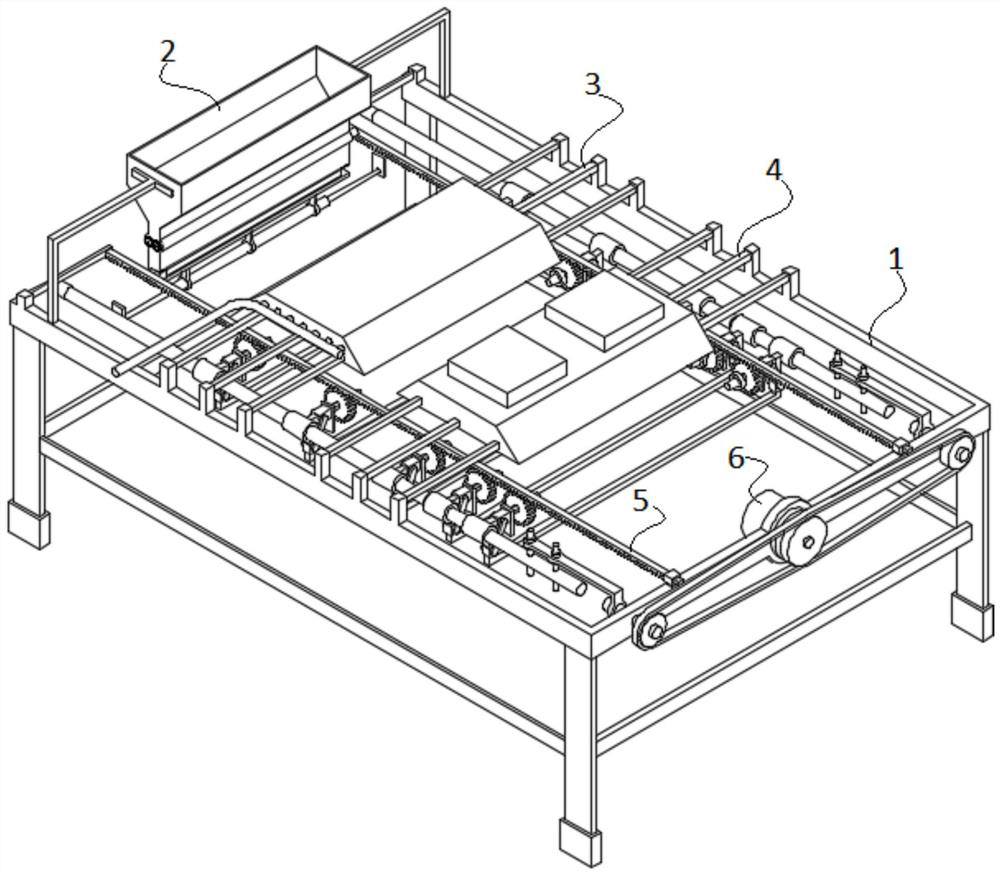

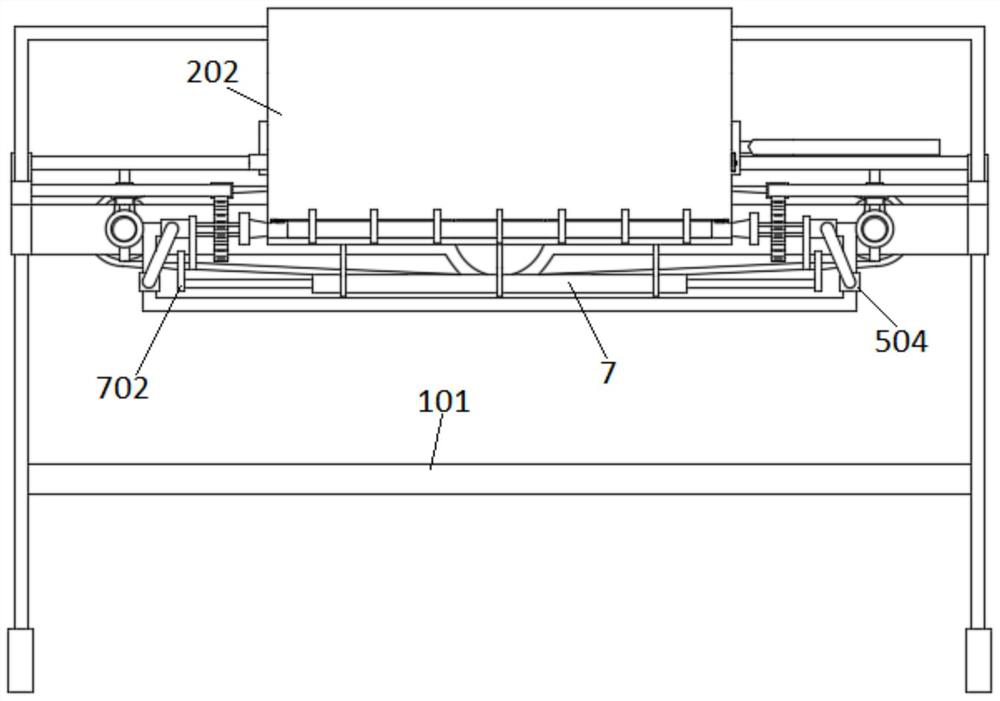

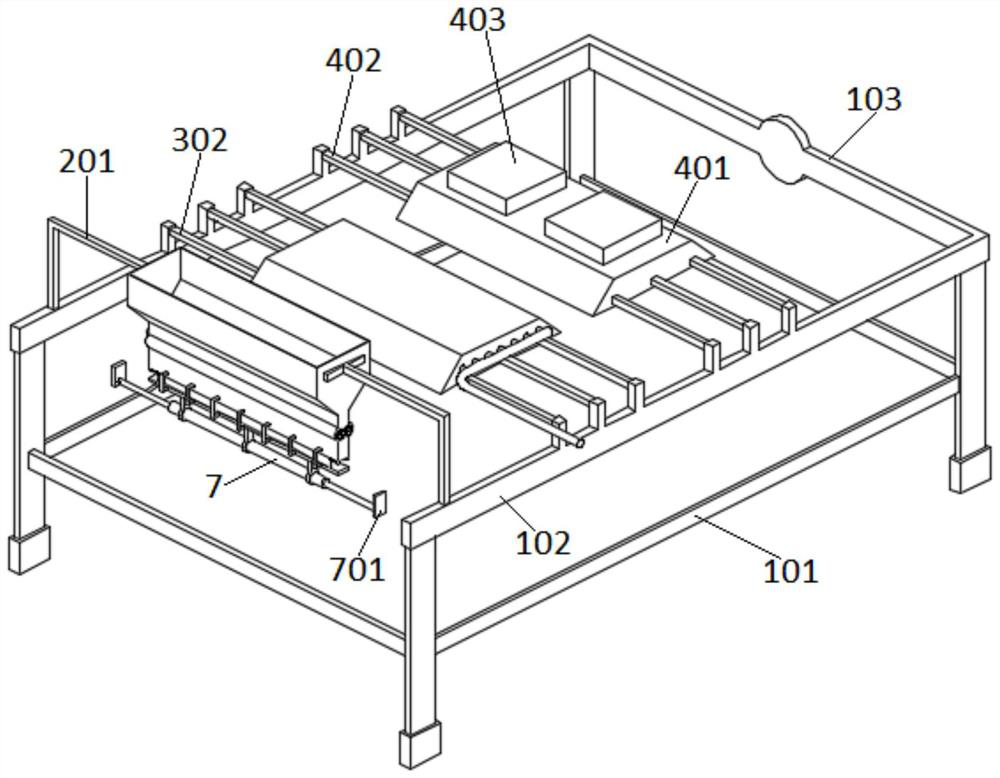

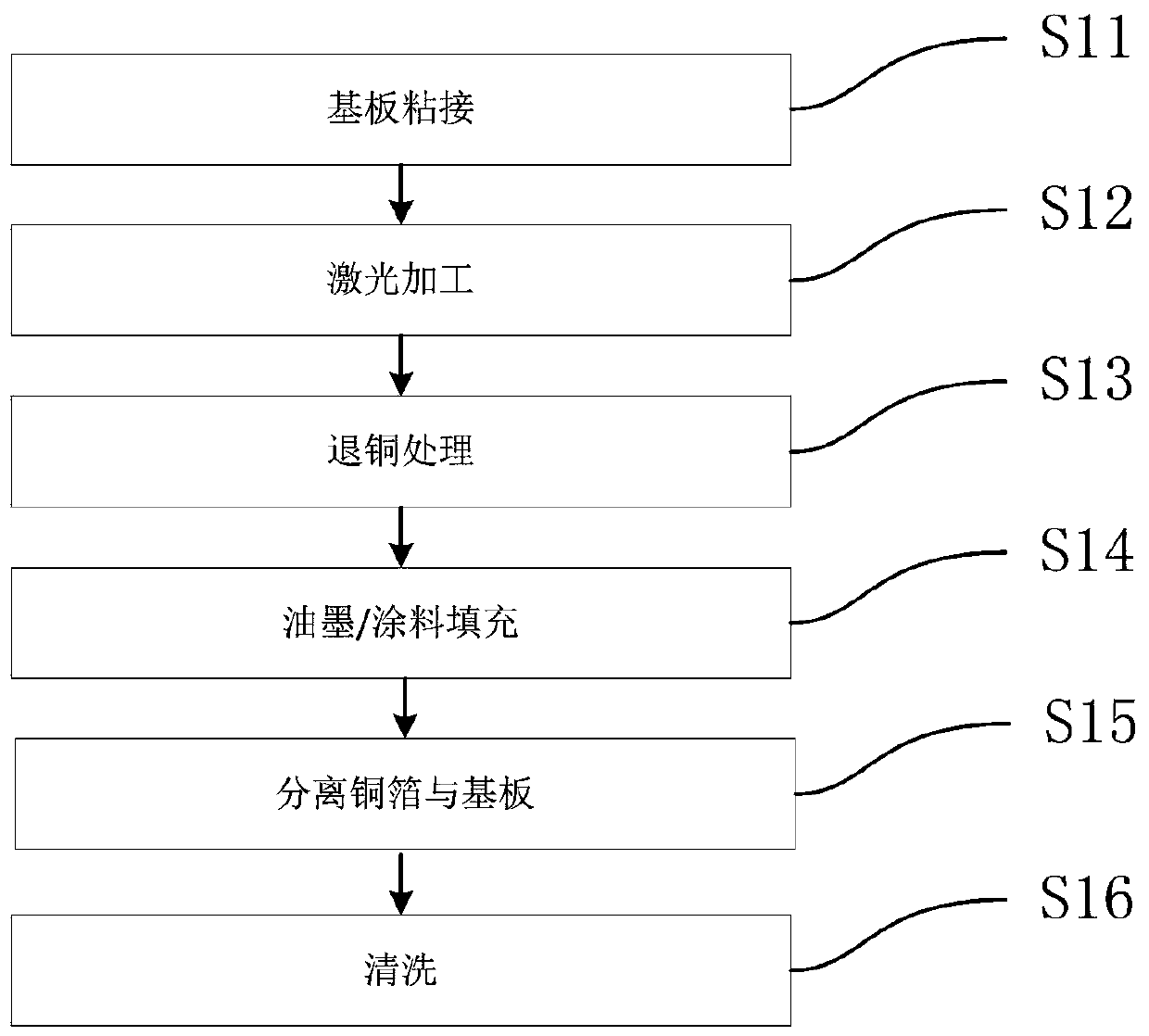

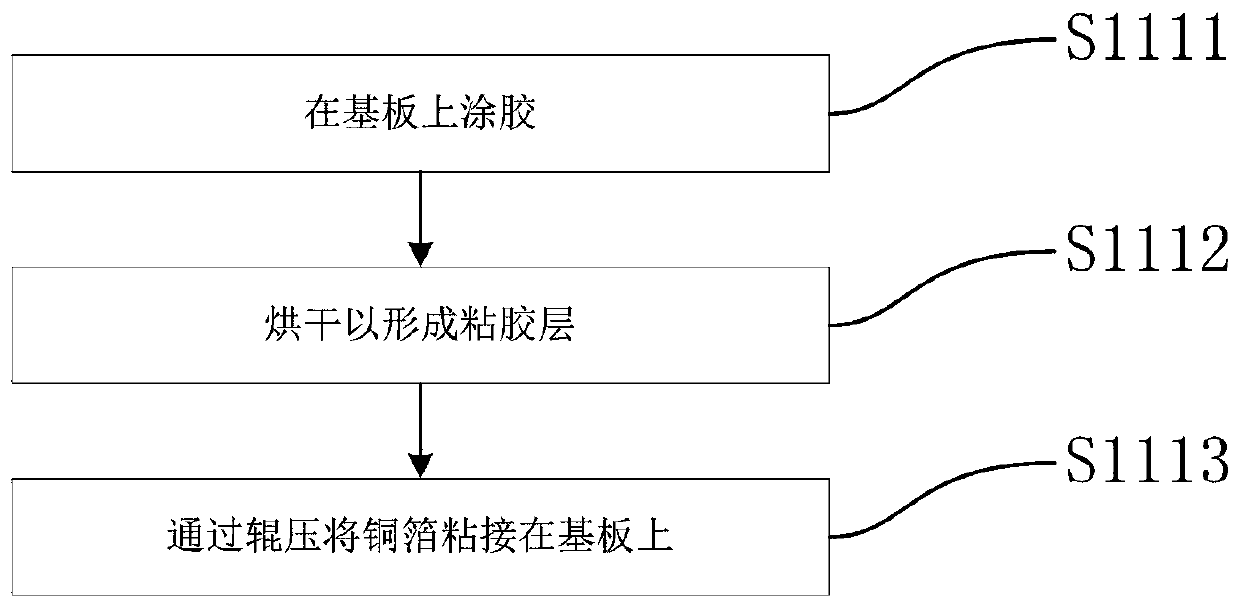

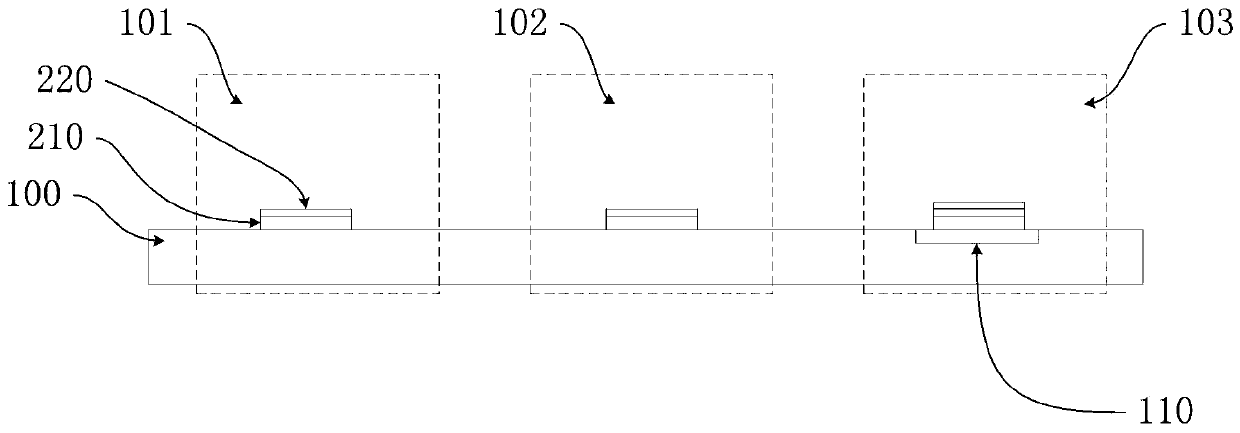

Processing method and processing system of circuit board

ActiveCN110035617APrevent heat warpingAvoid deformationTransfer patterningConductive material removal by irradiationLaser processingLaser cutting

The invention relates to the technical field of laser processing, in particular to a processing method and processing system of a circuit board. The processing method comprises the steps of pasting asubstrate, and arranging a copper foil on the substrate by a pasting layer; performing laser processing; performing copper withdrawing; filling ink or a coating material; separating the copper foil from the substrate; and cleaning to obtain a finished product of the circuit board. The copper foil is pasted onto the substrate and then is cut, warping or deformation of the copper foil after heatingduring laser cutting can be effectively prevented, so that error influence on a cutting line and depth is eliminated; meanwhile, a product with narrower line distance can be obtained; and moreover, agroove after cutting is filled with an insulation filler such as the ink after a cutting pattern is obtained, the pattern is further protected and fixed, a more accurate pattern is obtained, the processing method is simple in process and low in cost, and production demand on a large scale is facilitated.

Owner:奈米科技(深圳)有限公司

A flat roll packaging machine

ActiveCN104129529BGuarantee the quality of materialsIncrease productivityPackagingEngineeringJumping

The invention discloses a flat roll packaging machine, and relates to the field of tissue packaging machines. The flat roll packaging machine comprises conveying devices, a film conveying device, a bag opening and supporting device, a package pushing device and a negative pressure forming device and further comprises flattening devices and a laminating device. The conveying devices comprise the first conveying device, the second conveying device and the third conveying device. The laminating device comprises a first pushing platform and a second pushing platform, the first pushing platform and the second pushing platform are provided with pushing air cylinders respectively, and the first pushing platform and the second pushing platform are arranged on the two sides of the first conveying device respectively. According to the flat roll packaging machine, flattening is conducted on a paper roll twice, the paper roll is flattened and formedcompletely, the situations of jumping and warping can be avoided, automatic laminating processing can be achieved, laminating packaging is completed automatically, and packaging operation is completed efficiently.

Owner:SHANGHAI SOONTRUE MACHINERY EQUIP

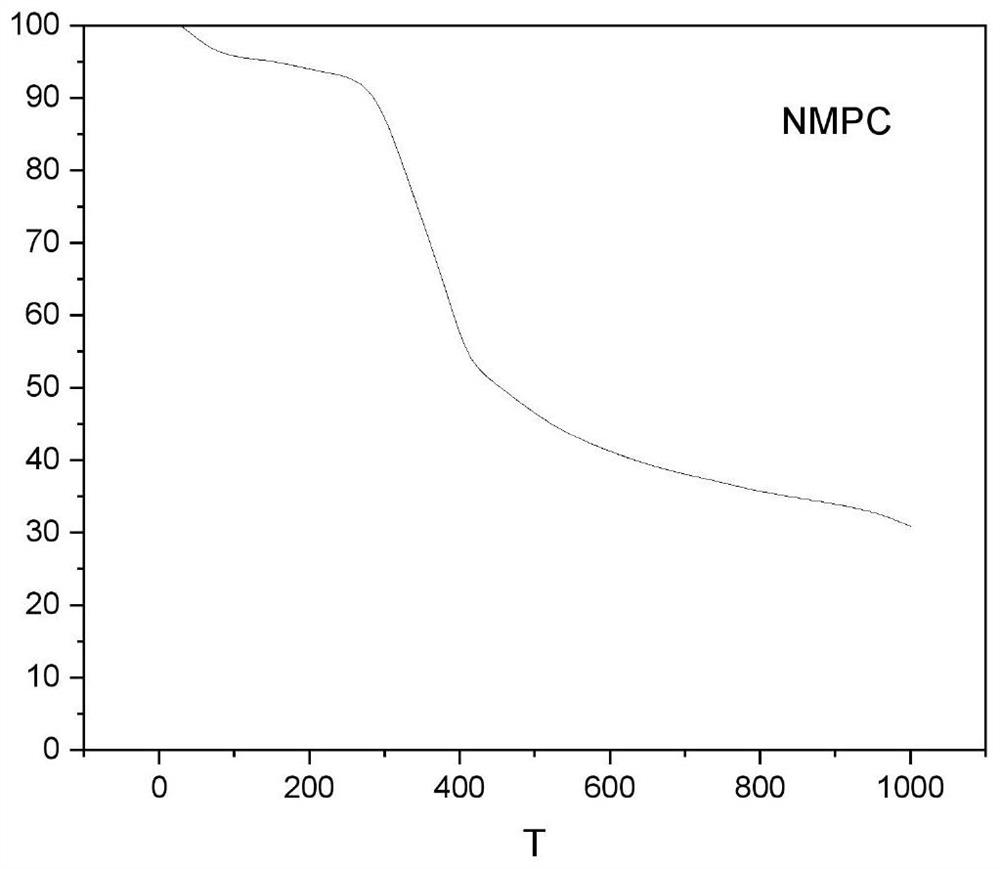

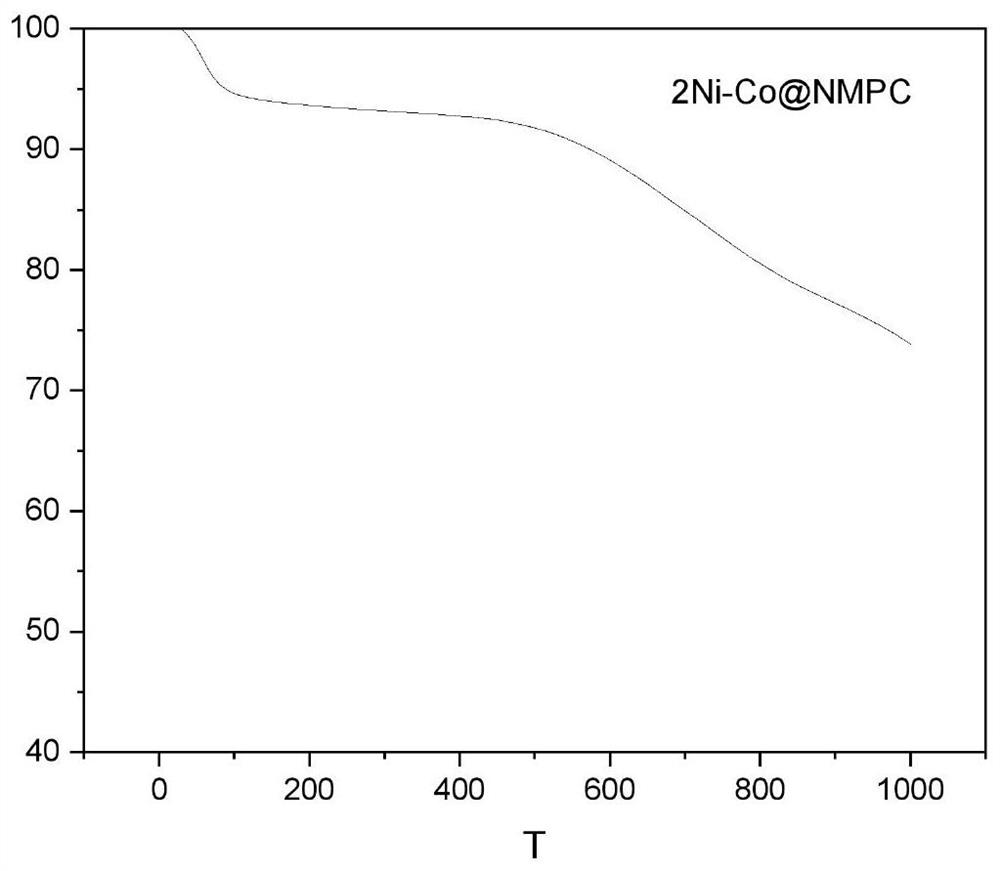

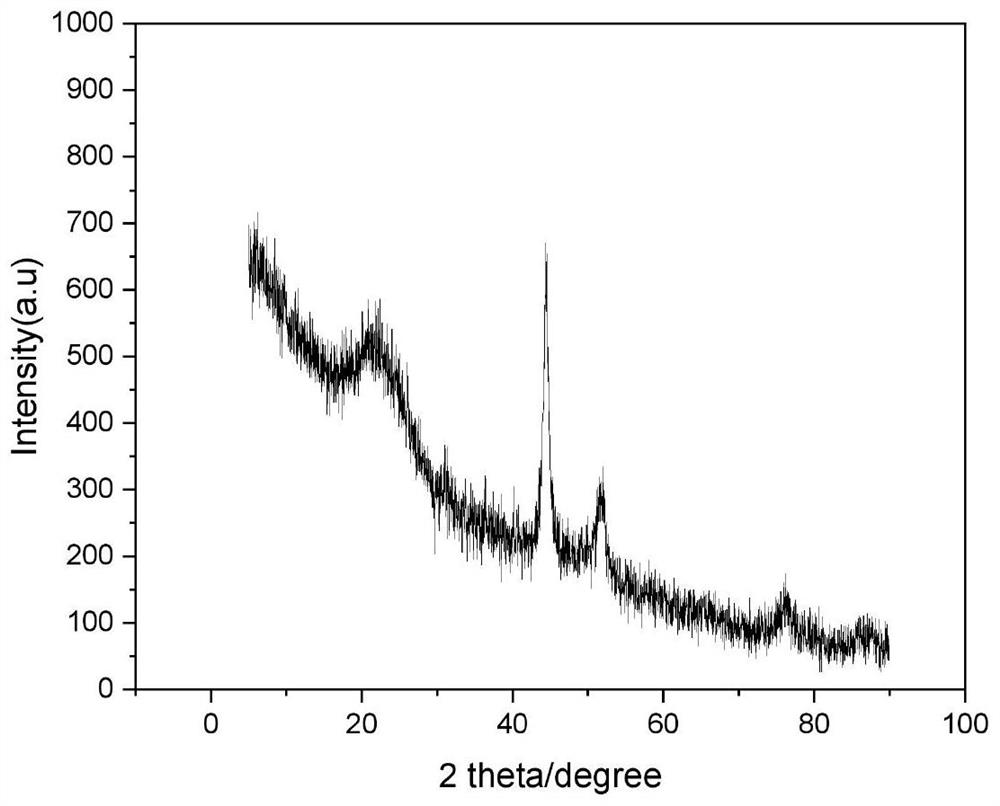

Nitrogen-doped mesoporous carbon supported alloy nano-catalyst and application thereof

PendingCN114849755AImprove conversion rateModulation of hydrogenation reduction activityPhysical/chemical process catalystsChemical recyclingNano catalystPtru catalyst

The invention belongs to the technical field of catalyst synthesis, and particularly relates to a nitrogen-doped mesoporous carbon supported alloy nano-catalyst and application of the nitrogen-doped mesoporous carbon supported alloy nano-catalyst to preparation of cyclopentanone by catalyzing furfural high-efficiency water-phase hydrogenation. The catalyst is composed of a carrier nitrogen-doped mesoporous carbon and metals M1 and M2 loaded on the nitrogen-doped mesoporous carbon, both the metals M1 and M2 are any one of Cu, Co, Fe, Ni, Al and Zn, the loading capacity in the catalyst is 5-30%, the catalyst is prepared by an impregnation method or an in-situ one-pot method, and the catalyst has a mesoporous structure, a relatively high specific surface area and a good pore structure, and can be used for preparing the catalyst. The catalyst can be recycled for multiple times, the catalytic efficiency is not obviously reduced, the cycle performance is relatively good, and the industrial production requirements are met. The catalyst is safe, non-toxic, green, efficient, environment-friendly and harmless to human bodies, meets industrial green production requirements and has a good application prospect.

Owner:HEFEI UNIV OF TECH

Fabric dyeing device with good wetting property

InactiveCN110438688AImprove sizing effectGood production demandTextile treatment with treating outlet contectTextile treatment by spraying/projectingArchitectural engineeringSlurry

The invention discloses a fabric dyeing device with a good wetting property. The device comprises a box, a vertical partition plate is fixed between the inner walls of the box, a grouting pump is mounted at the bottom of the partition plate, a traction device fixed onto the box is arranged on the right side of the partition plate, a spouting device fixed onto the inner wall of the bottom of the box is arranged on the left side of the partition plate, and a top plate is fixed at the left end of the top of the box. According to the fabric dyeing device, spray dyeing and sizing of a fabric can beimplemented in dip dyeing, a driving direction of the fabric is opposite to a spouting direction, so that sizing effect is better, the fabric can be flushed after sizing, excessive sizing agent cannot be retained on the fabric, and actual production requirements are more effectively met.

Owner:长兴东锦纺织品有限公司

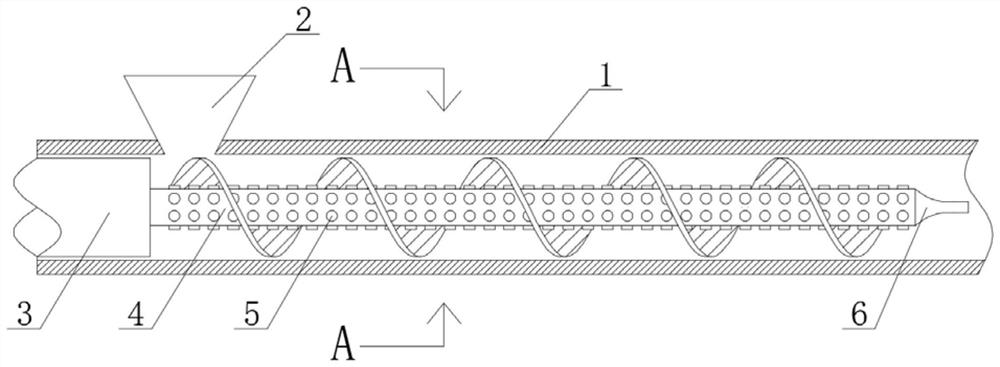

screw of extruder

The invention relates to the technical field of extruders, and discloses a screw of an extruder, which includes a cylinder body, a feed hopper is fixedly installed on the upper part of the cylinder body, and a connecting shaft is fixedly installed on one side inside the cylinder body , one end of the connecting shaft is fixedly installed with a rotating shaft, and the screw rod of the extruder changes the traditional threaded rod with a root diameter into a threaded rod with the same root diameter, and utilizes the thread groove of the threaded rod to increase the thickness The depth of the thread groove is changed by adding the number of thickened plates superimposed, and the volume size is changed, so that the depth of the threaded grooves on the rotating shaft can be freely controlled, and no or a small amount of thickened plates can be added in the solid conveying area. The number of thickened plates in the direction of the axial direction to the melt conveying area can be gradually increased to achieve the effect of compaction and increase the quality of subsequent discharges, and the number of thickened plates can be freely increased or decreased for different types of plastics In order to meet the best production requirements and maximize the quality of products.

Owner:江苏大维塑料技术(集团)有限公司

Flexible Positioning Mechanism for Body Frame Welding Top Cover

ActiveCN106392418BHigh degree of flexibilityHigh precisionWelding/cutting auxillary devicesAuxillary welding devicesMan machineCar manufacturing

The invention provides a flexible location mechanism of a welding top cap of a car body frame. The flexible location mechanism of the welding top cap of the car body frame comprises a base. A slippage base is arranged on the base, a location pin is arranged on the slippage base, and side body location hand grabs are arranged on the slippage base and fixed by the location pin. Pressure arms are arranged on the two sides of the location pin and through the pressure arms, the slippage base in place is fixed. Top cap of location hand grabs are arranged on the top of the slippage base. The utility rate of space is high, floor space is small, the structure is single, and breakdown is little; flexible degree of the mechanism is high, switching time is short, and precision is high; and equipment and manpower investment cost for multi-vehicle manufacture are lowered. Complicated structure switch before is evaded, the flexible degree is high, the cost is low and the utility rate of each device is improved, so that man-machine harmony and product quality are both highly promoted. Under the circumstance of low cost, an enterprise can obtain good manufacture requirements through the high-quality mechanism, flexible manufacture requirement of automobile manufacture industry nowadays is met, and the flexible location mechanism of the welding top cap of the car body frame is sure to win general consent of market.

Owner:ANHUI RUIXIANG IND

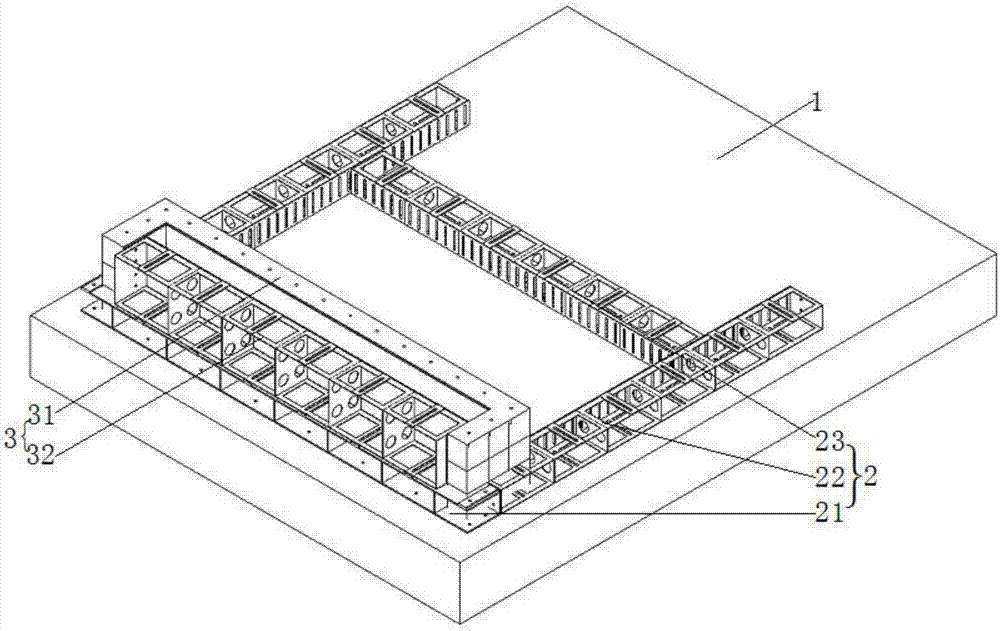

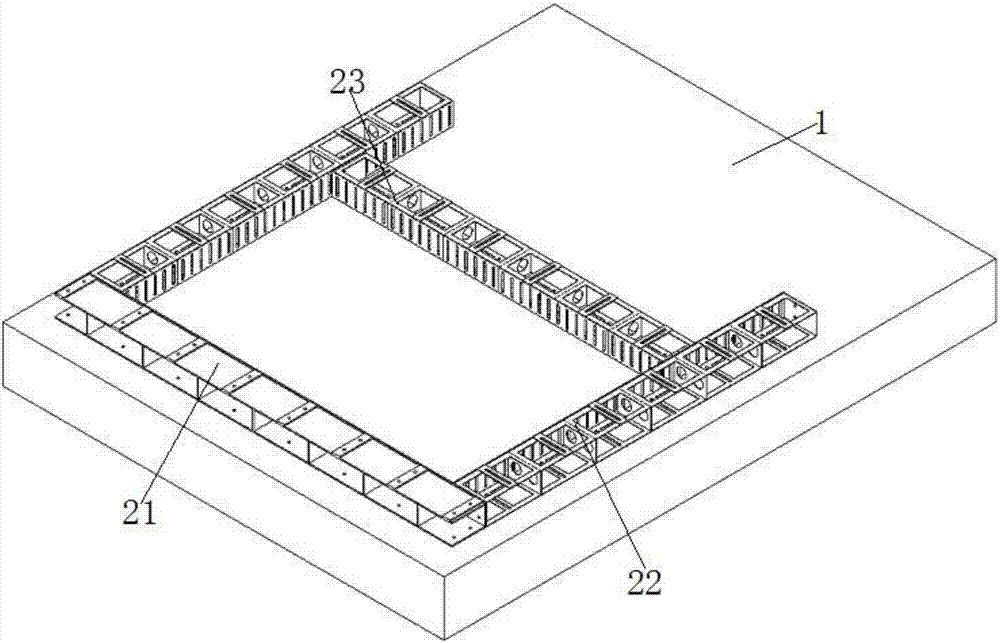

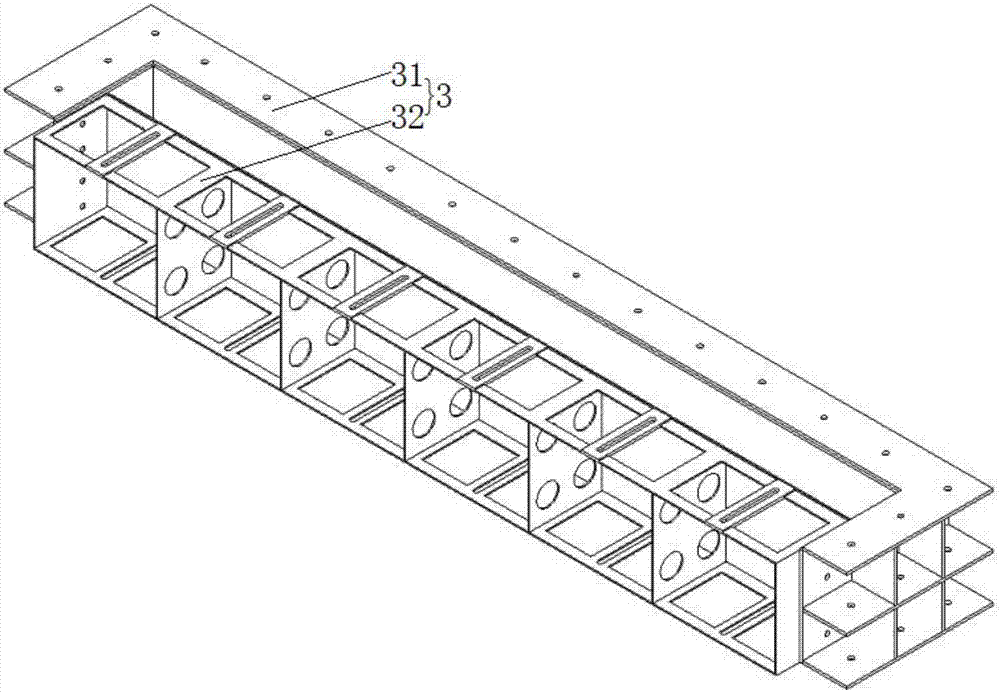

Die plate for prefabricated components

PendingCN107457888AFulfill production needsGood production demandMouldsMould fastening meansAgricultural engineeringEngineering

The invention discloses a die plate for prefabricated components. The die plate comprises a movable die platform and a lower combined die plate for machining the linear prefabricated components. The lower combined die plate comprises a lower-layer die plate and a first die plate connected to one side of the lower-layer die plate, and the interval between the lower-layer die plate and the first die plate can be adjusted. The die plate is simple in structure; the length and width of the lower combined die plate can be adjusted by adjusting the position of the first die plate and the position of a second die plate, accordingly the length and width of the required prefabricated components are adjusted, and the adjustment is convenient; the production requirements of the prefabricated components with different specifications and dimensions are achieved, and the application range is wide; all the die plates can be combined according to the use requirements, the linear or L-shaped prefabricated components can be manufactured according to the requirements, the assembly and disassembly are convenient and fast, and the assembly efficiency of the L-shaped prefabricated components is improved; and rebars are embedded into the manufactured prefabricated components, the strength and the structural stability of the prefabricated components are improved greatly, the prefabricated components can be widely used in prefabricated houses, and the cost can be lowered.

Owner:THE 4TH CONSTR ENG CO LTD OF CHINA RAILWAY NO 4 ENG GRP +1

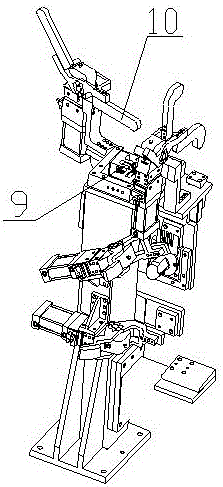

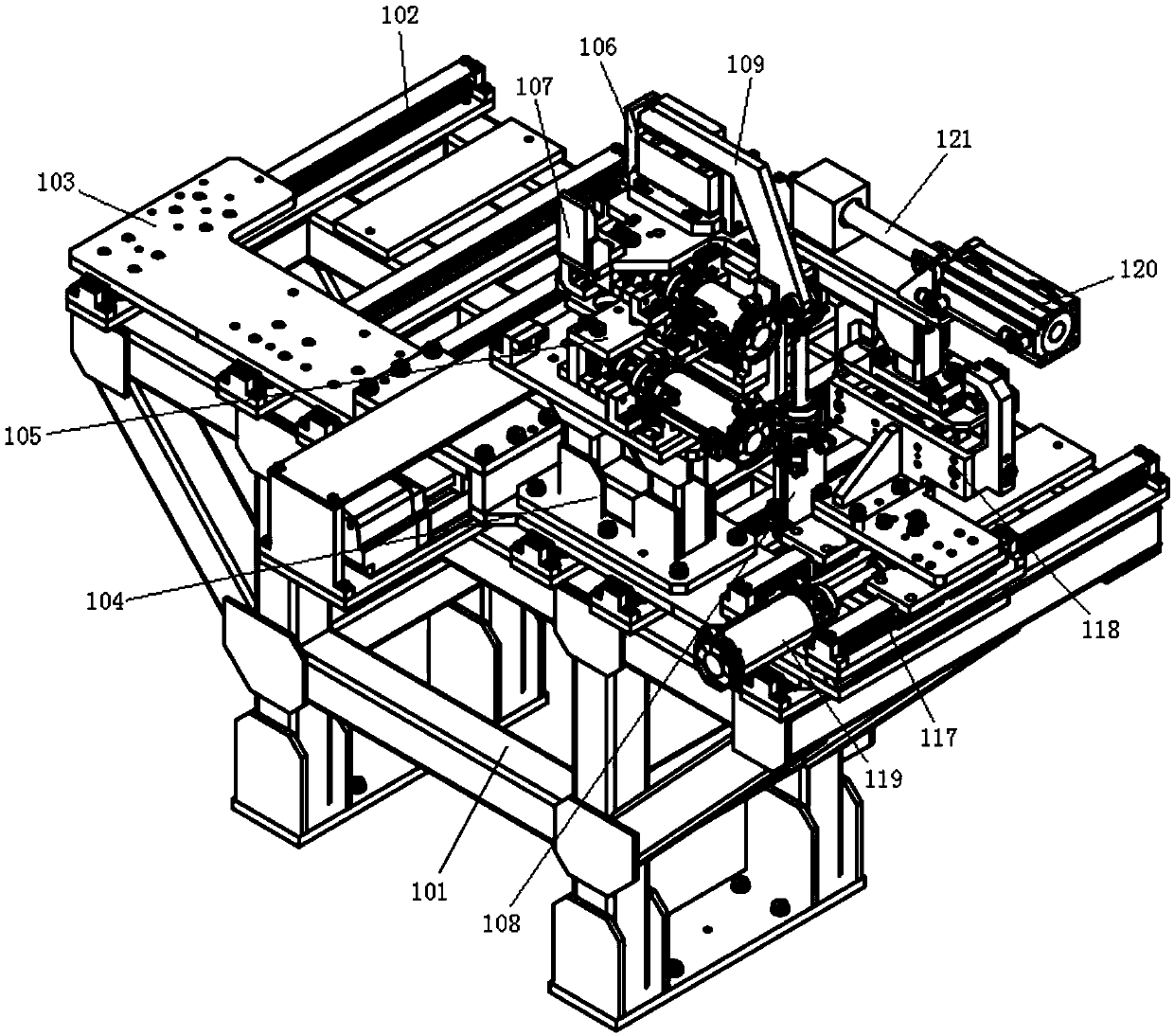

Forklift connector combined welding device

ActiveCN109676306AGood production demandExquisite structureWelding/cutting auxillary devicesAuxillary welding devicesRotation flapCanis lupus familiaris

The invention discloses a forklift connector combined welding device. The forklift connector combined welding device comprises a pallet fork front end clamping device, a pallet fork rear end clampingdevice and a connector clamping device; a first U-shaped clamping base is arranged on a front end fixed mounting frame; the front end of the first U-shaped clamping base is provided with a stop dog; afirst rotation fixed arm is connected with a first fixed air cylinder piston rod; the rear end of the first U-shaped clamping base is provided with a second fixed air cylinder; a second rotation fixed arm is connected with a second fixed air cylinder piston rod; a second U-shaped clamping base is arranged on a rear end mounting frame; a third rotation fixed arm is connected with a third fixed aircylinder piston rod; a fourth rotation fixed arm is connected with a fourth fixed air cylinder piston rod; the connector clamping device comprises a connector mounting frame; an ascending air cylinder piston rod is provided with a bottom support member; and a rear end fixed rotation arm is connected with the lower portion of a fifth fixed air cylinder piston rod, and a front end fixed rotation arm is connected with the top end of the piston rod. The forklift connector combined welding device is ingenious in structure, easy to use and high in automaton degree.

Owner:江苏鲁安特智能装备科技有限公司

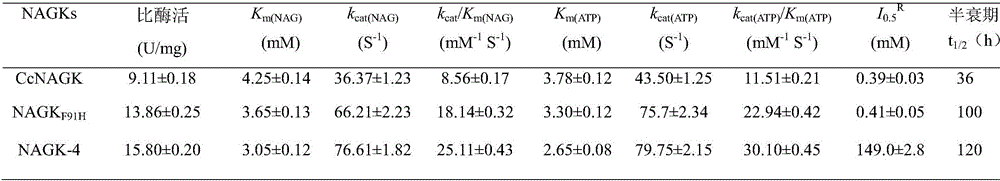

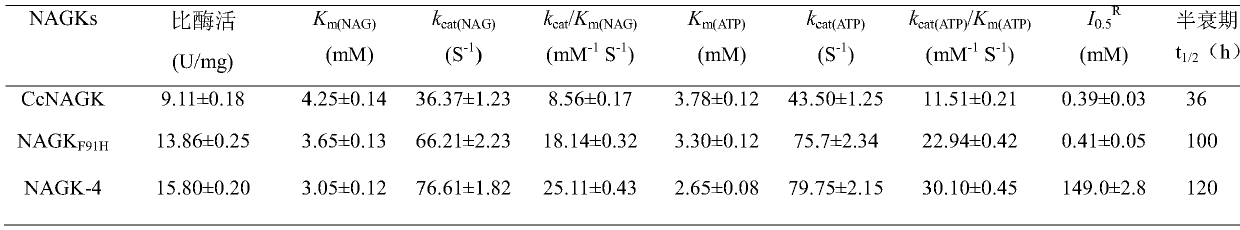

N-acetyl glutamic acid kinase mutant and application thereof

ActiveCN106434594AIncrease productionIncrease synthesis rateBacteriaTransferasesStructure analysisArginine

The invention provides an N-acetyl glutamic acid kinase mutant capable of relieving the feedback inhibition effect of L-arginine and obviously increasing the catalytic activity and thermal stability and belongs to the field of bioengineering. A molecular docking technique and the structure analysis for N-acetyl glutamic acid kinase (CcNAGK) from corynebacterium crenatum CGMCC NO:0890 are firstly adopted for confirming that the E19 locus plays an important role in inhibiting the feedback of arginine and three key amino residue loci I74, F91 and K234 located on a substrate combining bag have significant impacts on enzymatic catalytic activity and heat stability; the encoded amino acid is replaced and the gene argB4 after compound mutation is introduced into the corynebacterium crenatum highly yielding arginine through pDXW10, so that the compounding rate of the arginine in corynebacterium crenatum can be obviously increased; lastly, after fermentation for 98h in a 5L fermentation tank, the yield of arginine is increased to 61.2g / L from original 43.2g / L, and the yield of the L-arginine is increased by 41.8%.

Owner:JIANGNAN UNIV

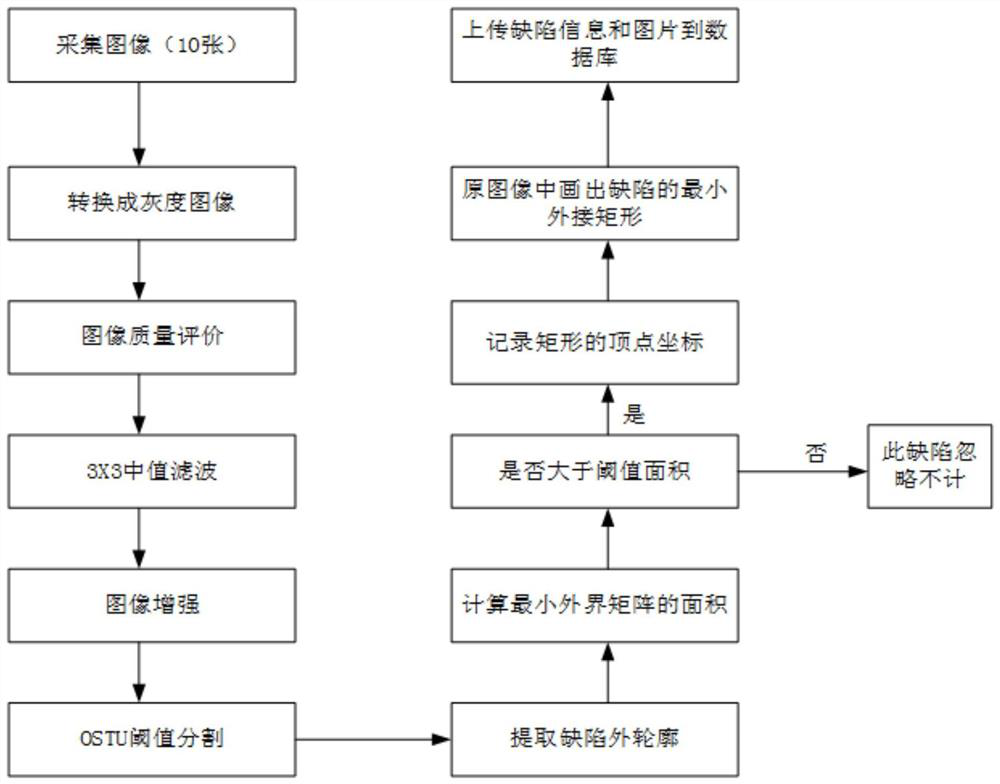

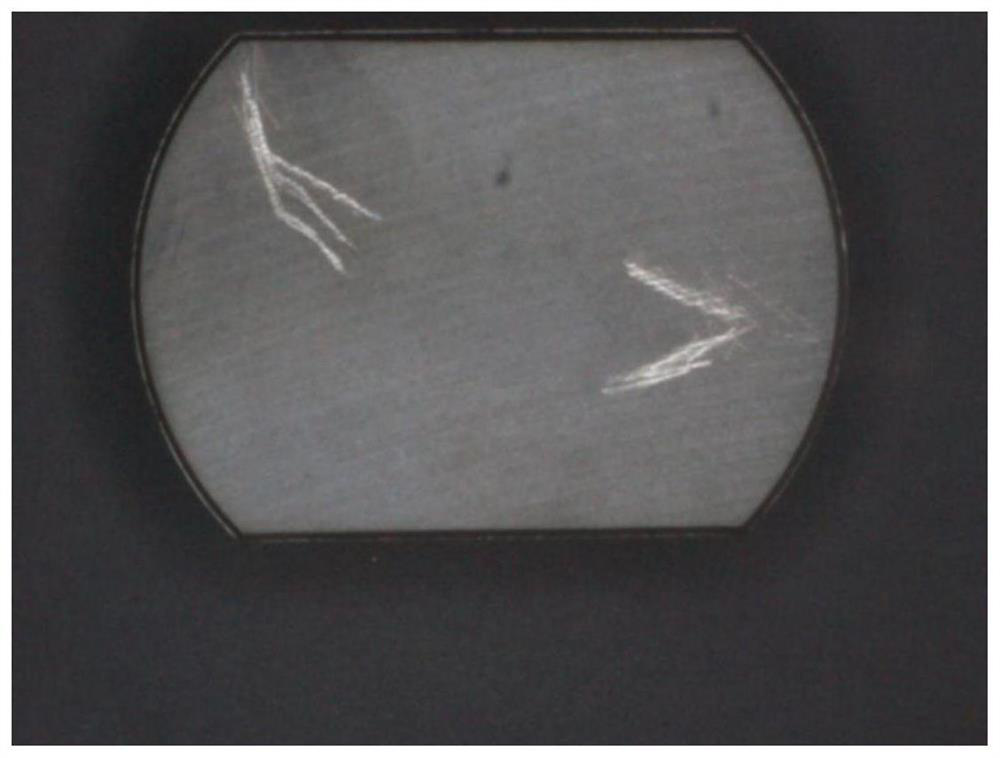

A method for detecting surface defects of magnetic cores based on machine vision

ActiveCN109507192BImprove detection accuracyIncrease flexibilityOptically investigating flaws/contaminationMachine visionImaging quality

Owner:三螺旋大数据科技(昆山)有限公司

Screw rod of plastic extruding machine

The invention relates to the technical field of plastic extruding machines, and discloses a screw rod of a plastic extruding machine. The screw rod comprises a cylinder body. A feeding hopper is fixedly mounted at the upper part of the cylinder body; a connecting shaft is fixedly mounted at one side in the cylinder body; and a rotating shaft is fixedly mounted at one end of the connecting shaft. According to the screw rod of the plastic extruding machine, a traditional threaded rod with a changed root diameter is changed into a threaded rod with a consistent root diameter, thickening plates are additionally arranged in a threaded groove of the threaded rod, and the depth of the threaded groove is changed by increasing the number of the overlaid thickening plates, and volume size is changed, so that the depth of each threaded groove on the rotating shaft can be freely controlled; no thickening plate is additionally arranged or a small number of thickening plates are additionally arranged in a solid conveying area, and the number of the thickening plates additionally arranged in the direction of the axial direction towards a melt transport zone can be gradually increased, so that thecompaction effect can be achieved, and the subsequent discharging quality can be improved; and the number of the thickening plates can be freely increased or decreased according to different kinds ofplastic so that the best production requirement can be met, and the product quality can be improved to the maximum degree.

Owner:江苏大维塑料技术(集团)有限公司

A kind of n-acetyl glutamate kinase mutant and its application

ActiveCN106434594BIncrease productionIncrease synthesis rateBacteriaTransferasesArginineAcetylglutamate kinase

Owner:JIANGNAN UNIV

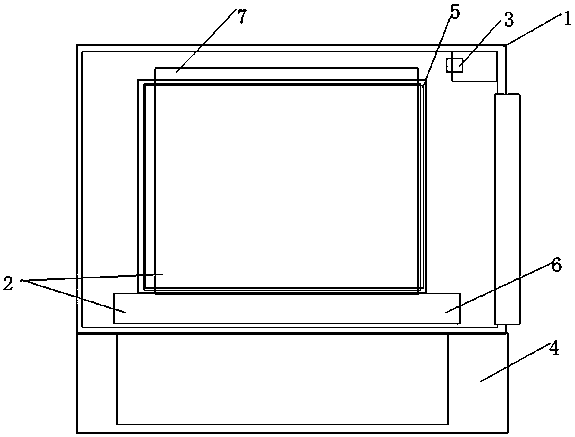

a vacuum oven

ActiveCN105318676BEasy to monitor at any timeAvoid big failuresDrying solid materials without heatDrying machines with local agitationLaboratory ovenEngineering

The invention discloses a vacuum drying box which comprises a box body, heating devices, a shooting device and a control device, wherein the heating devices are arranged in the box body; the shooting device is arranged at the top of the box body; and the control device is arranged at the bottom of the box body. According to the vacuum drying box disclosed by the invention, since the shooting device is arranged at the top of the box body, and is used for recording running conditions in the box and transmitting the shot information to a computer in time, a worker can conveniently monitor the whole working process at any time and handle problems immediately once finding any problem, thus, the large failure of the equipment is avoided, meanwhile, the running conditions in the drying box can be observed and abnormal conditions in the drying oven can be found in time, therefore, a good monitoring effect on running of the whole drying box is realized, the drying effect of the drying box is guaranteed effectively and further production demands are met better.

Owner:苏州晖恩源医疗器械配件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com