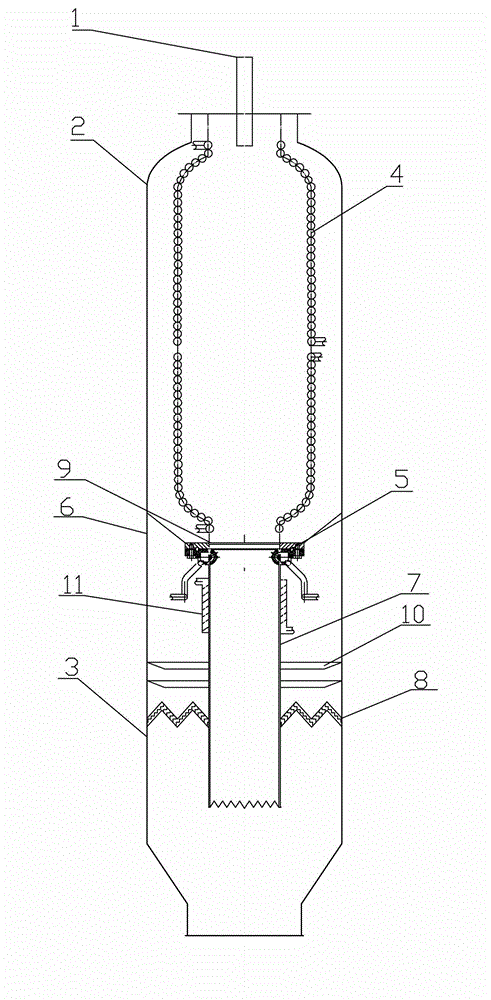

Multi-section water-cooling wall high-efficiency chilling gasification device

A technology of gasification device and water wall, which is applied in the details of gasification device, gasification process, granular/powdered fuel gasification, etc. It can solve the problem of unmaintainable liquid level in the quenching chamber, high ash content of syngas, and drop Tube burnout etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

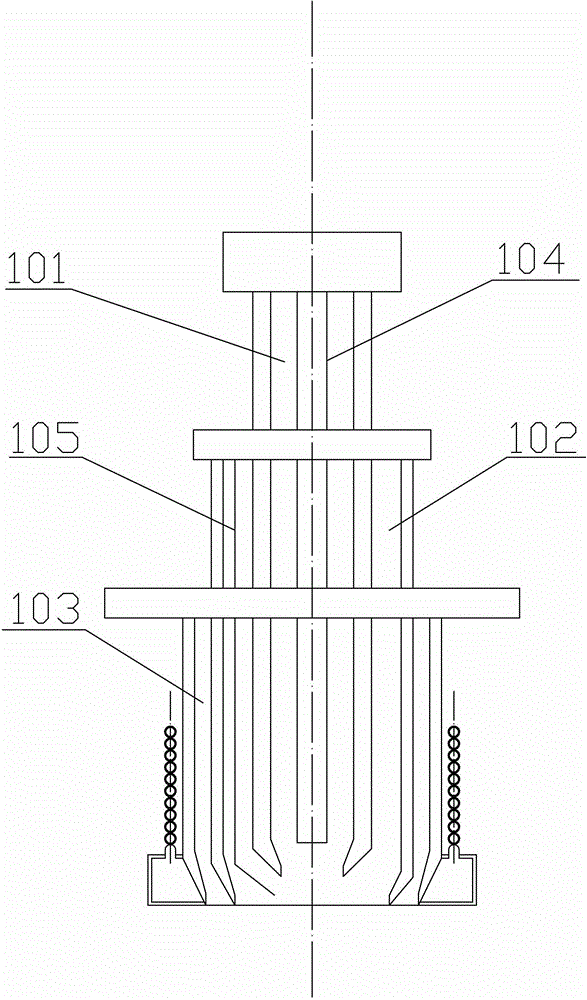

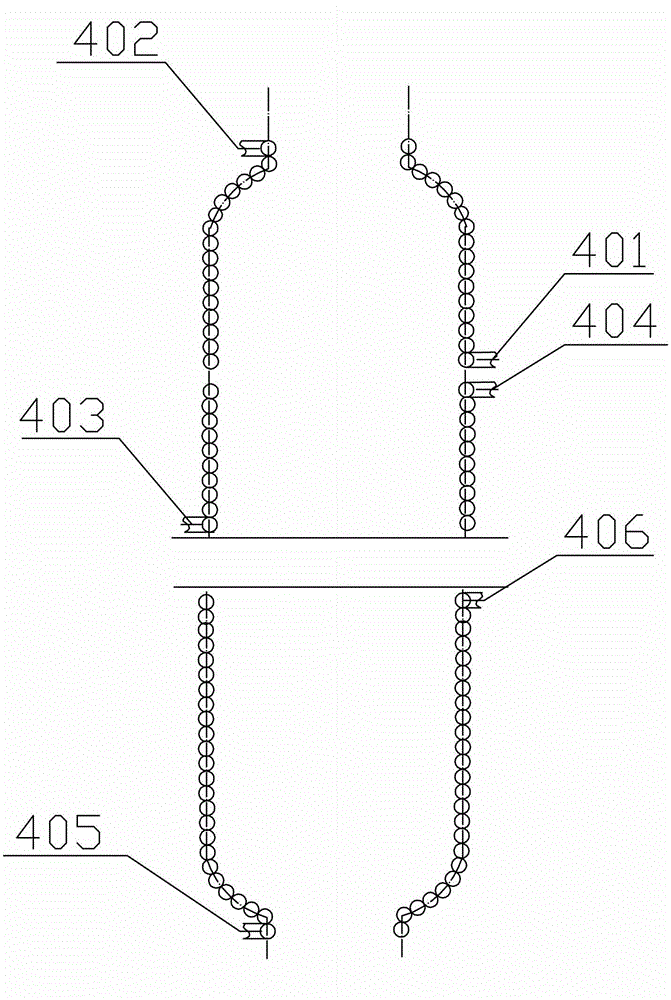

[0039] A thousand-ton gasification device, with four nozzles 1 on the top, a central nozzle in the center of the flange, and the remaining three nozzles 1 are evenly arranged on a circle centered on the center of the flange. The rotation of the internal airflow of the three nozzles 1 The directions are different, and the overall direction gathers toward the axis of the gasifier; the water wall 4 adopts a two-stage structure, the temperature of the deoxygenated water entering the water wall 4 is 200°C, and the temperature of the deoxygenated water exiting the water wall 4 is 240°C; gasification A high-efficiency chilling device with a height of about 8690mm and an inner diameter of about 3000mm is installed in the lower part of chamber 2, and the chilling space is about 61.4m3. The temperature of the syngas and ash entering the high-efficiency chilling device 3 is about 1500°C, the velocity is about 3.6m / s, and the gas velocity in the annular space is about 0.3m / s. Out of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com