a vacuum oven

A technology for vacuum ovens and cabinets, which is applied in drying, drying machines, lighting and heating equipment, etc. It can solve the problems of wasting time, not being able to know whether the oven temperature is needed, and being unable to observe the working conditions of the oven, etc., and achieve good monitoring results , Improve the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

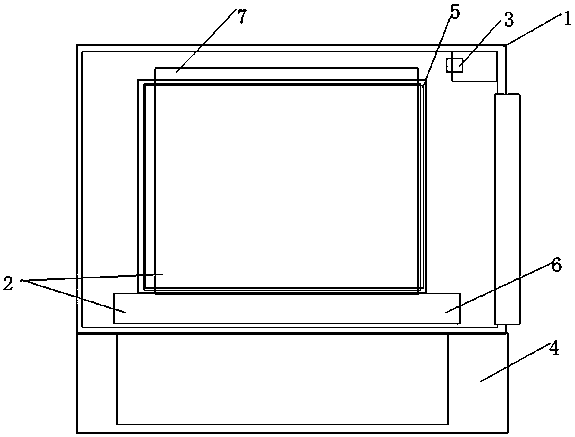

[0030] Such as figure 1 A vacuum oven shown includes: a box body 1, a heating device 2, a photographing device 3, a control device 4, a compensating heat dissipation heating shell 5, a first heating device 6, a second heating device 7, an automatic door, an isolation layer and Alarm.

[0031] The relationship between the above components is as follows:

[0032] The heating device 2 is arranged inside the casing 1, the photographing device 3 is arranged on the top of the casing 1, the control device 4 is arranged at the bottom of the casing 1, and the casing 1 is provided with There is an automatic door, the inner side of which is provided with a compensating heat dissipation heating shell 5, an isolation layer is arranged above, and an alarm is provided at the top, the automatic door is connected with the control device 4, and the photographing device 3 is arranged above the isolation layer.

[0033] The heating device 2 described in this embodiment is composed of a first he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com