Yarn feeder with adjustable yarn feeding speed

A yarn feeder and speed technology, used in textiles and papermaking, weft knitting, knitting, etc., can solve the problem of the complex structure of the yarn feeder, the lack of emphasis on the smoothness of the yarn feeding, and the manual adjustment of the yarn feeding speed. Axial fixation of the cylinder, etc., to achieve the effect of strong adjustability, simple structure and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

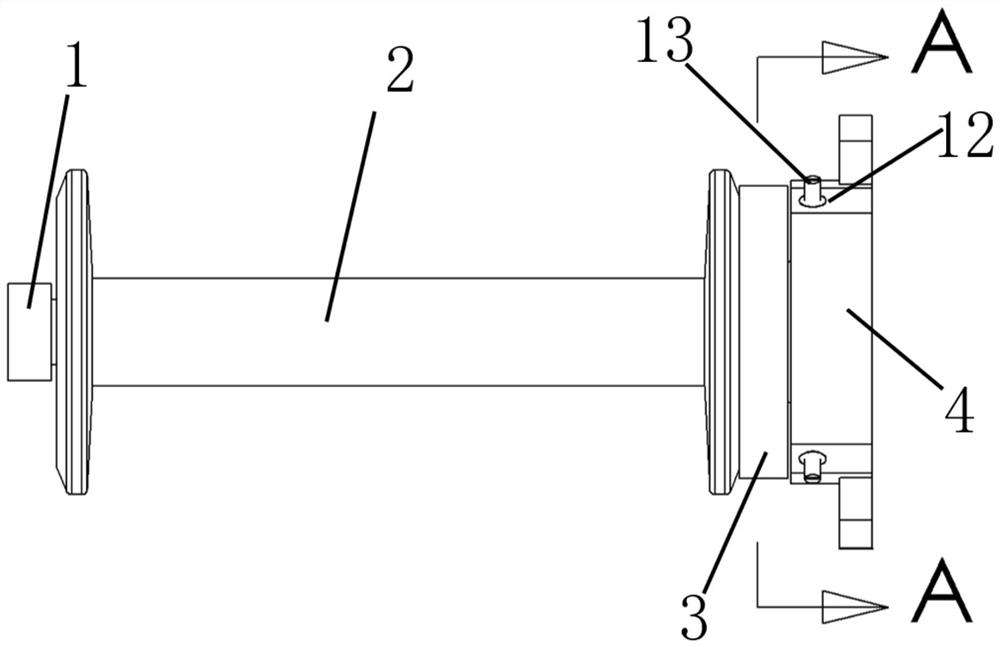

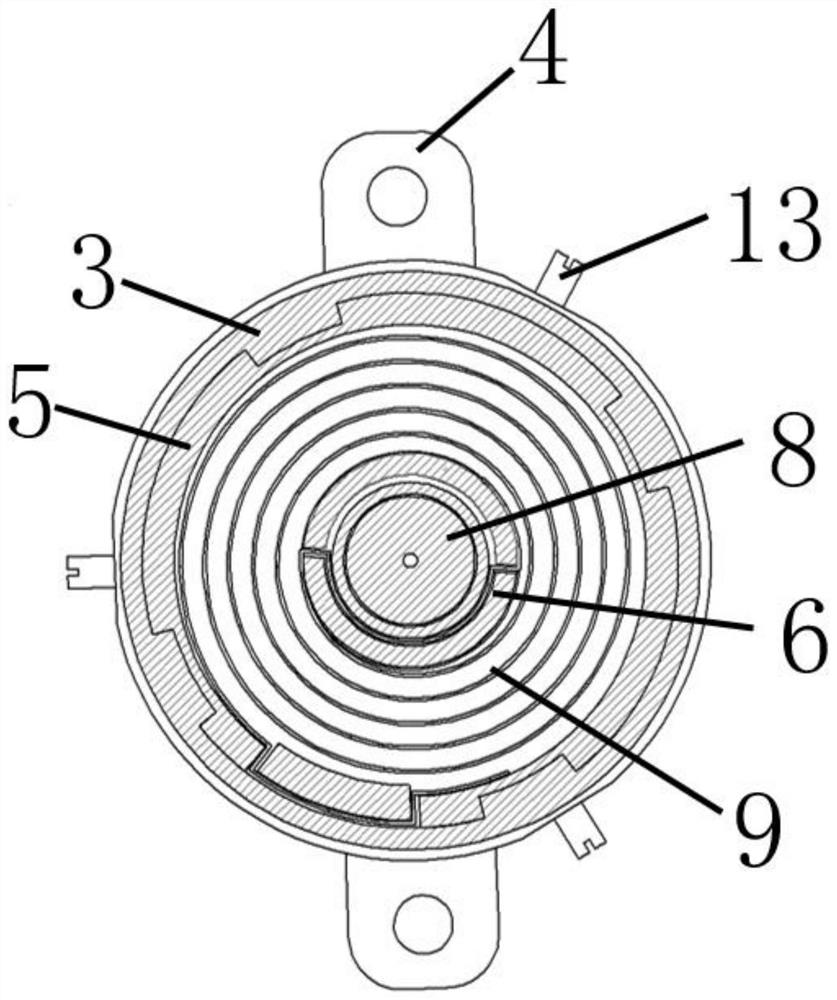

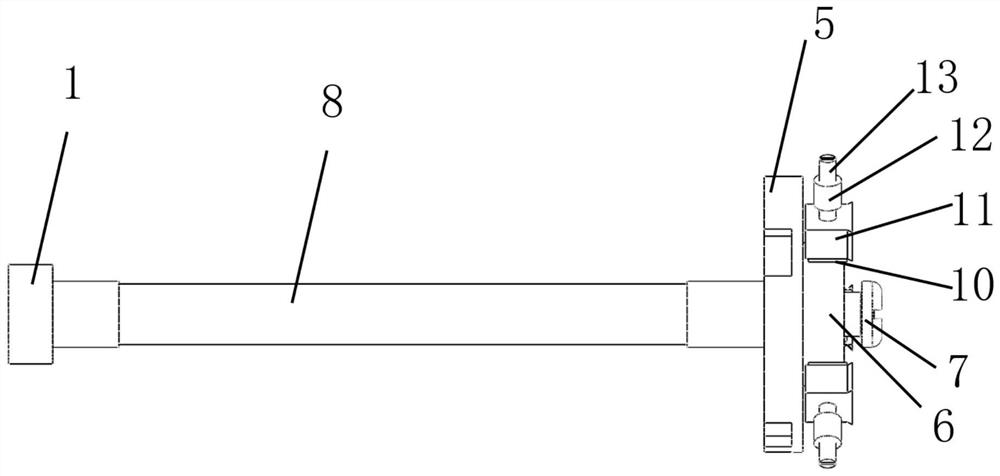

[0022] The present invention provides a yarn feeder with adjustable yarn feeding speed (short for yarn feeder), which is characterized in that the yarn feeder includes a terminal screw 1, a bobbin 2, a driven wheel cover 3, a bottom plate 4, and a driven wheel 5 , driving wheel 6, fixing screw 7, mandrel 8, coil spring 9, friction plate 11, insert block 12 and locking screw 13;

[0023] One end of the mandrel 8 is fixed on the base plate 4 by a fixing screw 7, and the other end is fixed with a head screw 1; the driving wheel 6 is located inside the base plate 4 and is mounted on the mandrel 8 by bearing rotation; the bobbin 2 is nested in the core The outer side of the shaft 8 is rotationally connected with the mandrel 8 through the bushin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com