Processing method and processing system of circuit board

A processing method and processing system technology, applied in the directions of printed circuit, printed circuit manufacturing, lithography/pattern, etc., can solve problems such as deformation, cutting near surface or point warping, etc., and achieve simple process, narrow line spacing and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

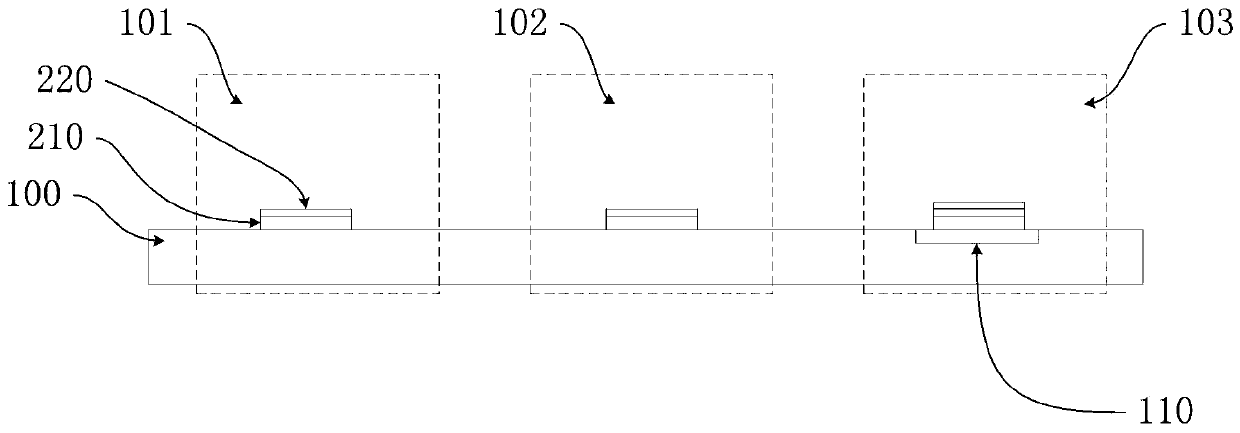

[0046] Now in conjunction with the accompanying drawings, the preferred embodiments of the present invention will be described in detail.

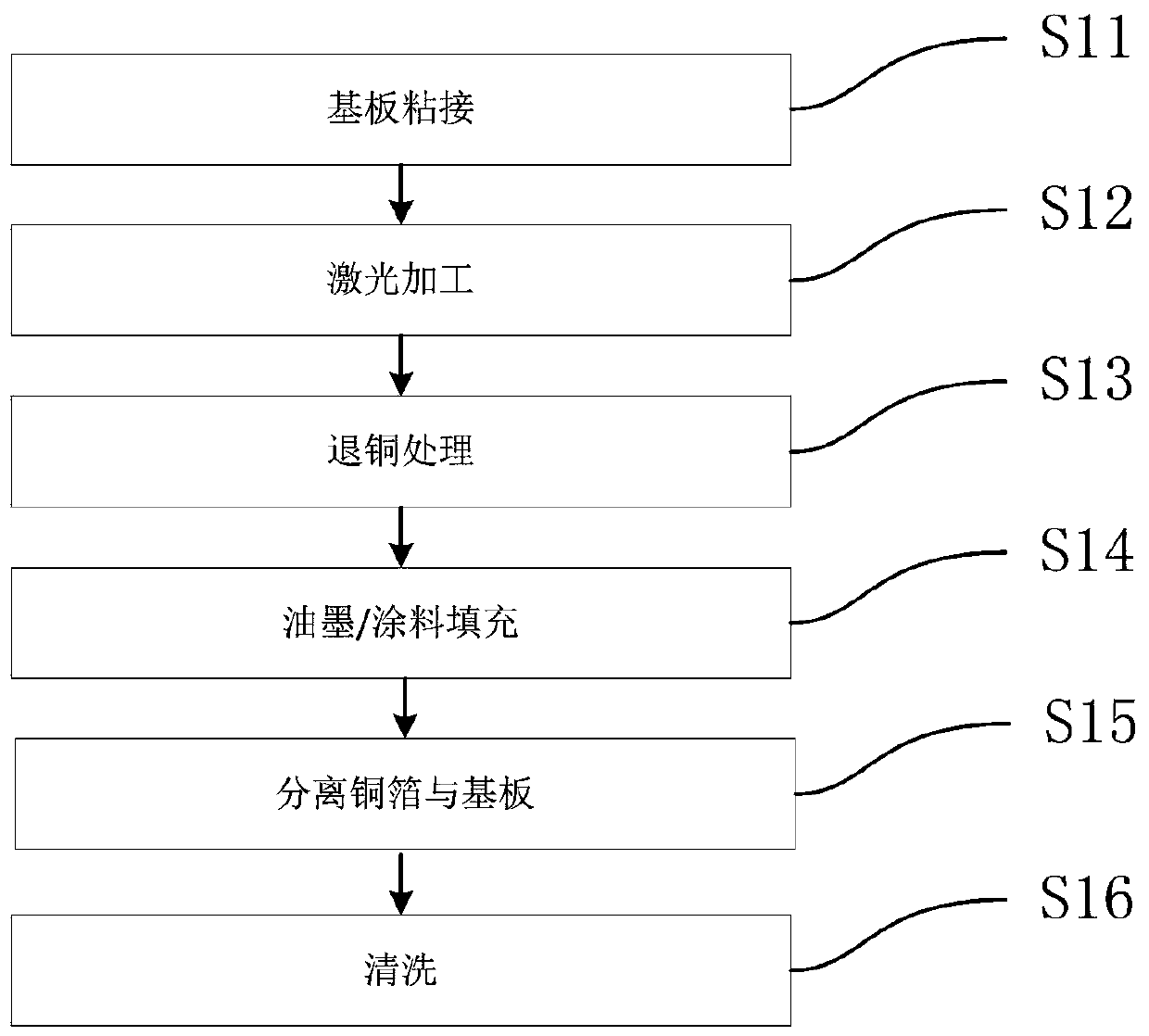

[0047] Such as figure 1 As shown, the present invention provides a preferred embodiment of a circuit board processing method.

[0048] A processing method for a circuit board, the steps of the processing method comprising:

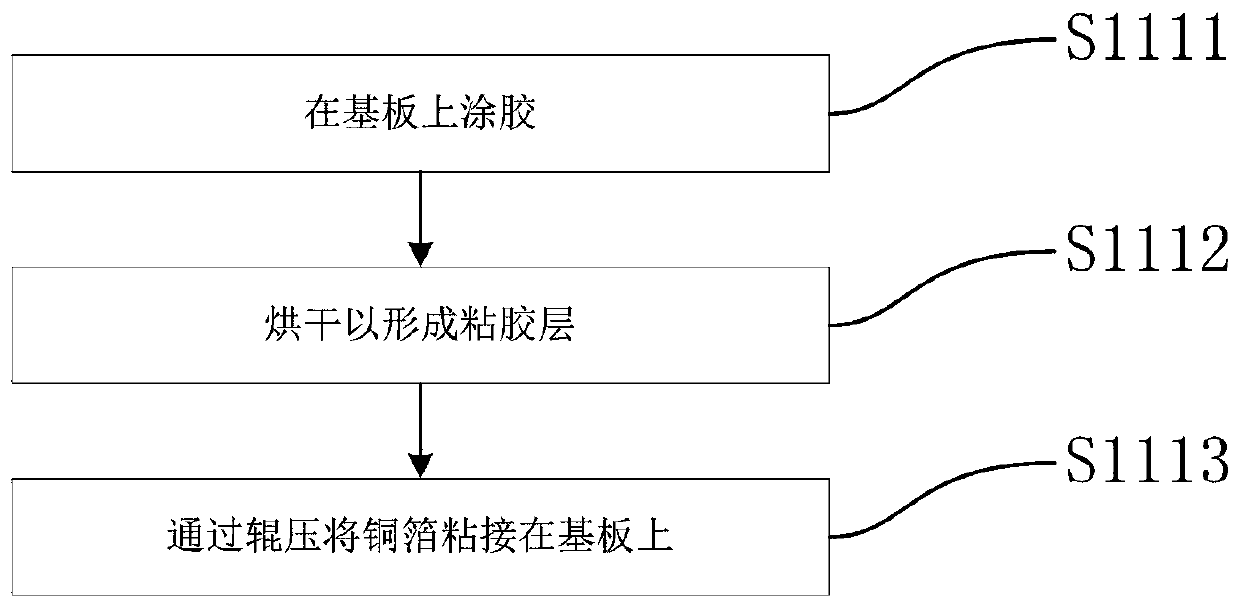

[0049] Step S11, bonding the substrate, setting a copper foil on the substrate through the adhesive layer;

[0050] Step S12, laser processing, laser cutting the copper foil according to the preset circuit diagram to obtain the first semi-finished circuit board;

[0051] Step S13, copper stripping treatment to obtain the second semi-finished circuit board;

[0052] Step S14, filling with ink or paint, using ink or paint to fill the laser-cut gap, and forming a layer of ink / paint on the surface of the copper foil to obtain a third semi-finished circuit board;

[0053] Step S15, separating the copper foil and the sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com